|

Me and my Tremec

#310388

Me and my Tremec

#310388

05/06/09 06:49 PM

05/06/09 06:49 PM

|

Joined: Jan 2003

Posts: 1,436

Oklahoma City OK

Cudajon

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Jan 2003

Posts: 1,436

Oklahoma City OK

|

Me and my Tremec

Let me start of with I love the extra gear and how smooth the shifts are compared to my old 883. But, let me tell the tale.

I ordered my tremec from Keisler a month or so ago. My car is a driver so the thought of having it set up while I measured and then waited for a drive shaft didn’t appeal to me. I talked to Gene and he said if I would measure the existing set up they could go ahead and make me a drive shaft. So I did and then ordered the whole kit plus a clutch disk and bell housing.

The kit arrived about 10 days later missing the driveshaft of course and the alignment tool (Couls have used that). Anyway the instructions were pretty good and there was a complete set of nuts bolts and adapters to make it all work. You have to mock it all up and of course check the alignment of the tranny on the engine and to make sure the tranny doesn’t hit the transmission tunnel. Everything checked out ok but that is installation number 1 of the tranny. Out it comes and now I can install the pressure plate, clutch disk and throwout bearing. The throw out bearing they supplied is a little fatter than the stock Mopar bearing I had in there. Back in goes the tranny and bolt it up.

The driveshaft came in 3 days later (you can install the tranny without the driveshaft because Keisler supplies a neat little rubber grommet that keeps the tranny from leaking while lifting it up – nice). I bolt the driveshaft up (a little snug) but in it goes. I finally get to start it up and shift them gears. Whoops the tranny keeps kicking outta of 1,3, and 5the gear =[Edited by Moparts - Keep it clean]. So I drop the whole mess again (install number 3) to look at it. Keisler keeps saying in their instructions to check the tranny to make sure it is free because the gears can get locked up during shipping. I thought I did that. Setting on the floor everything looks fine. So back in it goes. When I go to reinstall the driveshaft I notice the back of the shift rod from the tranny looks like it has been hit. I put the tranny in first and can see the driveshaft yoke in contacting the shift rod. They are very close. Well I accept the blame for this if I had of done it the way Gene told me i.e. measure and then order after the tranny is installed, maybe this wouldn’t have happened. I take the driveshaft to inland transmission here in OKC and have it shortened by 1”. Bring it home and it works just great.

However; I’m using a centerforce pressure plate and I am not getting enough adjustment to fully release the clutch – shoot! So I drop out the z-bar and cut and weld a ½” to the bottom actuator. Giving me about another inch to work with on the adjustment. Works great. Time to go cruising – yippee.

Transmission leaks like a sieve. At 15 bucks a quart watching the tranny fluid run out on the floor and all under the exhaust pipes hurts real bad. I can see where the leak is coming from, its on top where the shift fork cover is. Out the tranny comes again (by now it is by the numbers). Sure enough the top plate is leaking big time. Keisler puts these little micky mouse 10-34 hex screw in there and of course strips the hole so you can’t unscrew them. Out come the dremel to slot em and they come out easy. The gope they use to seal this metal plate is glopped all over but it ain’t sealing so I get out my trusty tube of permatex form a gasket and go to town. There is only about a ¼” of tranny case to seal to and the plate has to cross the top, then down, and the rest of the way across. Its these 90 degree bends that seem to be where its leaking and theres no screw or bolts there to draw the plate down. I let it set-up overnight and it looks good (ugly) the next morning so back in with the tranny (install Number #4). Out I go again and great no leaks. The speedo is off 15mph at 60 though, it registers 45. Thought it was funny that I was passing everything on the road – luckily no cops. Been driving it a couple of weeks ---- Leaks back. Guess I’ll be doing number 5 shortly.

Well there you go guys, I’m sure some of this can be my bad because of my haste, but a leak in a car just kills me. If you are going to do this modification good luck, hope its better than mine.

|

|

|

Re: Me and my Tremec

[Re: Cudajon]

#310390

Re: Me and my Tremec

[Re: Cudajon]

#310390

05/07/09 12:25 AM

05/07/09 12:25 AM

|

Joined: Dec 2007

Posts: 18,157

Mass

DAYCLONA

I Live Here

|

I Live Here

Joined: Dec 2007

Posts: 18,157

Mass

|

Well Jack you certainly have a tale of woe,........I'm a firm supporter of Keisler and their products, some of your issuses do sound self induced,(drive shaft) and some issuses are just from naivety with their product, which is understandable...... but the leaking trans sucks, sure blows when you have to rectify a mfg problem, I've had my share of rear main seals, and leaking head gaskets on $15,000 Mopar crate Hemis, and junk Comp Cams, junk out of the box PCS suspention parts, etc, etc.......and leaks on Keisler transmissions, .....like everything in life, either you complain, and generally nothing gets done or you suck it up, and rectify the problem yourself  .........regarding the speedo, sometimes even with the correct info to Keisler regarding rear gear, tire size, etc, the tooth count needs to be increased or decreased to "correct" true vehicle speed...........when you run the "factory" Z bar, mods are almost certain, to acheive correct geomerty and function, Jack, did you dial indicate the run out of the bellhousing bore to within .001-.0015 ? Jack, I can "feel" for you, I've done quite a few Keisler TKO swaps over the years,......after the first few you learn what "things" to avoid, and what things you need to rectify on your own, to insure a trouble free install, before you even begin.......I've driven Mopar 4 spd cars all my life from my first days of driving in the 70's to present,.....and with retrofiting them with Keislers the last 8 years or so,....I wouldn't go back to 4 spds ever IMHO, hopefully when you get your leak issuse resolved, I'm sure your aware of the benefits that the OD offers

|

|

|

Re: Me and my Tremec

[Re: Cudajon]

#310392

Re: Me and my Tremec

[Re: Cudajon]

#310392

05/07/09 08:51 AM

05/07/09 08:51 AM

|

Joined: Sep 2005

Posts: 211

Tennessee

Keisler Sales

|

Joined: Sep 2005

Posts: 211

Tennessee

|

Quote:

Me and my Tremec

Let me start of with I love the extra gear and how smooth the shifts are compared to my old 883. But, let me tell the tale.

I ordered my tremec from Keisler a month or so ago. My car is a driver so the thought of having it set up while I measured and then waited for a drive shaft didn’t appeal to me. I talked to Gene and he said if I would measure the existing set up they could go ahead and make me a drive shaft. So I did and then ordered the whole kit plus a clutch disk and bell housing.

The kit arrived about 10 days later missing the driveshaft of course and the alignment tool (Couls have used that). Anyway the instructions were pretty good and there was a complete set of nuts bolts and adapters to make it all work. You have to mock it all up and of course check the alignment of the tranny on the engine and to make sure the tranny doesn’t hit the transmission tunnel. Everything checked out ok but that is installation number 1 of the tranny. Out it comes and now I can install the pressure plate, clutch disk and throwout bearing. The throw out bearing they supplied is a little fatter than the stock Mopar bearing I had in there. Back in goes the tranny and bolt it up.

The driveshaft came in 3 days later (you can install the tranny without the driveshaft because Keisler supplies a neat little rubber grommet that keeps the tranny from leaking while lifting it up – nice). I bolt the driveshaft up (a little snug) but in it goes. I finally get to start it up and shift them gears. Whoops the tranny keeps kicking outta of 1,3, and 5the gear =[Edited by Moparts - Keep it clean]. So I drop the whole mess again (install number 3) to look at it. Keisler keeps saying in their instructions to check the tranny to make sure it is free because the gears can get locked up during shipping. I thought I did that. Setting on the floor everything looks fine. So back in it goes. When I go to reinstall the driveshaft I notice the back of the shift rod from the tranny looks like it has been hit. I put the tranny in first and can see the driveshaft yoke in contacting the shift rod. They are very close. Well I accept the blame for this if I had of done it the way Gene told me i.e. measure and then order after the tranny is installed, maybe this wouldn’t have happened. I take the driveshaft to inland transmission here in OKC and have it shortened by 1”. Bring it home and it works just great.

However; I’m using a centerforce pressure plate and I am not getting enough adjustment to fully release the clutch – shoot! So I drop out the z-bar and cut and weld a ½” to the bottom actuator. Giving me about another inch to work with on the adjustment. Works great. Time to go cruising – yippee.

Transmission leaks like a sieve. At 15 bucks a quart watching the tranny fluid run out on the floor and all under the exhaust pipes hurts real bad. I can see where the leak is coming from, its on top where the shift fork cover is. Out the tranny comes again (by now it is by the numbers). Sure enough the top plate is leaking big time. Keisler puts these little micky mouse 10-34 hex screw in there and of course strips the hole so you can’t unscrew them. Out come the dremel to slot em and they come out easy. The gope they use to seal this metal plate is glopped all over but it ain’t sealing so I get out my trusty tube of permatex form a gasket and go to town. There is only about a ¼” of tranny case to seal to and the plate has to cross the top, then down, and the rest of the way across. Its these 90 degree bends that seem to be where its leaking and theres no screw or bolts there to draw the plate down. I let it set-up overnight and it looks good (ugly) the next morning so back in with the tranny (install Number #4). Out I go again and great no leaks. The speedo is off 15mph at 60 though, it registers 45. Thought it was funny that I was passing everything on the road – luckily no cops. Been driving it a couple of weeks ---- Leaks back. Guess I’ll be doing number 5 shortly.

Well there you go guys, I’m sure some of this can be my bad because of my haste, but a leak in a car just kills me. If you are going to do this modification good luck, hope its better than mine.

You can ship the trans back to us and we will reseal it. This problem usually does not happen since we have employed the Air leak test machine.

I got your email on the speedo cable. This is an easy fix.

Sorry you having a few issue's.

Please let me know what I can do to help you resolve this.

Keisler Engineering www.keislerauto.com#1 Choice of Overdrive Transmissions with Over 14,000 Sold

|

|

|

Re: Me and my Tremec *update*

[Re: 72roadrunnergtx]

#310395

Re: Me and my Tremec *update*

[Re: 72roadrunnergtx]

#310395

05/08/09 02:14 AM

05/08/09 02:14 AM

|

Joined: Sep 2003

Posts: 1,168

Vancouver, WA

MoparMarq

super stock

|

super stock

Joined: Sep 2003

Posts: 1,168

Vancouver, WA

|

Quote:

1500 miles on my Keisler/Tremec TKO-600 now and still dry as a bone. I too, have logged many miles driving 833 equipped Mopars and will never go back, love this gear box, It’s a blast to drive. First speedo gear sent to me for my conversion, based on info I provided, so far appears dead on. It took me over two years after my initial purchase to get my restoration on the road, in that time the few minor assembly issues that arose were resolved fairly quickly by Keisler, and in most cases by Gene personally.

Thanks for the pic. It kinda helps motivate me to get on with getting mine in.

|

|

|

Re: Me and my Tremec *update*

[Re: Cudajon]

#310397

Re: Me and my Tremec *update*

[Re: Cudajon]

#310397

05/08/09 01:47 PM

05/08/09 01:47 PM

|

Joined: Oct 2008

Posts: 765

Shoreline, Washington

72roadrunnergtx

super stock

|

super stock

Joined: Oct 2008

Posts: 765

Shoreline, Washington

|

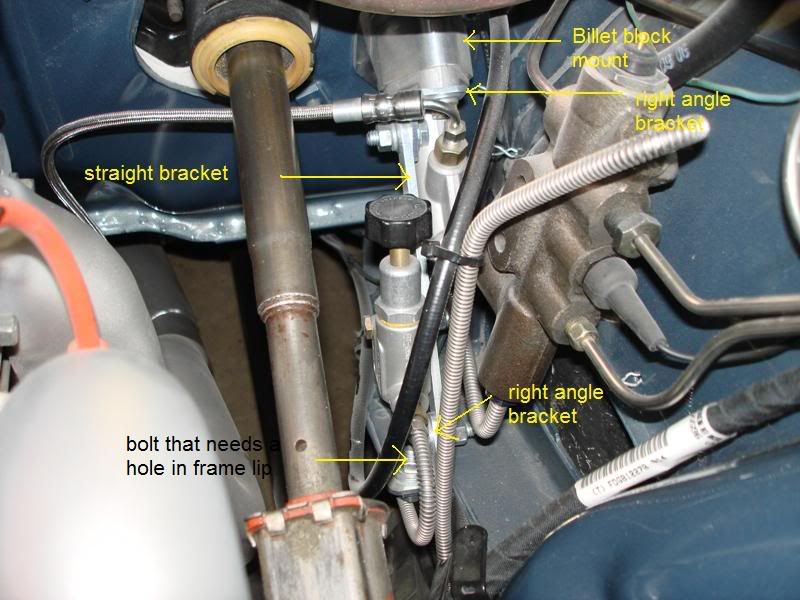

One of the snafus I experienced had to do with the bracket kit designed to reinforce the clutch master cylinder firewall mounting. The parts were missing from the initial shipment and the documentation referred to an older design that made didn’t make any sense with what components I did receive. Once I had the correct parts in hand and a clear understanding of where they go, installing the master cylinder was fairly simple. Granted not having the motor in place did make it easier to get at however you shouldn’t have to pull the brake booster or the motor to install. There is one small bolt hole that needs to be drilled in the frame rail flange, if you are running headers you may have to remove the driver’s side to get a drill motor in there or use a long drill bit and drill up from below. Self adjusting and minimal pedal effort, am looking forward to not having to deal with premature z-bar bushing and pivot wear problems I experienced back in the day with the factory set-up. Not mentioned in any of the documentation, I did have to clearance the brake light switch bracket a bit where the push rod bolts to the clutch pedal.

Last edited by 72roadrunnergtx; 05/08/09 02:43 PM.

|

|

|

Re: Me and my Tremec *update*

[Re: 72roadrunnergtx]

#310398

Re: Me and my Tremec *update*

[Re: 72roadrunnergtx]

#310398

05/08/09 02:47 PM

05/08/09 02:47 PM

|

Joined: Dec 2007

Posts: 18,157

Mass

DAYCLONA

I Live Here

|

I Live Here

Joined: Dec 2007

Posts: 18,157

Mass

|

you shouldn’t have to pull the brake booster or the motor to install. There is one small bolt hole that needs to be drilled in the frame rail flange, if you are running headers you may have to remove the driver’s side to get a drill motor in there or use a long drill bit and drill up from below. Self adjusting and minimal pedal effort, am looking forward to not having to deal with premature z-bar bushing and pivot wear problems I experienced back in the day with the factory set-up. Not mentioned in any of the documentation, I did have to clearance the brake light switch bracket a bit where the push rod bolts to the clutch pedal.

Guys, In several of the Keisler installs I've done, I was able to mount the hydualic pedal master assy. with the motor,exhaust, brake booster, etc in place, sure it's a biotch, but somethings allways are, no getting around them......Doug on the interference with the brake switch, common problem, nothing major, I usually substitute a shorter shoulder bolt for the clutch rod end, as the one Keisler supplies is too long, and causes interference, and possible hang up with either the brake or clutch,......when you install that hydraulic braided clutch line to the throwout bearing, I'll save you some grief now and FULLY recommend you insulate the line all the way from the pedal master to the bellhousing with a high heat shield tube covering, Summit has flexible heat tube coverings in 3 ft lengths from 1/2" dia up to 1 1/2 " diameters, the 1/2" will suffice, about $15, depending on what you buy some stuff is good to 1000 degrees.....and do not use any silicone brake fluids in the system, or general dot 4 or 5 brake fluids,.....spend the money about $40 a guart for Blue Racing Fluid, you can find it at Carquests (sometimes) or Porsche dealers as it has a boiling point of 550 degrees, plus it's viscosity is much more heavier than run of the "mill" brake fluid, and gives you more of a pedal feel, as the hydualic is so light in touch, it can be discerning at times (esp staging off the line)..... it is brake fluid, just "high end/performance" brake fluid,.....the reason being, esp, on header equipped cars the braided line passes very close to the headers and asorbes the heat directly into the fluid thru the braid, as this helps aggrivate problem, what you may experience, esp in traffic, or hot running days is no dis/engagement of the clutch!...this really blows in bumper to bumper traffic!....I've experienced it on some installs as have others, so rather than have to deal with it, avoid it, and sheath the intire line, and use a premium fluid, like Blue Racing Fluid.......this was the finial remedy/conclusion I arrived at after changing throwout bearings, pedal masters, pulling my hair out  bitcin at the Keisler guys (Grey bitcin at the Keisler guys (Grey  ) )

Mike

|

|

|

Re: Me and my Tremec *update*

[Re: 72roadrunnergtx]

#310399

Re: Me and my Tremec *update*

[Re: 72roadrunnergtx]

#310399

05/09/09 01:55 AM

05/09/09 01:55 AM

|

Joined: Sep 2003

Posts: 1,168

Vancouver, WA

MoparMarq

super stock

|

super stock

Joined: Sep 2003

Posts: 1,168

Vancouver, WA

|

Quote:

One of the snafus I experienced had to do with the bracket kit designed to reinforce the clutch master cylinder firewall mounting. The parts were missing from the initial shipment and the documentation referred to an older design that made didn’t make any sense with what components I did receive. Once I had the correct parts in hand and a clear understanding of where they go, installing the master cylinder was fairly simple. Granted not having the motor in place did make it easier to get at however you shouldn’t have to pull the brake booster or the motor to install. There is one small bolt hole that needs to be drilled in the frame rail flange, if you are running headers you may have to remove the driver’s side to get a drill motor in there or use a long drill bit and drill up from below. Self adjusting and minimal pedal effort, am looking forward to not having to deal with premature z-bar bushing and pivot wear problems I experienced back in the day with the factory set-up.

If you've got a picture of what you're talking about (I realize that may be difficult with everything in place), but I got some reinforcing hardware that came with my kit also. However, the directions for how it goes together are nowhere to be found (they either weren't included, or I've lost them). Either way, there's no real discernible way to put them together, and I've still got lots of room to manuever - since the engine isn't in yet.

Thanks.

Quote:

Not mentioned in any of the documentation, I did have to clearance the brake light switch bracket a bit where the push rod bolts to the clutch pedal.

I ran into the same brake light switch bracket issue. I ended up drilling a hole in the switch bracket. Then, using a pair of longer bolts and and the equivalent of some alternator spacers, made the bracket stand off from the pedal assembly bracket far enough not to interfere with the clutch pedal heim joint, but not so far as not to reach the brake pedal.

Apparently, since I purchased my setup in January 2004, (and yet to enjoy the benefits because of familial obligations), I have the 1st generation shift tower. (See pic below.) The upgrade to the 3rd gen tower, to eliminate the buzzsaw effect that's likely to occur, requires shipment back to Keisler for the work.

I sure hope when all is said and done for anyone who installs this trans that they're as happy with this setup when it's done as others claim to be. Right now, the aggravation factor is right up there...

|

|

|

Re: Me and my Tremec *update*

[Re: MoparMarq]

#310400

Re: Me and my Tremec *update*

[Re: MoparMarq]

#310400

05/09/09 05:18 PM

05/09/09 05:18 PM

|

Joined: Oct 2008

Posts: 765

Shoreline, Washington

72roadrunnergtx

super stock

|

super stock

Joined: Oct 2008

Posts: 765

Shoreline, Washington

|

I have yet to experience any heat related problems with this hydraulic clutch. The closest my line gets to any header tube is about an inch running perpendicular to one tube. The first summer driving season is coming up for this set-up however, I will watch for it, thanks for the heads-up Dayclona  Marq, I e-mailed some more details & pics to an old earthlink address I have for you, let me know if I should PM to you instead.

Last edited by 72roadrunnergtx; 05/09/09 05:18 PM.

|

|

|

Re: Me and my Tremec

[Re: DAYCLONA]

#310404

Re: Me and my Tremec

[Re: DAYCLONA]

#310404

05/11/09 03:14 PM

05/11/09 03:14 PM

|

Joined: Jan 2003

Posts: 2,045

MD

RTSE4ME

top fuel

|

top fuel

Joined: Jan 2003

Posts: 2,045

MD

|

Quote:

However; I’m using a centerforce pressure plate and I am not getting enough adjustment to fully release the clutch – shoot! So I drop out the z-bar and cut and weld a ½” to the bottom actuator. Giving me about another inch to work with on the adjustment. Works great. Time to go cruising – yippee

Quote:

..when you run the "factory" Z bar, mods are almost certain, to acheive correct geomerty and function,

hmmm....I had the opposite problem. I had too much pedal travel and had to adjust the finger height on my PP.

|

|

|

Re: Me and my Tremec

[Re: RTSE4ME]

#310405

Re: Me and my Tremec

[Re: RTSE4ME]

#310405

05/11/09 04:54 PM

05/11/09 04:54 PM

|

Joined: Oct 2003

Posts: 21,345

Marysville, O-H-I-O

70Cuda383

Too Many Posts

|

Too Many Posts

Joined: Oct 2003

Posts: 21,345

Marysville, O-H-I-O

|

you can adjust the height of the fingers on the pressre plate? or only on certain pressure plates?

only problem I had with my tremec is a leaky throw out bearing. don't buy the tilton stuff. they ship it with these cute little fittings that I suppose would stand up to the pressures of a stock honda pressure plate, but nowhere near the pressures needed to operate a high clamp load, high hp/torque clutch.

if I don't have it fixed this time, I'm throwing it all away and will be trying something else.

the transmission shifts great under relaxed driving, I don't even need the clutch, but every time I try power shifting it, I can't get it into gear, I'm not even spinning it that fast, as my motor is all torque, and doesn't need to spin faster than 6K.

**Photobucket sucks**

|

|

|

Re: Me and my Tremec *update*

[Re: MoparMarq]

#310406

Re: Me and my Tremec *update*

[Re: MoparMarq]

#310406

05/12/09 01:40 PM

05/12/09 01:40 PM

|

Joined: Feb 2006

Posts: 227

Tennessee

rj8806

enthusiast

|

enthusiast

Joined: Feb 2006

Posts: 227

Tennessee

|

MoparMarq.... I don't recall any "shifter buzz" phone calls from guys with the early style shifter like yours, I don't believe you have anything to worry about.  As for the "overheating" the brake fluid for the hydraulics, anyone who has gotten our kit within the last 3 years shouldn't be experiencing this anymore. I haven't dealt with any heat related phone calls since 2005 to MAYBE early '06. We still recommend DOT 4 or better yet, ATE Super Blue. Under no circumstance can you use a DOT 5. The silicone based fluids are not compatable with the seals and o-rings in the systems and it will leak. To the OP, I am really sorry for your troubles with the leaking, I'm still not sure how it is leaking since we now use a pressurized leak down machine and test every TKO before it leaves the door. If it leaks on the machine, it gets re-sealed and then re-tested. If it doesn't leak, it ships. This machine pumps the case up with air pressure. More pressure than it would see under normal driving conditions. While it's under pressure, if the gauge doesn't start leaking down, then we hold it at that pressure for X amount of minutes. I am really curious as to how one that passed the leak down test, ended up leaking. Please let me know if there is anything I can do for you.  Richard Tech Support

Last edited by rj8806; 05/12/09 01:42 PM.

|

|

|

Re: Me and my Tremec *update*

[Re: rj8806]

#310407

Re: Me and my Tremec *update*

[Re: rj8806]

#310407

05/12/09 01:47 PM

05/12/09 01:47 PM

|

Joined: Jan 2003

Posts: 2,836

Detroit boy in Saugerties, NY

BrianShaughnessy

master

|

master

Joined: Jan 2003

Posts: 2,836

Detroit boy in Saugerties, NY

|

Richard,

Just where are the normal leakage points that you were seeing?

I've had to add a pint every few months. Get a drip onto the X pipe occassionally. While it looks like it could be coming from the seam between the case / tailhousing I'm wondering if it could be from up top.

Black Betty: '69 Charger RT: 440 6 pack, TKO600 5 speed, 3.73 Dana.

Sinnamon: '69 Charger RT: 440, 727, 4.30 8.75. High School Sweetheart.

El Grande: '98 Grand Cherokee 5.9 Limited.

|

|

|

|

|