|

Re: Moving up to Jesel

[Re: 70Dustmite440]

#33920

Re: Moving up to Jesel

[Re: 70Dustmite440]

#33920

01/17/07 10:08 PM

01/17/07 10:08 PM

|

Joined: Jan 2003

Posts: 3,136

Palm Coast, FL (near Daytona B...

Blown_Hemi

master

|

master

Joined: Jan 2003

Posts: 3,136

Palm Coast, FL (near Daytona B...

|

When installing the crank cog make sure to check the installation dot. Some Mopar kits had the dot in the incorrect place. I returned mine to Jesel and had them check it for me. They told me that only a few kits went out the door with the incorrect indexing. I e-mailed you the instructions that came with my beltdrive kit. I could not attatch them for some reason?

Ask me my opinion of Frank Mitchell....... A Mopar crook!

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33922

Re: Moving up to Jesel

[Re: AndyF]

#33922

01/28/07 12:22 AM

01/28/07 12:22 AM

|

Joined: Jan 2003

Posts: 31,045

Oregon

AndyF

OP

OP

I Win

|

OP

OP

I Win

Joined: Jan 2003

Posts: 31,045

Oregon

|

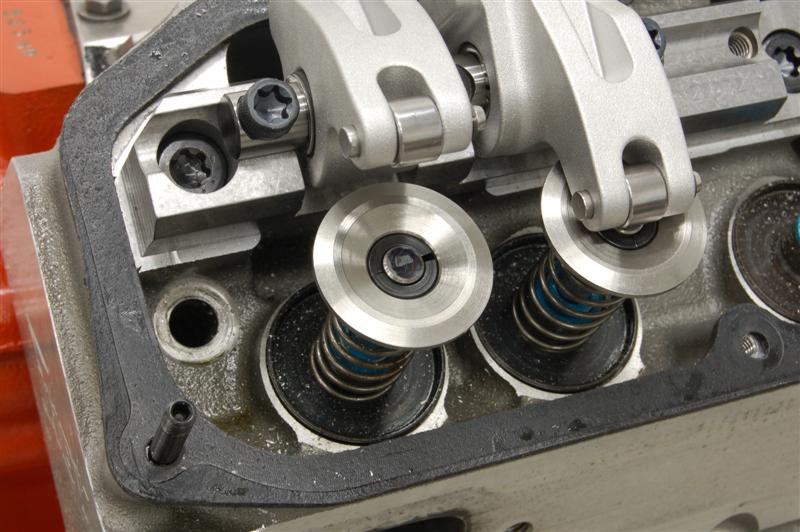

I finished up the machine work today to mount the Jesel stand onto the EZ heads. I had to machine down the pads some more and then drill and tap the 7 holes for 7/16-14 thread. The bolts included in the Jesel kit are a little too long so I'm going to order new ones. I sure am glad that Jesel faxed me a blueprint. Without that I would have had a really hard time getting the holes drilled and tapped in the correct locations. Here is a shot of the pattern left by the roller tip for .800 lift. It looks pretty good. It could be moved out on the valve stem by 0.020 or so to be perfect but there isn't any easy way to do that once the holes in the head are drilled and tapped.

Last edited by AndyF; 02/02/07 12:01 PM.

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33923

Re: Moving up to Jesel

[Re: AndyF]

#33923

01/28/07 09:48 PM

01/28/07 09:48 PM

|

Joined: Jan 2003

Posts: 31,045

Oregon

AndyF

OP

OP

I Win

|

OP

OP

I Win

Joined: Jan 2003

Posts: 31,045

Oregon

|

Here is how the head looks after the pads have been machined down and the new holes drilled and tapped for the hold down screws. The Jesel stand uses seven 7/16-14 bolts to hold it down rather than the five 3/8-16 bolts for the factory setup. It is a little tricky re-drilling the end holes for the larger 7/16 screws since the proper tap drill is smaller than 3/8ths. So basically a small amount of the existing threads are left in the hole and you then have to retap thru that. It cleans up okay but if you're going to run the Jesel setup you should really buy the heads setup that way in the beginning.

Last edited by AndyF; 01/28/07 09:49 PM.

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33925

Re: Moving up to Jesel

[Re: AndyF]

#33925

01/28/07 10:28 PM

01/28/07 10:28 PM

|

Joined: Jan 2003

Posts: 14,504

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,504

So. Burlington, Vt.

|

will you be pushrod oiling, or using spray bar valve covers for the roller cam tests?

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

Re: Moving up to Jesel

[Re: Monte_Smith]

#33929

Re: Moving up to Jesel

[Re: Monte_Smith]

#33929

01/29/07 08:15 AM

01/29/07 08:15 AM

|

Joined: Jan 2003

Posts: 75,042

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 75,042

U.S.S.A.

|

Quote:

Andy, In my own experience with this setup, you should probably go ahead and use heli-colis or thread-inserts. With large cams and the large spring pressure that goes with them, I have yet to have the threads NOT pull out of the heads, especially the end holes. I have had to make this repair so many times at the track, it is ridiculous. Now I just do them up front.

Monte

i was going to say something similar regarding using helicoils in those end holes , everything we do at work that is milspec , satellites and portable radars ,uses helicoils in alum .

|

|

|

Re: Moving up to Jesel

[Re: JohnRR]

#33930

Re: Moving up to Jesel

[Re: JohnRR]

#33930

02/01/07 07:47 PM

02/01/07 07:47 PM

|

Joined: Jan 2003

Posts: 31,045

Oregon

AndyF

OP

OP

I Win

|

OP

OP

I Win

Joined: Jan 2003

Posts: 31,045

Oregon

|

Just got some super good news from Jesel. They created instructions for this kit and posted them on their webpage. The instructions show the proper machining operations for various installed valve heights. Basically, the longer the valves are then the closer you need to move your rocker shaft to the intake side of the head. Here is a link to the Jesel instruction page. The kit of the Indy head is INS-07238 in the middle of the page. Maybe someone knows how to link directly to a pdf document? http://www.jeselonline.com/index.php?categoryid=49

|

|

|

Re: Moving up to Jesel

[Re: 2QUICK4U]

#33934

Re: Moving up to Jesel

[Re: 2QUICK4U]

#33934

02/03/07 07:25 PM

02/03/07 07:25 PM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

I wrote the article you referred to in www.moparmax.com and the initial one in www.dragracingonline.com as well. The fixture tool came with mine and I am surprised Jesel missed it on yours. Two years, ZERO problems. We set the final plate height pretty much like you did and ended up with a very similar rocker tip print on the valve. I would recommend the offset intake roller from Comp Cams to straighten the pushrod. (We send the rollers in at 150 runs to prevent a disaster, only $165.00 for rebuild and peasce of mind. We will be doing more and more Mopar Tech now that our newest magazine is getting over 3500 readers per day, check it our when you get a chance- www.MoparMax.comGreat series of photos and tech on your install I just read here on Moparts, nicely done. Jok Nicholson dragsterboy@mchsi.com

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33936

Re: Moving up to Jesel

[Re: AndyF]

#33936

02/04/07 11:59 PM

02/04/07 11:59 PM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

I think you are right, they should offer a kit for those heads. The Jesels have been the best thing I have done to my 572. I ate up Indy rockers at about 3 per year. So I was buying a new set each year. When I talked to Jesel they said I am done replacing rockers from fatigue, 450 runs later, they are still correct!

This is a great site, enjoting looking at all the Mopar Stuff...;-)

Jok

|

|

|

|

|