So, heres the basic numbers. I was going to provide coords from my DRO, but it started skipping, and I wasn't going to stop to clean it. You can duplicate the way i did, layout dye, punch a spindle center, and create arcs useing calipers. Find what looks good with known bolt hole spacing and center punch, drill on center punch marks.

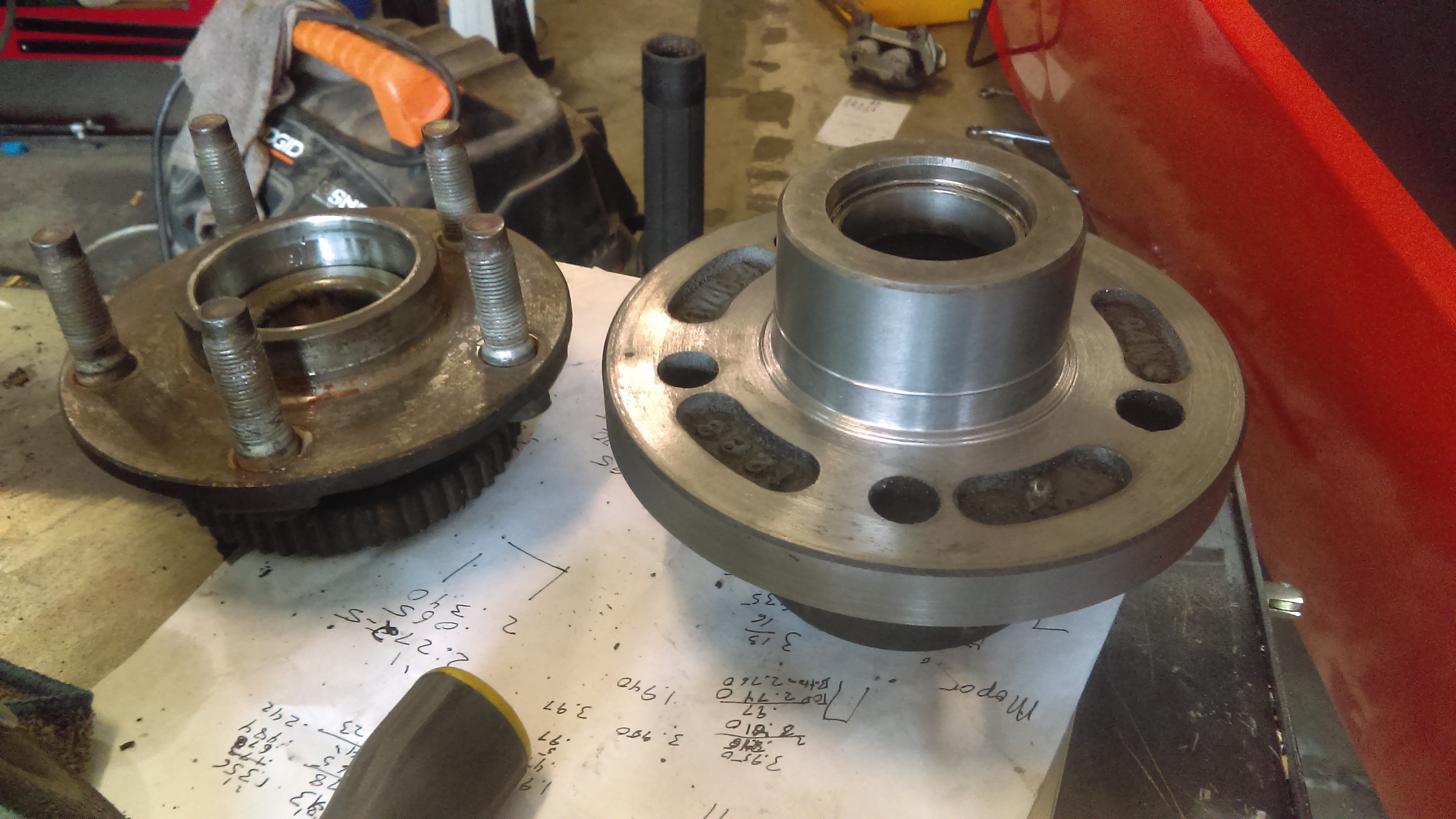

I used the old bearings when i set it up on my lathe, worked, but i was planning to replace them anyway. Your going to need carbide tooling to cut on the hub, that thing is HARD. Also, at the bottom is a comparison of the SN95 hub vs the cut down E body. I was concerned about strength, until I saw how thick the e body hub really was.

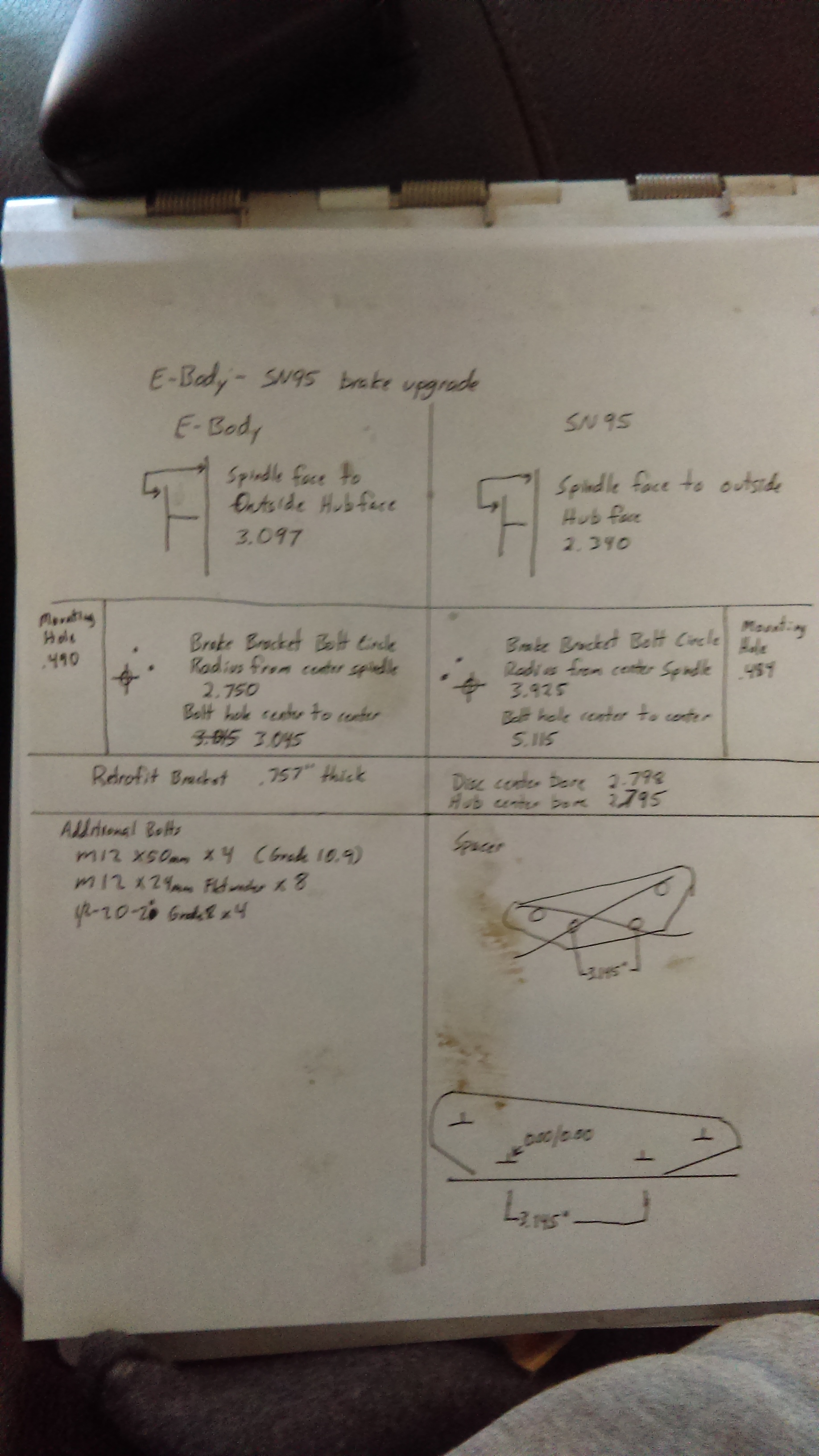

Basic Drawing and Dimensions

Basic Drawing and Dimensions Remove factory brakes, cut disk from "hub" with plasma cutter.

Remove factory brakes, cut disk from "hub" with plasma cutter. Place "hub" in lathe on centers, clean up plasma cut, turn hub snout OD to accept mustang disk, I also faced off the mounting surface.

Place "hub" in lathe on centers, clean up plasma cut, turn hub snout OD to accept mustang disk, I also faced off the mounting surface.