Moparts

ARP L19 rod bolt torque

Posted By: mopar dave

ARP L19 rod bolt torque - 12/30/22 01:21 AM

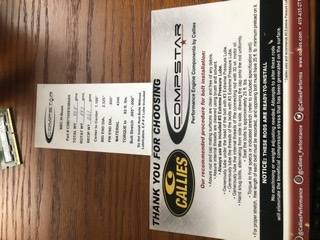

Pistons and Callies H beams are ready to install. The rods have L19 arp bolts and Callies spec is 92 lbft using Callies #3 extreme pressure lube. Seems high, but i'm curious to what you guys have been torquing the L19 bolt to with good results?

Posted By: sr4440

Re: ARP L19 rod bolt torque - 12/30/22 03:26 AM

I use the stretch method, but I end up right at 92-95 lb-ft.

Joe

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 12/30/22 04:26 AM

I have dabbled with a stretch gauge in the past with not so good results. The gauge would never repeat each time it was removed and my numbers where all over the place. I prefer to torque and forget. Callies suggest torque to 25lbft then to final spec. Was this your method? I like to torque in three even steps if possible. Not sure it really matters.

Posted By: dart9ss

Re: ARP L19 rod bolt torque - 12/30/22 04:45 AM

Stretch & Torque Values

Stretch: 0.0065 - 0.0070 in.

Bolt Torque Value: 80 ft-lbs (108 Nm) with ARP Ultra-Torque Fastener Assembly Lubricant

saw this on there website for that particular bolt

Posted By: blue_stocker

Re: ARP L19 rod bolt torque - 12/30/22 04:51 AM

Posted By: dvw

Re: ARP L19 rod bolt torque - 12/30/22 02:32 PM

Make sure you don't handle L 19 bolts with your hands. They are very suseptible to corosion. I'd read up on them.

Doug

Posted By: Diplomat360

Re: ARP L19 rod bolt torque - 12/30/22 02:51 PM

I have dabbled with a stretch gauge in the past with not so good results. The gauge would never repeat each time it was removed and my numbers where all over the place...

I feel your pain as that was pretty much my experience as I attempted to do this for the very first time. After a few tries I discovered that the gauge tension needed to be much higher to make it less susceptible to even the tiniest movement. Replacing the dial indicator spring helped greatly. Still, I would have a steady reading that all of a sudden would jump by like 0.005" or so...ugh???

Well, the 2nd part was to make sure that the rod bolt ends and my gauge and dial indicator locating pin/foot left no room for the bolt to move around. Off shopping I went, picked up a set of these attachments with different shapes and found one that would mate very well.

These two steps were key to getting repeatable results.

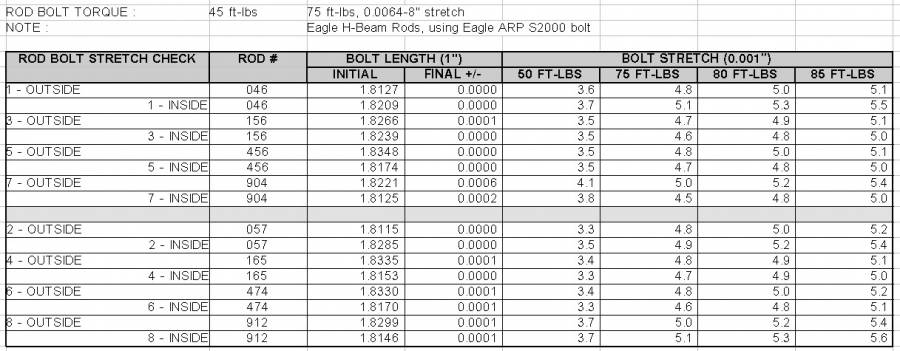

Having said that...my Eagle H-beam rods had the Eagle ARP S2000 bolts, spec'ed for 0.0064-8" stretch at 75 ft-lbs. I went through 3 ON/OFF cycles, in the proper connecting rod vise, using the ARP lube, eventually got them to 85 ft-lbs and stopped there. The numbers were repeatable but I could not get them to that 0.0064-8 stretch.

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 12/30/22 03:20 PM

Yes, the tip style does matter and it seemed like the measuring surface in the bolt head was not very uniform on the Molnar 2000 bolts. I gave up and just torque them using torque to yield method Molnar suggested. Rods are still in the block 5 years later. Callies included an instruction card with torque suggested torque method, torque to 25lbft then to 92. I just question that as that is not my method of torquing a bolt and the final spec seems very high for that size of bolt, but then again i have never dealt with L19 bolts. Thanks for the info. I might check stretch on all them if the numbers look trustworthy.

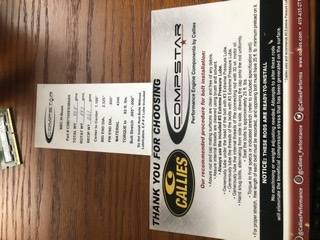

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 12/30/22 03:32 PM

Here’s what they gave me.

Posted By: Cab_Burge

Re: ARP L19 rod bolt torque - 12/30/22 08:48 PM

I would, and have and do, call ARP for the straight scoop to make sure I get it done correctly

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 12/31/22 12:51 AM

torqued the rod bolts to 92lbft and measuring bolt stretch along to way netted the same results as last time i tried that. numbers all over the place, but i did average .004-.0045 on stretch. I dont put alot of clout into those numbers because zeroing the gauge and moving the upper locater the smallest bit resulted in .002-.004 differences. ARP needs to put accurate locating divits into both ends of the bolts. I measured .003 to .005 between the different bolts. My spec was .005-.006 or 92lbft.

Posted By: an8sec70cuda

Re: ARP L19 rod bolt torque - 01/03/23 01:57 PM

Glad I'm not the only one who's had trouble with the rod bolt stretch measurement.

I tried to do that w/ my hemi when I built it in 2006 w/ Oliver rods. Had a heck of a time getting consistent measurements...real sensitive. Ended up just torqueing them to Oliver's spec. That was 2006 and I've beat on this motor pretty good w/ no issues. That stretch gauge hasn't left my toolbox since.

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 01/03/23 02:24 PM

Glad i'm not the only one having trouble with that as well. If ARP would just machine a divit into each end of the bolt to positively locate the gauge, problem solved.

Posted By: Cab_Burge

Re: ARP L19 rod bolt torque - 01/04/23 02:01 AM

All the ARP 8640 (I think that is the correct number for the cheaper ARP rod bolts) and all the ARP 2000 bolts I've used had nice machine recesses, divots, in both ends for the rod bolt stretch dial indicator ends

I do remember reading on the stock 440 and 383 ARP replacement rod bolts with nuts to stretch them and release them three times before using them with their stretch methods a long time ago

IHTHs

Posted By: PROSTOCKTOM

Re: ARP L19 rod bolt torque - 01/04/23 07:10 AM

The best thing you can do with L19 bolts is to toss them in the trash. Those bolts have cause more rod failures than any other bolt ever has.

They are so strong to the point the are brittle and will snap off. Call Tom Molnar who has 41 years in the rod business start at Oliver, then K-1, and now his own company Molnar Technologies we will tell you many

horror stories of rods failing with L19 bolts.

Tom

Posted By: Cab_Burge

Re: ARP L19 rod bolt torque - 01/04/23 07:59 AM

The best thing you can do with L19 bolts is to toss them in the trash. Those bolts have cause more rod failures than any other bolt ever has.

They are so strong to the point the are brittle and will snap off. Call Tom Molnar who has 41 years in the rod business start at Oliver, then K-1, and now his own company Molnar Technologies we will tell you many

horror stories of rods failing with L19 bolts.

Tom

This is the first I have heard of this issue on those bolts

My understanding on the ranking of strengths on ARP after market race rod bolt is ARP 8740 7/16 depending on he under head length is the cheapest and on the bottom of the strength charts, the ARP 2000 are in the middle and the L19 and SPS bolts are the strongest and the best

I will say this on the ARP 2000 7/16 bolts Tom uses is they are all custom made to his design and manufacturing specs and they are the only ARP 2000 rod bolt I have had any issue with on the strength when using the bolt stretch method of tightening them: work :

ARP will not stand behind them whiney: He has to cover his custom made products warrantee

Posted By: PROSTOCKTOM

Re: ARP L19 rod bolt torque - 01/04/23 09:04 AM

The best thing you can do with L19 bolts is to toss them in the trash. Those bolts have cause more rod failures than any other bolt ever has.

They are so strong to the point the are brittle and will snap off. Call Tom Molnar who has 41 years in the rod business start at Oliver, then K-1, and now his own company Molnar Technologies we will tell you many

horror stories of rods failing with L19 bolts.

Tom

This is the first I have heard of this issue on those bolts

My understanding on the ranking of strengths on ARP after market race rod bolt is ARP 8740 7/16 depending on he under head length is the cheapest and on the bottom of the strength charts, the ARP 2000 are in the middle and the L19 and SPS bolts are the strongest and the best

I will say this on the ARP 2000 7/16 bolts Tom uses is they are all custom made to his design and manufacturing specs and they are the only ARP 2000 rod bolt I have had any issue with on the strength when using the bolt stretch method of tightening them: work :

ARP will not stand behind them whiney: He has to cover his custom made products warrantee

Molnar will not and does not use any L19 bolts in their products. Just for fun call Tom and talk to him about it. I myself have no interest in blowing up an engine from bad rod bolts.

Tom

Posted By: an8sec70cuda

Re: ARP L19 rod bolt torque - 01/04/23 01:26 PM

Interesting.

I sent my Oliver rods back to Oliver 3 years ago to be rebuilt. They installed new rod bolts, which are ARP L19.

Posted By: dvw

Re: ARP L19 rod bolt torque - 01/04/23 04:21 PM

Google L-19 bolt corosion.

Doug

Posted By: mopar_mark

Re: ARP L19 rod bolt torque - 01/04/23 09:56 PM

I also read up on L19 bolts, contamination if handled without gloves, hydrogen embrittlement….definitely not a bolt I would use. I decided to run Custom Age 625

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 01/12/23 04:27 AM

Gonna revisit this L19 bolt torque gig again. I spoke with my shop and Callie rods. Callies said it was fine to torque to 92lbft and forget. My shop suggested measuring stretch, so i bought another stretch gauge. I will do this one more time and if i get the same results as last, it will be the last time i measure rod bolt stretch.

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 01/12/23 04:53 AM

Here's what i bought.

.JPG)

Posted By: dvw

Re: ARP L19 rod bolt torque - 01/12/23 12:41 PM

I use this gauge. You have to wiggle it around a little to find your number. I measured a few rod bolt lengths and made a standard with drilled ends that mimic the bolt divets. This standard is marked top/bottom. Set the gauge to zero on the standard. Measure all the bolts 1st. Then you will know how they compare. Some will be longer, some shorter. Add you stretch figure to the measured numbers. Write all the measurements down keeping track of each bolts rod location in or out. So for example; say rod #1 inner bolt measures + .0005 and the outer is -.0006 vs the std. Lets say the spec is .0060-.0064. Now when you measure after stretching the inner should measure .0069-.0073 The outer should be .0054-.0058, This way you don't zero the gauge everytime. You can go back to your standard at anytime to check zero.

Doug

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 01/12/23 03:49 PM

Thanks for that info. Callies suggest to torque bolt to 20lbft, zero the gauge. Then torque to full spec and measure. Not sure of the stretch at 20lbft.

Posted By: Cab_Burge

Re: ARP L19 rod bolt torque - 01/12/23 08:34 PM

Measure it and let us know

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 01/13/23 04:11 AM

The locator on the gauge is fatter possibly fitting the head of the bolt better and giving better accuracy in the reading.

Posted By: mopar dave

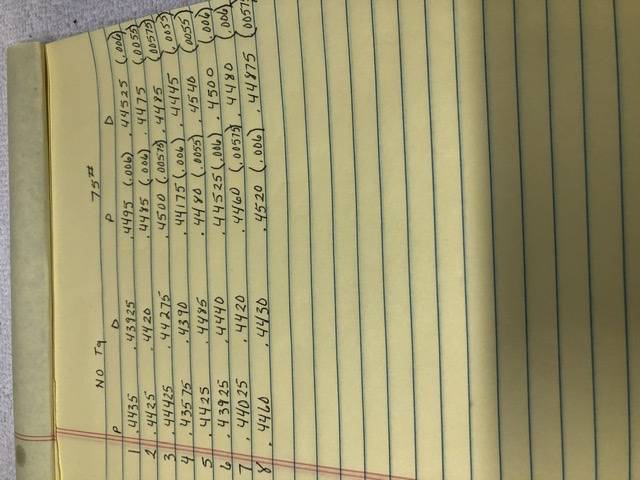

Re: ARP L19 rod bolt torque - 01/15/23 02:19 AM

Been working on this a couple hrs now. The new arp gauge works real nice with repeatability within .0005. Sometimes the gauge will not always return to dead 0. No big deal, close enough for me. I was measuring .007-.0085 stretch with 92lbft. I backed the wrench to 90lbft and still got .007 stretch range. Backed it down to 80lbft and now between .0055 and .0065 stretch. I have a torque wrench checker and wrench seems very accurate . Both wrenches measure same readings. I have an old craftsman wrench and a newer Eastwood wrench. I will record and post some numbers later.

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 01/15/23 09:17 AM

Not sure I quite understand your standard zero method. I just zero gauge once before I start. Measure bolts loose, torque both bolts and remeasure for stretch. Go to next rod.

Posted By: Diplomat360

Re: ARP L19 rod bolt torque - 01/15/23 04:02 PM

Not sure I quite understand your standard zero method. I just zero gauge once before I start. Measure bolts loose, torque both bolts and remeasure for stretch. Go to next rod.

I think the main idea is to have a repeatable 'reference point' (that being the fabricated standard) that you can always go back to. This takes out the +/- that might be introduced by the gauge/fixture as you are actively measuring the rod bolts. Basically, think of the inner workings of the gauge, or the potential movement of the components. So while resetting the gauge to 0 (zero) each time works for actual measurements, it does not provide you with the SAME starting point for EACH bolt...whereas the standard would, and it would remain that same for the remainder of time you needed to reference it (at least that's my interpretation of the procedure dvw uses.

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 01/15/23 04:51 PM

Ok, i understand. If any issues were to arise with the engine and needed a rebuild i would just buy new rods. I would never reuse these rods. Its now looking like 75lbft of torque on the bolts keeps the stretch in spec of .005-.006.

Posted By: Cab_Burge

Re: ARP L19 rod bolt torque - 01/15/23 08:01 PM

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 01/15/23 08:34 PM

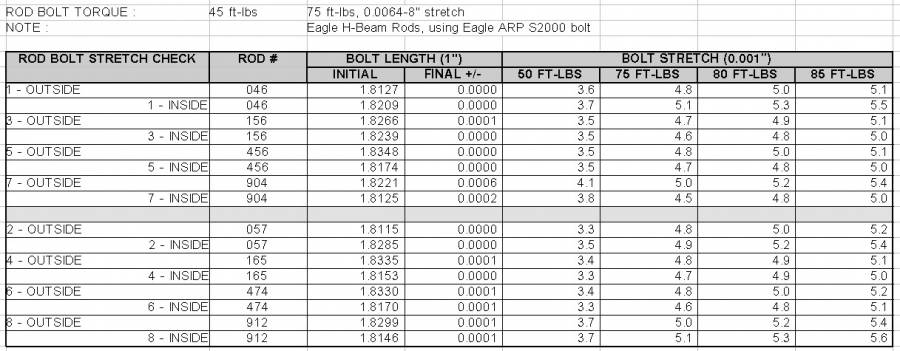

I did rezero the gauge for each pair of rod bolts. Fully lubed up and loose i get a free length measure, then torque both bolts to 30lbft, then to full at 75# and remeasure for stretch. They were all between .0055 and .006, most being .006. Makes me a bit nervous knowing Callies suggested 92# and me finding 75# to get their stretch spec. Gonna have to learn to fully trust my measuring tools.

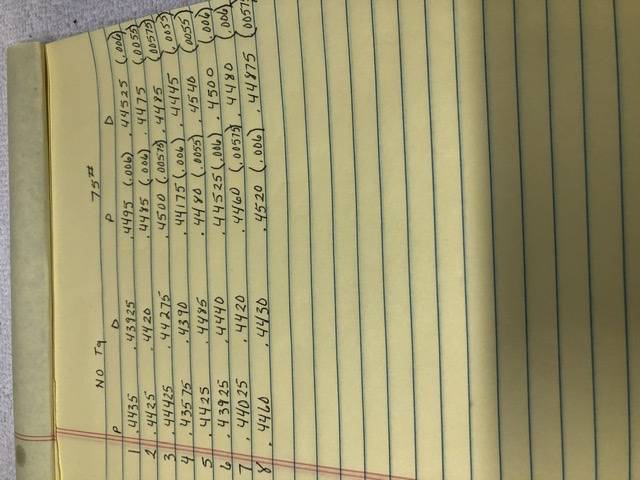

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 01/16/23 12:25 AM

Final numbers:

Posted By: Cab_Burge

Re: ARP L19 rod bolt torque - 01/16/23 03:37 AM

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 01/16/23 04:26 AM

Thanks cab. It just bothers me the spec was 92lbft to arrive at the stretch spec and i got there with 75lbft. I might give Callie another call about this. Thanks again guys.

Posted By: Cab_Burge

Re: ARP L19 rod bolt torque - 01/16/23 07:32 AM

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 01/16/23 03:28 PM

I thought Molnar wanted his rod bolts torqued to yield? I have Molnar rods with his arp2000 bolts in my 511. I used his angle torqueing method, so i dont know the stretch on any of them.

Posted By: A727Tflite

Re: ARP L19 rod bolt torque - 01/16/23 04:37 PM

I thought Molnar wanted his rod bolts torqued to yield? I have Molnar rods with his arp2000 bolts in my 511. I used his angle torqueing method, so i dont know the stretch on any of them.

May want to check back with him. I don't think he would advocate "torque to yield".

What is a torque-to-yield bolt? It is a one-time-use fastener that is designed to stretch during the torquing process (installation). Because of this stretching, the integrity of the bolt is compromised. These bolts cannot and should not be reused due to the stress caused to the bolt during its first installation.

Posted By: dvw

Re: ARP L19 rod bolt torque - 01/16/23 06:02 PM

Molnar supplies both stretch length and a low torque then torque angle spec.

Doug

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 01/16/23 08:28 PM

The Molnar method is 30lbft then 44* i think. It is a specified degree for sure. According to him, you do it that way and you dont need to measure stretch with his arp2000 bolts.

Posted By: Cab_Burge

Re: ARP L19 rod bolt torque - 01/17/23 03:17 AM

Posted By: mopar dave

Re: ARP L19 rod bolt torque - 01/17/23 03:59 AM

I did play with those a little bit and found his arp2000 bolts would give same stretch at 75lbft as with his torque and angle method. Take that for what its worth as i was using my old bolt stretch gauge which is hard to get consistant numbers.