Hey guys, I was about to check/adjust hot lash on my 340 when I ran into what might be a potential problem, although I'm really not sure as I don't have much experience with shaft mounted aftermarket rocker setups.

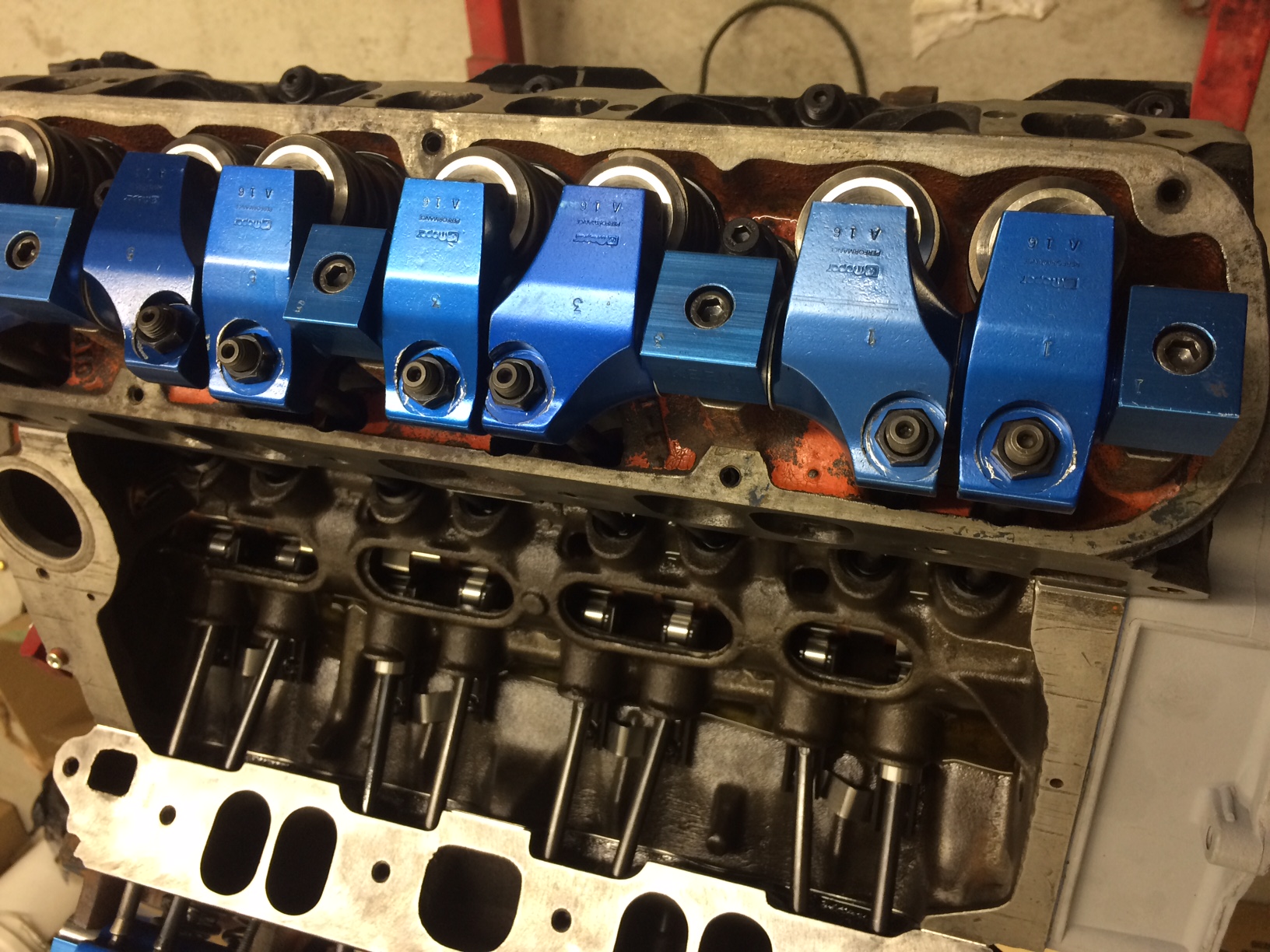

It's a w2 econo head with Mopar Performance shaft mounted rockers, my machinist put the engine together.

When I went to adjust the first rocker, I cinched it down and realized it no longer moved freely on its own. I realized that when I loosened it and tightened it again, I must have change the end play. I ended up having to pry carefully with a screwdriver before tightening it to keep it off the shaft hold down so that it would move freely.

When I got to the the cylinder number 5 rockers I found that both rockers would slide left to right freely a pretty good amount (didn't measure it but I would say probably 3/16 inch of play). It was actually difficult to adjust lash because the lash seemed to change depending on how far left or right I slid the rockers.

I'm a little lost here. Is there supposed to be a specific tolerance between rocker arms or is the fact that some go side to side and others need prying while tightening to move freely OK?

I've never used a setup like this so i'm a little confused by how it's supposed to work.

Pictures of the rocker setup attached.

Last edited by 1mean340; 03/27/18 02:30 PM.