So, here is the latest. The K frame is all welded up and ready to go. We tacked the perch on, and then I did a test fit, and it was perfect, so we finished off the welding.

I decided to stick with this (instead of going for a MegaParts hemi K frame, I have the Schumacher mounts), for the following reason. When you look at the photos, you will see how ungodly horrific the welds that held this perch on were. It's absolutely astonishing to me that as bad as these welds were, that the thing lasted this long. The welds along the seams that make the perch itself are very, very nice welds, so no worry at all there. When you compare what was there before, and what is there now, I have full confidence that it will outlive me!

I also put the FirmFeel braces on the LCA's, a few pictures of those.

We also reinforced a number of other areas on the K frame. Some welds I ground away and we redid, and some we just added in places that can only help. Pictures should say everything.

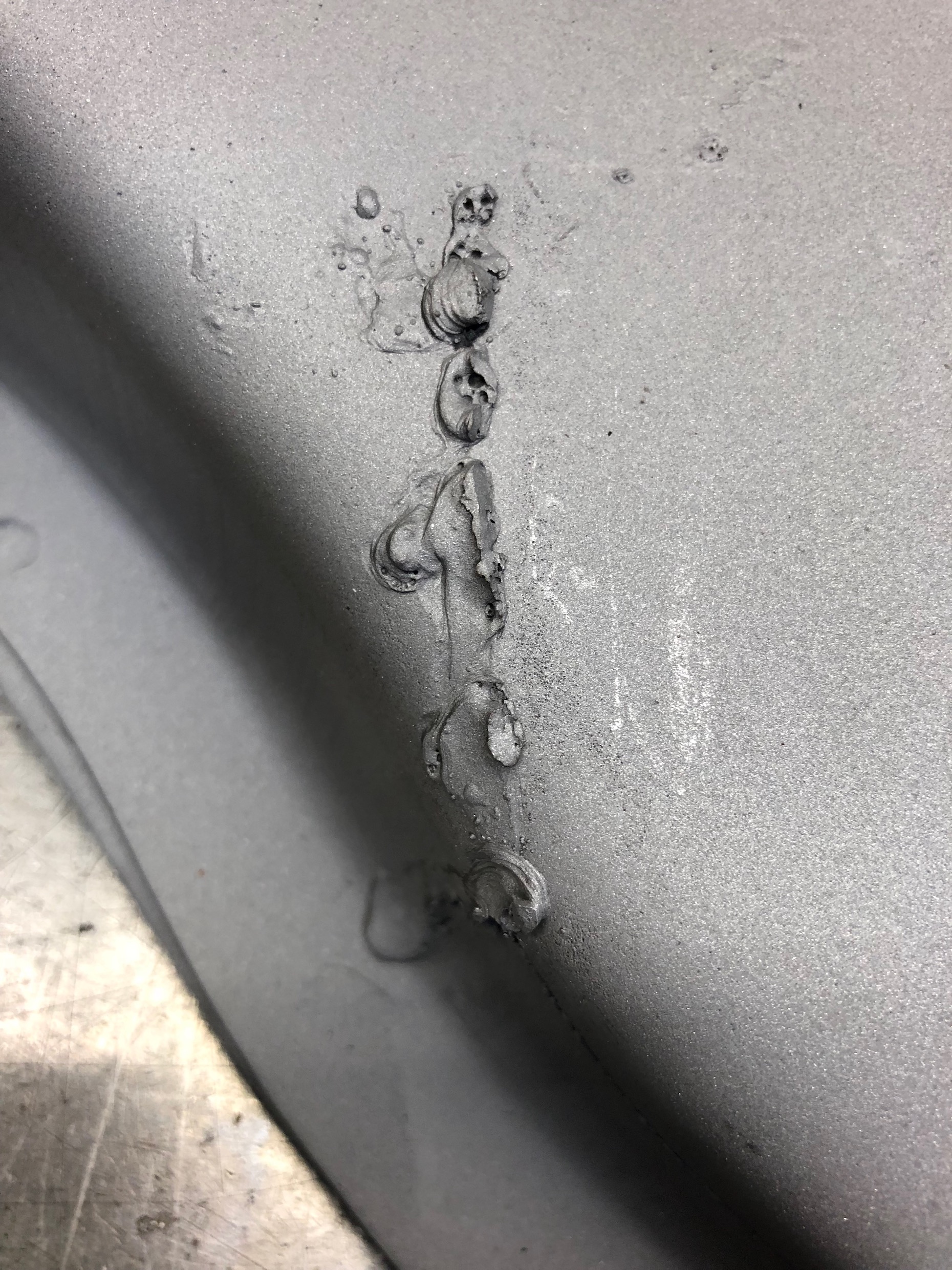

This is where the perch was welded on the top. You can see that the weld barely penetrated the metal of the perch.

This is where the perch was welded on the top. You can see that the weld barely penetrated the metal of the perch. This is along the side. Again, astonishing these held as long as they did.

This is along the side. Again, astonishing these held as long as they did. A zoomed out shot.

A zoomed out shot. Control arm with FirmFeel brace.

Control arm with FirmFeel brace.