Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

[Re: Jeremiah]

#2569851

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

[Re: Jeremiah]

#2569851

10/26/18 05:48 PM

10/26/18 05:48 PM

|

Joined: Jun 2009

Posts: 1,212

QLD Australia

Keith Black®

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Jun 2009

Posts: 1,212

QLD Australia

|

Jeremiah:

The Pro block is a water block and limited to:

• tall deck

• STD (10.725) deck

This is because we have not yet developed the water jacket core tooling for low-deck casting.

With no other changes, as you reduce the deck height the deck material thins-out. This requires that you have a different water jacket to maintain the super-thick deck surface that our block has.

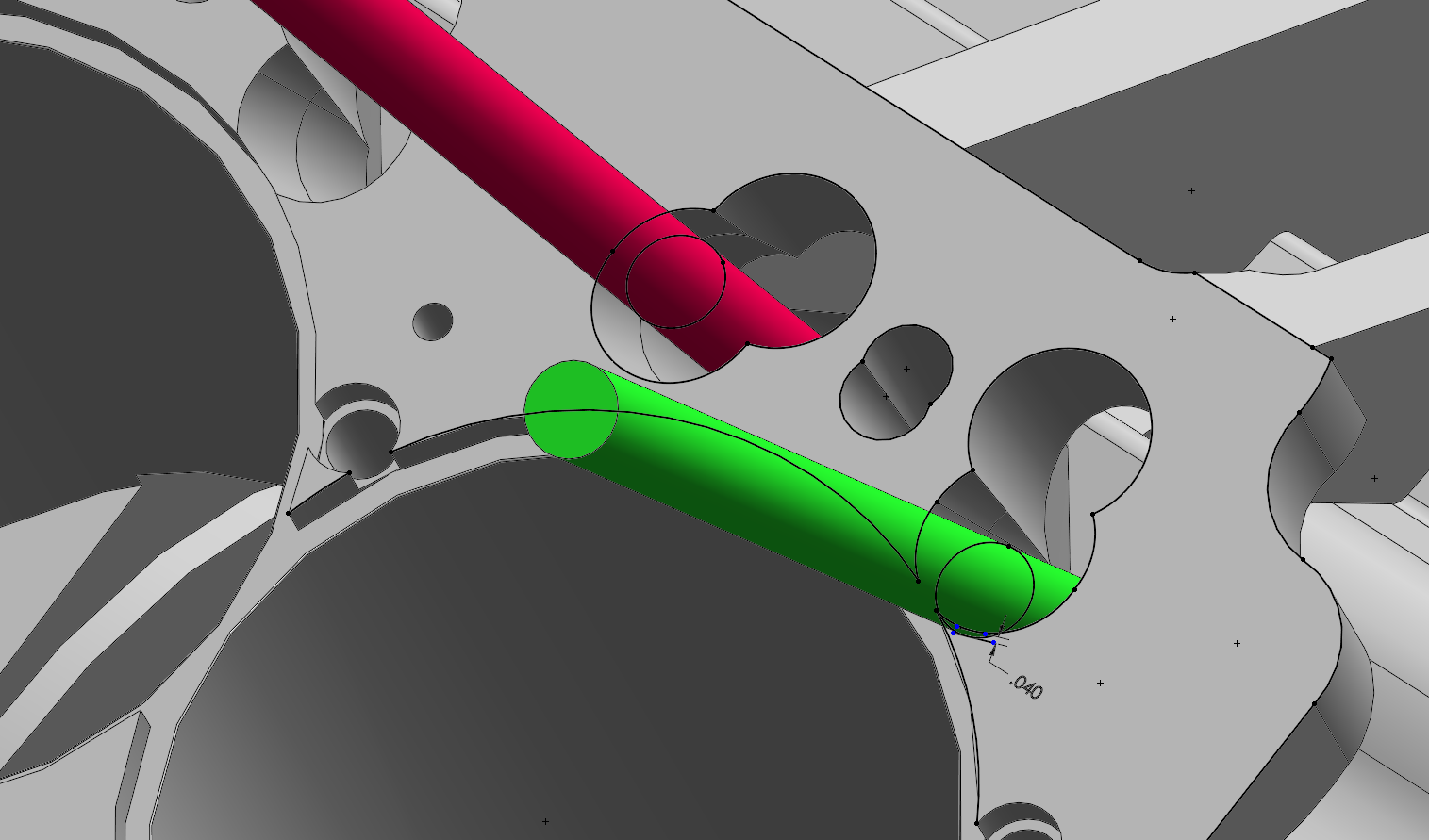

There are other considerations with the water jacket cores on low deck blocks: the valvetrain setup on the HEMI block is terrible, when you lower everything – it gets even worse (see attached image of pushrod angularity and proximity on STD blocks alone). This makes the water jacket core design super critical to avoid thin areas. While the same pushrod clearance issues wouldn’t apply to a low-deck Wedge-type-head setup, we could not justify making two different sets of cores for Wedge and HEMI Low-deck blocks given their low demand.

If we had sufficient numbers of people committed to placing orders for low-deck water blocks I would investigate introducing low deck Part Numbers (P/N’s) (and we may get there over time). However, new P/N’s require new digital design assets, new CAM with tool-path programs by our machinists, and adapted QC processes to probe and verify block integrity at completion as well. Right now we are flat out on conventional blocks.

Additionally, if people are seeking 400-style main journal diameters we would need to make design changes & machine different 4340 main bearing caps, run minimum batch lots and carry inventory of these items. The machining of the main-line is a critical and tight-tolerance operation (given material differences between A356 and 4340 billet), and we would need to adequately test this with the smaller I/D main caps as well.

Hopefully this provides enough background to the current status of the short-deck block.

--------------------------------

Darren Beale

Keith Black Racing Engines®

|

|

|

|

Entire Thread

|

Keith Black, Inc. - New HEMI and WEDGE engine blocks

Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Keith Black®

|

10/26/18 06:55 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Jeremiah

|

10/26/18 08:21 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

pittsburghracer

|

10/26/18 04:07 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Keith Black®

|

10/26/18 09:48 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

AndyF

|

10/26/18 10:54 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Keith Black®

|

10/26/18 11:17 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

WedgeFED

|

10/28/18 02:28 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

fullmetaljacket

|

10/26/18 04:29 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Mopar_Rich

|

10/26/18 05:00 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

dart games

|

10/26/18 05:34 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

cudatom

|

10/26/18 06:56 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

dart games

|

10/26/18 05:35 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

sr4440

|

10/26/18 06:25 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Keith Black®

|

10/26/18 10:05 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

sr4440

|

10/27/18 03:35 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Hemi_Joel

|

10/26/18 07:32 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

rickseeman

|

10/26/18 07:43 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

6PKRTSE

|

10/26/18 07:51 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

pittsburghracer

|

10/26/18 08:06 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Keith Black®

|

10/26/18 10:26 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Anonymous

|

10/26/18 10:40 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Skeptic

|

10/26/18 11:28 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Spaceman Spiff

|

10/27/18 12:16 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

BradH

|

10/27/18 04:20 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Spaceman Spiff

|

10/28/18 12:11 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

BradH

|

10/28/18 04:47 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

cudatom

|

10/27/18 01:54 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

sr4440

|

10/27/18 03:45 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

moetown

|

10/26/18 11:50 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

ozymaxwedge

|

10/27/18 02:55 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

tex013

|

10/27/18 03:58 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Harry's Taxi 2

|

10/27/18 08:16 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

cdwmotorsports

|

10/27/18 04:00 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Anonymous

|

10/27/18 04:31 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

ric3xrt

|

10/27/18 05:13 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

340Cuda

|

10/27/18 07:04 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

dvw

|

10/27/18 10:28 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

BANDIT

|

10/28/18 12:27 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

pittsburghracer

|

10/28/18 12:47 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Spaceman Spiff

|

10/28/18 01:44 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

pittsburghracer

|

10/28/18 01:53 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

madscientist

|

10/28/18 01:55 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

camastomcat

|

10/28/18 04:48 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

moetown

|

10/29/18 11:07 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

pittsburghracer

|

10/29/18 11:12 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Old School

|

10/29/18 11:21 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

moetown

|

10/29/18 11:39 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

BANDIT

|

10/28/18 12:58 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

hemicar1971

|

10/28/18 06:22 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

RUNCHARGER

|

10/28/18 04:56 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Jeremiah

|

10/29/18 09:24 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

camastomcat

|

10/30/18 05:22 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

pittsburghracer

|

10/30/18 05:36 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

10sec440

|

10/31/18 06:10 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Al_Alguire

|

10/31/18 06:37 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

racerx

|

10/31/18 11:51 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Al_Alguire

|

10/31/18 09:27 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Anonymous

|

10/31/18 03:14 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

madscientist

|

10/31/18 03:58 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Anonymous

|

10/31/18 04:30 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

madscientist

|

10/31/18 10:24 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

EchoSixMike

|

10/31/18 04:49 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Al_Alguire

|

10/31/18 10:31 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Keith Black®

|

11/02/18 07:23 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Keith Black®

|

11/02/18 07:43 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

racerx

|

11/03/18 08:59 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Keith Black®

|

11/03/18 09:57 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

racerx

|

11/03/18 11:07 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

racerx

|

11/02/18 11:45 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Keith Black®

|

11/02/18 01:07 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

OhioMopar

|

11/04/18 06:00 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Keith Black®

|

11/28/18 02:15 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

jughed

|

11/29/18 03:06 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

racerx

|

12/01/18 04:23 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

ric3xrt

|

11/02/18 03:06 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

6PKRTSE

|

11/28/18 07:12 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Old School

|

11/28/18 10:49 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Skeptic

|

11/29/18 02:53 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

dthemi

|

11/28/18 11:46 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

sgcuda

|

11/29/18 02:40 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Keith Black®

|

11/29/18 02:15 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Keith Black®

|

11/29/18 02:20 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

moparx

|

11/29/18 06:44 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

AndyF

|

11/29/18 07:05 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

markz528

|

11/29/18 07:11 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

hemienvy

|

11/30/18 03:17 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

racerx

|

11/29/18 03:22 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Keith Black®

|

11/29/18 01:51 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

TRENDZ

|

11/30/18 05:36 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

dthemi

|

11/30/18 02:27 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

AndyF

|

11/30/18 03:18 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

mr_340

|

12/01/18 07:17 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

dthemi

|

11/30/18 06:26 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

AndyF

|

11/30/18 06:44 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

RAMM

|

12/01/18 04:21 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

moparx

|

12/01/18 04:42 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

RAMM

|

12/01/18 05:06 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

astjp2

|

12/11/18 10:26 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

dthemi

|

11/30/18 07:02 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

dogdays

|

12/01/18 12:27 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

TRENDZ

|

12/01/18 07:40 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Biginchmopar

|

12/03/18 07:35 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

dthemi

|

12/01/18 09:13 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

dthemi

|

12/03/18 08:40 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Biginchmopar

|

12/03/18 11:47 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Stewart

|

12/05/18 03:05 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

dthemi

|

12/05/18 04:54 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Stewart

|

12/05/18 05:48 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

dthemi

|

12/05/18 11:29 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

dthemi

|

12/05/18 11:47 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Stewart

|

12/07/18 09:46 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

dthemi

|

12/08/18 02:47 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Stewart

|

12/08/18 10:30 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

dthemi

|

12/09/18 05:06 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

a493demon

|

12/11/18 06:39 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

Al_Alguire

|

12/11/18 07:25 AM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

racerx

|

09/20/19 01:05 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

jughed

|

09/23/19 11:20 PM

|

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

Re: Keith Black, Inc. - New HEMI and WEDGE engine blocks

|

hudsonhornet7x

|

09/24/19 12:45 PM

|

|

|

|