I managed to sneak out to the garage for a few more hours this afternoon. I need to attach my tone ring to the crank, I bought a 440source aluminum crank pulley but it is too thin to drill and tap this is the best solution I could come up. Basically I will machine a washer that will have three bolts that bolt from the inside of the pulley, then I can drill and tap the "washer" for the ring.

I started out with some left over stuff from the accy. bracket, I wanted to save as much as I could so I used the rotatory table to cut it out.

As you can see, I'm no damn machinist....

Test fit, and then rough cut it with the band saw..

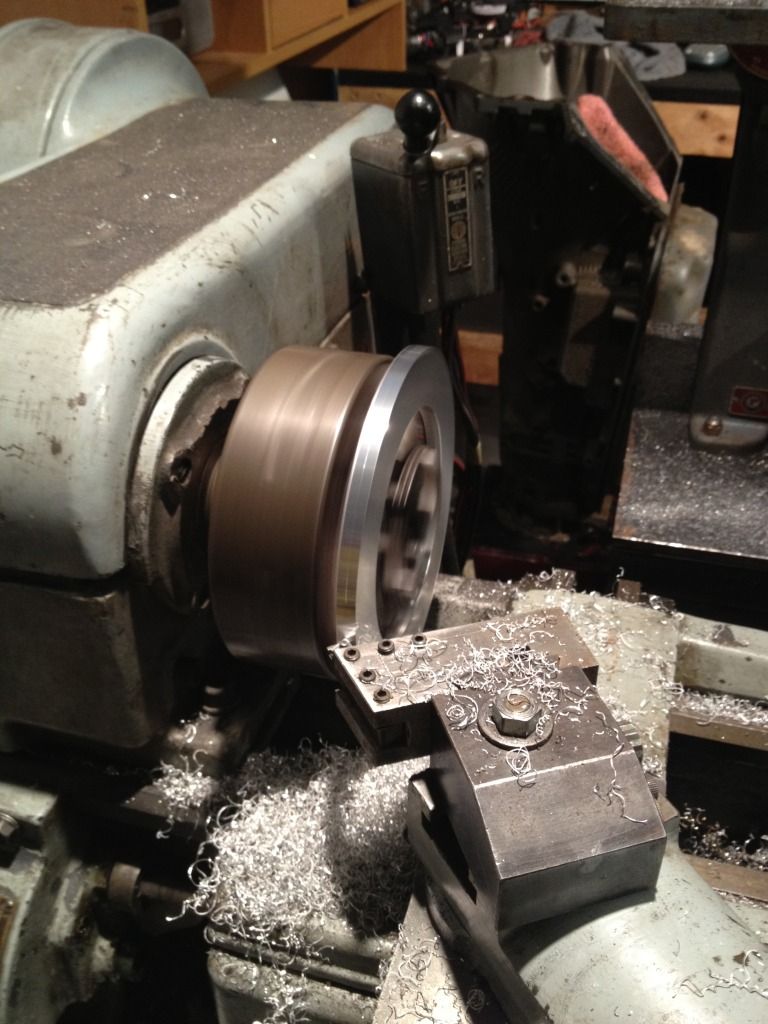

Thinning it up a bit.

Chuck it in the lathe and spend an hour or two making it round and adding a taper..

Pretty good I think, just need a bit more out for the taper, then I need to drill and tap all the holes.

Here is what it will look like once it is finished.