Posted By: Cudajon

Me and my Tremec - 05/06/09 10:49 PM

Me and my Tremec

Let me start of with I love the extra gear and how smooth the shifts are compared to my old 883. But, let me tell the tale.

I ordered my tremec from Keisler a month or so ago. My car is a driver so the thought of having it set up while I measured and then waited for a drive shaft didn’t appeal to me. I talked to Gene and he said if I would measure the existing set up they could go ahead and make me a drive shaft. So I did and then ordered the whole kit plus a clutch disk and bell housing.

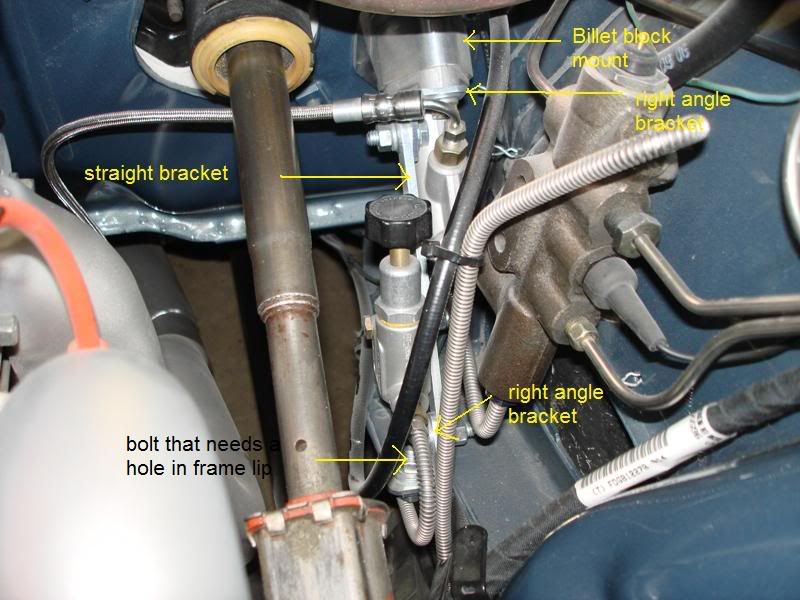

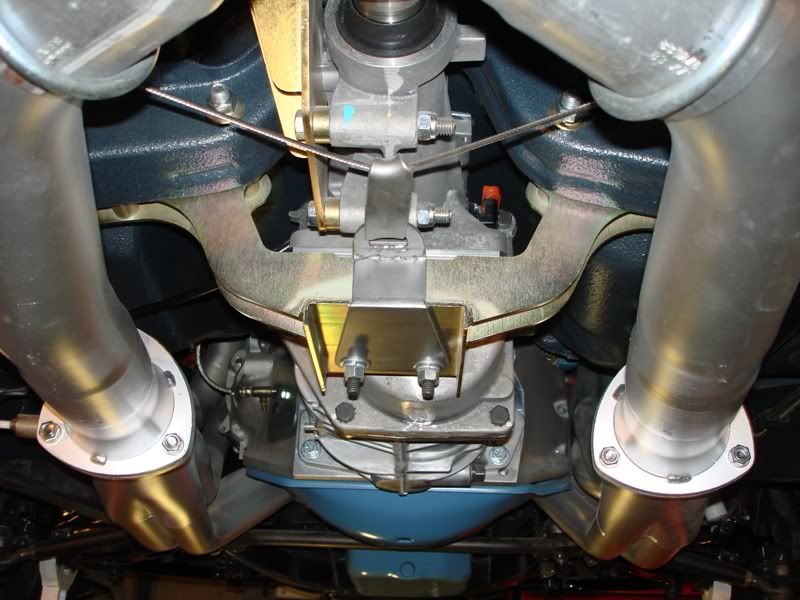

The kit arrived about 10 days later missing the driveshaft of course and the alignment tool (Couls have used that). Anyway the instructions were pretty good and there was a complete set of nuts bolts and adapters to make it all work. You have to mock it all up and of course check the alignment of the tranny on the engine and to make sure the tranny doesn’t hit the transmission tunnel. Everything checked out ok but that is installation number 1 of the tranny. Out it comes and now I can install the pressure plate, clutch disk and throwout bearing. The throw out bearing they supplied is a little fatter than the stock Mopar bearing I had in there. Back in goes the tranny and bolt it up.

The driveshaft came in 3 days later (you can install the tranny without the driveshaft because Keisler supplies a neat little rubber grommet that keeps the tranny from leaking while lifting it up – nice). I bolt the driveshaft up (a little snug) but in it goes. I finally get to start it up and shift them gears. Whoops the tranny keeps kicking outta of 1,3, and 5the gear =[Edited by Moparts - Keep it clean]. So I drop the whole mess again (install number 3) to look at it. Keisler keeps saying in their instructions to check the tranny to make sure it is free because the gears can get locked up during shipping. I thought I did that. Setting on the floor everything looks fine. So back in it goes. When I go to reinstall the driveshaft I notice the back of the shift rod from the tranny looks like it has been hit. I put the tranny in first and can see the driveshaft yoke in contacting the shift rod. They are very close. Well I accept the blame for this if I had of done it the way Gene told me i.e. measure and then order after the tranny is installed, maybe this wouldn’t have happened. I take the driveshaft to inland transmission here in OKC and have it shortened by 1”. Bring it home and it works just great.

However; I’m using a centerforce pressure plate and I am not getting enough adjustment to fully release the clutch – shoot! So I drop out the z-bar and cut and weld a ½” to the bottom actuator. Giving me about another inch to work with on the adjustment. Works great. Time to go cruising – yippee.

Transmission leaks like a sieve. At 15 bucks a quart watching the tranny fluid run out on the floor and all under the exhaust pipes hurts real bad. I can see where the leak is coming from, its on top where the shift fork cover is. Out the tranny comes again (by now it is by the numbers). Sure enough the top plate is leaking big time. Keisler puts these little micky mouse 10-34 hex screw in there and of course strips the hole so you can’t unscrew them. Out come the dremel to slot em and they come out easy. The gope they use to seal this metal plate is glopped all over but it ain’t sealing so I get out my trusty tube of permatex form a gasket and go to town. There is only about a ¼” of tranny case to seal to and the plate has to cross the top, then down, and the rest of the way across. Its these 90 degree bends that seem to be where its leaking and theres no screw or bolts there to draw the plate down. I let it set-up overnight and it looks good (ugly) the next morning so back in with the tranny (install Number #4). Out I go again and great no leaks. The speedo is off 15mph at 60 though, it registers 45. Thought it was funny that I was passing everything on the road – luckily no cops. Been driving it a couple of weeks ---- Leaks back. Guess I’ll be doing number 5 shortly.

Well there you go guys, I’m sure some of this can be my bad because of my haste, but a leak in a car just kills me. If you are going to do this modification good luck, hope its better than mine.

Let me start of with I love the extra gear and how smooth the shifts are compared to my old 883. But, let me tell the tale.

I ordered my tremec from Keisler a month or so ago. My car is a driver so the thought of having it set up while I measured and then waited for a drive shaft didn’t appeal to me. I talked to Gene and he said if I would measure the existing set up they could go ahead and make me a drive shaft. So I did and then ordered the whole kit plus a clutch disk and bell housing.

The kit arrived about 10 days later missing the driveshaft of course and the alignment tool (Couls have used that). Anyway the instructions were pretty good and there was a complete set of nuts bolts and adapters to make it all work. You have to mock it all up and of course check the alignment of the tranny on the engine and to make sure the tranny doesn’t hit the transmission tunnel. Everything checked out ok but that is installation number 1 of the tranny. Out it comes and now I can install the pressure plate, clutch disk and throwout bearing. The throw out bearing they supplied is a little fatter than the stock Mopar bearing I had in there. Back in goes the tranny and bolt it up.

The driveshaft came in 3 days later (you can install the tranny without the driveshaft because Keisler supplies a neat little rubber grommet that keeps the tranny from leaking while lifting it up – nice). I bolt the driveshaft up (a little snug) but in it goes. I finally get to start it up and shift them gears. Whoops the tranny keeps kicking outta of 1,3, and 5the gear =[Edited by Moparts - Keep it clean]. So I drop the whole mess again (install number 3) to look at it. Keisler keeps saying in their instructions to check the tranny to make sure it is free because the gears can get locked up during shipping. I thought I did that. Setting on the floor everything looks fine. So back in it goes. When I go to reinstall the driveshaft I notice the back of the shift rod from the tranny looks like it has been hit. I put the tranny in first and can see the driveshaft yoke in contacting the shift rod. They are very close. Well I accept the blame for this if I had of done it the way Gene told me i.e. measure and then order after the tranny is installed, maybe this wouldn’t have happened. I take the driveshaft to inland transmission here in OKC and have it shortened by 1”. Bring it home and it works just great.

However; I’m using a centerforce pressure plate and I am not getting enough adjustment to fully release the clutch – shoot! So I drop out the z-bar and cut and weld a ½” to the bottom actuator. Giving me about another inch to work with on the adjustment. Works great. Time to go cruising – yippee.

Transmission leaks like a sieve. At 15 bucks a quart watching the tranny fluid run out on the floor and all under the exhaust pipes hurts real bad. I can see where the leak is coming from, its on top where the shift fork cover is. Out the tranny comes again (by now it is by the numbers). Sure enough the top plate is leaking big time. Keisler puts these little micky mouse 10-34 hex screw in there and of course strips the hole so you can’t unscrew them. Out come the dremel to slot em and they come out easy. The gope they use to seal this metal plate is glopped all over but it ain’t sealing so I get out my trusty tube of permatex form a gasket and go to town. There is only about a ¼” of tranny case to seal to and the plate has to cross the top, then down, and the rest of the way across. Its these 90 degree bends that seem to be where its leaking and theres no screw or bolts there to draw the plate down. I let it set-up overnight and it looks good (ugly) the next morning so back in with the tranny (install Number #4). Out I go again and great no leaks. The speedo is off 15mph at 60 though, it registers 45. Thought it was funny that I was passing everything on the road – luckily no cops. Been driving it a couple of weeks ---- Leaks back. Guess I’ll be doing number 5 shortly.

Well there you go guys, I’m sure some of this can be my bad because of my haste, but a leak in a car just kills me. If you are going to do this modification good luck, hope its better than mine.

.........regarding the speedo, sometimes even with the correct info to Keisler regarding rear gear, tire size, etc, the tooth count needs to be increased or decreased to "correct" true vehicle speed...........when you run the "factory" Z bar, mods are almost certain, to acheive correct geomerty and function,

.........regarding the speedo, sometimes even with the correct info to Keisler regarding rear gear, tire size, etc, the tooth count needs to be increased or decreased to "correct" true vehicle speed...........when you run the "factory" Z bar, mods are almost certain, to acheive correct geomerty and function,

bitcin at the Keisler guys (Grey

bitcin at the Keisler guys (Grey