[/quote]

.012"-.015" per friction is what most of us shoot for. So with 4 friction it should be .048"-.060" clearance. You easily tig weld reinforcement to the band strut .Make sure the ends of the reinforcement don't interfere with the band or band anchor.The ratio levers multiple servo force times ratio. The 3.8 or 4.2 seem to work well. The higher the ratio the longer the servo travels to engage the band.

Doug [/quote]

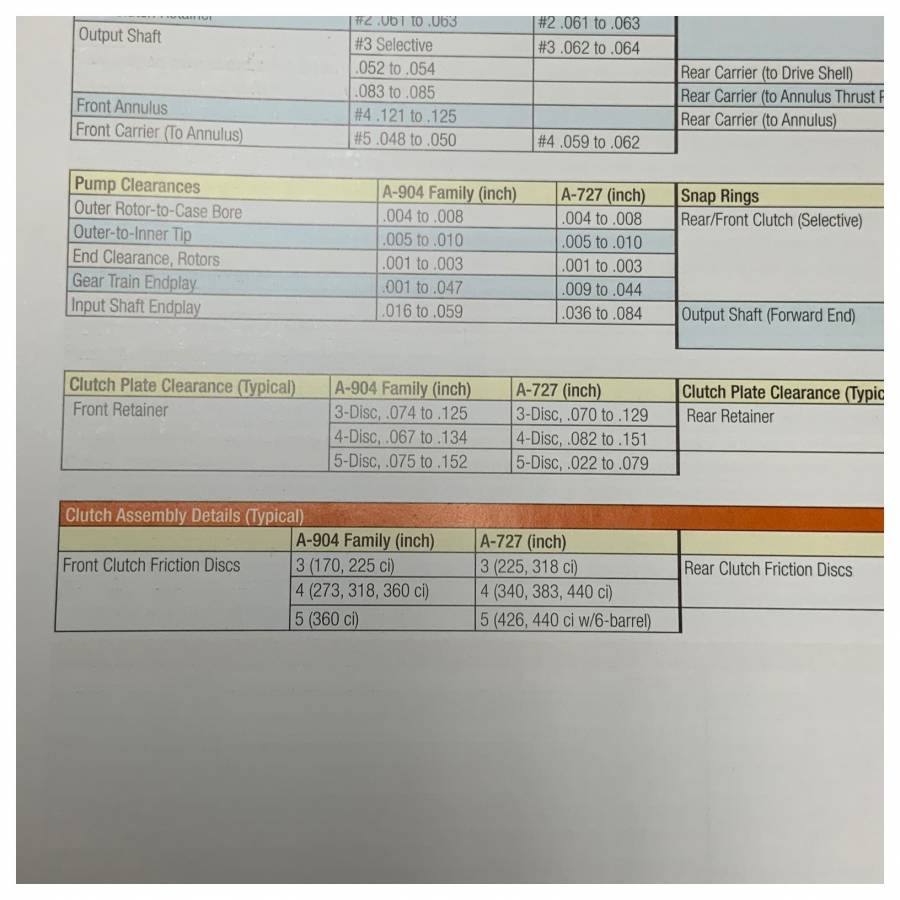

Dang I feel like I read this before which is why I thought I could get away with it at .045 when I first built it. Then this week going back through my Tom Hand book he lists the spec for 4 fibers at .082-.151 which is a lot more!

The last thing I want to do is pull this trans again real soon because my front clutches are burning up because I spend a lot of time in 2nd gear hotrodding and they are heating up instead of slipping. All the reading I’ve done talked about how the forward clutch has a small unapplied gap because it’s almost always applied where the front clutch needs some room to slip because it actually does a lot of on and off.

This is all book learning though- I come here for real world experience.

So by my book I’m at the bottom 1/3rd of spec and by your suggestion I’m at double the spec. Not sure if the wave snap ring figures into this? I’m guessing if I went straight snap ring it would apply harder with no cushion which would be harsher but easier on clutches wear wise?

It’s too late to un-shave my pressure plate but I could swap the .050 wave washer for a thicker flat one if it is a big deal?

Last edited by radar; 04/09/19 09:38 PM.