|

R3 sonic results, need help

#1130815

R3 sonic results, need help

#1130815

12/09/11 08:06 PM

12/09/11 08:06 PM

|

Joined: Dec 2004

Posts: 128

Finland

mopster

OP

OP

member

|

OP

OP

member

Joined: Dec 2004

Posts: 128

Finland

|

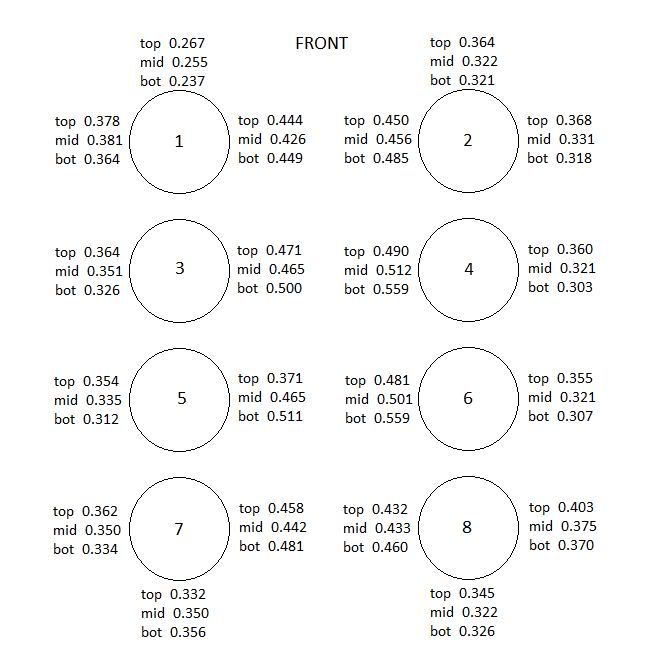

I have a brand new siamese R3 48* tall deck that I just got back from sonic test, and Iīm not very pleased with the results. This is 3.99" bore as it comes, and it seems to have core shift to every possible directions leaving some areas a bit thin. Thinnest spot is in front of cyl 1. Outer walls are thinner than inner walls on both sides, worst spot on major thrust sides is in the bottom of cyl 4.  Are these typical results for R3 block or do I have a bad one? I hoped that I could build a 4.185" bore 700-800hp N/A engine at first, but leave room for another rebuild, and if I decide to, be able to go forced induction and about 1200-1400hp power level. Not going to happen with this block? I could fix some of the core shift by moving the bores away from the thin sides. My machine shop guy told me he could move the bore centers individually up to .060" if my head gaskets and combustion chambers allow it. I donīt think the combustion chambers will be a problem since I have untouched W9 heads and I will do all the headwork myself and I can fit the chambers to the cylinders. The head gaskets may be a problem, and I probably should get them first and do some measuring. I think the left side bores should be moved some towards back, and both sides should be moved inwards. Could this be done and which head gaskets should I get? I could also do a smaller bore like 4.165" for the first build if required. Also I could do a partial fill since the thinnest spots are all in the bottom of the bores.

|

|

|

Re: R3 sonic results, need help

[Re: mopster]

#1130816

Re: R3 sonic results, need help

[Re: mopster]

#1130816

12/09/11 09:00 PM

12/09/11 09:00 PM

|

Joined: Jun 2003

Posts: 52,972

Romeo MI

MR_P_BODY

Master

|

Master

Joined: Jun 2003

Posts: 52,972

Romeo MI

|

When I did my R3(very early block)it had at least .200 walls or better even if it was bored to 4.22... I guess you could slide that front cyl back .050 if you work the head... even with the thick bores on mine I had to sleeve 1 bore when it blew up

|

|

|

Re: R3 sonic results, need help

[Re: Hot 340]

#1130818

Re: R3 sonic results, need help

[Re: Hot 340]

#1130818

12/09/11 10:40 PM

12/09/11 10:40 PM

|

Joined: Nov 2004

Posts: 4,330

Lynchburg, VA

Leon441

master

|

master

Joined: Nov 2004

Posts: 4,330

Lynchburg, VA

|

My tall deck was also thin there. Can't remember how bad it was. We were wanting to bore 4.245".

Block filler is a wonderful thing. This what I did and it worked great. Or you could just sleeve #1.

Leon

Career best 8.02 @ 169 at 3050# and 10" tires small block power.

|

|

|

Re: R3 sonic results, need help

[Re: mopster]

#1130822

Re: R3 sonic results, need help

[Re: mopster]

#1130822

12/10/11 06:25 AM

12/10/11 06:25 AM

|

Joined: Jul 2009

Posts: 413

Norway (old world)

Oyvind Mopar

mopar

|

mopar

Joined: Jul 2009

Posts: 413

Norway (old world)

|

If you move the bore centers as your machinist proposes you could solve that part of the problem. If you are willing to accept the spec out of blueprint. Or a half partial fill: An idea for you, as I know you are capable of doing the most: Fill the block with fat first up to the lower level of where you want the bottom of the block fill, let solidify, then cast blockfiller from that level up to the upper level (an inch thick or so would do!). You can add some tubes stuck into the fat, before blockfiller, to enable waterchannels from the lower level to the upper. In this way you can copy the watersystem from the R5 block, it has a manifold below, distributing water into the cylinder jacket from holes. When block filler is stiff, you simply heat up the block and drain the fat, and you have a supporting band of blockfiller exactly where you want it, in the middle of the cylinder to support it (or higher up where the forces are bigger). Do it all before machining is done! Yoy can use cocos fat (melts at 29 dC), take car that it does not climb up to the walls where the blockfiller will go... Better than baking for X-mas!!! My

|

|

|

Re: R3 sonic results, need help

[Re: mopster]

#1130824

Re: R3 sonic results, need help

[Re: mopster]

#1130824

12/10/11 09:47 AM

12/10/11 09:47 AM

|

Joined: Oct 2010

Posts: 2,433

Ambridge, Pa.

rickraw

top fuel

|

top fuel

Joined: Oct 2010

Posts: 2,433

Ambridge, Pa.

|

i bought a world hemi block from ray barton. rear seal kept leaking. after doing some inspection, i found out the groove for the rear seal was machined too wide & wasn't centered to the crank. called chrysler, they wanted the block back & shipped me a new one. as stated by other members here, u could have it corrected $$, or try for another. that would be ur choice. good luck. stay safe, seeya.

|

|

|

Re: R3 sonic results, need help

[Re: mopster]

#1130828

Re: R3 sonic results, need help

[Re: mopster]

#1130828

12/10/11 03:48 PM

12/10/11 03:48 PM

|

Joined: Nov 2006

Posts: 1,090

north cakalaky

instigator

super stock

|

super stock

Joined: Nov 2006

Posts: 1,090

north cakalaky

|

If you plan on going boosted...don't go so big on the bore...will just cause head gasket problems later on....power will not be a problem later on with out the huge bore....

65 Barracuda

All aluminum Indy HEMI with some boost!

COMING TO A TRACK NEAR YOU!

|

|

|

Re: R3 sonic results, need help

[Re: mopster]

#1130829

Re: R3 sonic results, need help

[Re: mopster]

#1130829

12/11/11 12:00 AM

12/11/11 12:00 AM

|

Joined: Nov 2006

Posts: 370

Queensland Australia

moparmacka

enthusiast

|

enthusiast

Joined: Nov 2006

Posts: 370

Queensland Australia

|

Mopster,

I feel your pain my friend. I have now been through 2 blocks and now waiting for the 3rd attempt. I must admit that mine are P5153478AB 59 degree siamese finished at 4.040" and I was aiming for 4.125" bore. However, you would think for what Mopar charge for these blocks they would get it right, not to mention the fact that we have them shipped half way around the world. The first picture is the sonic report of the first two blocks I recieved and the second is of friends 48 degree low deck for comparison. At the end of the day I may just go for a smaller bore to make way for a rebuild down the track. Pitty I already have the pistons.

Macka

Last edited by moparmacka; 12/11/11 12:13 AM.

|

|

|

Re: R3 sonic results, need help

[Re: moparmacka]

#1130831

Re: R3 sonic results, need help

[Re: moparmacka]

#1130831

12/11/11 12:59 AM

12/11/11 12:59 AM

|

Joined: Jul 2010

Posts: 2,091

Delray beach, Florida

Performance Only

top fuel

|

top fuel

Joined: Jul 2010

Posts: 2,091

Delray beach, Florida

|

going only by the sonic test reports alone is not the best way to approach a solution IMO. it's just the beginning step. we routinely sonic test blocks but we also follow up by fixturing the block in our CNC machining center to find out if the bores are in the correct location to start with. i can tell you on many of the R blocks and X blocks we've tested, they very often aren't. sometimes that works for you, and other times against you. you do have the ability to move bores in the front to rear plane up to a point, but i don't suggest moving them away from the true 45 degree angle from the crankshaft/camshaft centerlines. quite often that crank/cam 45 degree angle is already out of spec as well. if you have a shop with a CNC block machining center that can check all of the important measurements it would be a good decision to use them IMO. i probably have some pics i could post of different R blocks we've done where the bores were actually at 47 degrees as cast. some of the bores were considerably out of blueprint spec in the front/rear plane as well. when we corrected the geometry it actually helped the sonic numbers. like i said, you just never know unless you have the abilty to follow up with the newer type of equipment available today.

Last edited by Performance Only; 12/11/11 01:00 AM.

machine shop owner and engine builder

|

|

|

Re: R3 sonic results, need help

[Re: Performance Only]

#1130832

Re: R3 sonic results, need help

[Re: Performance Only]

#1130832

12/11/11 01:21 AM

12/11/11 01:21 AM

|

Joined: Jul 2010

Posts: 2,091

Delray beach, Florida

Performance Only

top fuel

|

top fuel

Joined: Jul 2010

Posts: 2,091

Delray beach, Florida

|

here's an example. this bore started out at 3.910. this pic was taken after the first .090" cut was done. as you can see it still didn't clean up the bores all the way. as i recall that block was almost 2 degrees off from the blueprint spec, which is a lot, but not uncommon.

machine shop owner and engine builder

|

|

|

|

|