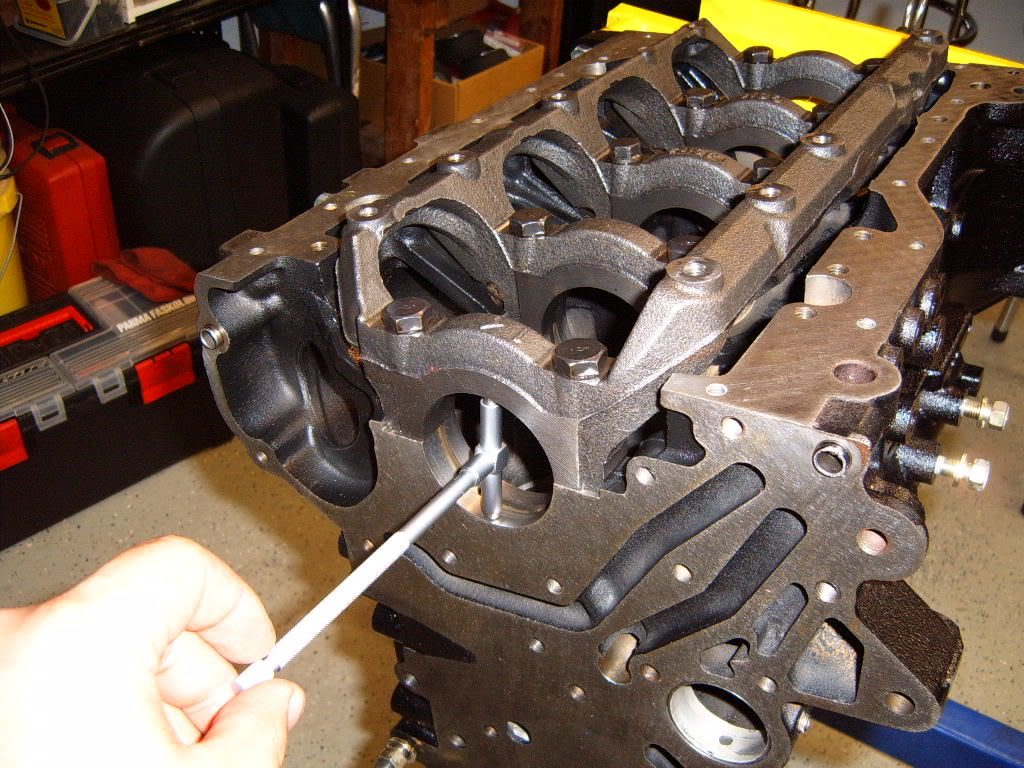

I like to learn things from different sources. I posted this a couple of years ago but feel like repeating myself. Mu Taurus SHO engine uses a block designed by Yamaha because the stock Ford Vulcan 3.0 block couldn't handle the power the Yamaha heads were making. Yamaha makes some pretty good engines. Their block uses a girdle that ties all four main bearing caps together. The girdle bolts to each main cap with two capscrews. The windage tray bolts to the girdle with other bolts.

This compact block purpose built by Yamaha is a very high quality casting and is plenty beefy yet the designers used a girdle to tie all the main bearings and webs together. By comparison the B/RB engine is less compact and less rigid. Why wouldn't it also benefit from tying the main caps and webs together? Picture of the girdle and windage tray attached.

R.

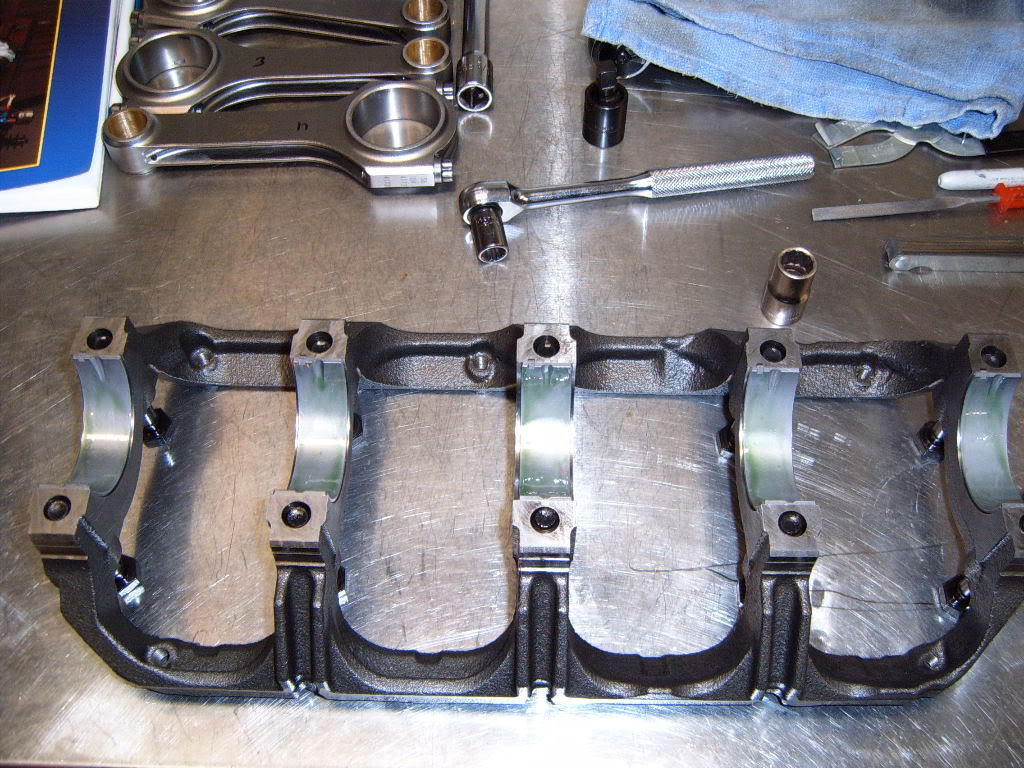

it seems like a popular addition to 4 cylinders, here are some pictures of a Mitsubishi 2.3l (4G63).

The main caps are cast together, forming what I believe they call a cradle. There has to be at least some truth to the practice, would be interesting to see one of these for a BB mopar but it would be some crazy $$$$