I thought I would get the ball rolling with a few suggestions.

1. Remove the rubber grommet from the shifter arm before reconditioning shaft, it is easily removed.

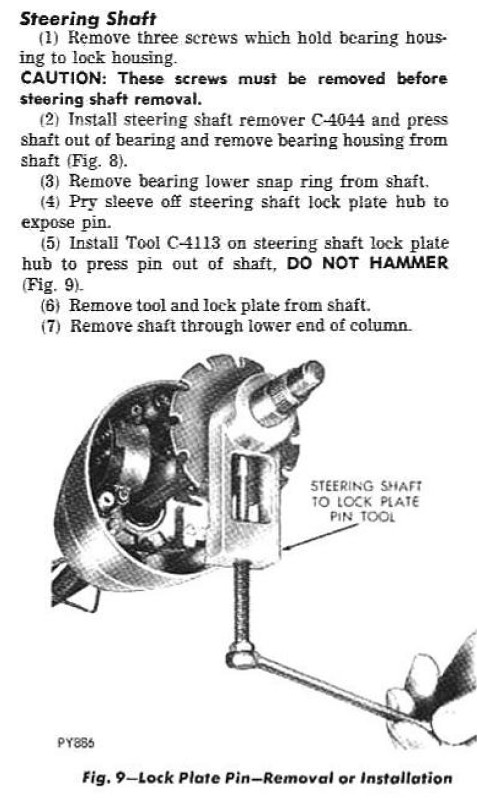

2. Support lock plate at hub or shaft and not the edge of the plate when removing and installing split pin.

Here is how the factory wanted it done, notice they support the hub and warn against using a hammer. They are trying to prevent damaging the lock plate, shaft and bearing.

3. If you don't paint the splines on the shaft or can, the collapsible can will set down on the splined shaft far enough to get a nut on it so you can pull the can in place with the nut and without the use of a hammer.

4. Inspect the insulator on the back of the horn contact ring before reusing. I noticed many cracks on the insulator in your column. The insulator prevents the contact ring from coming into contact with the adapter can. If contact is made the horn will honk.

5. List torque values and warnings from the factory manual. They were in the manual for a good reason.

6. Don't use a hammer when working on the column, there is always a way to get the job done without one.

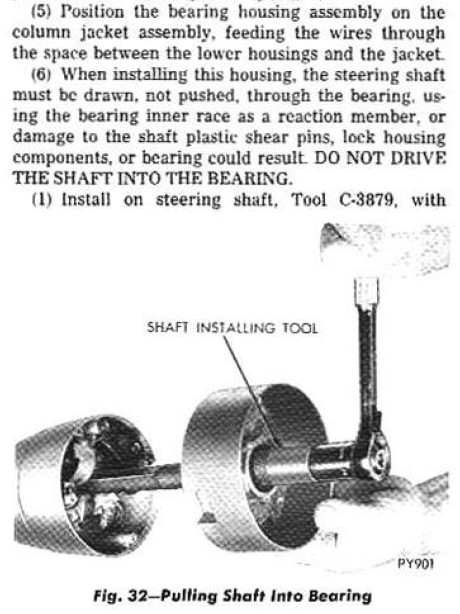

Here is how the factory installed the bearing housing assembly.

The following is personal preference:

The correct finish on the shifter tube is unplated steel on the tube and yellow zinc on the arm.

The steering shaft is unplated steel and the only part that gets painted is the section that shows in the engine compartment.