Ok so...

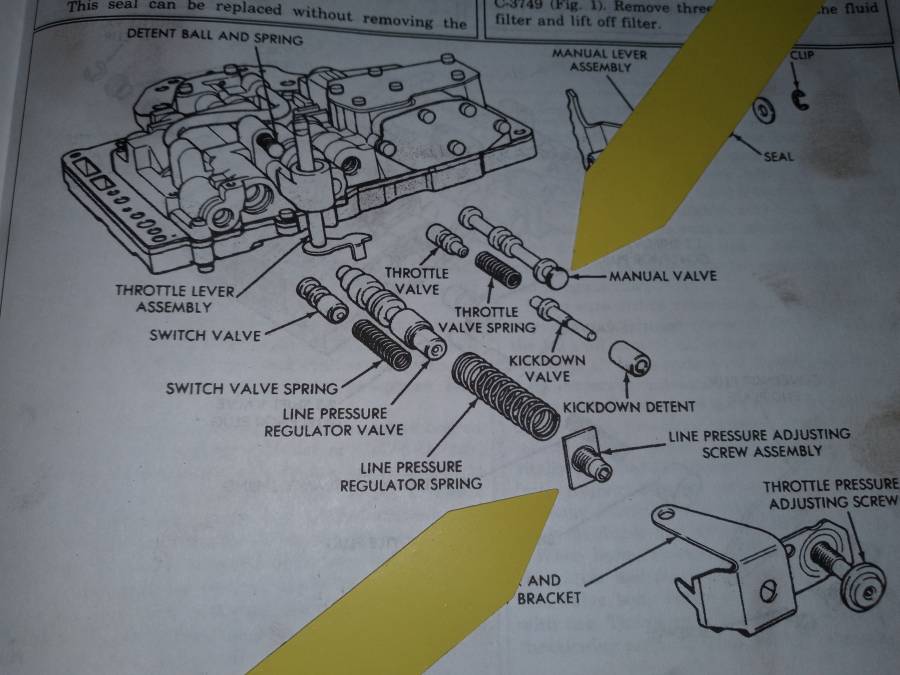

I now have to decide if I want quicker and firmer shifts in reverse or not...

Once I do that I should have it all back together today hopefully... The tranny not the install...

It usually takes me a whole day to get the tranny in the van because I don't have the proper equipment and I'm doing it all on dirt so it makes it a little more difficult to roll heavy objects around...

I appreciate all the help I've received from everyone so far! Thank you!

Transman, you've had an answer for me in every thread I post and I appreciate that!

We've figured out why it had no reverse but still not clear about the misalignment. A bad torque converter? Maybe... I really don't think it was the flex plate but I bought a new one anyway just in case...

Hopefully this works out in the end. It's my first rebuild and honestly I'm almost glad they messed up the tranny because now I have this new knowledge about transmissions and new found confidence to actually work on them.

It wasn't as bad as I thought.

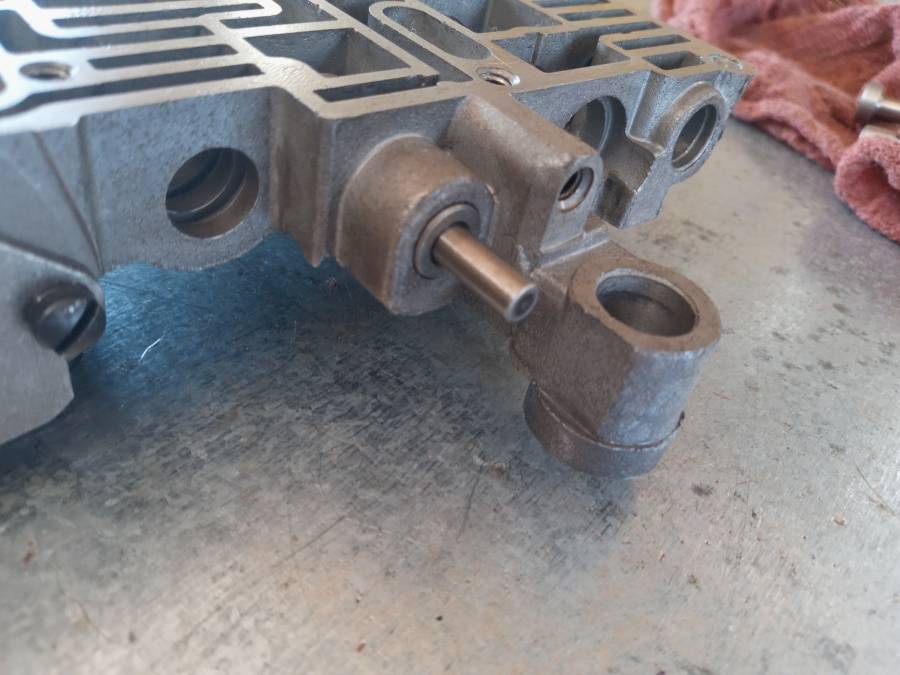

Once the unit is built properly on the bench with correct input shaft (drivetrain end play) and the converter is installed correctly you should only have to verify that the converter is indexed properly to the flex plate. My suggestion is find the offset lug on the flexplate and put a paint mark on it and set it at 6 O’Clock by turning the crank.

Lightly lube the converter pilot and the crank pilot pocket.

Then make sure once the trans is married to the engine that you have the offset lug at 6. You should have no problem sliding the converter in to the pilot. You should have about an 1/8” gap between the converter drive lugs and the flex at this point.

Snug the bolts up finger right up until they are all in. Then torque them.

Don’t torque the first bolt then move to the rest, that can cock the converter.

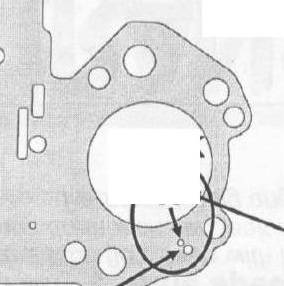

I think I mentioned it before - make sure both block dowel pins are there and the holes for them in the trans case are in good shape and not elongated.

You should be good from that point on.