|

Re: 727 valve body tear down and inspection

[Re: 4406bbl]

#2934023

Re: 727 valve body tear down and inspection

[Re: 4406bbl]

#2934023

06/16/21 07:18 PM

06/16/21 07:18 PM

|

Joined: May 2021

Posts: 324

Chino Valley

B300 VanDanage

OP

OP

enthusiast

|

OP

OP

enthusiast

Joined: May 2021

Posts: 324

Chino Valley

|

You were talking about putting a shaft kit in it, that would give you the instructions on lining up the cage to the manual valve, and how to measure the pressure regulator. The old b@m and trans go kits came with a template to set it. You could either find the instructions online or I could send you a pic of the template later. I don't recall mentioning a shift kit in any of my threads... I'm pretty sure I won't be getting a new shift kit. I just need to make sure this one's adjusted, thanks!

|

|

|

Re: 727 valve body tear down and inspection

[Re: B300 VanDanage]

#2934099

Re: 727 valve body tear down and inspection

[Re: B300 VanDanage]

#2934099

06/16/21 10:46 PM

06/16/21 10:46 PM

|

Joined: Jan 2003

Posts: 1,908

Nebraska

4406bbl

top fuel

|

top fuel

Joined: Jan 2003

Posts: 1,908

Nebraska

|

You were talking about putting a shaft kit in it, that would give you the instructions on lining up the cage to the manual valve, and how to measure the pressure regulator. The old b@m and trans go kits came with a template to set it. You could either find the instructions online or I could send you a pic of the template later. I don't recall mentioning a shift kit in any of my threads... I'm pretty sure I won't be getting a new shift kit. I just need to make sure this one's adjusted, thanks! OIC, I saw the firmer shifts and guess I mistook that. Tighten all the valve body screws to 35 inch pounds except the 3 holding the regulator cage, then measure 1-7/8" between the edge of the regulator valve adjusting screw, the allen head one, yr yto the edge of the manual valve, tighten the 3 screws. The pressure regulator is adjusted to 1-9/32" from the casting to the regulator spring adjusting plate. These are trans go specs, I would not turn a stock trans up more. One other thing I need to address is the rear band breaking, harsh engagement does break the band and fold over the apply strut, especially after installing a shift kit because reverse pressure is so high. In the 70s a buddy that owned an ammco trans shop said that is why they did the 2 holes and a single ball, maybe he was wrong. He also told me to drill a .060 hole in the reverse servo on plow trucks because of the constant forward reverse slam,and not use the shim shift kits had in the rear servo, to not break things with the pressure turned up. I have never worn a rear band, only broke the ears off. Anyway this guy was pretty successful, had to warranty transmissions, and did not have many failures so who knows if he was right. All I know is he sold us red clutch rebuild kits for $30, red bands for $15, and showed us how to modify the rear support and cooler feed to stop those failures. Oh yeah, he used to call Chrysler reverse engagement "The Direct Connection" lmao.

Last edited by 4406bbl; 06/16/21 11:09 PM.

|

|

|

Re: 727 valve body tear down and inspection

[Re: 4406bbl]

#2934121

Re: 727 valve body tear down and inspection

[Re: 4406bbl]

#2934121

06/17/21 02:33 AM

06/17/21 02:33 AM

|

Joined: Mar 2011

Posts: 3,075

Michigan

A727Tflite

master

|

master

Joined: Mar 2011

Posts: 3,075

Michigan

|

You were talking about putting a shaft kit in it, that would give you the instructions on lining up the cage to the manual valve, and how to measure the pressure regulator. The old b@m and trans go kits came with a template to set it. You could either find the instructions online or I could send you a pic of the template later. I don't recall mentioning a shift kit in any of my threads... I'm pretty sure I won't be getting a new shift kit. I just need to make sure this one's adjusted, thanks! OIC, I saw the firmer shifts and guess I mistook that. Tighten all the valve body screws to 35 inch pounds except the 3 holding the regulator cage, then measure 1-7/8" between the edge of the regulator valve adjusting screw, the allen head one, yr yto the edge of the manual valve, tighten the 3 screws. The pressure regulator is adjusted to 1-9/32" from the casting to the regulator spring adjusting plate. These are trans go specs, I would not turn a stock trans up more. One other thing I need to address is the rear band breaking, harsh engagement does break the band and fold over the apply strut, especially after installing a shift kit because reverse pressure is so high. In the 70s a buddy that owned an ammco trans shop said that is why they did the 2 holes and a single ball, maybe he was wrong. He also told me to drill a .060 hole in the reverse servo on plow trucks because of the constant forward reverse slam,and not use the shim shift kits had in the rear servo, to not break things with the pressure turned up. I have never worn a rear band, only broke the ears off. Anyway this guy was pretty successful, had to warranty transmissions, and did not have many failures so who knows if he was right. All I know is he sold us red clutch rebuild kits for $30, red bands for $15, and showed us how to modify the rear support and cooler feed to stop those failures. Oh yeah, he used to call Chrysler reverse engagement "The Direct Connection" lmao. I think the rear servo got the two check balls around 94. So for 32 years Chrysler used one ball. You think they would have needed to come up with a fix for broken bands before then if that was an issue. Like I said before, we went to the two ball from customer complaint of harsh reverse, especially in Jeep.

|

|

|

Re: 727 valve body tear down and inspection

[Re: 4406bbl]

#2934199

Re: 727 valve body tear down and inspection

[Re: 4406bbl]

#2934199

06/17/21 11:17 AM

06/17/21 11:17 AM

|

Joined: May 2021

Posts: 324

Chino Valley

B300 VanDanage

OP

OP

enthusiast

|

OP

OP

enthusiast

Joined: May 2021

Posts: 324

Chino Valley

|

You were talking about putting a shaft kit in it, that would give you the instructions on lining up the cage to the manual valve, and how to measure the pressure regulator. The old b@m and trans go kits came with a template to set it. You could either find the instructions online or I could send you a pic of the template later. I don't recall mentioning a shift kit in any of my threads... I'm pretty sure I won't be getting a new shift kit. I just need to make sure this one's adjusted, thanks! OIC, I saw the firmer shifts and guess I mistook that. Tighten all the valve body screws to 35 inch pounds except the 3 holding the regulator cage, then measure 1-7/8" between the edge of the regulator valve adjusting screw, the allen head one, yr yto the edge of the manual valve, tighten the 3 screws. The pressure regulator is adjusted to 1-9/32" from the casting to the regulator spring adjusting plate. These are trans go specs, I would not turn a stock trans up more. One other thing I need to address is the rear band breaking, harsh engagement does break the band and fold over the apply strut, especially after installing a shift kit because reverse pressure is so high. In the 70s a buddy that owned an ammco trans shop said that is why they did the 2 holes and a single ball, maybe he was wrong. He also told me to drill a .060 hole in the reverse servo on plow trucks because of the constant forward reverse slam,and not use the shim shift kits had in the rear servo, to not break things with the pressure turned up. I have never worn a rear band, only broke the ears off. Anyway this guy was pretty successful, had to warranty transmissions, and did not have many failures so who knows if he was right. All I know is he sold us red clutch rebuild kits for $30, red bands for $15, and showed us how to modify the rear support and cooler feed to stop those failures. Oh yeah, he used to call Chrysler reverse engagement "The Direct Connection" lmao. No, I was just being told I had the option and I decided to leave the rear clutch ball in for a smoother shift... The most I'll do to that engine is replace the carb, headers and that's pretty much it. I'm just keeping it stock so no need for any fancy kits... So yea awesome! Thanks for the info! I really don't want to overlook anything since I've found so many mistakes...

|

|

|

Re: 727 valve body tear down and inspection

[Re: 4406bbl]

#2935479

Re: 727 valve body tear down and inspection

[Re: 4406bbl]

#2935479

06/22/21 12:25 AM

06/22/21 12:25 AM

|

Joined: May 2021

Posts: 324

Chino Valley

B300 VanDanage

OP

OP

enthusiast

|

OP

OP

enthusiast

Joined: May 2021

Posts: 324

Chino Valley

|

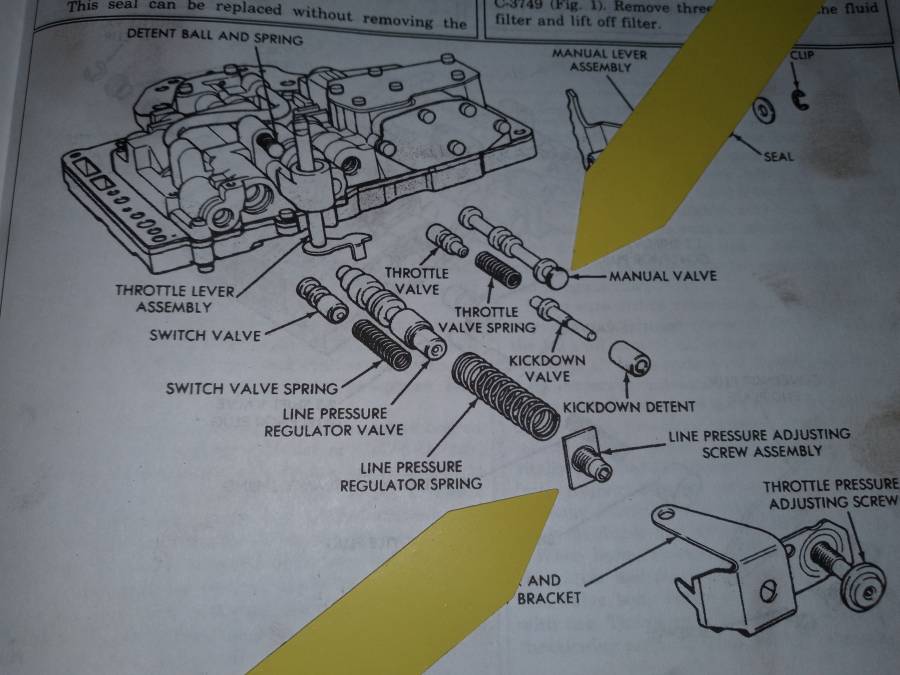

You were talking about putting a shaft kit in it, that would give you the instructions on lining up the cage to the manual valve, and how to measure the pressure regulator. The old b@m and trans go kits came with a template to set it. You could either find the instructions online or I could send you a pic of the template later. I don't recall mentioning a shift kit in any of my threads... I'm pretty sure I won't be getting a new shift kit. I just need to make sure this one's adjusted, thanks! OIC, I saw the firmer shifts and guess I mistook that. Tighten all the valve body screws to 35 inch pounds except the 3 holding the regulator cage, then measure 1-7/8" between the edge of the regulator valve adjusting screw, the allen head one, yr yto the edge of the manual valve, tighten the 3 screws. The pressure regulator is adjusted to 1-9/32" from the casting to the regulator spring adjusting plate. These are trans go specs, I would not turn a stock trans up more. One other thing I need to address is the rear band breaking, harsh engagement does break the band and fold over the apply strut, especially after installing a shift kit because reverse pressure is so high. In the 70s a buddy that owned an ammco trans shop said that is why they did the 2 holes and a single ball, maybe he was wrong. He also told me to drill a .060 hole in the reverse servo on plow trucks because of the constant forward reverse slam,and not use the shim shift kits had in the rear servo, to not break things with the pressure turned up. I have never worn a rear band, only broke the ears off. Anyway this guy was pretty successful, had to warranty transmissions, and did not have many failures so who knows if he was right. All I know is he sold us red clutch rebuild kits for $30, red bands for $15, and showed us how to modify the rear support and cooler feed to stop those failures. Oh yeah, he used to call Chrysler reverse engagement "The Direct Connection" lmao. So I decided to finally get to the adjusting screws and I'm having trouble understanding your instructions... I've provided a picture for reference... You said "measure 1-7/8" between the edge of the regulator valve adjusting screw, the allen head one, yr yto the edge of the manual valve, tighten the 3 screws. " First off both throttle and line pressure adjusting screws are Allen head... How am I suppose to measure from the regulator valve screw(line pressure adjusting screw) to the edge of the manual valve? I've pointed this out in the picture with yellow arrows.

|

|

|

Re: 727 valve body tear down and inspection

[Re: B300 VanDanage]

#2935599

Re: 727 valve body tear down and inspection

[Re: B300 VanDanage]

#2935599

06/22/21 11:55 AM

06/22/21 11:55 AM

|

Joined: Sep 2003

Posts: 19,396

north of coder

moparx

"Butt Crack Bob"

|

"Butt Crack Bob"

Joined: Sep 2003

Posts: 19,396

north of coder

|

here is the picture in a B&M shift kit instruction sheet. the 1 7/8" measurement is from the edge of the manual valve to the edge of the pressure adjustment screw. the main reason to do this is to keep the "cage" parallel so nothing binds. i hope this isn't too small to see.

|

|

|

Re: 727 valve body tear down and inspection

[Re: B300 VanDanage]

#2935822

Re: 727 valve body tear down and inspection

[Re: B300 VanDanage]

#2935822

06/22/21 09:27 PM

06/22/21 09:27 PM

|

Joined: Jan 2003

Posts: 1,908

Nebraska

4406bbl

top fuel

|

top fuel

Joined: Jan 2003

Posts: 1,908

Nebraska

|

You were talking about putting a shaft kit in it, that would give you the instructions on lining up the cage to the manual valve, and how to measure the pressure regulator. The old b@m and trans go kits came with a template to set it. You could either find the instructions online or I could send you a pic of the template later. I don't recall mentioning a shift kit in any of my threads... I'm pretty sure I won't be getting a new shift kit. I just need to make sure this one's adjusted, thanks! OIC, I saw the firmer shifts and guess I mistook that. Tighten all the valve body screws to 35 inch pounds except the 3 holding the regulator cage, then measure 1-7/8" between the edge of the regulator valve adjusting screw, the allen head one, yr yto the edge of the manual valve, tighten the 3 screws. The pressure regulator is adjusted to 1-9/32" from the casting to the regulator spring adjusting plate. These are trans go specs, I would not turn a stock trans up more. One other thing I need to address is the rear band breaking, harsh engagement does break the band and fold over the apply strut, especially after installing a shift kit because reverse pressure is so high. In the 70s a buddy that owned an ammco trans shop said that is why they did the 2 holes and a single ball, maybe he was wrong. He also told me to drill a .060 hole in the reverse servo on plow trucks because of the constant forward reverse slam,and not use the shim shift kits had in the rear servo, to not break things with the pressure turned up. I have never worn a rear band, only broke the ears off. Anyway this guy was pretty successful, had to warranty transmissions, and did not have many failures so who knows if he was right. All I know is he sold us red clutch rebuild kits for $30, red bands for $15, and showed us how to modify the rear support and cooler feed to stop those failures. Oh yeah, he used to call Chrysler reverse engagement "The Direct Connection" lmao. So I decided to finally get to the adjusting screws and I'm having trouble understanding your instructions... I've provided a picture for reference... You said "measure 1-7/8" between the edge of the regulator valve adjusting screw, the allen head one, yr yto the edge of the manual valve, tighten the 3 screws. " First off both throttle and line pressure adjusting screws are Allen head... How am I suppose to measure from the regulator valve screw(line pressure adjusting screw) to the edge of the manual valve? I've pointed this out in the picture with yellow arrows. The throttle pressure adjusting screw varied in style thru the years as you can see in the B&M instructions, and it does not measure that 1-7/8. The cage just needs to be parallel to the valve body. Slide the manual valve out and measure it is what I do.

|

|

|

Re: 727 valve body tear down and inspection

[Re: 4406bbl]

#2935867

Re: 727 valve body tear down and inspection

[Re: 4406bbl]

#2935867

06/23/21 12:33 AM

06/23/21 12:33 AM

|

Joined: May 2021

Posts: 324

Chino Valley

B300 VanDanage

OP

OP

enthusiast

|

OP

OP

enthusiast

Joined: May 2021

Posts: 324

Chino Valley

|

It took me a while of starring back and fourth from my valve body to the B&M instructions on my phone but I got it figured out...

I think I finally understand, appreciate the help so far!

I measured from the casting to the very end of the line pressure adjusting screw and it's exactly 1 7/8"'s... I'm still going to measure from the casting to the adjusting plate... According to the B&M instructions I have 3 options? I'll probably go with the heavy duty... It's stock but the converter is HD and the clutches are HD...idk...

Here's a picture of the style cage and bolt I have in my 727...

The cage is a bit off in the picture because none of the screws are tight, waiting on a new torque wrench!

Last edited by B300 VanDanage; 06/23/21 12:36 AM.

|

|

|

Re: 727 valve body tear down and inspection

[Re: moparx]

#2935870

Re: 727 valve body tear down and inspection

[Re: moparx]

#2935870

06/23/21 01:09 AM

06/23/21 01:09 AM

|

Joined: May 2021

Posts: 324

Chino Valley

B300 VanDanage

OP

OP

enthusiast

|

OP

OP

enthusiast

Joined: May 2021

Posts: 324

Chino Valley

|

here is the picture in a B&M shift kit instruction sheet. the 1 7/8" measurement is from the edge of the manual valve to the edge of the pressure adjustment screw. the main reason to do this is to keep the "cage" parallel so nothing binds. i hope this isn't too small to see.  Awesome! Appreciate it... Isn't too small?... What matters is that it's focused, I can always zoom in!😁👍 As for the 3 options given in the instructions for the line pressure adjustment... That does apply to my setup correct? Since I have hd discs and hd converter I was thinking I'll be doing the Heavy Duty option. What is the difference between those adjustments anyway??

|

|

|

Re: 727 valve body tear down and inspection

[Re: B300 VanDanage]

#2935871

Re: 727 valve body tear down and inspection

[Re: B300 VanDanage]

#2935871

06/23/21 01:20 AM

06/23/21 01:20 AM

|

Joined: May 2021

Posts: 324

Chino Valley

B300 VanDanage

OP

OP

enthusiast

|

OP

OP

enthusiast

Joined: May 2021

Posts: 324

Chino Valley

|

Ok so I noticed the throttle adjustment screw has some discoloration on the threads from where it was originally adjusted correctly. I measured the gap with the 1/8" bit and the throttle screw is off by at least 1/8th"! The shop that rebuilt this made too many rookie mistakes IMO... Makes me suspicious...  Is that thread locker or just paint on those threads?

Last edited by B300 VanDanage; 06/23/21 01:40 AM.

|

|

|

Re: 727 valve body tear down and inspection

[Re: B300 VanDanage]

#2935971

Re: 727 valve body tear down and inspection

[Re: B300 VanDanage]

#2935971

06/23/21 11:23 AM

06/23/21 11:23 AM

|

Joined: Jan 2003

Posts: 1,908

Nebraska

4406bbl

top fuel

|

top fuel

Joined: Jan 2003

Posts: 1,908

Nebraska

|

Ok so I noticed the throttle adjustment screw has some discoloration on the threads from where it was originally adjusted correctly. I measured the gap with the 1/8" bit and the throttle screw is off by at least 1/8th"! The shop that rebuilt this made too many rookie mistakes IMO... Makes me suspicious...  Is that thread locker or just paint on those threads? Threadlocker, they used a locknut on earlier valve bodies. I would go with the first spec I gave you for the regulator, but it is your call. Yes they made a few mistakes.

Last edited by 4406bbl; 06/23/21 11:24 AM.

|

|

|

Re: 727 valve body tear down and inspection

[Re: 4406bbl]

#2936663

Re: 727 valve body tear down and inspection

[Re: 4406bbl]

#2936663

06/25/21 11:27 AM

06/25/21 11:27 AM

|

Joined: May 2021

Posts: 324

Chino Valley

B300 VanDanage

OP

OP

enthusiast

|

OP

OP

enthusiast

Joined: May 2021

Posts: 324

Chino Valley

|

Ok so I noticed the throttle adjustment screw has some discoloration on the threads from where it was originally adjusted correctly. I measured the gap with the 1/8" bit and the throttle screw is off by at least 1/8th"! The shop that rebuilt this made too many rookie mistakes IMO... Makes me suspicious...  Is that thread locker or just paint on those threads? Threadlocker, they used a locknut on earlier valve bodies. I would go with the first spec I gave you for the regulator, but it is your call. Yes they made a few mistakes. I really don't understand the difference of the pressure adjustment... What difference will it make setting the line pressure at 1 1/4" vs 1 9/32? Is it that the tighter the adjustment the more "umph" it will have for shifting?

|

|

|

Re: 727 valve body tear down and inspection

[Re: B300 VanDanage]

#2936699

Re: 727 valve body tear down and inspection

[Re: B300 VanDanage]

#2936699

06/25/21 01:19 PM

06/25/21 01:19 PM

|

Joined: Mar 2011

Posts: 3,075

Michigan

A727Tflite

master

|

master

Joined: Mar 2011

Posts: 3,075

Michigan

|

Ok so I noticed the throttle adjustment screw has some discoloration on the threads from where it was originally adjusted correctly. I measured the gap with the 1/8" bit and the throttle screw is off by at least 1/8th"! The shop that rebuilt this made too many rookie mistakes IMO... Makes me suspicious...  Is that thread locker or just paint on those threads? Threadlocker, they used a locknut on earlier valve bodies. I would go with the first spec I gave you for the regulator, but it is your call. Yes they made a few mistakes. I really don't understand the difference of the pressure adjustment... What difference will it make setting the line pressure at 1 1/4" vs 1 9/32? Is it that the tighter the adjustment the more "umph" it will have for shifting? Tighter adjustment means more line pressure. That’s means a more firm clutch or band application, more holding effort. Each full turn is around 1 to 1-3/4 more psi depending on spring condition.

|

|

|

Re: 727 valve body tear down and inspection

[Re: A727Tflite]

#2936707

Re: 727 valve body tear down and inspection

[Re: A727Tflite]

#2936707

06/25/21 02:34 PM

06/25/21 02:34 PM

|

Joined: May 2021

Posts: 324

Chino Valley

B300 VanDanage

OP

OP

enthusiast

|

OP

OP

enthusiast

Joined: May 2021

Posts: 324

Chino Valley

|

W Ok so I noticed the throttle adjustment screw has some discoloration on the threads from where it was originally adjusted correctly. I measured the gap with the 1/8" bit and the throttle screw is off by at least 1/8th"! The shop that rebuilt this made too many rookie mistakes IMO... Makes me suspicious...  Is that thread locker or just paint on those threads? Threadlocker, they used a locknut on earlier valve bodies. I would go with the first spec I gave you for the regulator, but it is your call. Yes they made a few mistakes. I really don't understand the difference of the pressure adjustment... What difference will it make setting the line pressure at 1 1/4" vs 1 9/32? Is it that the tighter the adjustment the more "umph" it will have for shifting? Tighter adjustment means more line pressure. That’s means a more firm clutch or band application, more holding effort. Each full turn is around 1 to 1-3/4 more psi depending on spring condition. Ah I see. Yeah I can visualize it now thanks. It was apparently set at 1 9/32" and I decided on 1 1/4"... Just 1/32" closer and a tad more line pressure for the heavy duty clutches I installed. I'm happy with that...

|

|

|

Re: 727 valve body tear down and inspection

[Re: 4406bbl]

#2936708

Re: 727 valve body tear down and inspection

[Re: 4406bbl]

#2936708

06/25/21 02:38 PM

06/25/21 02:38 PM

|

Joined: May 2021

Posts: 324

Chino Valley

B300 VanDanage

OP

OP

enthusiast

|

OP

OP

enthusiast

Joined: May 2021

Posts: 324

Chino Valley

|

Ok so I noticed the throttle adjustment screw has some discoloration on the threads from where it was originally adjusted correctly. I measured the gap with the 1/8" bit and the throttle screw is off by at least 1/8th"! The shop that rebuilt this made too many rookie mistakes IMO... Makes me suspicious...  Is that thread locker or just paint on those threads? Threadlocker, they used a locknut on earlier valve bodies. I would go with the first spec I gave you for the regulator, but it is your call. Yes they made a few mistakes. Decided on 1 1/4" only because I installed the heavy duty clutches and kick down band. I hope that's not too much for my application.

|

|

|

Re: 727 valve body tear down and inspection

[Re: A727Tflite]

#2937018

Re: 727 valve body tear down and inspection

[Re: A727Tflite]

#2937018

06/26/21 02:50 PM

06/26/21 02:50 PM

|

Joined: Jan 2003

Posts: 25,786

Rio Linda, CA

John_Kunkel

Too Many Posts

|

Too Many Posts

Joined: Jan 2003

Posts: 25,786

Rio Linda, CA

|

Tighter adjustment means more line pressure. That’s means a more firm clutch or band application, more holding effort. Each full turn is around 1 to 1-3/4 more psi depending on spring condition.

The dimension shown in the snip from the B&M instructions is based on a different regulator spring supplied with their kit, the stiffer blue spring from the kit would yield more like 4-5 psi for each full turn.

The INTERNET, the MISinformation superhighway

|

|

|

|

|