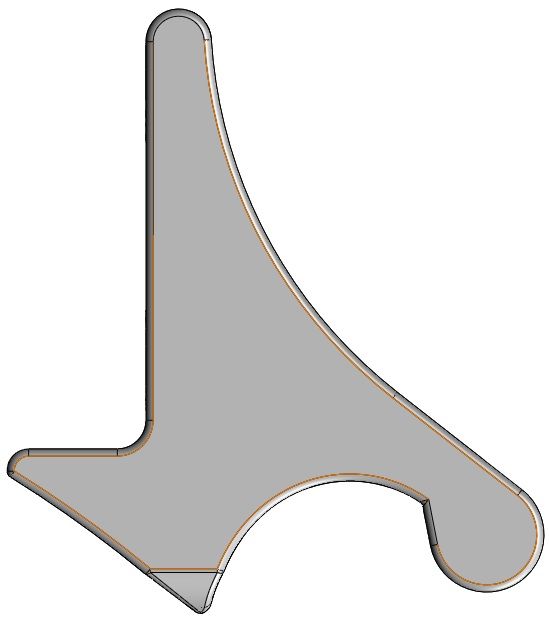

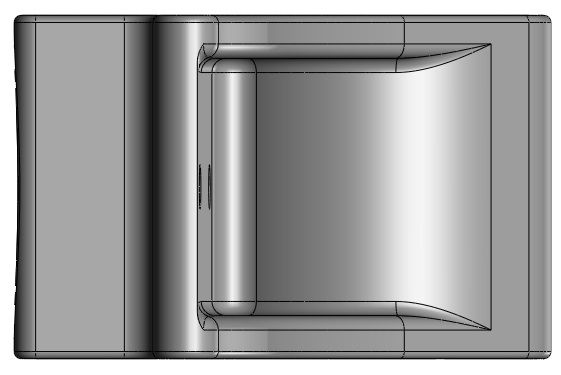

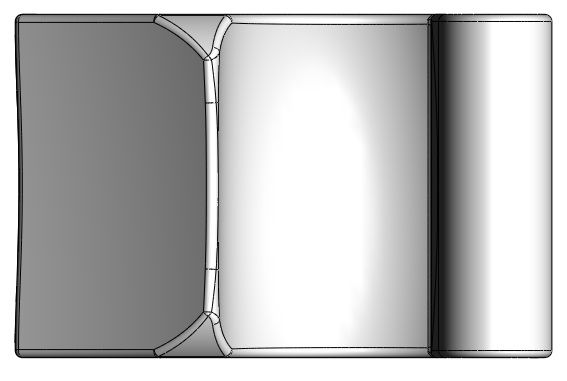

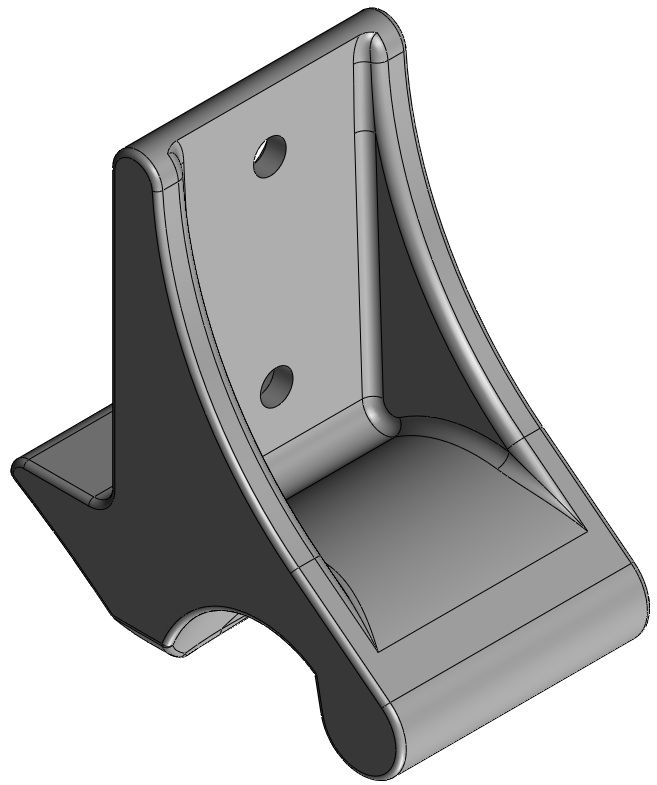

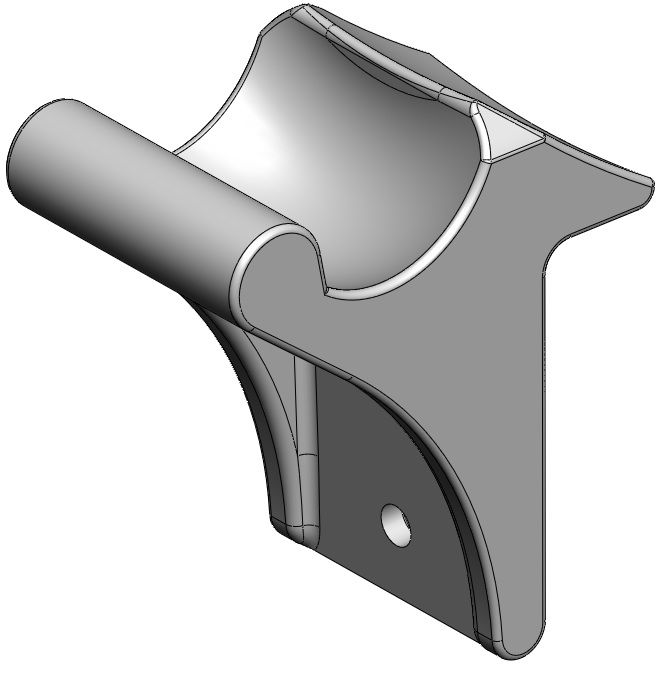

Hello Everyone. I know it's been a long time since the last post on this topic, but I wanted to report back on the latest progress. I tried many months ago to make a new nylon piece from the nylon bar stock using a dremel and various cutting/carving bits. I got close to finishing one piece, but decided to put the project on the "back burner" so I could work on other stuff the car needed. The carving/cutting was very tedious and time consuming, and VERY messy (nylon shavings everywhere). Toward the end of the year I decided to revisit the project. Someone here posted a 3D image of the piece, and I thought about having my one good piece 3D scanned, and have it "printed" in nylon using a 3D printing service provider. I researched 3D printing, and sourced a small company in the Los Angeles area that provided both scanning and printing. Not all 3D printers can print using nylon (most print using ABS, or similar plastic materials). Anyway, after my approval of the 3D images (see attached), the new pieces were printed, and I received the first pair several weeks ago, but they were slightly smaller in size compared to the original (probably due to cleaning up the 3D scan). I provided caliper measurements of the new and original pieces, and asked if the 3D data file could be manipulated so that the dimensions matched the original. The answer was "Yes". The 3D scan file was adjusted and new pieces were made. I just got them today (see photos of new vs. old pieces). The turnaround was relatively quick; and quite surprisingly, the cost was really not that bad. 3D scan was $25.00, and printing (2) pieces was $13.00 + $10.00 shipping (total = $48.00). I also received the 3D data file (STL format), so I can send this to any 3D printing company and have more pieces made. Let me know if anyone needs some.