You have to remember that the servo piston is restrained from moving by a large coil spring that keeps it seated in the bore when no pressure is applied. When pressure is applied to the servo, the spring resists piston movement until a certain pressure is attained to overcome the spring but the same pressure is also entering the small hole in the piston and its weaker spring allows the plunger in the piston to move at a faster rate than the piston itself, thus the pressure under the plunger gives a cushioning affect on application and a delay on release. Plugging the hole or blocking the plunger defeats the cushioning and makes the servo, in effect, the same as the early servo.

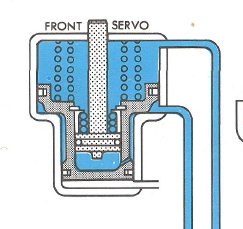

The thing I dislike about the controlled-load servo, other than the cushioning effect, is that the plunger remains extended from the piston even after the 2-3 upshift; this closes up some of the free play that is adjusted in and mandates looser band adjustments. As you can see in the pic below of the piston in 3rd gear, the plunger is still extended even though the piston is firmly seated in its bore.