Posted By: mopster

R3 sonic results, need help - 12/10/11 01:06 AM

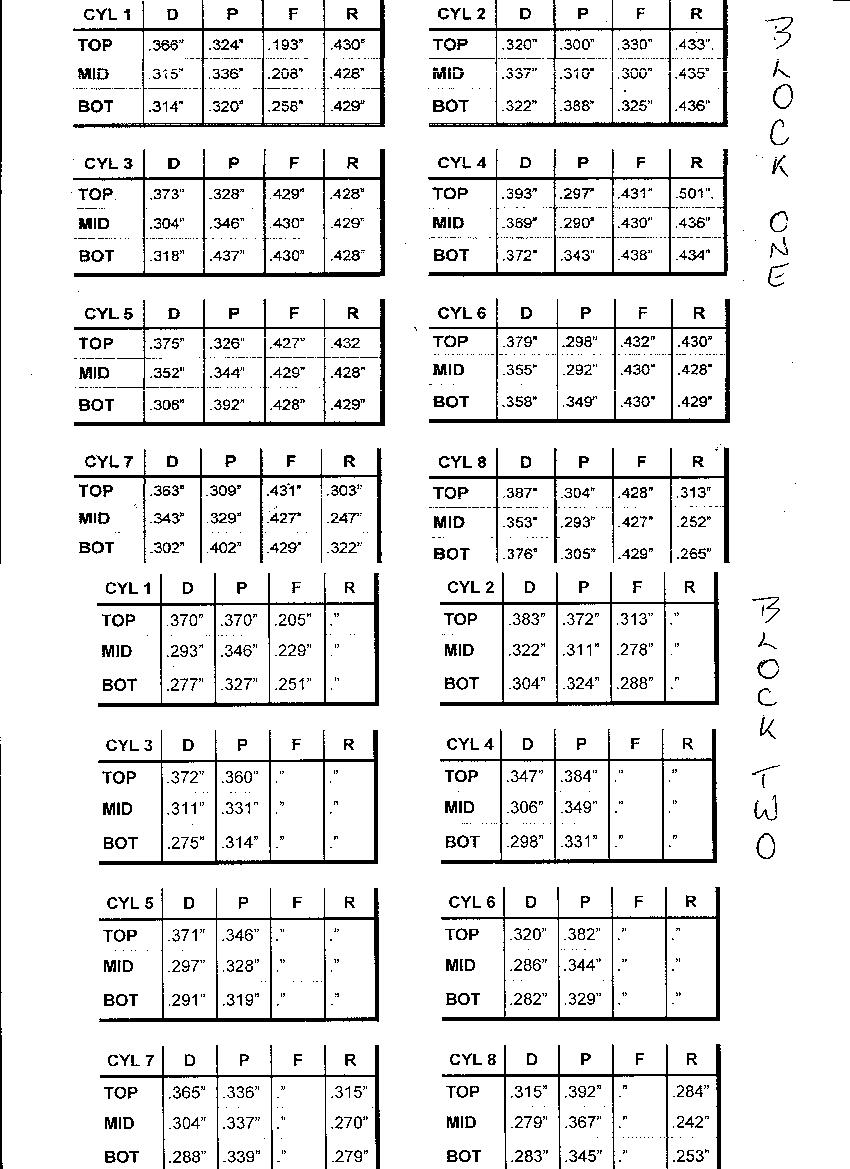

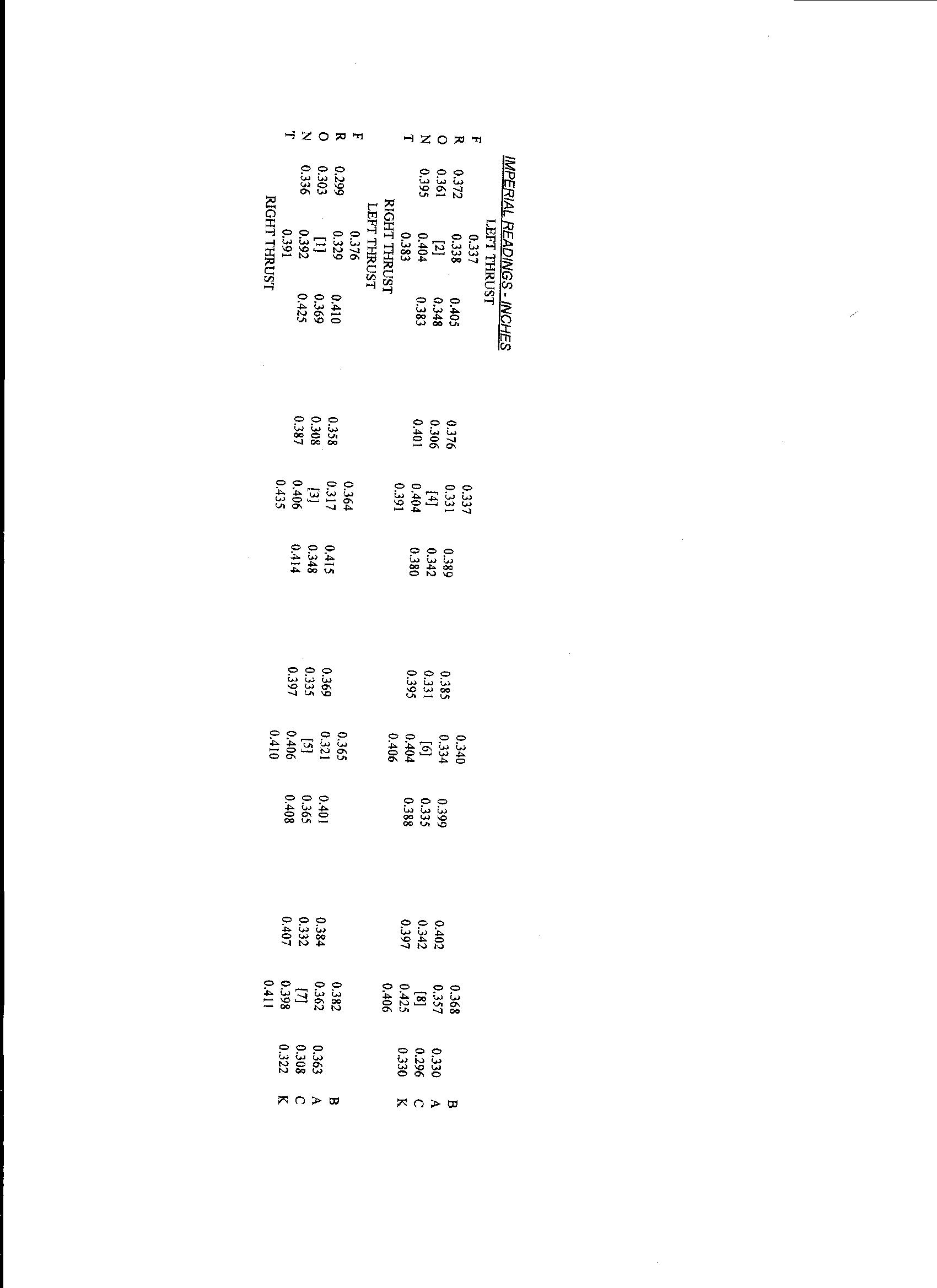

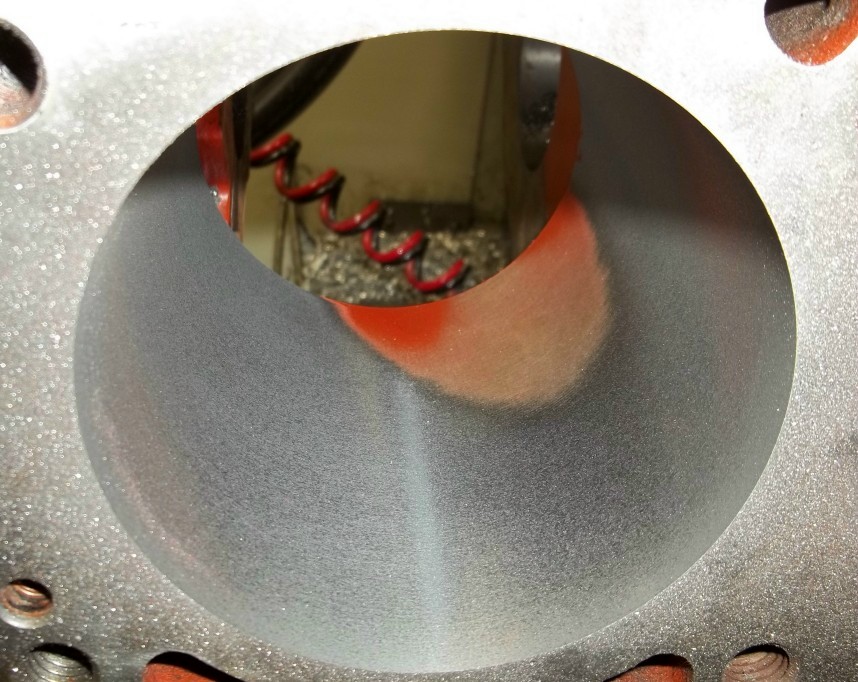

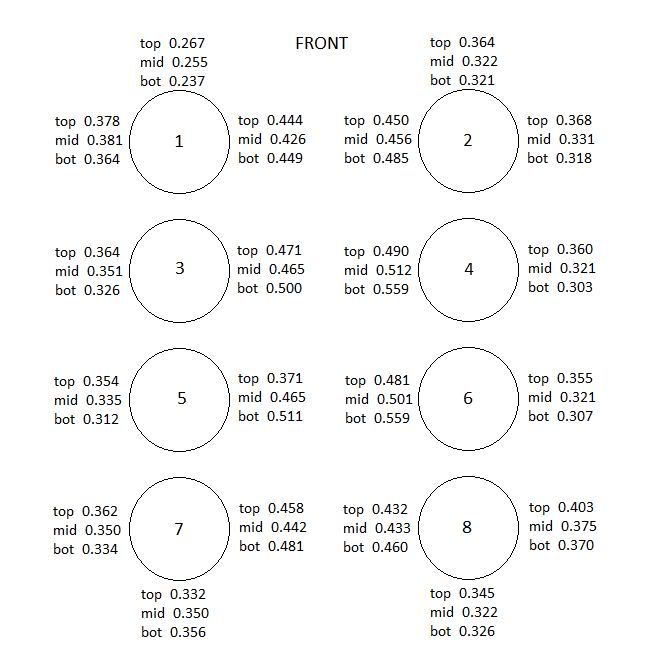

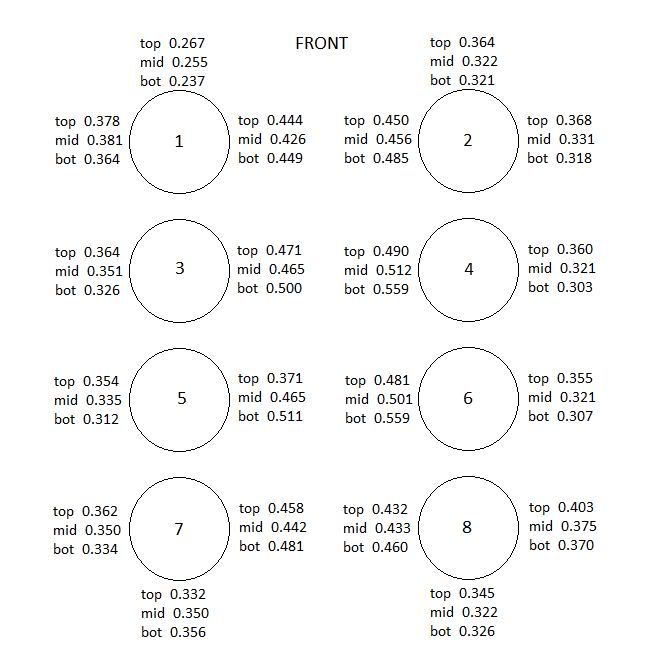

I have a brand new siamese R3 48* tall deck that I just got back from sonic test, and Iīm not very pleased with the results. This is 3.99" bore as it comes, and it seems to have core shift to every possible directions leaving some areas a bit thin. Thinnest spot is in front of cyl 1. Outer walls are thinner than inner walls on both sides, worst spot on major thrust sides is in the bottom of cyl 4.

Are these typical results for R3 block or do I have a bad one? I hoped that I could build a 4.185" bore 700-800hp N/A engine at first, but leave room for another rebuild, and if I decide to, be able to go forced induction and about 1200-1400hp power level. Not going to happen with this block?

I could fix some of the core shift by moving the bores away from the thin sides. My machine shop guy told me he could move the bore centers individually up to .060" if my head gaskets and combustion chambers allow it. I donīt think the combustion chambers will be a problem since I have untouched W9 heads and I will do all the headwork myself and I can fit the chambers to the cylinders. The head gaskets may be a problem, and I probably should get them first and do some measuring. I think the left side bores should be moved some towards back, and both sides should be moved inwards. Could this be done and which head gaskets should I get?

I could also do a smaller bore like 4.165" for the first build if required. Also I could do a partial fill since the thinnest spots are all in the bottom of the bores.

Are these typical results for R3 block or do I have a bad one? I hoped that I could build a 4.185" bore 700-800hp N/A engine at first, but leave room for another rebuild, and if I decide to, be able to go forced induction and about 1200-1400hp power level. Not going to happen with this block?

I could fix some of the core shift by moving the bores away from the thin sides. My machine shop guy told me he could move the bore centers individually up to .060" if my head gaskets and combustion chambers allow it. I donīt think the combustion chambers will be a problem since I have untouched W9 heads and I will do all the headwork myself and I can fit the chambers to the cylinders. The head gaskets may be a problem, and I probably should get them first and do some measuring. I think the left side bores should be moved some towards back, and both sides should be moved inwards. Could this be done and which head gaskets should I get?

I could also do a smaller bore like 4.165" for the first build if required. Also I could do a partial fill since the thinnest spots are all in the bottom of the bores.