|

727 clutch and manual valve body install

#1858224

727 clutch and manual valve body install

#1858224

06/27/15 03:10 PM

06/27/15 03:10 PM

|

Joined: Jun 2013

Posts: 1,521

Tacoma, Washington USA

Adam71Charger

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Jun 2013

Posts: 1,521

Tacoma, Washington USA

|

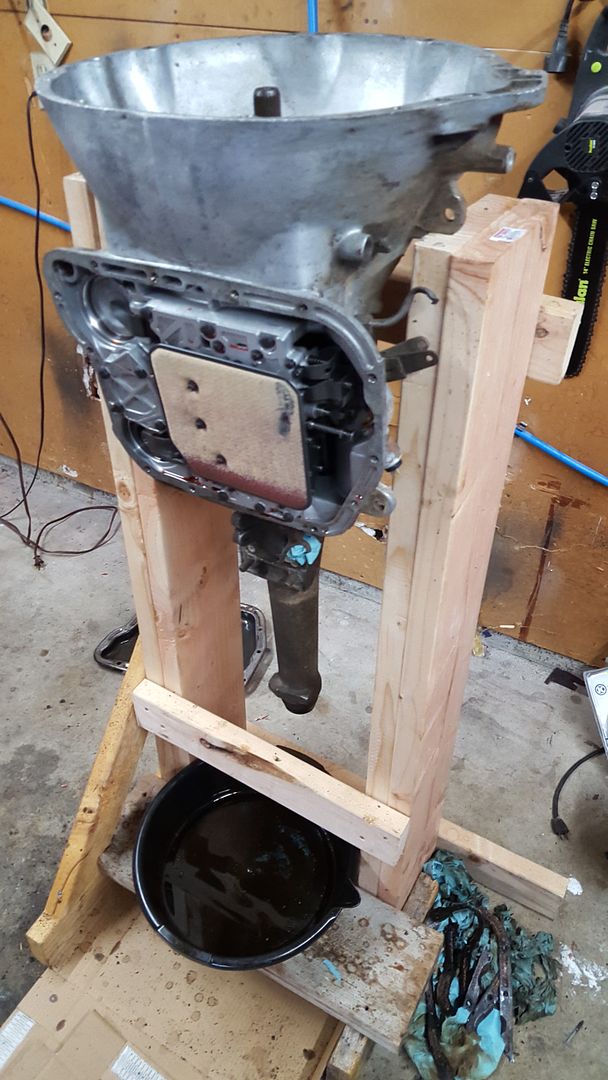

Just got my upgrade kit for my BB 727. I got the reverse manual valve body WITH low band apply from Tranzact and I also got kevlar bands, HD friction plates, and a rings, seals and bushings kit. Tranzact advertises that their RMVB is designed to work off stock pump pressures, which means less stuff I have to change/replace. Im starting this thread hoping that some tranny experts will chime in as I go along so I can avoid as many mistakes as possible. I have some experience with transmissions, but this will be my first 727 rebuild. Im following the rebuild instructions in the "Torqueflite A-727 Transmission Handbook; by Carl H. Munroe" It's a 1969 A727 that came behind a 440 C-Body. It's going behind a mild 440 around 550hp and over 500 ft/lbs of torque, with a 200 shot of nitrous (I've been told by some with my tight LSA cam I probably wont be seeing a 200hp increase, closer to 100hp). The whole overall goal is to have a FUN street/strip car that can take a beating. 1st thing I did was build a wooden structure to get the tranny vertical. Next, cleaned the inside and outside of the bellhousing and anywhere else that could possibly contaminate the inside of the tranny once the front pump and valve body are off. got the pan off and the front pump bolts out. Now, I need a slide hammer to take off the front pump (3/8 I believe). The 1st problem.. my seal and ring kit is labed "1971-On". Pretty sure I have to send it back due to differences in the 1971 and up front drum bushing size and sealing ring style, and also different bushings in the 71-up reaction shaft support. Anything else Im missing? 2nd, Im unsure if I should upgrade the servos. If the stock servos will be ok in this application, I will stick with them. 3rd, I think my tranny has 6 return springs, and can hold up to 15, not sure how many I should install for my application?

|

|

|

Re: 727 clutch and manual valve body install

[Re: Adam71Charger]

#1858240

Re: 727 clutch and manual valve body install

[Re: Adam71Charger]

#1858240

06/27/15 03:35 PM

06/27/15 03:35 PM

|

Joined: May 2003

Posts: 1,751

Graham, WA

Polarapete

top fuel

|

top fuel

Joined: May 2003

Posts: 1,751

Graham, WA

|

That is a lovely piece that you built to do the final assembly of the tranny, but it is working against you when it comes to disassembly.

1) put the pan back on.

2) tighten the 2nd gear band

3) lay the trans on a flat surface on the pan.

4) take all the bolts out of the front pump assembly

5) get a good length of chain with end links big enough to pass a 3/8" NC bolt with a washer. There are two places on the front pump that are threaded for above, assemble your chain to those places and holding one hand on the case, whip the chain and it will pull the front pump w/o a slide hammer.

1st time I used this method was over 30 years ago. Works every time.

I have seen guys do something similar in the dirt at the yard, they just pull the pump bolts, pick up the tranny and drop it. Of course this is only the start of the disassembly, read the book. If you think you need bushings, take the parts to a tranny shop and have them install them while you watch, if possible.

1986 Dodge Ramcharger 440 2wd, Bracket Racer Under Construction

1998 Ram 2500 QuadCab, new daily driver.

2008 Honda Element

2014 Carry-On 7x14 Cargo Trailer

|

|

|

Re: 727 clutch and manual valve body install

[Re: Polarapete]

#1858294

Re: 727 clutch and manual valve body install

[Re: Polarapete]

#1858294

06/27/15 05:05 PM

06/27/15 05:05 PM

|

Joined: Jan 2003

Posts: 27,254

Rio Linda, CA

John_Kunkel

The Erection Connection

|

The Erection Connection

Joined: Jan 2003

Posts: 27,254

Rio Linda, CA

|

I agree that that "fixture" isn't ideal, you'd be better off salvaging the wood and making a stand to hold the trans on its back with the pan facing up.

The chain pump puller works or get a couple of lengths of 3/8"-16 all-thread and makes some weights to slide on them.

You need to determine the actual year of the trans, look for the part number stamped in the drivers side pan rail.

The INTERNET, the MISinformation superhighway

|

|

|

Re: 727 clutch and manual valve body install

[Re: barracuda7199]

#1858485

Re: 727 clutch and manual valve body install

[Re: barracuda7199]

#1858485

06/27/15 09:45 PM

06/27/15 09:45 PM

|

Joined: Jan 2003

Posts: 13,437

Benton, IL.

DaveRS23

Master of nothing...

|

Master of nothing...

Joined: Jan 2003

Posts: 13,437

Benton, IL.

|

Drop the valve body and tap the pump housing off from the inside out. I use a long 1/2" extension.

I always use A&A's bearing that replaces the thrust washer between the input and output shafts. I have beat that thrust bushing out on a couple of trannies. You loose 3rd gear just all of a sudden and it requires a near total tear down to replace.

Master, again and still

|

|

|

Re: 727 clutch and manual valve body install

[Re: barracuda7199]

#1858956

Re: 727 clutch and manual valve body install

[Re: barracuda7199]

#1858956

06/28/15 03:23 PM

06/28/15 03:23 PM

|

Joined: Jun 2013

Posts: 1,521

Tacoma, Washington USA

Adam71Charger

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Jun 2013

Posts: 1,521

Tacoma, Washington USA

|

Thread 2 3/8 bell housing bolts in the holes on the pump and use a small crow bar to bump the pump out. if it is a 69 it should already have the good non controlled load servo on the kickdown band. I would eliminate the cushion spring on the rear servo. They make a spacer but you can stack some washers to do the same thing. How thick is that spacer?

|

|

|

Re: 727 clutch and manual valve body install

[Re: DaveRS23]

#1858957

Re: 727 clutch and manual valve body install

[Re: DaveRS23]

#1858957

06/28/15 03:24 PM

06/28/15 03:24 PM

|

Joined: Jun 2013

Posts: 1,521

Tacoma, Washington USA

Adam71Charger

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Jun 2013

Posts: 1,521

Tacoma, Washington USA

|

Drop the valve body and tap the pump housing off from the inside out. I use a long 1/2" extension.

I always use A&A's bearing that replaces the thrust washer between the input and output shafts. I have beat that thrust bushing out on a couple of trannies. You loose 3rd gear just all of a sudden and it requires a near total tear down to replace. Whats that bearing called?

|

|

|

Re: 727 clutch and manual valve body install

[Re: Adam71Charger]

#1859019

Re: 727 clutch and manual valve body install

[Re: Adam71Charger]

#1859019

06/28/15 04:56 PM

06/28/15 04:56 PM

|

Joined: Jan 2003

Posts: 27,254

Rio Linda, CA

John_Kunkel

The Erection Connection

|

The Erection Connection

Joined: Jan 2003

Posts: 27,254

Rio Linda, CA

|

Yes it's a 69

Driver's pan rail: PK3410669L 3065 xxxx

passenger partial vin: 0C191109 Actually, it's a '70; only a few differences from a '69 and the kit will be the same.

The INTERNET, the MISinformation superhighway

|

|

|

Re: 727 clutch and manual valve body install

[Re: Adam71Charger]

#1859308

Re: 727 clutch and manual valve body install

[Re: Adam71Charger]

#1859308

06/28/15 10:18 PM

06/28/15 10:18 PM

|

Joined: Jan 2003

Posts: 13,437

Benton, IL.

DaveRS23

Master of nothing...

|

Master of nothing...

Joined: Jan 2003

Posts: 13,437

Benton, IL.

|

Drop the valve body and tap the pump housing off from the inside out. I use a long 1/2" extension.

I always use A&A's bearing that replaces the thrust washer between the input and output shafts. I have beat that thrust bushing out on a couple of trannies. You loose 3rd gear just all of a sudden and it requires a near total tear down to replace. Whats that bearing called? I don't think there is a part number for it. I just order it by description. You will need to have one shaft machined for clearance. I think it is .060, but ask them how much when you order the bearing.

Master, again and still

|

|

|

Re: 727 clutch and manual valve body install

[Re: Adam71Charger]

#1859499

Re: 727 clutch and manual valve body install

[Re: Adam71Charger]

#1859499

06/29/15 08:06 AM

06/29/15 08:06 AM

|

Joined: Apr 2011

Posts: 280

GEORGIA

barracuda7199

enthusiast

|

enthusiast

Joined: Apr 2011

Posts: 280

GEORGIA

|

Thread 2 3/8 bell housing bolts in the holes on the pump and use a small crow bar to bump the pump out. if it is a 69 it should already have the good non controlled load servo on the kickdown band. I would eliminate the cushion spring on the rear servo. They make a spacer but you can stack some washers to do the same thing. How thick is that spacer? 1/4 inch I do believe. There is an ad in the classifieds on here for a nice billet servo that does the same thing as well as an accumulator with a built in blocker rod that's a nice piece as well.

|

|

|

Re: 727 clutch and manual valve body install

[Re: Adam71Charger]

#1859699

Re: 727 clutch and manual valve body install

[Re: Adam71Charger]

#1859699

06/29/15 02:45 PM

06/29/15 02:45 PM

|

Joined: Jan 2003

Posts: 27,254

Rio Linda, CA

John_Kunkel

The Erection Connection

|

The Erection Connection

Joined: Jan 2003

Posts: 27,254

Rio Linda, CA

|

Are you talking about the model year it went into? I was referring to build date being 69, am I wrong? The model year is what you order parts by.

The INTERNET, the MISinformation superhighway

|

|

|

Re: 727 clutch and manual valve body install

[Re: Adam71Charger]

#1861707

Re: 727 clutch and manual valve body install

[Re: Adam71Charger]

#1861707

07/01/15 11:24 PM

07/01/15 11:24 PM

|

Joined: Apr 2011

Posts: 280

GEORGIA

barracuda7199

enthusiast

|

enthusiast

Joined: Apr 2011

Posts: 280

GEORGIA

|

It's normal and you have the desirable 4 pinion planetaries. Should have a 4 clutch front drum too. Nice looking trans! What ratio is stamped in the kickdown lever? I run a 4.2 but a 3.8 is good too.

Last edited by barracuda7199; 07/01/15 11:26 PM.

|

|

|

|

|