|

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2989339

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2989339

11/26/21 02:45 PM

11/26/21 02:45 PM

|

Joined: Nov 2011

Posts: 287

PA

Harry's Taxi 2

enthusiast

|

enthusiast

Joined: Nov 2011

Posts: 287

PA

|

I'd suggest verifying cam specs.

'86 Maple Grove KOS Mopar low qualifier......true street legal with no power adders.

NOS-used when losing since 1940.

|

|

|

Re: 572 B1 org Part 5 - Build Notes

[Re: Harry's Taxi 2]

#2989449

Re: 572 B1 org Part 5 - Build Notes

[Re: Harry's Taxi 2]

#2989449

11/26/21 10:08 PM

11/26/21 10:08 PM

|

Joined: Jan 2003

Posts: 16,928

NC

440Jim

OP

OP

I Live Here

|

OP

OP

I Live Here

Joined: Jan 2003

Posts: 16,928

NC

|

I'd suggest verifying cam specs. Did you miss this post on Nov 18th? [url=https://board.moparts.org/ubbthreads/ubbthreads.php/topics/2986438/re-572-b1-org-part-5-build-notes.html#Post2986438][/url]

|

|

|

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2989451

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2989451

11/26/21 10:15 PM

11/26/21 10:15 PM

|

Joined: Jan 2003

Posts: 16,928

NC

440Jim

OP

OP

I Live Here

|

OP

OP

I Live Here

Joined: Jan 2003

Posts: 16,928

NC

|

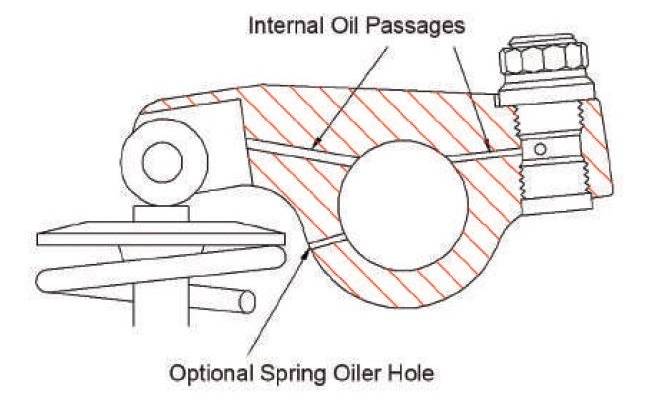

I was hoping to have the heads torqued today, but it didn't happen. I have the heads on the studs, with head gasket, etc. But tomorrow will have to be the day to lube and torque all the head stud nuts. I was happy to finish the setup of the heads with proper valve spring heights, seals, etc. Lots of little details seem to take me a lot of time. But that makes me happy.  I did buy a new crank/damper bolt, some 10-32 set screws , and new spark plugs on my way home from lunch today. The set screws go in the head holes that can be used to restrict rocker oiling from the block to the rockers/heads. They are under the rocker stands. So if somebody wanted to remove the paired T&D rockers and put the long single shaft rockers on these heads (which oil from the block), they would not have to pull the heads, just the rockers and replace these solid set screws. But I am using pushrod oiling... hence the solid set screws (instead of drilled restrictors.) These are in the heads, not the block (which can be restricted/plugged also, since the block is threaded.)

|

|

|

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2989506

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2989506

11/27/21 07:32 AM

11/27/21 07:32 AM

|

Joined: Nov 2011

Posts: 287

PA

Harry's Taxi 2

enthusiast

|

enthusiast

Joined: Nov 2011

Posts: 287

PA

|

I'd suggest verifying cam specs. Did you miss this post on Nov 18th? [url=https://board.moparts.org/ubbthreads/ubbthreads.php/topics/2986438/re-572-b1-org-part-5-build-notes.html#Post2986438][/url] Apparently i did.....sorry to say that i don't follow your every post. i have bought 4 cams lately that have been from 2-6 degrees off on intake lobes and 2 of those are from the same grinder you used. You're welcome for the reminder just the same.

Last edited by Harry's Taxi 2; 11/27/21 07:38 AM.

'86 Maple Grove KOS Mopar low qualifier......true street legal with no power adders.

NOS-used when losing since 1940.

|

|

|

Re: 572 B1 org Part 5 - Build Notes

[Re: Harry's Taxi 2]

#2989531

Re: 572 B1 org Part 5 - Build Notes

[Re: Harry's Taxi 2]

#2989531

11/27/21 10:40 AM

11/27/21 10:40 AM

|

Joined: Jan 2003

Posts: 16,928

NC

440Jim

OP

OP

I Live Here

|

OP

OP

I Live Here

Joined: Jan 2003

Posts: 16,928

NC

|

i have bought 4 cams lately that have been from 2-6 degrees off on intake lobes and 2 of those are from the same grinder you used.

You're welcome for the reminder just the same. Thanks for letting me know of your experience. I bought this cam from another racer that never used it. It came in a package deal with my B1 heads, intake, valve covers, valley plate, etc. I measured the lobes using a dial indicator type follower with 0.810" dia. My roller lifters (Comp 892 offset seats, pushrod oiling) have 0.800" dia wheels. If the dia is significantly different, it can change lobe numbers slightly. Both intake and exhaust measured 1-2 degrees more than the cam card. I actually measured 5 intake and exhaust lobes (different cylinders).

|

|

|

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2992221

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2992221

12/05/21 12:19 PM

12/05/21 12:19 PM

|

Joined: Jan 2003

Posts: 16,928

NC

440Jim

OP

OP

I Live Here

|

OP

OP

I Live Here

Joined: Jan 2003

Posts: 16,928

NC

|

Part 5 – Intake Gaskets. Build NotesThis note may be fairly specific to the porting on my heads/intake, but the gasket info may be of interest to other B1 head users. I had previously bought gaskets from Koffel's Place, and those are 1.60 x 2.66. Those are smaller than the ports on my heads. I bought these intake manifold gaskets from FlatOut Gaskets and they fit my head ports very well. They are part number 8185 and their catalog lists the size as 1.75 x 2.82 FlatOut makes lots of different gaskets, this link is to the various thicknesses of the #8185 FlatOut Gaskets 8185The gaskets have two corners clipped, and they fit my heads with those corners on the bottom! This way, the top of the gasket aligns well with the valve cover sealing surface. And just like the Koffel's gaskets, I need to trim the area under the bolt holes for the B1 valley plate.

|

|

|

Re: 572 B1 org Part 5 - Build Notes

[Re: moparx]

#2992285

Re: 572 B1 org Part 5 - Build Notes

[Re: moparx]

#2992285

12/05/21 03:00 PM

12/05/21 03:00 PM

|

Joined: Jan 2003

Posts: 16,928

NC

440Jim

OP

OP

I Live Here

|

OP

OP

I Live Here

Joined: Jan 2003

Posts: 16,928

NC

|

I like the FlatOut gaskets. And several choices even a steel core.

FWIW, this pic shows the port misalignment if I put the cropped corners UP. The gasket hole centerline is 0.030" different than the port centerline.

So flipping the gasket moves the port opening 0.060"

Last edited by 440Jim; 12/05/21 04:03 PM.

|

|

|

Re: 572 B1 org Part 5 - Build Notes

[Re: AndyF]

#2992305

Re: 572 B1 org Part 5 - Build Notes

[Re: AndyF]

#2992305

12/05/21 04:04 PM

12/05/21 04:04 PM

|

Joined: Jan 2003

Posts: 16,928

NC

440Jim

OP

OP

I Live Here

|

OP

OP

I Live Here

Joined: Jan 2003

Posts: 16,928

NC

|

You should send those pictures to the mfg and see what they say. They might have their drawing wrong or they might not know. The aftermarket is full of parts that are built wrong because somebody made an error and nobody ever pointed it out. I will do that. But the shop that ported my heads (before I bought them) may have moved the ports too. But I just thought the gasket hole centerline would be the same as the gasket port centerline.

|

|

|

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2992366

Re: 572 B1 org Part 5 - Build Notes

[Re: 440Jim]

#2992366

12/05/21 07:11 PM

12/05/21 07:11 PM

|

Joined: Jan 2003

Posts: 14,506

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,506

So. Burlington, Vt.

|

I built a 572 several years ago using 572-13 heads and a Bill Mitchell/Mopar aluminum block.

The heads used Jesel rockers and I thought I’d be clever and pushrod oil with the 892 lifters.

As it turned out, the Chevy oriented oil holes in the lifters lined up perfectly with the oil feed hole in the lifter bushing with the .484 lobe lift cam with it on the base circle.

When I went to prime the oil system, as soon as the drill started to lug down from the load of pumping the oil....... oil shot out of the top of a few of the adjuster screws about 20ft across the shop.

The correct oil hole orientation in the lifter for a Mopar is to have them parallel to the axle...... not perpendicular.

For proper oil “metering” to the top end with edge orifice oiling type lifters, the pressurized oil in the oil band squeezes between the lifter bore and the lifter body to get into the pushrod feed hole above the band.

In my situation, with the oil hole in the lifter bore/lifter body lined right up with each other, I had totally unrestricted oil to the top end whenever the lifter was close to being on the cams base circle.

Which wouldn’t have been good at all.

So, I took the path of least resistance........ 87019 lifters(892’s with no oil hole) and spray bar valve covers.

Jim, If you haven’t verified this isn’t a problem on your build, I wouldn’t wait until the last thing to check it.

On my build, even running the drill very slow resulted in oil just gushing out of any rocker that was nearly closed.

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

Re: 572 B1 org Part 5 - Build Notes

[Re: AndyF]

#2992408

Re: 572 B1 org Part 5 - Build Notes

[Re: AndyF]

#2992408

12/05/21 10:02 PM

12/05/21 10:02 PM

|

Joined: Jan 2003

Posts: 16,928

NC

440Jim

OP

OP

I Live Here

|

OP

OP

I Live Here

Joined: Jan 2003

Posts: 16,928

NC

|

Does the gasket line up with the ports in the intake? If all three parts line up together then you have a winner. I don't know what the cut corners are for. Maybe they are supposed to go down but that does seem odd. Andy, The intake runners are tapered toward the heads. So at the intake manifold, the ports are smaller then the large CNC ported heads. Although the previous owner did open up the intake manifold some, the rest of the transition occurs in the ~0.75" thick RB intake manifold spacers. My intake manifold exit is actually larger than the Koffel's gaskets, but not as big as the heads. Remember, the B1 intake fits a low deck block and the RB spacers are used for a RB block. Fast68plymouth, I have done lots of measurements on the BMP block lifter bore bushing 0.035" oil hole, the cam base circle, and the Comp 892 lifter oil hole. That is an entire topic on its own. Thanks for the heads-up. Just like my KB motor, I will prime the system after it is all together to see what the rocker oiling looks like. Fingers crossed. I have T&D rockers, rather than Jesel. FWIW The cam I have for this engine has a slightly different base circle diameter, than the one on my buddies 440-SR headed engine with BMP aluminum block. But he used Indy oil lines, not pushrod. I used the same Comp lifters on my last 440-1 heads and KB aluminum block engine and the head oiling was perfect. But there are lots of differences.... The valve covers that came with my heads have spray bars if that is needed. But if the lifters/pushrods put too much oil to the heads, it will require changes. Ugh!

|

|

|

Re: 572 B1 org Part 5 - Build Notes

[Re: AndyF]

#2992493

Re: 572 B1 org Part 5 - Build Notes

[Re: AndyF]

#2992493

12/06/21 10:22 AM

12/06/21 10:22 AM

|

Joined: Jan 2003

Posts: 14,506

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,506

So. Burlington, Vt.

|

The Comp AMC lifters have the pushrod oil feed hole in the correct position for a Mopar....... parallel with the axle.

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

|

|