I’ve been working mostly on collecting, cleaning and inspecting parts. One of my concerns was getting the water jackets in the heads and block clean. The old caustic Hot Tanks that the machine shops used to use did a good job on dissolving the rust and scale but around here the last one of those went away 20 years ago. I’ve used citric acid in the past to de-rust old tools etc and always wanted to see how well it would do on engine parts.

I picked up the largest tub WalMart and a 5 pound bag of citric acid off Amazon.

Y Citric

Y Citric by

M Patterson, on Flickr

The first batch to go in was the HEMI heads, a spare set of rockers and the main caps.

Y Soak

Y Soak by

M Patterson, on Flickr

I put in enough water to submerge the parts and started out with about 2 pounds of citric acid……I eventually added another 2 pounds as the solution became more saturated with rust and gunk and I changed out the cylinder heads eventually doing all 4 Poly heads too. It took about 4 days for the parts to soak to get them clean but I’m pretty happy with the results. From past experience it would have taken about half that time if I was doing this in the summer when it‘s warmer.

H3

H3 by

M Patterson, on Flickr

I’m happy with the water jackets, which was really the main reason for doing this,

WJ

WJ by

M Patterson, on Flickr

With the heads cleaned (jet washed and bead blasted after the acid bath) I was able to start getting some of the information I’ve been curious about.

Almost every article about the Polys indicates that Chrysler started producing them to create a “cheaper and lighter head and valve train”. They succeeded on 2 out of 3. After moving the heads around I was not surprised to find out the bare HEMI heads weighed in at 64 pounds…….the bare Poly heads was a “light weight” 63 pounds.

With the heads cleaned, but before any machine work was done, I CC’ed the combustion chambers to get an idea about where I was going to be compression wise with the different heads.

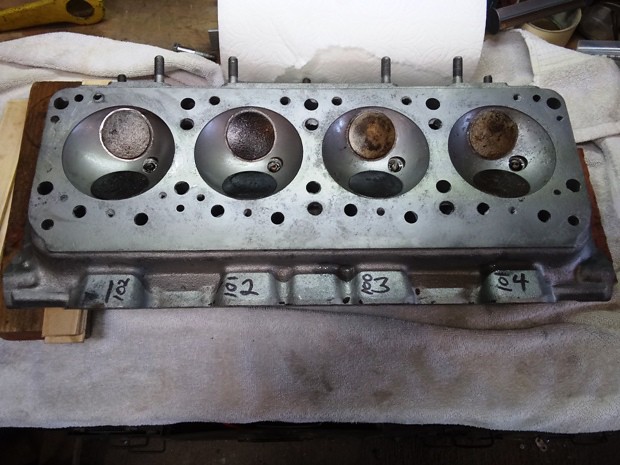

The Hemi heads came in between 100 and 102 CCs.

HH

HH by

M Patterson, on Flickr

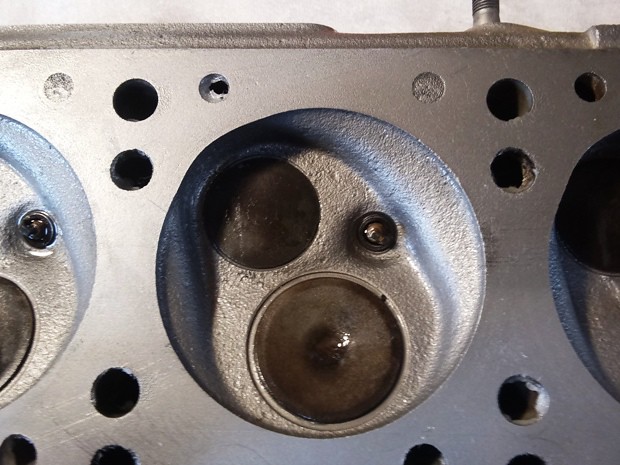

And then came the biggest surprise so far. Common belief (including mine) is that Poly heads have a much smaller combustion chamber than the Hemi heads and that when doing a head swap to convert a Poly to a Hemi that a piston change is required to get the compression back up. A glance at the chambers would seem to confirm that.

P2

P2 by

M Patterson, on Flickr

Actually CCing the chambers tells a completely different story. On the first 2 heads that I checked chamber volume ranged between 102 to 104 CC (the 104 cc chamber was on the other head). Practically speaking going from Poly to Hemi or the other way around will not cause a compression change.

P1

P1 by

M Patterson, on Flickr

Once I get the other pair of heads cleaned and inspected we'll make the decision on what two to build. These 301 Poly heads and the 331 2 bbl heads use a 1.812 intake valves. I've already picked up a set of the 331 4bbl/354 intake valves that are 1.94s. All the Poly heads used a 1.5 exhaust valve and Dave and I are currently looking into a cheaper and larger alternative to the stock exhaust valve.

I've also been looking at the options for a roller cam.......any of the early HEMI guys out running a street roller cam they would recommend?