Moparts

727 clutch and manual valve body install

Posted By: Adam71Charger

727 clutch and manual valve body install - 06/27/15 08:10 PM

Just got my upgrade kit for my BB 727. I got the reverse manual valve body WITH low band apply from Tranzact and I also got kevlar bands, HD friction plates, and a rings, seals and bushings kit. Tranzact advertises that their RMVB is designed to work off stock pump pressures, which means less stuff I have to change/replace.

Im starting this thread hoping that some tranny experts will chime in as I go along so I can avoid as many mistakes as possible. I have some experience with transmissions, but this will be my first 727 rebuild. Im following the rebuild instructions in the "Torqueflite A-727 Transmission Handbook; by Carl H. Munroe" It's a 1969 A727 that came behind a 440 C-Body. It's going behind a mild 440 around 550hp and over 500 ft/lbs of torque, with a 200 shot of nitrous (I've been told by some with my tight LSA cam I probably wont be seeing a 200hp increase, closer to 100hp). The whole overall goal is to have a FUN street/strip car that can take a beating.

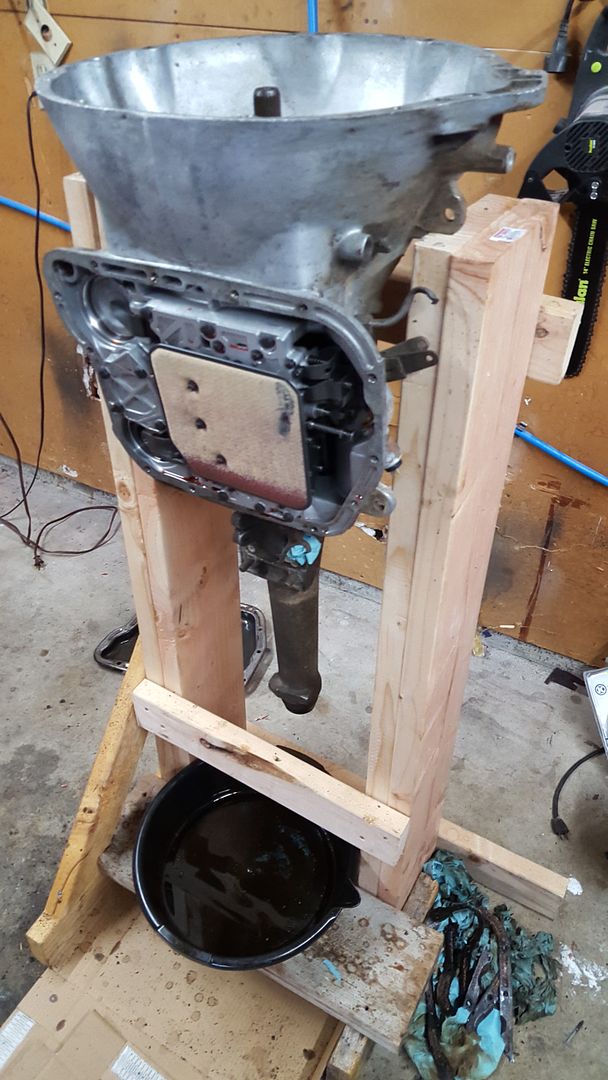

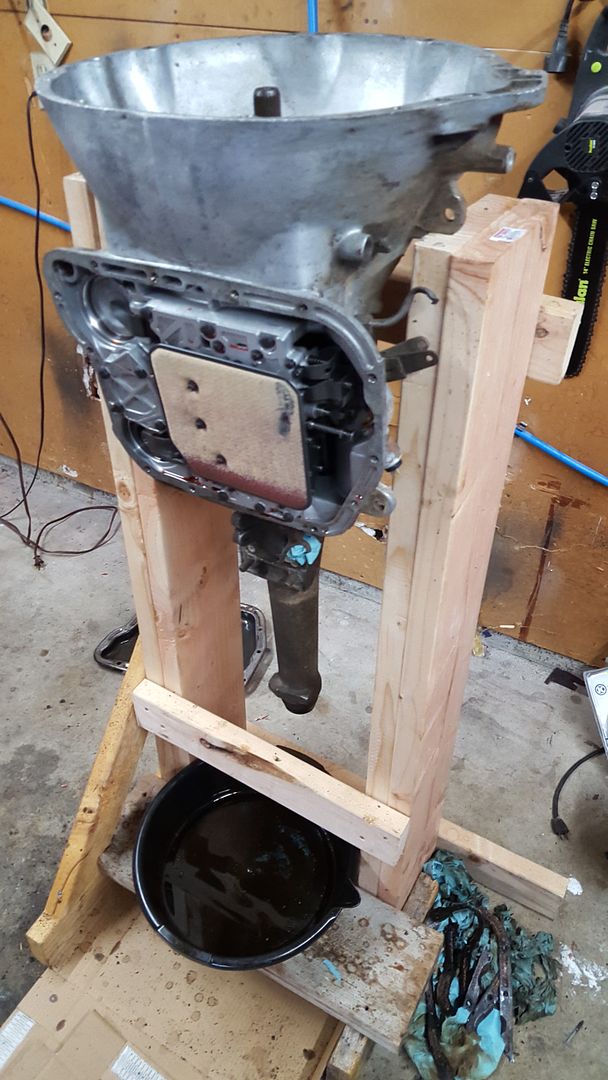

1st thing I did was build a wooden structure to get the tranny vertical. Next, cleaned the inside and outside of the bellhousing and anywhere else that could possibly contaminate the inside of the tranny once the front pump and valve body are off. got the pan off and the front pump bolts out. Now, I need a slide hammer to take off the front pump (3/8 I believe).

The 1st problem.. my seal and ring kit is labed "1971-On". Pretty sure I have to send it back due to differences in the 1971 and up front drum bushing size and sealing ring style, and also different bushings in the 71-up reaction shaft support. Anything else Im missing?

2nd, Im unsure if I should upgrade the servos. If the stock servos will be ok in this application, I will stick with them.

3rd, I think my tranny has 6 return springs, and can hold up to 15, not sure how many I should install for my application?

Posted By: Polarapete

Re: 727 clutch and manual valve body install - 06/27/15 08:35 PM

That is a lovely piece that you built to do the final assembly of the tranny, but it is working against you when it comes to disassembly.

1) put the pan back on.

2) tighten the 2nd gear band

3) lay the trans on a flat surface on the pan.

4) take all the bolts out of the front pump assembly

5) get a good length of chain with end links big enough to pass a 3/8" NC bolt with a washer. There are two places on the front pump that are threaded for above, assemble your chain to those places and holding one hand on the case, whip the chain and it will pull the front pump w/o a slide hammer.

1st time I used this method was over 30 years ago. Works every time.

I have seen guys do something similar in the dirt at the yard, they just pull the pump bolts, pick up the tranny and drop it. Of course this is only the start of the disassembly, read the book. If you think you need bushings, take the parts to a tranny shop and have them install them while you watch, if possible.

Posted By: John_Kunkel

Re: 727 clutch and manual valve body install - 06/27/15 10:05 PM

I agree that that "fixture" isn't ideal, you'd be better off salvaging the wood and making a stand to hold the trans on its back with the pan facing up.

The chain pump puller works or get a couple of lengths of 3/8"-16 all-thread and makes some weights to slide on them.

You need to determine the actual year of the trans, look for the part number stamped in the drivers side pan rail.

Posted By: barracuda7199

Re: 727 clutch and manual valve body install - 06/28/15 12:21 AM

Thread 2 3/8 bell housing bolts in the holes on the pump and use a small crow bar to bump the pump out. if it is a 69 it should already have the good non controlled load servo on the kickdown band. I would eliminate the cushion spring on the rear servo. They make a spacer but you can stack some washers to do the same thing.

Posted By: DaveRS23

Re: 727 clutch and manual valve body install - 06/28/15 02:45 AM

Drop the valve body and tap the pump housing off from the inside out. I use a long 1/2" extension.

I always use A&A's bearing that replaces the thrust washer between the input and output shafts. I have beat that thrust bushing out on a couple of trannies. You loose 3rd gear just all of a sudden and it requires a near total tear down to replace.

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 06/28/15 08:21 PM

Yes it's a 69

Driver's pan rail: PK3410669L 3065 xxxx

passenger partial vin: 0C191109

Got some good feedback here for pump removal, thank you. The reason I put it vertical was I was afraid if I laid the transmission horizontal something might fall out of place when I pulled the guts out.

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 06/28/15 08:23 PM

Thread 2 3/8 bell housing bolts in the holes on the pump and use a small crow bar to bump the pump out. if it is a 69 it should already have the good non controlled load servo on the kickdown band. I would eliminate the cushion spring on the rear servo. They make a spacer but you can stack some washers to do the same thing.

How thick is that spacer?

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 06/28/15 08:24 PM

Drop the valve body and tap the pump housing off from the inside out. I use a long 1/2" extension.

I always use A&A's bearing that replaces the thrust washer between the input and output shafts. I have beat that thrust bushing out on a couple of trannies. You loose 3rd gear just all of a sudden and it requires a near total tear down to replace.

Whats that bearing called?

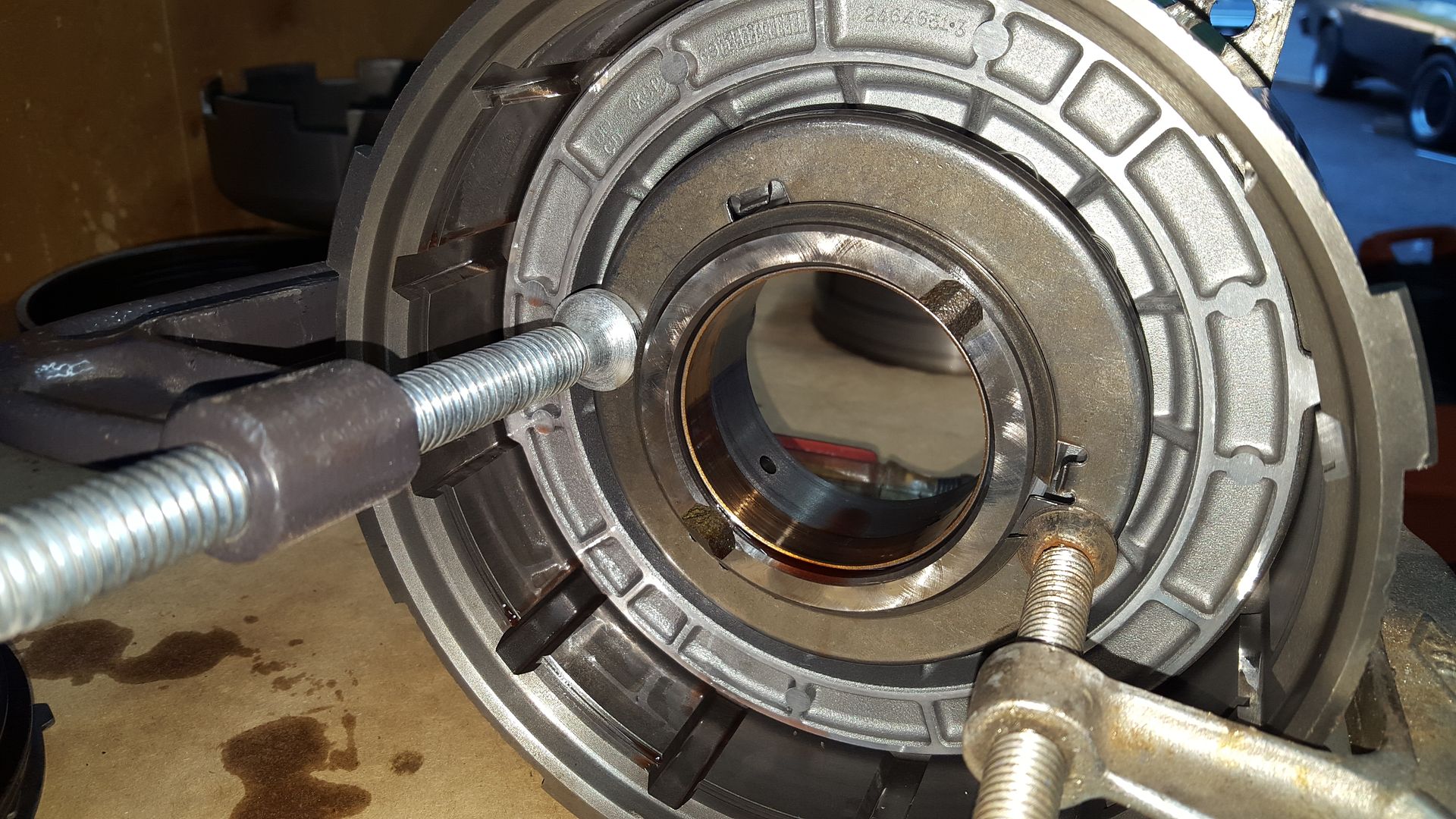

Posted By: Dodgem

Re: 727 clutch and manual valve body install - 06/28/15 09:03 PM

I use this 3/8 threaded rod the two holes are threaded 3 oclock and 9 oclock. pull by slowly tightening nuts down.

Posted By: John_Kunkel

Re: 727 clutch and manual valve body install - 06/28/15 09:56 PM

Yes it's a 69

Driver's pan rail: PK3410669L 3065 xxxx

passenger partial vin: 0C191109

Actually, it's a '70; only a few differences from a '69 and the kit will be the same.

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 06/28/15 11:06 PM

Are you talking about the model year it went into? I was referring to build date being 69, am I wrong?

Posted By: DaveRS23

Re: 727 clutch and manual valve body install - 06/29/15 03:18 AM

Drop the valve body and tap the pump housing off from the inside out. I use a long 1/2" extension.

I always use A&A's bearing that replaces the thrust washer between the input and output shafts. I have beat that thrust bushing out on a couple of trannies. You loose 3rd gear just all of a sudden and it requires a near total tear down to replace.

Whats that bearing called?

I don't think there is a part number for it. I just order it by description. You will need to have one shaft machined for clearance. I think it is .060, but ask them how much when you order the bearing.

Posted By: barracuda7199

Re: 727 clutch and manual valve body install - 06/29/15 01:06 PM

Thread 2 3/8 bell housing bolts in the holes on the pump and use a small crow bar to bump the pump out. if it is a 69 it should already have the good non controlled load servo on the kickdown band. I would eliminate the cushion spring on the rear servo. They make a spacer but you can stack some washers to do the same thing.

How thick is that spacer?

1/4 inch I do believe. There is an ad in the classifieds on here for a nice billet servo that does the same thing as well as an accumulator with a built in blocker rod that's a nice piece as well.

Posted By: John_Kunkel

Re: 727 clutch and manual valve body install - 06/29/15 07:45 PM

Are you talking about the model year it went into? I was referring to build date being 69, am I wrong?

The

model year is what you order parts by.

Posted By: Adam71Charger

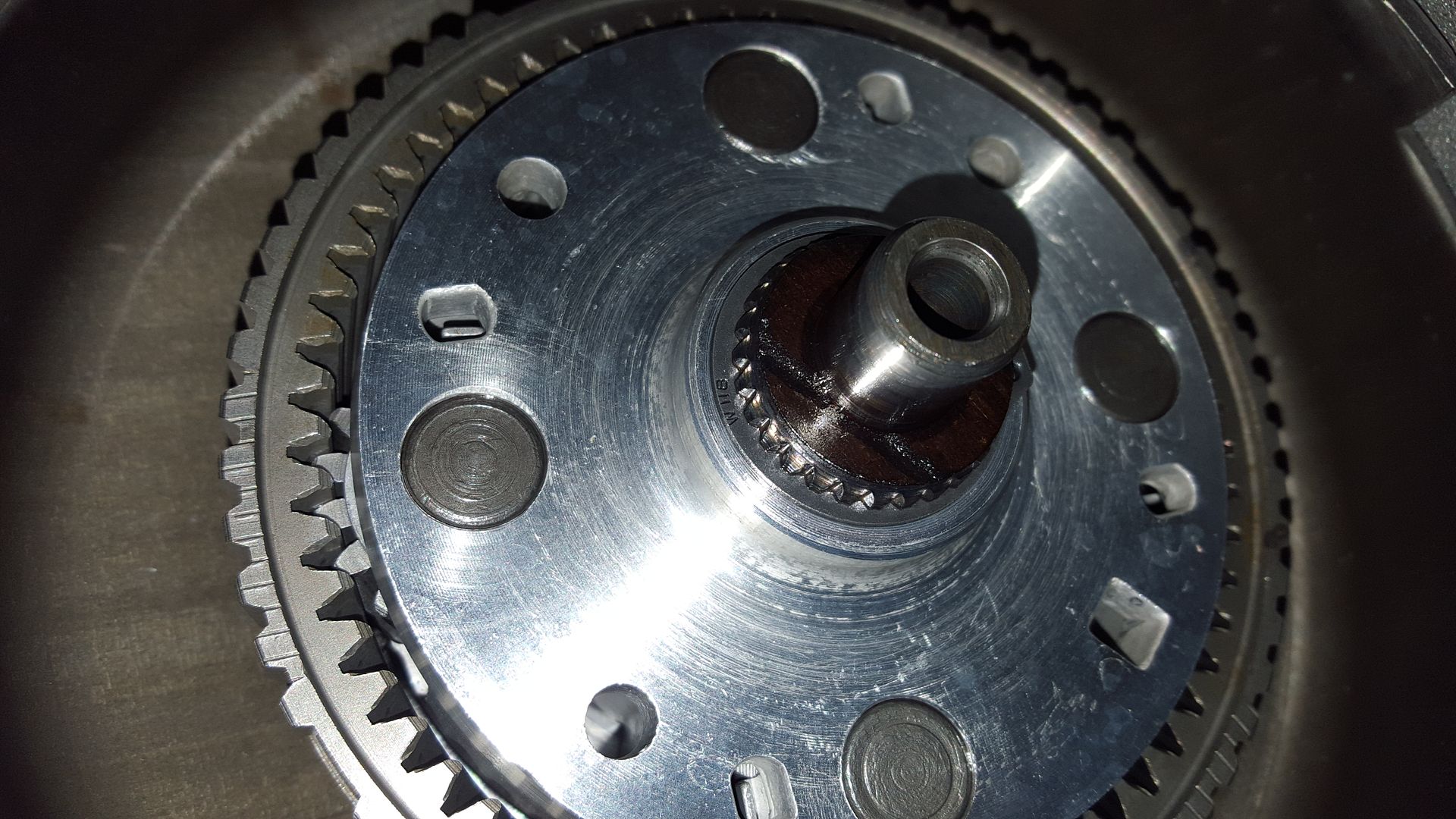

Re: 727 clutch and manual valve body install - 07/02/15 03:45 AM

Posted By: barracuda7199

Re: 727 clutch and manual valve body install - 07/02/15 04:24 AM

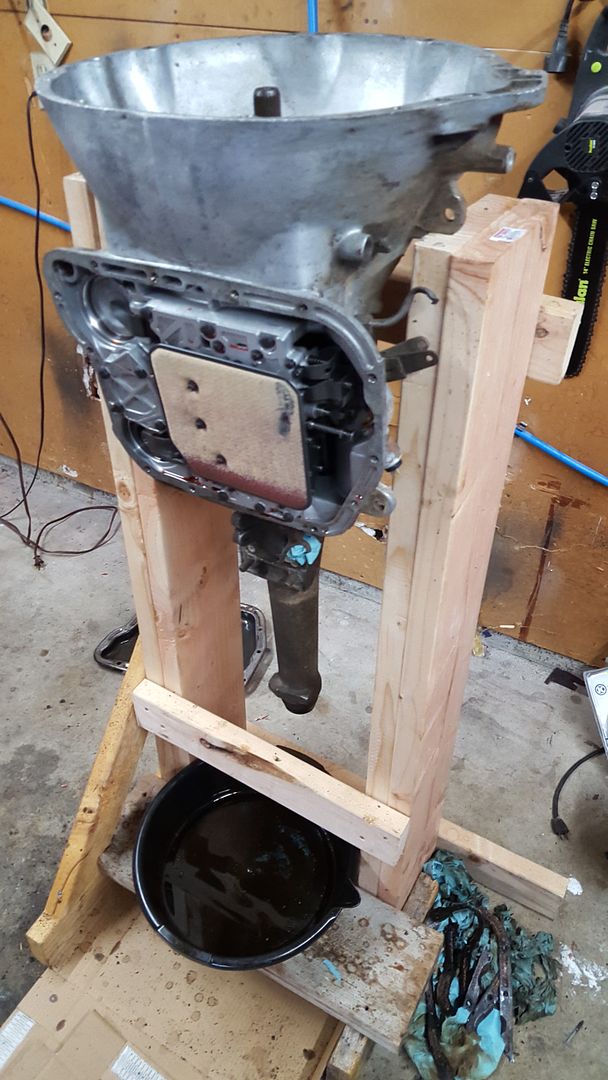

It's normal and you have the desirable 4 pinion planetaries. Should have a 4 clutch front drum too. Nice looking trans! What ratio is stamped in the kickdown lever? I run a 4.2 but a 3.8 is good too.

Posted By: AndyF

Re: 727 clutch and manual valve body install - 07/02/15 04:56 AM

Having an assembly stand is a good idea. I built an adapter so I could hang the transmission from my motor stand. That way I can rotate it vertical or flip it over on its back. I found that being able to flip it end over end made it easy to measure the end play.

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 07/02/15 06:15 AM

Thats a really good idea Andy, do you sell those adapter brackets?

@Barracuda7199, I cannot find a number on my kickdown lever, is it really tiny?

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 07/02/15 06:34 AM

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 07/02/15 09:41 AM

EDITED, non relevant .

Posted By: barracuda7199

Re: 727 clutch and manual valve body install - 07/02/15 12:20 PM

Not that lever I'm talking about the one inside the transmission that engages the front band. It is on the left in the second pic you posted when you pulled the pump out.

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 07/02/15 07:45 PM

Ok I'll check that lever.

If I use dexron can I use dexron VI?

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 07/02/15 09:03 PM

My lever has 3.8 stamped on it.

Posted By: Polarapete

Re: 727 clutch and manual valve body install - 07/03/15 01:31 AM

Thats a really good idea Andy, do you sell those adapter brackets?

@Barracuda7199, I cannot find a number on my kickdown lever, is it really tiny?

What you have pictured is the throttle pressure lever and since you are going to a RMVB you will not be using it when you put the transmission back in. The kickdown lever is the one that pushes on the strut that closes the 2nd gear band and they are numbered.

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 07/27/15 12:39 AM

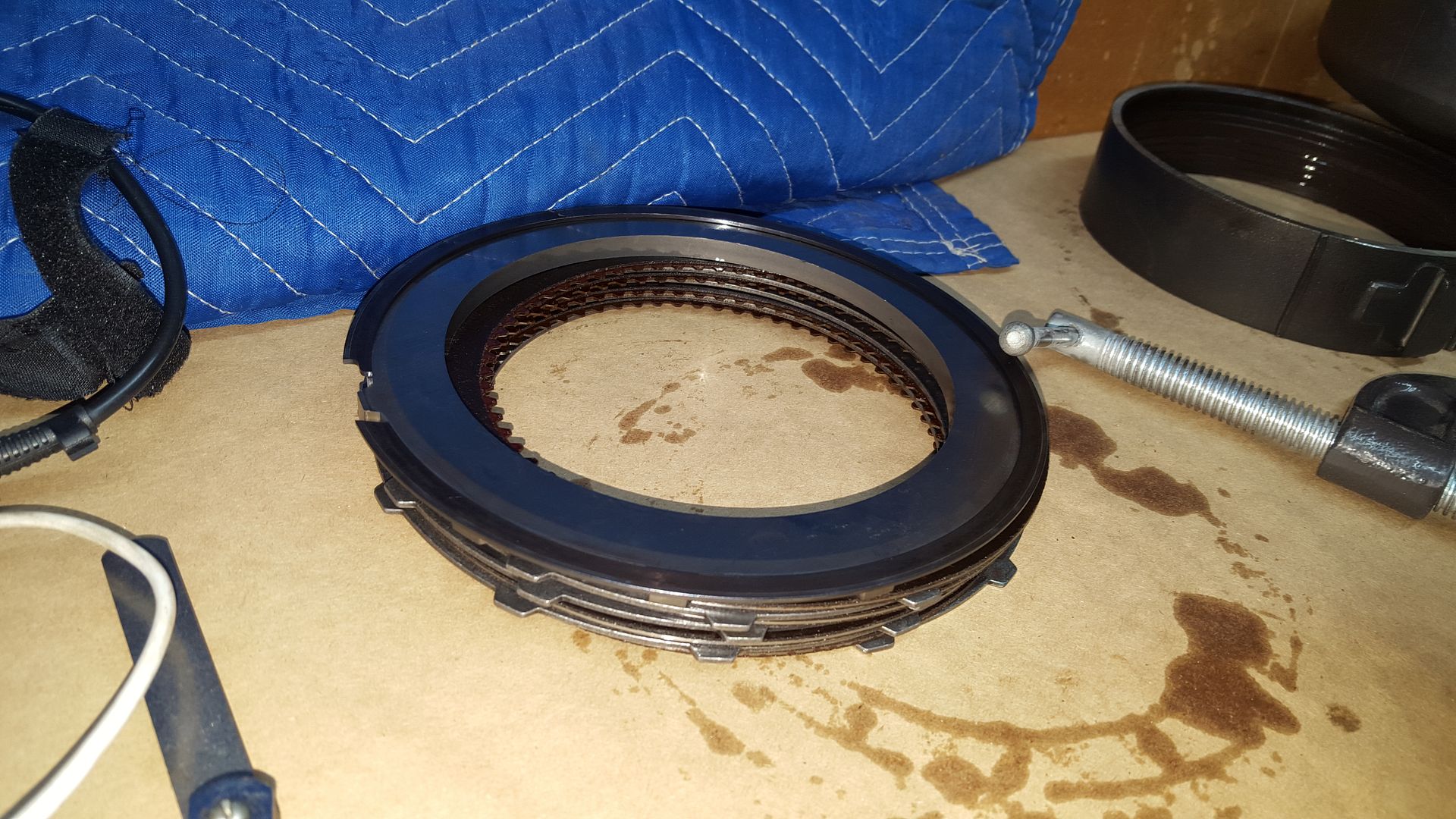

Finally got time to reassemble my tranny. Ive got 15 springs in my front clutch, and 4 frictions and steels. Tranzact specifies that a front clutch clearance of .060 and .050 is required for their valve body. I had almost .080. So I switched my front drum snap ring with the rear drum snap ring, but I still have about .072 clearance, too much. The snap ring is .076", so i guess my only solution is to order a set of thicker snap rings.

After assembling the rear drum, even with the thinner snap ring (.062"), I barely have .010 clearance. I dont know how to solve that issue, as Im supposed to have .030 to .040

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 07/27/15 12:46 AM

If Im overlooking something please let me know. I havent seen any snap rings or pressure plates that are thinner than stock to help me achieve the proper rear drum clearance. Maybe I could just have my pressure plate machined?

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 07/27/15 01:08 AM

The only thing I can think of that has affected my clearance is that I soaked the clutches and steels in tranny fluid for a few days before I installed and checked clearance. Could my frictions have swelled and given me a inaccurate clearance reading?

Posted By: 70AARcuda

Re: 727 clutch and manual valve body install - 07/27/15 03:32 AM

Suppose to check the clearance with the disc dry....

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 07/27/15 07:38 PM

Ok. Well I talked to a transmission guy and he says that wet friction disks would not be throwing my reading off that much. I'll take it apart and measure my old disks/steels and compare to new stuff and see where the difference is

Posted By: John_Kunkel

Re: 727 clutch and manual valve body install - 07/27/15 09:38 PM

My lever has 3.8 stamped on it.

You're good to go.

Friction discs are generally about the same thickness but thicker steel plates are available...you might have those and they'll tighten up the clutch pack. Standard thickness is .070" and the thicker ones are .090".

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 08/02/15 09:57 PM

OK I found the problem. My front drum steels are .070 and the steels in my rear drum are .090.

I guess this would be a simple swap, except my kit only came with 3 of the .090 and my front drum uses 5 steels.

Is it a bad idea to mix and match the different thickness steel plates until I get the desired clearances?

If I do need to order more of the .090's, should I upgrade to the kolene? Every part I got in my rebuild kit was high performance except my steels. tranny going behind 600hp 440 with 150 shot

Posted By: John_Kunkel

Re: 727 clutch and manual valve body install - 08/03/15 07:22 PM

Mix the thick/thin steels any way you desire...personally, I use the thicker steels at the outer end of the clutch pack, toward the snap ring.

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 08/04/15 12:28 AM

I called TSR and ordered some thick steels, and also some thicker snap rings just in case. He talked me into a bolt in sprag as well..

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 08/04/15 12:29 AM

good to know I can mix the steels. Ill try what you do with the thicker steels towards the outside edges

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 08/04/15 10:21 PM

Is there a good upgrade for the stock filler tube grommet?

Posted By: Adam71Charger

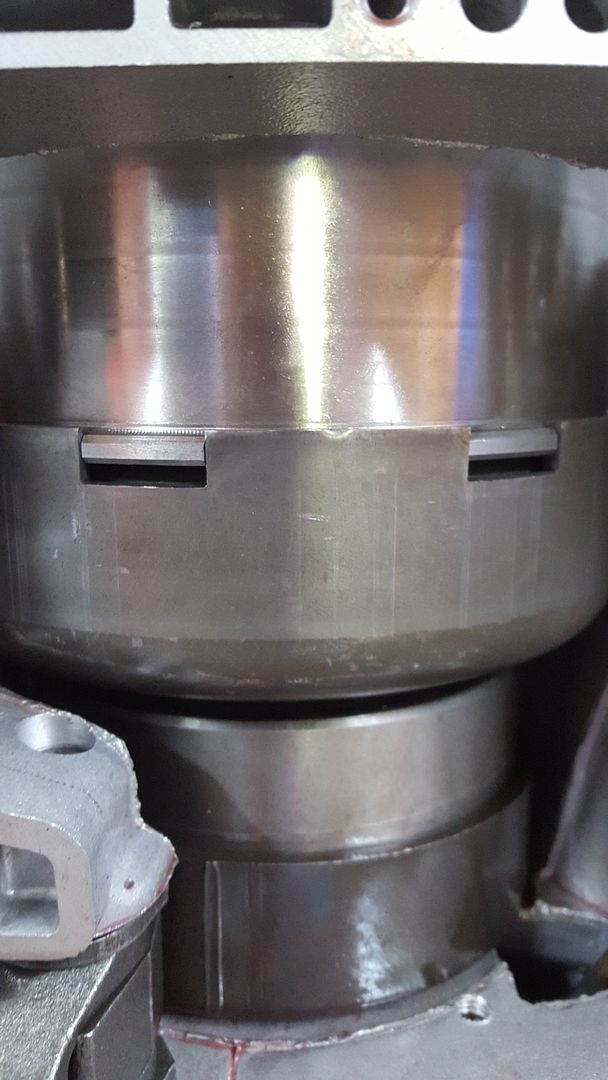

Re: 727 clutch and manual valve body install - 08/10/15 03:24 AM

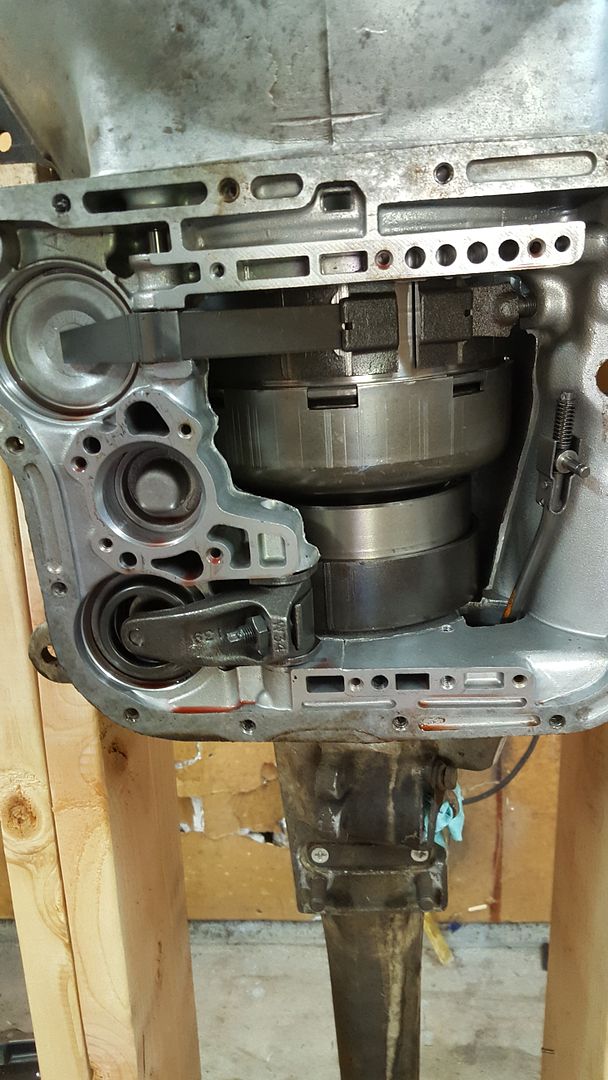

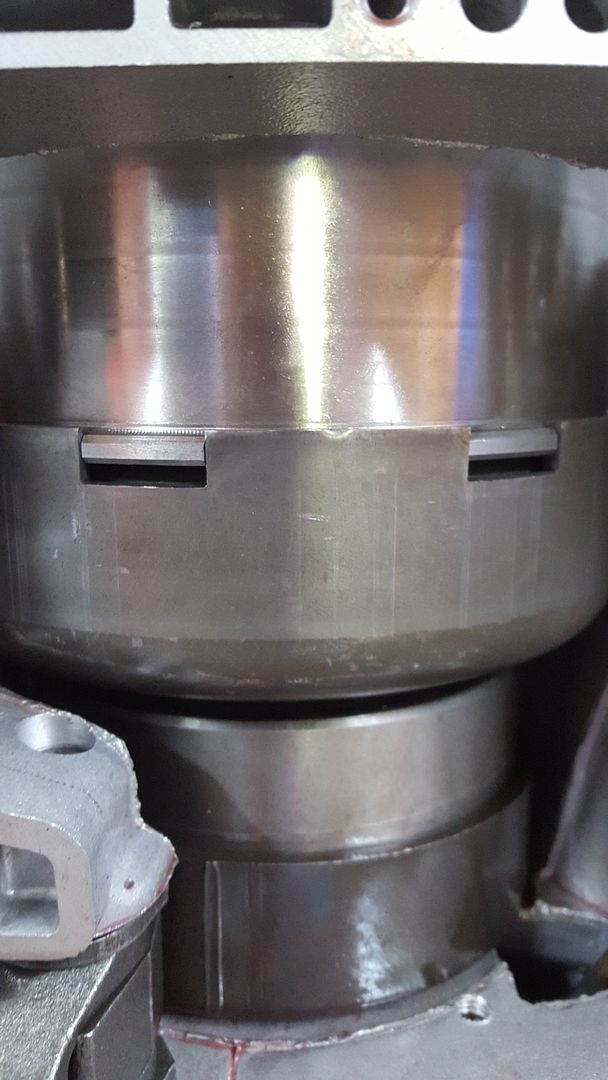

Hey Guys I need help, I cannot tell if my forward clutch drum is fully seated! There is a slight gap between the ears of the clutch drum and the sun shell it sits in, is this normal? Is it fully seated?

Posted By: John_Kunkel

Re: 727 clutch and manual valve body install - 08/10/15 07:52 PM

Looks OK...if in doubt, look at the witness marks where the drum tangs previously wore on the driving shell slots.

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 11/09/15 04:38 AM

Will my transmission be using the accumulator any more since I'm installing a manual valve body? If not, do I even need to re install it?

Posted By: John_Kunkel

Re: 727 clutch and manual valve body install - 11/09/15 08:18 PM

Depends on the valve body, if the large hole in the separator plate over the accumulator is there the accumulator will still be in use....if there is no hole in the plate you can omit the accumulator piston.

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 11/14/15 01:54 AM

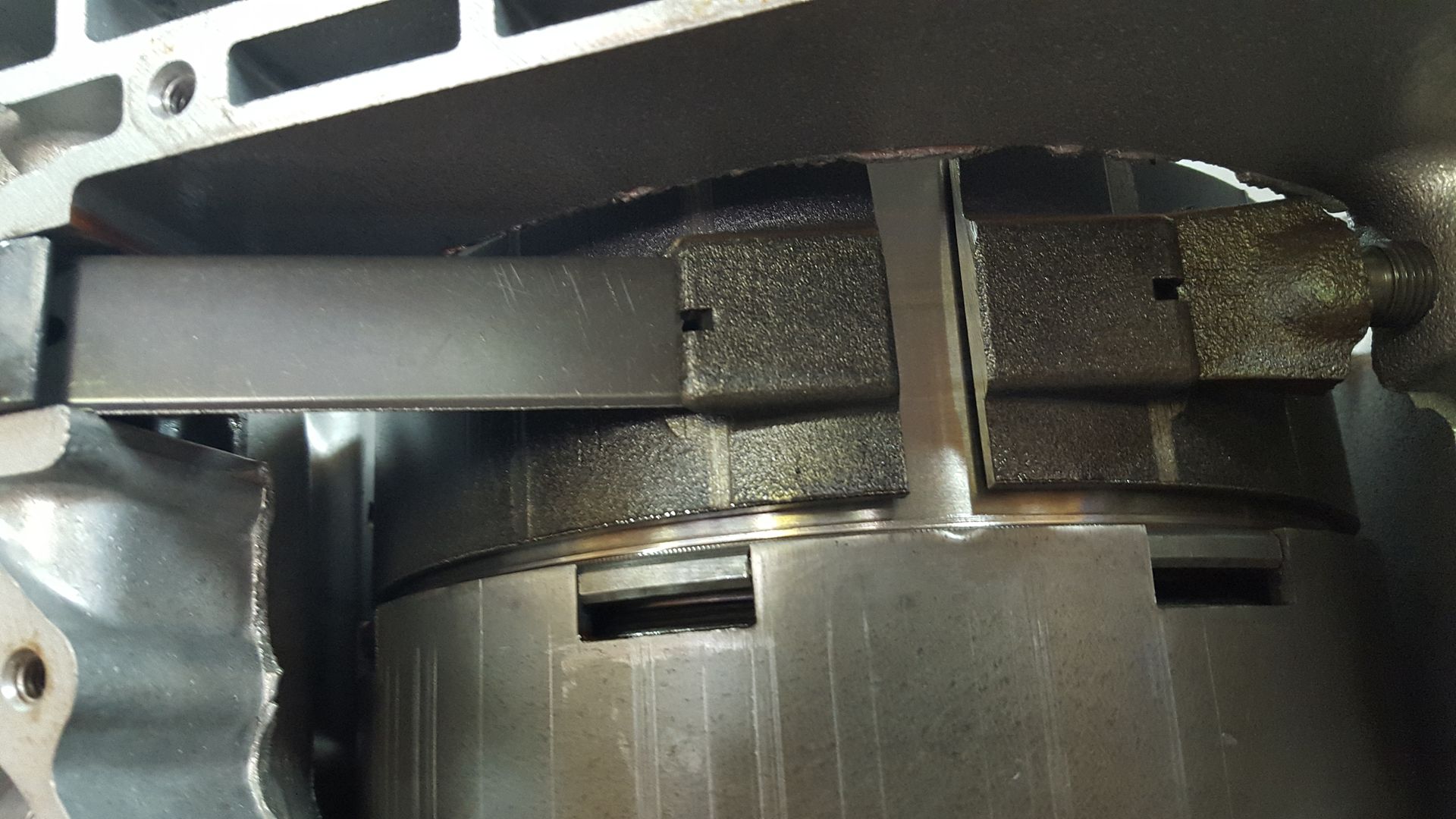

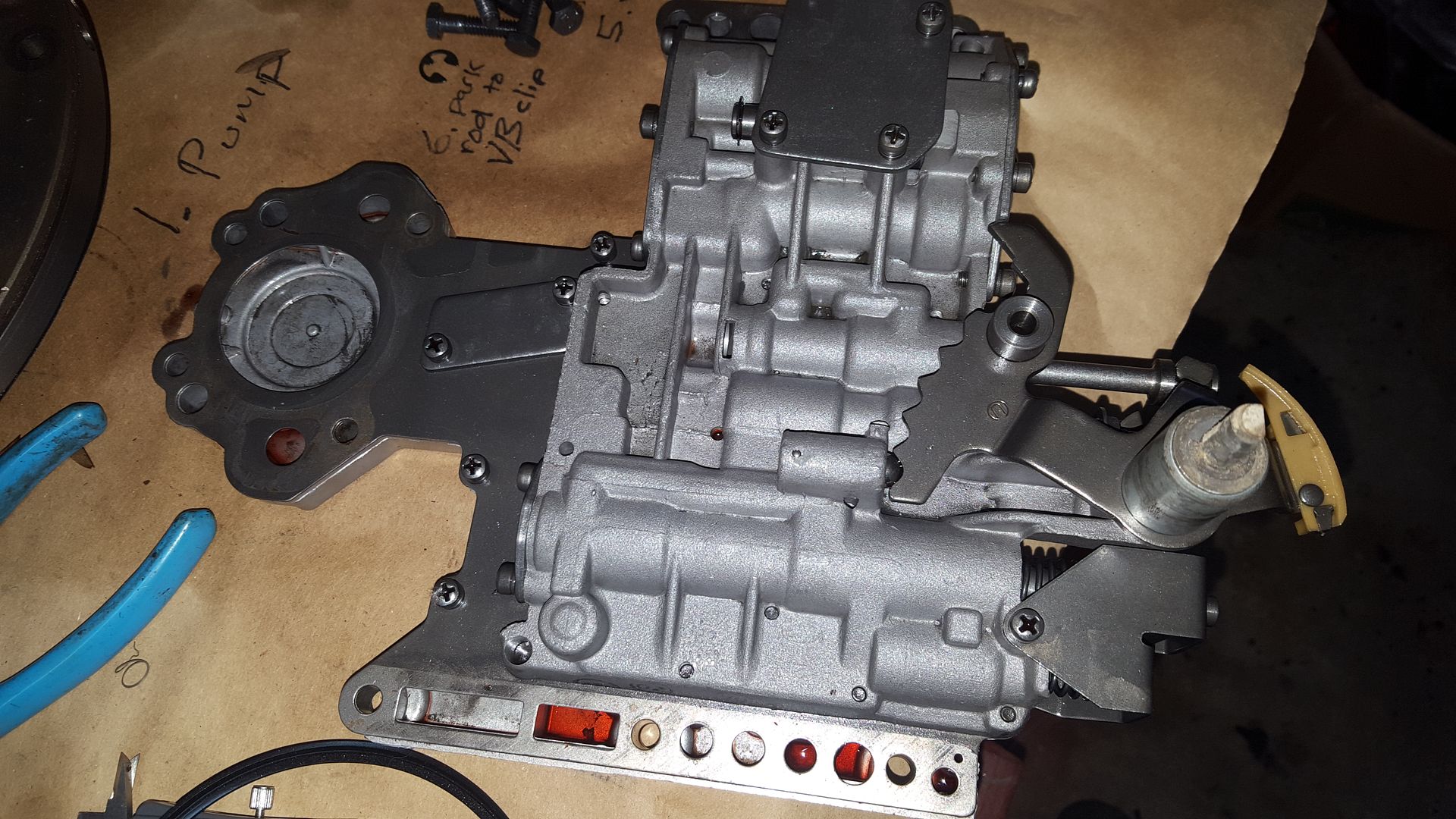

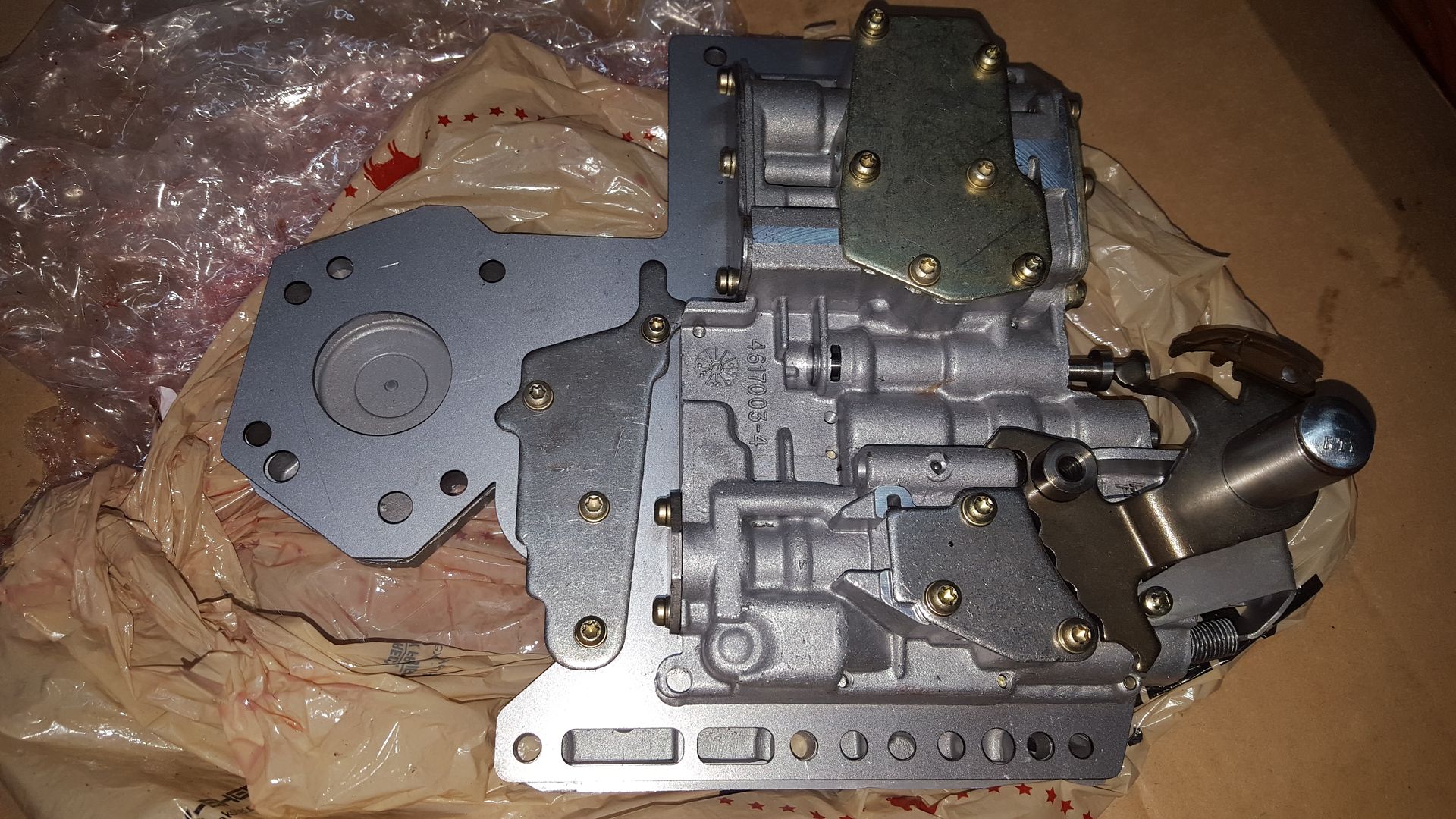

OK, the large open hole in the middle isnt covered, but some of the holes on its perimeter are covered. Not sure if the hole(s) you're talking about. Ive included pictures of both.

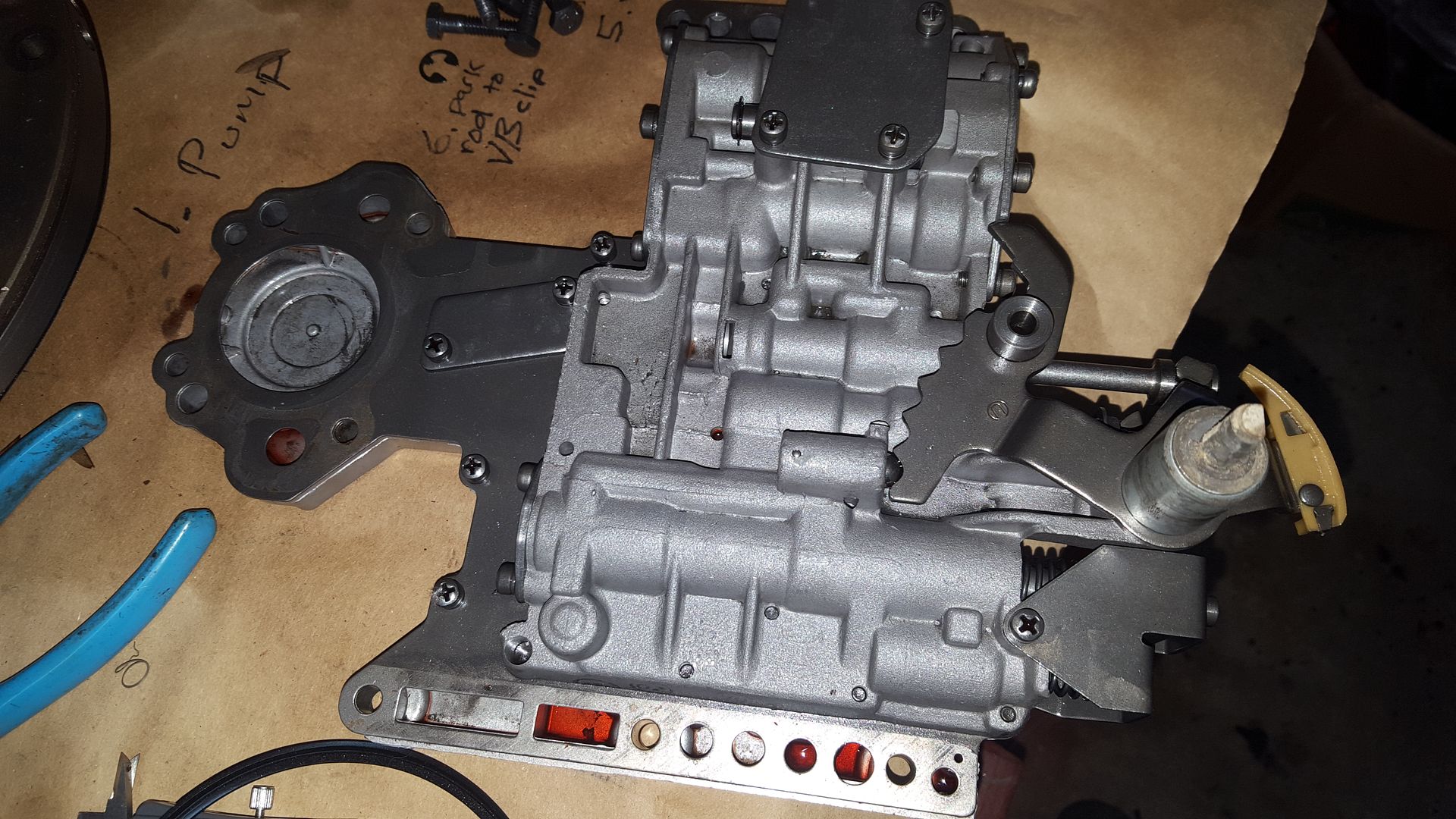

Here is my original valve body

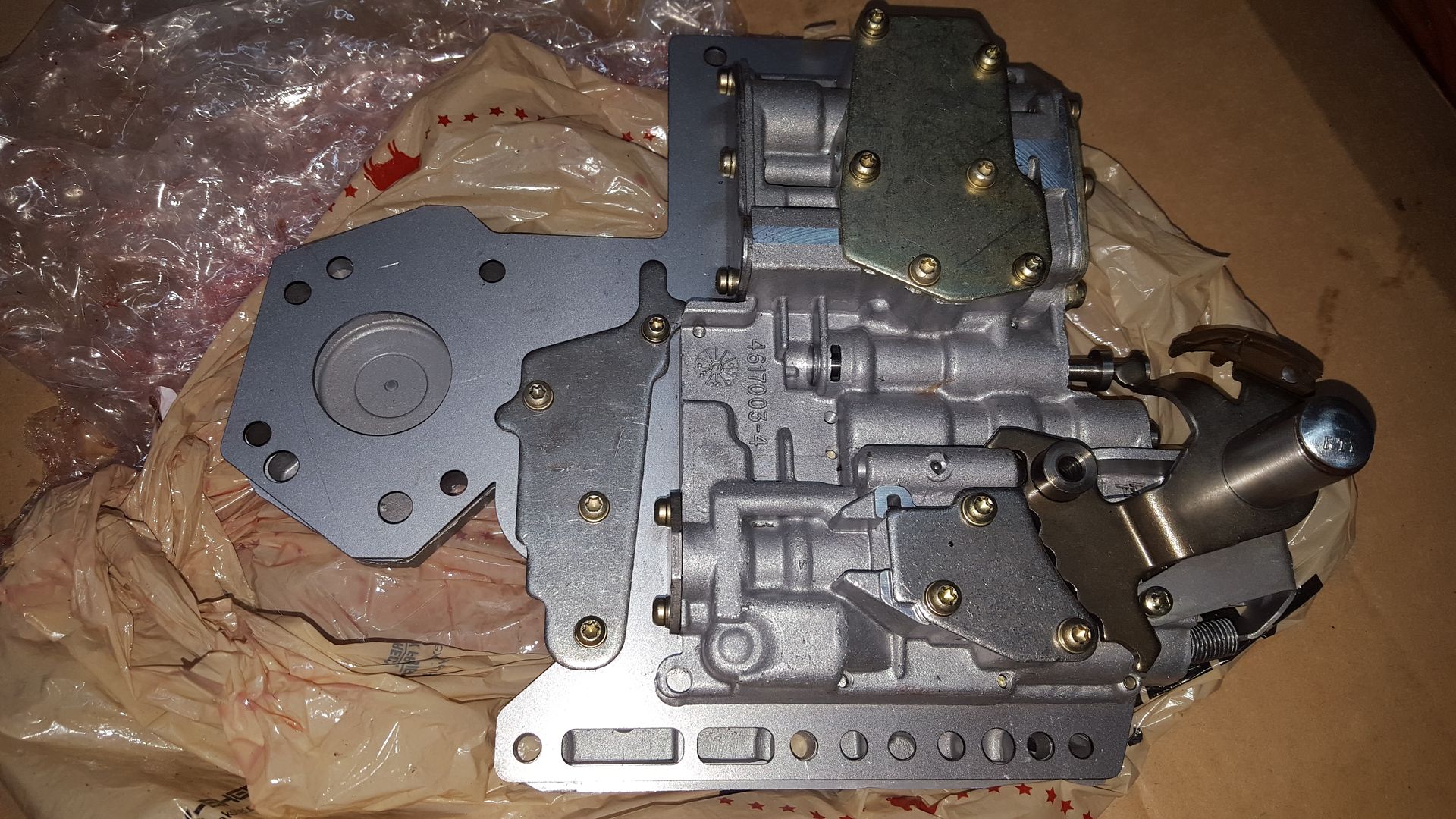

Here is the new reverse manual valve body.

Posted By: John_Kunkel

Re: 727 clutch and manual valve body install - 11/14/15 08:28 PM

That VB needs the piston installed.

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 11/14/15 08:44 PM

Ok will do.

On to my front pump. I've taken the stator off and I'm ready to remove the old bearing. During removal the inner pump gear jumped out and now I don't know the correct position it needs to go into the outer pump gear, so I'm getting a new set.

I talked to a transmission shop and he recommended a babbitt or a dimpled bronze bushing but I'm not sure which one, I see many TC companies recommended babbitt . I can't find much info on dimpled bronze, why would I use it over babbitt?

Posted By: John_Kunkel

Re: 727 clutch and manual valve body install - 11/14/15 09:55 PM

I wouldn't replace the rotors if there's no damage.

Babbit bushings are softer so they don't wear the converter snout, bronze bushings wear longer but are harder on converter snouts....dimples act as tiny oil reservoirs but they decrease the actual bearing surface.

Posted By: Polarapete

Re: 727 clutch and manual valve body install - 11/15/15 12:27 AM

Glad you are not in a hurry to get this done. By the time you are finished and with the help of

www.moparts.com you should know enough to build another one over a weekend.

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 11/15/15 10:44 PM

That's the goal Pete, plus is about time I started working on my own 727's.

How does my stator bearing look to you guys? There is discoloration but no grooves or scratches I can feel

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 04/02/16 01:57 PM

Sent my front pump and stator out to be rebuilt with new gears and have bushing pressed in. Surprised they didnt replace the stator bushing.. but everything else looked alright. They threw the gasket on when the paint was still curing, so it tore when taking it off. No big deal, I got another gasket from the master rebuild kit.

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 04/02/16 01:59 PM

Put my fiber washer and rings on the pump. Dont know why the rings are white, but they are definitely the rings for the pump.

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 04/02/16 02:01 PM

all ready to install

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 04/02/16 02:02 PM

Dropped the band back in, and also used some studs to keep the gasket and pump aligned as I dropped them in.

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 04/02/16 02:06 PM

front pump in and torqued to 175 in/lbs

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 04/02/16 02:10 PM

Got my accumulator back in, dont know if the spring is necessary though since Im installing a reverse manual valve body.

Posted By: DusterW2

Re: 727 clutch and manual valve body install - 04/03/16 11:23 PM

Most reverse manual VB instructions state to discard the spring. I typically add a 1/2" diameter x 3" steel rod between the bottom of the accumulator bore and the piston. Double check that the valvebody sits down on the case before tightening the bolts. If the piston holds the VB from sitting flush on the case, you would need to shorten the blocker rod a small amount. Discarding the spring and blocking the piston down firms the 1-2 shift.

Posted By: John_Kunkel

Re: 727 clutch and manual valve body install - 04/04/16 12:51 AM

There is no logical reason to leave the spring out unless you're installing the blocker rod described above.

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 04/04/16 01:23 AM

I just installed the spring. First put the accumulator piston in the bore, then the spring, then the valve body. The spring fit perfectly into vb, and I made sure the spring didn't bind as I installed the vb

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 04/05/16 07:19 PM

made sure parking rod was clipped in before vb install

With the rod and accumulator spring lined up, the vb was tightened up. in a star pattern little by little, to 100 in/lbs.

The plate in the VB blocks off the hole for the center bottom bolt. I thought about drilling it but decided against it and just left the bolt out

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 04/05/16 07:23 PM

Used an in/lb torque wrench to tighten the front and rear bands to 72in/lbs, which felt really tight, but thats what it called for. My Reverse Manual Valve Body said to loosen the front out 2 full turns, and the rear 1/34-2 turns. I ended up setting the both out 2 turns

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 04/05/16 07:29 PM

After the new filter was installed i cleaned my pan and gasket surfaces to like new condition, made sure the pan was flat and installed a cork gasket dry to 95 in/lbs. The book calls for 150 in/lbs but 95 felt plenty tight for a tranny pan.

After that I plugged up any holes and got to work cleaning the case from head to toe. I used Lacquer Thinner to get the surface clean, then primed and painted with high temp engine paint.

Hopefully everything works ok when it goes in the car!

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 04/05/16 07:45 PM

Posted By: John_Kunkel

Re: 727 clutch and manual valve body install - 04/05/16 09:29 PM

The plate in the VB blocks off the hole for the center bottom bolt. I thought about drilling it but decided against it and just left the bolt out

Once the governor is removed, there isn't a need for a perfect seal back there so a missing bolt doesn't matter. The 904 and 727 have different hole locations at that point, thus the elongated hole.

Posted By: dvw

Re: 727 clutch and manual valve body install - 04/05/16 10:38 PM

Air check before bolting on the valve body. The pump rings are coated, therefore the silver color. You're doing a great job. Same way I started years ago.

Doug

Posted By: Adam71Charger

Re: 727 clutch and manual valve body install - 04/05/16 11:20 PM

Thanks Doug. I did air check with about 35 psi, everything engaged, no leaks or hissing sounds