|

Re: ARP L19 rod bolt torque

[Re: mopar dave]

#3106523

Re: ARP L19 rod bolt torque

[Re: mopar dave]

#3106523

12/29/22 11:26 PM

12/29/22 11:26 PM

|

Joined: Feb 2008

Posts: 714

Central TEXAS!!!!

sr4440

super stock

|

super stock

Joined: Feb 2008

Posts: 714

Central TEXAS!!!!

|

I use the stretch method, but I end up right at 92-95 lb-ft.

Joe

Without Data, you’re just another guy with an opinion.

|

|

|

Re: ARP L19 rod bolt torque

[Re: mopar dave]

#3106542

Re: ARP L19 rod bolt torque

[Re: mopar dave]

#3106542

12/30/22 12:51 AM

12/30/22 12:51 AM

|

Joined: Nov 2003

Posts: 1,362

Out of the State of Confusion

blue_stocker

pro stock

|

pro stock

Joined: Nov 2003

Posts: 1,362

Out of the State of Confusion

|

Last edited by blue_stocker; 12/30/22 01:36 AM.

I predict future happiness for Americans if they can prevent the government from wasting the labors of the people under the pretense of taking care of them.

Thomas Jefferson

Freedom must be repurchased by every new generation

General Daniel Jones, WW2 Tuskegee Airmen

|

|

|

Re: ARP L19 rod bolt torque

[Re: mopar dave]

#3106604

Re: ARP L19 rod bolt torque

[Re: mopar dave]

#3106604

12/30/22 10:51 AM

12/30/22 10:51 AM

|

Joined: Jan 2003

Posts: 1,757

Windsor, ON, Canada

Diplomat360

top fuel

|

top fuel

Joined: Jan 2003

Posts: 1,757

Windsor, ON, Canada

|

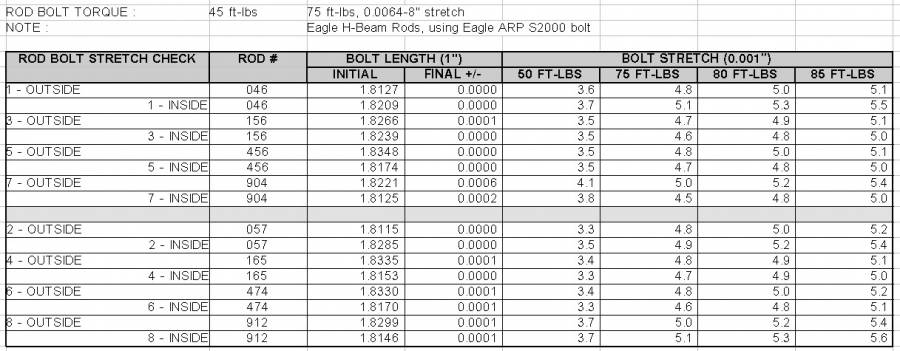

I have dabbled with a stretch gauge in the past with not so good results. The gauge would never repeat each time it was removed and my numbers where all over the place... I feel your pain as that was pretty much my experience as I attempted to do this for the very first time. After a few tries I discovered that the gauge tension needed to be much higher to make it less susceptible to even the tiniest movement. Replacing the dial indicator spring helped greatly. Still, I would have a steady reading that all of a sudden would jump by like 0.005" or so...ugh??? Well, the 2nd part was to make sure that the rod bolt ends and my gauge and dial indicator locating pin/foot left no room for the bolt to move around. Off shopping I went, picked up a set of these attachments with different shapes and found one that would mate very well. These two steps were key to getting repeatable results. Having said that...my Eagle H-beam rods had the Eagle ARP S2000 bolts, spec'ed for 0.0064-8" stretch at 75 ft-lbs. I went through 3 ON/OFF cycles, in the proper connecting rod vise, using the ARP lube, eventually got them to 85 ft-lbs and stopped there. The numbers were repeatable but I could not get them to that 0.0064-8 stretch.

|

|

|

Re: ARP L19 rod bolt torque

[Re: Diplomat360]

#3106614

Re: ARP L19 rod bolt torque

[Re: Diplomat360]

#3106614

12/30/22 11:20 AM

12/30/22 11:20 AM

|

Joined: Jan 2007

Posts: 8,032

Mt Morris Michigan

mopar dave

OP

OP

master

|

OP

OP

master

Joined: Jan 2007

Posts: 8,032

Mt Morris Michigan

|

Yes, the tip style does matter and it seemed like the measuring surface in the bolt head was not very uniform on the Molnar 2000 bolts. I gave up and just torque them using torque to yield method Molnar suggested. Rods are still in the block 5 years later. Callies included an instruction card with torque suggested torque method, torque to 25lbft then to 92. I just question that as that is not my method of torquing a bolt and the final spec seems very high for that size of bolt, but then again i have never dealt with L19 bolts. Thanks for the info. I might check stretch on all them if the numbers look trustworthy.

Last edited by mopar dave; 12/30/22 11:27 AM.

|

|

|

Re: ARP L19 rod bolt torque

[Re: mopar dave]

#3107929

Re: ARP L19 rod bolt torque

[Re: mopar dave]

#3107929

01/03/23 09:57 AM

01/03/23 09:57 AM

|

Joined: Jan 2003

Posts: 13,360

Marion, South Carolina [><]

an8sec70cuda

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 13,360

Marion, South Carolina [><]

|

Glad I'm not the only one who's had trouble with the rod bolt stretch measurement.  I tried to do that w/ my hemi when I built it in 2006 w/ Oliver rods. Had a heck of a time getting consistent measurements...real sensitive. Ended up just torqueing them to Oliver's spec. That was 2006 and I've beat on this motor pretty good w/ no issues. That stretch gauge hasn't left my toolbox since.

CHIP

'70 hemicuda, 575" Hemi, 727, Dana 60

'69 road runner, 440-6, 18 spline 4 speed, Dana 60

'71 Demon, 340, low gear 904, 8.75

'73 Chrysler New Yorker, 440, 727, 8.75

'90 Chevy 454SS Silverado, 476" BBC, TH400, 14 bolt

'06 GMC 2500HD LBZ Duramax

|

|

|

Re: ARP L19 rod bolt torque

[Re: mopar dave]

#3108298

Re: ARP L19 rod bolt torque

[Re: mopar dave]

#3108298

01/03/23 10:01 PM

01/03/23 10:01 PM

|

Joined: Aug 2003

Posts: 43,157

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,157

Bend,OR USA

|

All the ARP 8640 (I think that is the correct number for the cheaper ARP rod bolts) and all the ARP 2000 bolts I've used had nice machine recesses, divots, in both ends for the rod bolt stretch dial indicator ends  I do remember reading on the stock 440 and 383 ARP replacement rod bolts with nuts to stretch them and release them three times before using them with their stretch methods a long time ago  IHTHs

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: ARP L19 rod bolt torque

[Re: mopar dave]

#3108334

Re: ARP L19 rod bolt torque

[Re: mopar dave]

#3108334

01/04/23 03:10 AM

01/04/23 03:10 AM

|

Joined: Sep 2012

Posts: 39

West Central Indiana

PROSTOCKTOM

member

|

member

Joined: Sep 2012

Posts: 39

West Central Indiana

|

The best thing you can do with L19 bolts is to toss them in the trash. Those bolts have cause more rod failures than any other bolt ever has.

They are so strong to the point the are brittle and will snap off. Call Tom Molnar who has 41 years in the rod business start at Oliver, then K-1, and now his own company Molnar Technologies we will tell you many

horror stories of rods failing with L19 bolts.

Tom

Last edited by PROSTOCKTOM; 01/04/23 03:12 AM.

Molnar Technologies Full Service Dealer - Crankshafts & Connecting Rods

|

|

|

Re: ARP L19 rod bolt torque

[Re: PROSTOCKTOM]

#3108338

Re: ARP L19 rod bolt torque

[Re: PROSTOCKTOM]

#3108338

01/04/23 03:59 AM

01/04/23 03:59 AM

|

Joined: Aug 2003

Posts: 43,157

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,157

Bend,OR USA

|

The best thing you can do with L19 bolts is to toss them in the trash. Those bolts have cause more rod failures than any other bolt ever has.

They are so strong to the point the are brittle and will snap off. Call Tom Molnar who has 41 years in the rod business start at Oliver, then K-1, and now his own company Molnar Technologies we will tell you many

horror stories of rods failing with L19 bolts.

Tom This is the first I have heard of this issue on those bolts  My understanding on the ranking of strengths on ARP after market race rod bolt is ARP 8740 7/16 depending on he under head length is the cheapest and on the bottom of the strength charts, the ARP 2000 are in the middle and the L19 and SPS bolts are the strongest and the best   I will say this on the ARP 2000 7/16 bolts Tom uses is they are all custom made to his design and manufacturing specs and they are the only ARP 2000 rod bolt I have had any issue with on the strength when using the bolt stretch method of tightening them: work : ARP will not stand behind them whiney: He has to cover his custom made products warrantee

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: ARP L19 rod bolt torque

[Re: Cab_Burge]

#3108342

Re: ARP L19 rod bolt torque

[Re: Cab_Burge]

#3108342

01/04/23 05:04 AM

01/04/23 05:04 AM

|

Joined: Sep 2012

Posts: 39

West Central Indiana

PROSTOCKTOM

member

|

member

Joined: Sep 2012

Posts: 39

West Central Indiana

|

The best thing you can do with L19 bolts is to toss them in the trash. Those bolts have cause more rod failures than any other bolt ever has.

They are so strong to the point the are brittle and will snap off. Call Tom Molnar who has 41 years in the rod business start at Oliver, then K-1, and now his own company Molnar Technologies we will tell you many

horror stories of rods failing with L19 bolts.

Tom This is the first I have heard of this issue on those bolts  My understanding on the ranking of strengths on ARP after market race rod bolt is ARP 8740 7/16 depending on he under head length is the cheapest and on the bottom of the strength charts, the ARP 2000 are in the middle and the L19 and SPS bolts are the strongest and the best   I will say this on the ARP 2000 7/16 bolts Tom uses is they are all custom made to his design and manufacturing specs and they are the only ARP 2000 rod bolt I have had any issue with on the strength when using the bolt stretch method of tightening them: work : ARP will not stand behind them whiney: He has to cover his custom made products warrantee   Molnar will not and does not use any L19 bolts in their products. Just for fun call Tom and talk to him about it. I myself have no interest in blowing up an engine from bad rod bolts. Tom

Molnar Technologies Full Service Dealer - Crankshafts & Connecting Rods

|

|

|

Re: ARP L19 rod bolt torque

[Re: PROSTOCKTOM]

#3108365

Re: ARP L19 rod bolt torque

[Re: PROSTOCKTOM]

#3108365

01/04/23 09:26 AM

01/04/23 09:26 AM

|

Joined: Jan 2003

Posts: 13,360

Marion, South Carolina [><]

an8sec70cuda

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 13,360

Marion, South Carolina [><]

|

Interesting.  I sent my Oliver rods back to Oliver 3 years ago to be rebuilt. They installed new rod bolts, which are ARP L19.

CHIP

'70 hemicuda, 575" Hemi, 727, Dana 60

'69 road runner, 440-6, 18 spline 4 speed, Dana 60

'71 Demon, 340, low gear 904, 8.75

'73 Chrysler New Yorker, 440, 727, 8.75

'90 Chevy 454SS Silverado, 476" BBC, TH400, 14 bolt

'06 GMC 2500HD LBZ Duramax

|

|

|

|

|