|

Re: 572 B1 org Part 5 - Build Notes

[Re: Cab_Burge]

#2980904

Re: 572 B1 org Part 5 - Build Notes

[Re: Cab_Burge]

#2980904

11/02/21 12:19 PM

11/02/21 12:19 PM

|

Joined: Jan 2003

Posts: 16,942

NC

440Jim

OP

OP

I Live Here

|

OP

OP

I Live Here

Joined: Jan 2003

Posts: 16,942

NC

|

Is that 30 Lbs. the break away or rotational torque? That is turning it as close to a constant rate as I can using a beam style torque wrench. I always use a tacky assembly lube designed for bearings. You never know how long the engine will sit (until spring?) before you start it.

|

|

|

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2985837

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2985837

11/16/21 03:57 PM

11/16/21 03:57 PM

|

Joined: Jan 2003

Posts: 10,140

MN

JERICOGTX

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 10,140

MN

|

I decided to use a Jesel cam belt drive instead of the Australian unit. I didn't like the interference with the ATI SuperDamper.

My block did need a little more clearance work to fit the Jesel baseplate. Between the bolt holes at 45 degrees to the top. Just looked at pictures of my INDY block, and it doesn't have the oil boss, and it looked like it was clearanced at the top of the cover like yours just a bit. Good write up Jim.

69 GTX

68 Road Runner

|

|

|

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2986341

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2986341

11/18/21 08:48 AM

11/18/21 08:48 AM

|

Joined: Jan 2003

Posts: 4,309

Shelby Twp. Mi

HardcoreB

master

|

master

Joined: Jan 2003

Posts: 4,309

Shelby Twp. Mi

|

Jesel installation complete.

I did one cam degree check after installation and it was good.

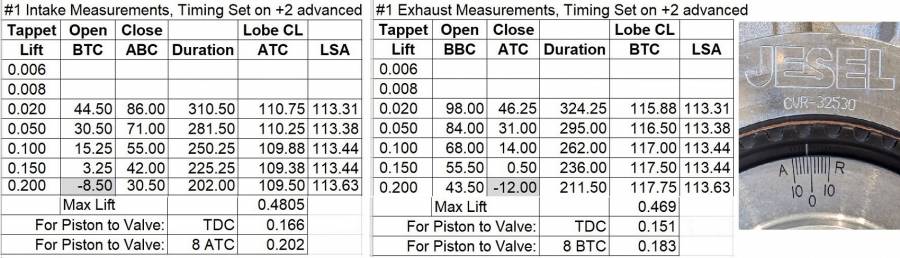

Today I will "map" the cam at several installed positions (+2, 0, -2) for lobe lift near TDC. I use that to know how piston to valve clearance will change if I change cam degree later.

Hey Jim! I'm assuming this pic has the ICL about where you want it to be? If so, Jesel hasn't changed the indexing on the cam pulley. Every Jesel I have seen true "0" shows-up retarding, if that makes sense!?

|

|

|

Re: 572 B1 org Part 5 - Build Notes

[Re: HardcoreB]

#2986438

Re: 572 B1 org Part 5 - Build Notes

[Re: HardcoreB]

#2986438

11/18/21 01:13 PM

11/18/21 01:13 PM

|

Joined: Jan 2003

Posts: 16,942

NC

440Jim

OP

OP

I Live Here

|

OP

OP

I Live Here

Joined: Jan 2003

Posts: 16,942

NC

|

Hey Jim! I'm assuming this pic has the ICL about where you want it to be? If so, Jesel hasn't changed the indexing on the cam pulley. Every Jesel I have seen true "0" shows-up retarding, if that makes sense!? No, that was the starting point for today's ton of measurements. Two degrees retarded is the last place I expect to leave it, so I start there and change it for all my measurements. Part 5 – Cam Mapping. Build NotesThis morning I completed mapping the cam lobe events at three positions. Every mark on the Jesel did result in 2 crankshaft degrees change in timing (within measurement tolerance). The cam card recommends 111 deg intake, 115 deg exhaust (113 LSA). I call that 2 degrees actual advance. When I set the Jesel marks to +2 advanced, this is what I measured. It might be more information than most people want... Many should just look at the measurements at 0.050" lobe lift. The way I look at it and the way this cam is ground, to get the intake lobe centerline at 113 ATC ("true zero"), the Jesel would be set at 1/4 deg retarded. When I did these measurements with the Jesel at the zero mark, I came up with the intake lobe centerline 112.75 ATC (at 0.050" tappet lift). I might set it at +4 this afternoon, just for more piston to valve information. But I don't plan to run it there based on these measurements.

Last edited by 440Jim; 11/19/21 11:32 AM. Reason: Added "true zero" comment

|

|

|

Re: 572 B1 org Part 5 - Build Notes

[Re: AndyF]

#2987094

Re: 572 B1 org Part 5 - Build Notes

[Re: AndyF]

#2987094

11/20/21 08:12 AM

11/20/21 08:12 AM

|

Joined: Jan 2003

Posts: 16,942

NC

440Jim

OP

OP

I Live Here

|

OP

OP

I Live Here

Joined: Jan 2003

Posts: 16,942

NC

|

Did you measure valve drop at TDC? I always keep track of valve drop since it gives a baseline to work against if I decide to change cams. Also, on you PV measurements are you using checking springs or the real springs? Real springs add some clearance since everything bends away from the piston. I have never tried to push the valve down to the piston with real racing valve springs installed. As far as valve drop, I measure the cam lobe lift at TDC (and other positions) and the piston to valve clearance at TDC (and other positions); so I have the information you need to compare to other cams. See the tables I have posted. It is nice when some cam vendors publish the lobe lift at TDC. Even though it only applies to a certain installed lobe centerline.

|

|

|

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2987291

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2987291

11/20/21 07:43 PM

11/20/21 07:43 PM

|

Joined: Jan 2003

Posts: 10,184

Frostbitefalls MN (Rocky&Bullw...

gregsdart

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 10,184

Frostbitefalls MN (Rocky&Bullw...

|

These new Pistons were cut using a piston from the old short block, same cam , same 440/1 heads cut to 62cc.

Had . 104 intake clearance at 110 cl. .140 ex at same installed centerline.

8.582, 160.18 mph best, 2905 lbs 549, indy 572-13, alky

|

|

|

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2987740

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2987740

11/22/21 09:03 AM

11/22/21 09:03 AM

|

Joined: Feb 2004

Posts: 2,073

Tulsa, Ok

WadeMetzinger

top fuel

|

top fuel

Joined: Feb 2004

Posts: 2,073

Tulsa, Ok

|

Very interesting and informative, thanks for sharing Jim. I wouldn't have a clue how to take/do all those measurements you did.

I degree the cam to ensure it's installed where I want it. Then I check P-to-V, find the tightest spot and when using belt system, I'll check the P-to-V at +/- 4 degrees from that tightest spot incase we want to try different locations (although I've never move one after dyno and installed).

Wade Metzinger 918-809-0987 71 Cuda 9.28@145 -1s, Pglide 68 Cuda 10.64@124 1.45 60's 318->390 eddys Moparts discount code on WIX - moparts www.Filter1.com

|

|

|

|

|