It's always worth checking the advance curve first!

You can do it on the engine with timing tape.

Measuring the slots will usually give a close idea, but there are other variables.

In general, with 'hot' cam (ie more overlap) and same compression, the engine wants more initial timing. So shortening the inside of the slot compensates for that. Bonus of doing it that way is, the timing will stay in the right range to work with vacuum advance. The real win at the track doing that way is the engine never sees any loss of tiiming in the upper rpms due to slew rate. The extreme example of that is the DC/MP race distributors. (aka 'tach drive')

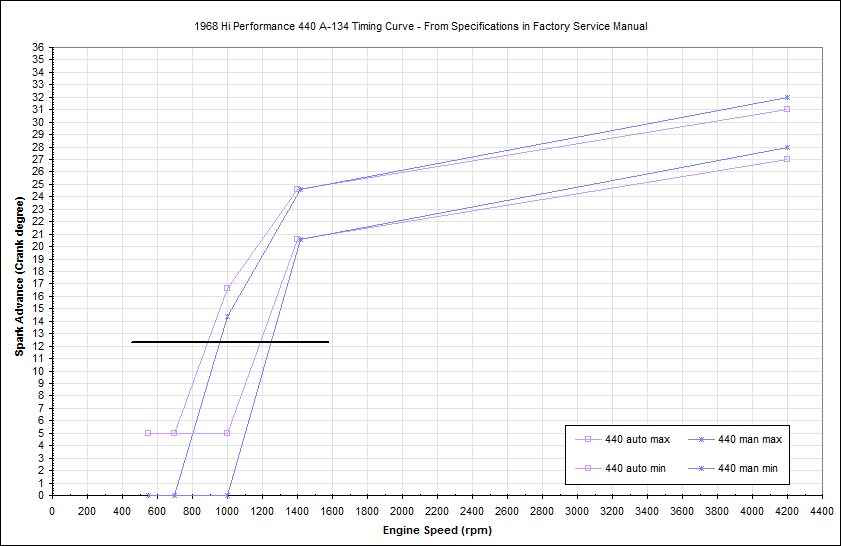

Here's an illustration of how welding effects the advance.

Its the acceptable timing for a smogged '68 set at the suggested initial. But it could be any distributor with a longer advance than will work with the initial.

The heavy black line shows what happens when the slots are shortened on the inside.

It's drawn at 12.5* because that was the recommended initial timing for non-CAP version of the same engine in 1967.