Sorry, I didn't attach sketch

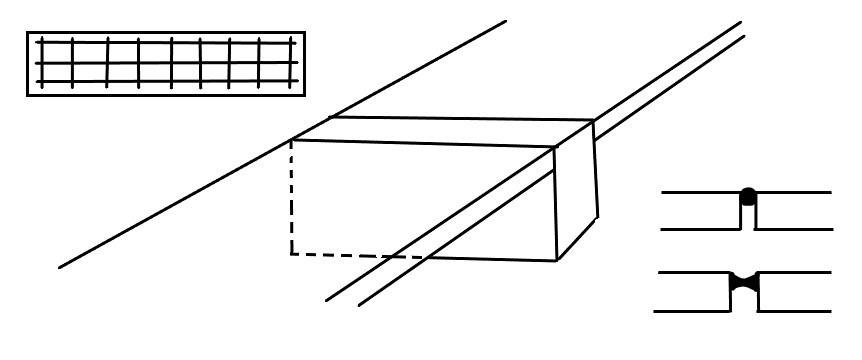

p.s. It appears there is an e.j. where the loop drive intersects. Is the main drive in that location migrating away from the intersecting loop?

If it is you have the same situation there where the slab of the concrete of the loop section pushes the main drive in the summer. Again think e.j.'s with a good rubberized sealant.

I'd like to hear back with what you hear back from contractors.

I recall one GA airport project I worked on where the runway was over 4,200' long and 60' wide. It was "flexible" ac "Type A" (all crushed rock) pavement built on base and subase of FAA spec.

Longitudinal cracks appeared every 12' (width of the spreader box on paver x 5 = 60') and the edges of the runway were clearly not a straight line. Those long strips wiggled more than a snake on hot pavement. Transverse cracks were random and some were a couple inches wide.

Over the years several attempts at sealing the cracks failed and ribbons of sealant would pull out from the cracks.

To fix the plan consisted of routing all the transverse cracks 5/5" wide, foam backer pushed down 3/4 below top surface and hot rubberized material was poured in (and not squeegeed off).

Squeege would spread the material on top in a thin "bandaid" that would pull up on landing and takeoff. Well, the cracks reappeared and only when a runway light project was constructed (trench across runway every couple hundted feet for conduit)did the problem become obvious. Overnight we noticed the trench crumbling and the asphalt pulled back, through the day (115* summer temps) the cut edge of the ac would grow and move over the trench.

Once we figured it out when the trenches were filled and compacted, ac was placed and compacted and a saw and router opened up the edges (1/4" groove) backer and rubberized material.

No more cracks.