Mike, Wade and Brian came over to my parents place this Saturday to help get the car running.

Here is the rundown of events that led up to the car running...

My car wasn't wired for a starter relay and didn't have one. After a few days of wondering why it wouldn't engage the starter relay...I then came to the conclusion that it's a GM wiring harness and thats why my ignition switch didn't have the power to push out the solenoid and turn it over at the same time. Big DUH moment for me, but Mr. HandyGoody wired a new one in for me on Saturday...that's what I was lacking. Felt good to add another mopar style part to this car lol.

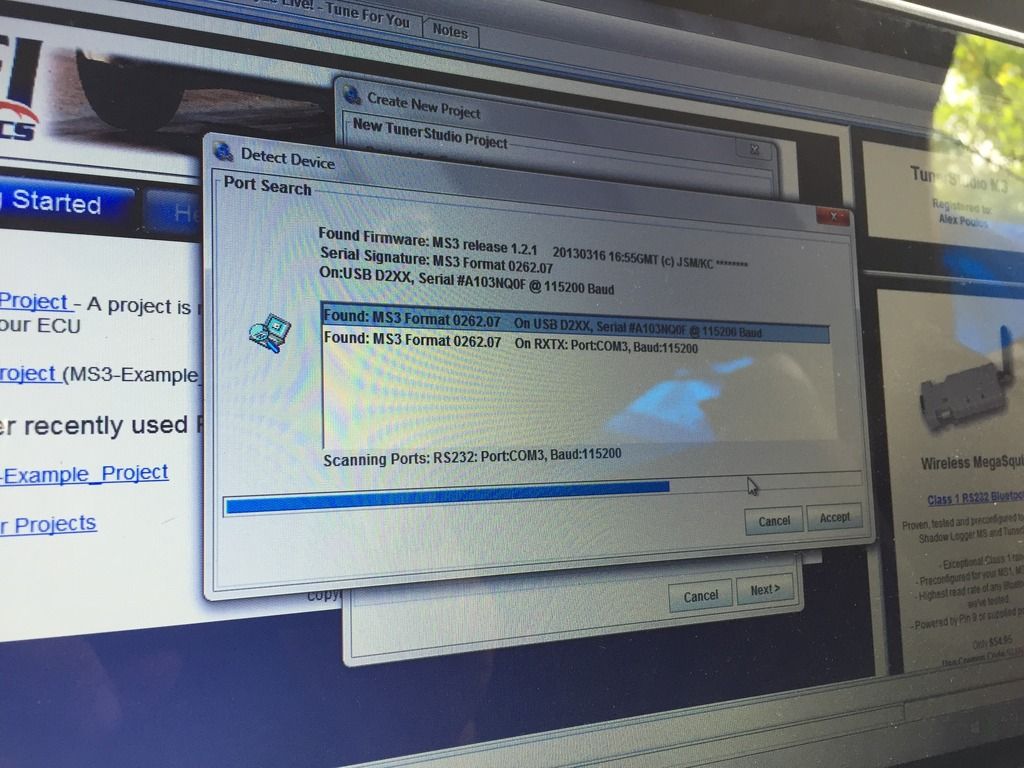

I had laptop issues...it wouldn't talk to my EFI box. I had to reinstall the driver for the usb cable as "administrator" to get it to talk. It worked easily after that little bit of advice from Wade.

I also figured out that this harness picks up power from the harness, so I wired my harness back to the starter with a 60a maxi fuse (was omitted before) and it came to life. I regained power to the cabin and lots of my accessories. That was one of the best moments in the last five years, I was very happy to see it start feeling like a car again.

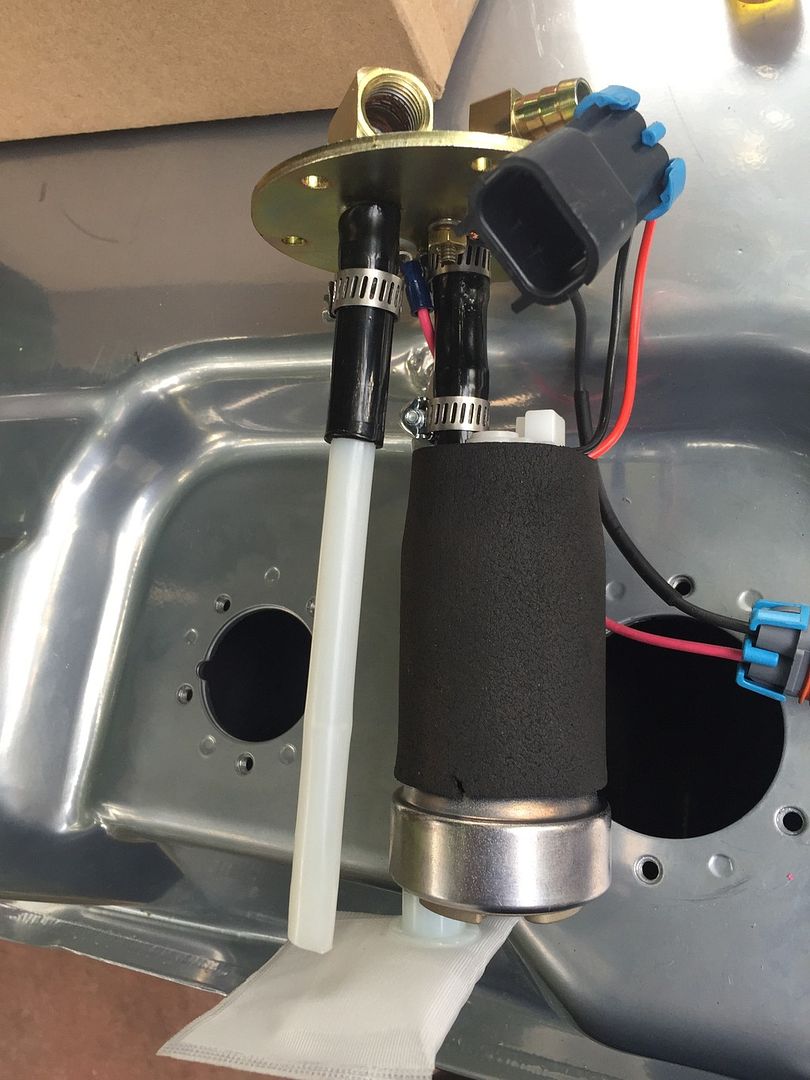

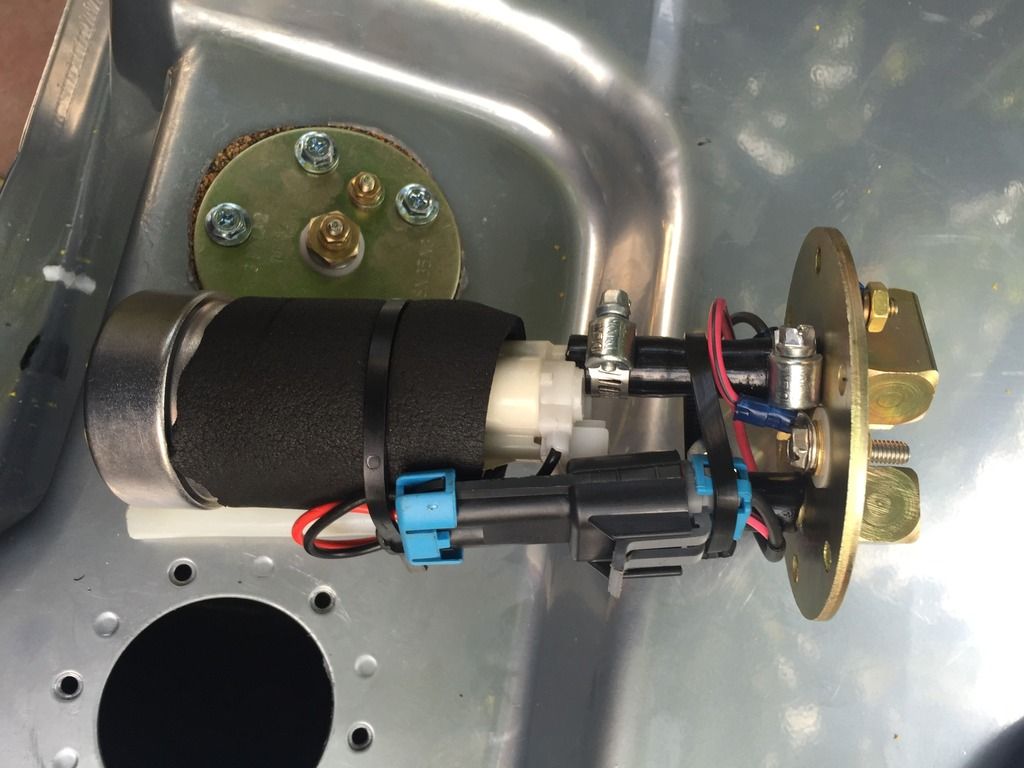

Once I had power back to the car, I was able to focus on the fuel system. I mocked up the new tanks inc system with the 460LPH e85 pump and sending unit. I cut the module down a bunch. I've only got about 6.75" of depth in this pump, so the entire module with sock is about 6 5/8" from bottom of the plate to the sock.

This is one super quiet pump! You won't be able to hear it even with the car off unless you really listen. The sound of the fuel dumping and returning is almost louder.

The first time I installed it for mockup, I pushed too hard and frayed the ground wire against the side of the tank. My mistake...if you use a pump like mine...be very careful!

I tidied up the the module with some zip ties, and I was able to get it in with out catching anything but the nylon return tube. It went in much easier once I cleaned it up.

The sending unit took some thinking and careful reading of the instructions, but nothing that going over it all a few times couldn't fix. It's very universal...but thats a good thing for me. No pics of that

Just read the graph.

While were on the topic of fuel...I had originally intended to reuse the tank that I bought when I replaced the fuel system in 2008 ish. That didn't work out like I planned, here is what was waiting for me after being sealed for that whole time.

It would have caused me immense problems, I'm really surpised a tank that was not even that old could get that back. Makes me think that a gas tank should just be replaced periodically.

Here is the old girl before she came back to life.

We worked Saturday to get the car ready for start up. That involved isntalling the fuel system, pressure testing the fuel system. A few leaks popped up, but were fixed with some quick thinking by wade.

We then worked on getting the oil system primed. I made two huge rookie mistakes. One was that I didn't pre-fill the oil filter and the other was that I didn't check all the block plugs to make sure they were in. We hooked up a simple mechanical oil pressure gauge and I'm glad we did. I forgot a plug in the front of the block that is mostly concealed....that would have made a huge mess...wade gets props for catching that mistake.

After we realized that pressure wasn't building, we figured that the gerotor pump was not happy pumping air. Brians idea of turning it over with the oil filter off the motor meant it dripped a bit of oil, but the air bubble was gone. After a few more revolutions we had 50 psi at the mechanical gauge and we were ready to fire.

We popped the fuses back in for the coils and fuel pump, and then we crossed our fingers and toes.

I kid you not, the first try is all it took. Within three revolutions it fired under its own power with Brian running the throttle. It idled high, but we were expecting it to be off on the first try. He was able to get it down to 800 rpm and we ran it for a few minutes. Cooled off and restarted with ease. We didn't run it for long with the open headers and a radiator hose I don't trust.

It went down to 800rpm and a 14.5:1 AF ratio even with the headers. With my PS hose fittings leaking and a few mins of runtime on her...we called it quits. I didn't want a smoke show and just those few minutes showed me all of the areas of concern that need to be addressed before I start it again.

Fuel system needs a slight re-do on lines.

PS fittings on the AQP high pressure stuff need work. I didn't do them right.

Radiator hoses need a more attention, no leaks yet...but my multipiece solution looks bad.

I need to get the exhaust hooked back up.

Driveshaft needs to go back on the car before the other 2 quarts of gear oil make for an even worse day.

I need a throttle cable.

Once I fix all these issues, I'll start it back up and move it around for some clean up on the idle tune and it's manners. Once safe tune is in it, I'll start worry about driving it and tuning for power.

Mike at EFI source supplies a killer start up tune that worked flawlessly. I really owe him for the awesome product.