Re: Six Pack Idle question

[Re: Warrant_Officer]

#704200

Re: Six Pack Idle question

[Re: Warrant_Officer]

#704200

05/21/10 11:12 AM

05/21/10 11:12 AM

|

Joined: Aug 2003

Posts: 8,828

Houston, Tx

hemi68charger

master

|

master

Joined: Aug 2003

Posts: 8,828

Houston, Tx

|

I do know from my experience, six packs need vacuum. I had issues a long time ago in my younger days with my original v-code '70 Charger with the Purple Shaft .484 cam. Because of the low vacuum levels, I had to take the power booster off for the brakes. I think six packs need vacuum because of the dual-plane nature of the intake. What camshaft are you running and which ignition system/timing do you have?

I eventually swapped out the .484 for the "then new" mopar reproduction '68-'70 440 magnum camshaft. It ran great.... Even with the smaller cam and back to exhaust manifolds, the six pack was a screamer..

TroyHouston Mopar Connection Club'69 Charger Daytona 440 - auto - 4.10 Dana (now with 426 hemi) '69 Charger 500 440 - 4speed - 3.54 Dana '70 Road Runner 383 - 4speed - a/c (now with 440)

|

|

|

Re: Six Pack Idle question

[Re: Warrant_Officer]

#704206

Re: Six Pack Idle question

[Re: Warrant_Officer]

#704206

05/21/10 02:16 PM

05/21/10 02:16 PM

|

Joined: Oct 2008

Posts: 765

Shoreline, Washington

72roadrunnergtx

super stock

|

super stock

Joined: Oct 2008

Posts: 765

Shoreline, Washington

|

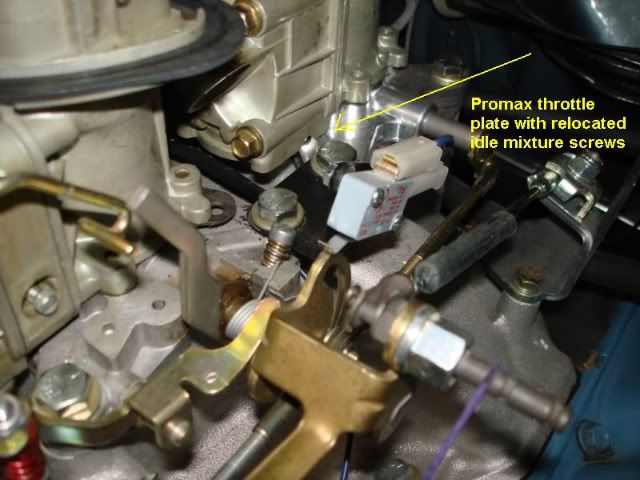

As with any Holley externally adjustable float, at the bottom of the sight holes, plug removed, fuel should just start to dribble out. Outboard idle mixture is important and hard to fine tune without a Promax throttle plate on the rear carb allowing for adjustment while running. Without the Promax throttle plate, it is necessary to remove the rear carb to adjust the mixtures, usually multiple times before you get it right. Best way I found to set outboard mixture is the “cover the air bleed” method, one at a time, covering the outer air bleeds with a finger and adjusting mixture screws for no or little idle speed change. My engine runs best with a 20-30 rpm drop from curb idle speed, which translates to just a tad rich from the published ideal.  I’m running an Innovate Motorsports LC-1/XD-16 combination wideband O2 sensor, available most anywhere. I think I got mine from Summit racing.

|

|

|

Re: Six Pack Idle question

[Re: Warrant_Officer]

#704214

Re: Six Pack Idle question

[Re: Warrant_Officer]

#704214

05/21/10 06:22 PM

05/21/10 06:22 PM

|

Joined: Nov 2005

Posts: 836

lancaster, new york

macmic87

super stock

|

super stock

Joined: Nov 2005

Posts: 836

lancaster, new york

|

here is a copy of a post made awhile back, but is always useful. i am not the author.

I have to agree strongly with Mike(HPMike) I've been running six pack inductions for about 30 years now, sm blk, big blk, and even the custom 6 pak cast HEMI intake manifolds that I made for the 71 wingcars,.....I don't have anything but, sixpack cars,,,,,,,,I've rebuilt countless numbers of carbs, along with countless installations and tunings,....when there are troubles, it usally due to someone unfamilar with there tuning or functions, or attempts at trying to improve them,......which usally results in "problem" carbs, starting, stalling, flooding issuse!.....seeing your have "new" carbs/ set-uo,....I'd recommend you use a Carter street pump, don't use rubber hose, it's problems down the road!, use a factory style/ repro steel, or stainless steel fuel line kit,a good quality hi flow fuel filter, AFTER the pump!, not before!, you'll restrict the fuel flow, Factory style linkage, no junk progrssive/ mech linkage!, change out the brass side float screw on the fuel bowls (all 3 bowls) with Holleys clear sight plugs, this way you can see your float level, and no gas spills trying to adjust, their like $4 each,.....when setting the fuel level, I've found that it's best to bring it up to half the height of the clear sight plug, (can't do this with the brass sight screw!, unless you have X-ray vision, hence the need to install the clear plastic sights).....plus "if" you ever have a starting problem, just shaking the car side to side will slosh the fuel in the clear site, and you'll know wether or not you have fuel in the bowl,....after you have basically installed the set-up, and started the car, and set an acceptable idle after warm up, with the engine running, set the floats, start with the center carb, the slotted screw on top of the float adjuster, is just a lock screw, you can remove it for now, the 5/8" nut is the adjuster/needle seat nut, rotating it counter clockwise will raise fuel level in the bowl, clockwise will lower it, make small 1/2 turns let the car run a bit, check the fuel in the clear site window, half the window is ideal height, esp. in the front and rear carbs, when they dump in, you don't wanna lean the engine, which on a sixpack car, might "melt" a piston or two!....really!, been, there, done that!....after you set the fuel level in all 3 carbs, reset the idle on the center carb, by disconnecting the linkage on the end carbs, if your using an idle solenoid, make sure it's energized in the up position contacting the center carbs solenoid idle arm screw, set the desired idle, that keeps your car running, factory specs are a guide line, your cam, vacumm, etc, will affect your desired RPM range, after you establish this idle, this is what your car will run with, now de-energize the solenoid, using the idle srew located on the ceter carbs main throttle shaft, set the idle to a bare minimum running idle, this is were your throttle shaft will close down too when you shut off the car, and the idle solenoid de-energizes, if later you have shut down problems of the car desieling, (sputtering run on after shut down) keep lowering the idle screw on the center carb main shaft, untill this is condition is eliminated, the idle solenoid was added to maintain an idle, and allow the throttle blade to choke off the engine on shutdown if needed, when it de-energized, after your center card idle is set, now comes the fun, start the car, in idle, the front and rear carbs are still disconnected at their main throttle linkage, (important note: make sure no vacumm source is hooked up to the front and rear carbs when main linkage is disconnected, cause any reving you may do, might tip in a end carb! with vacumm!, and if you can't shut it down in time, you might lose an engine!....seen it done!)to properly set the fuel/ air mixture idle screws, start with the center carb, hook up a tach.......warmed up, good idle (low)....turn the fuel/ air mixture screws (2) located on each side of the center carb metering block, do one at a time, run it in slowly, until the engine begins to stumble, slowy back it out watching the tach needle, stop when you've obtained the highest rpm reading,....you can also do this with a vacumm gauge attached to MANIFOLD vacumm, I like to use both at the same time, ...repeat the process for the other side, when done, now re-do-it, again, just to confirm settings, now some of the end carbs, have their fuel idle screws "plugged" with lead, they are located in the base, in the front of the carb base plate, under the bowl, if plugged, dig out lead plug, most people think ones for fuel, ones for air , their not!, you'll adjust these screws just like the center carb, except you can't just use a vacumm/ tach gauge,....look into the top of the front end carb, you see 2 small projections in each bore on each side, just below the neck, these are the air bleeds, block off the outer bleed using your finger over the small tiny hole, with the motor running at idle (low), it should stumble or pick up in idle, when you block off, either outboard bleed, set the front carb first, pick a bore, left or right, with it's coresponding baseplate idle screw, block the bleed off with your finger,(make sure the carbs throttle plate is fully closed) do one side at a time, when you block the bleed, if the idle increases, too much fuel, remove your finger, turn the base screw on the side your blocking the bleed on, in, one turn, block the bleed again, listen for the idle, (you could use a tach gauge at this point), if it stumbles/ decreases, no fuel, back the base screw off a half turn, block the air bleed again see where the "idle" is,......keep adjusting in this fashion until there's no change in idle, no increase/ decrease, you now have the ideal fuel/ air ratio for the vacummm requirement on your motor, complete this for both sides of the front carb, shut off the motor, disconnect this carb remove it, re-install it in the rear,....install the rear carb, now in the front, adjust this carb like you did to the last one, after you hook up everything, now here's when most guys will balk at this move,....they'll insist the air/fuel mixture won't be 100% by moving the tuned front carb to the rear, well if your truly familiar with the sixpack set-up, you know getting to the rear carbs base screws is fustrating to say the least, unless your squeezeing every ounze of effeciency out of the motor, this technique is far better than leaving the factory setting/ lead plugs in, with is usally a lean set-up,,,,,,, after setting this relocated carb up, if you wish you can "play" trying to "tweak" the rear carb, this may include a round of removal the "tweak" the screws to obtain that last ounze of "tuning", I've yet to see a "tool", truly capable of fitting into the installed rear carbs "idle screws"......anybody?,

Well, when your "done" setting the air/ fuel "idle" mixtures on the end carbs, connect the end linkages, to the end carbs, do it with the idle solenoid energized, the rods are threaded were they join together on the center carb, they install on the end carbs with rod clips, there is a F/R or left?right handed clip, energize solenoid, do the front carb first, make sure the linkage is pulled far forward on the center carb secondary rail, thread the rod, in or out, until it fits nicely in the hole, then proceed to the rear, repeat this proceedure, now check the linkage for any binding, you should be able to chrack open (engine off!) the center car, WOT, and manually open both carbs by rotating the front carb throttle arm, close the center carb, check all linkage for binding, readjust if needed, now de-energize the idle solenoid, see if any bind is preventing the center carb from closing on the main throttle shaft idle screw, you may have to comprimise on some idle/ and or end carb linkage adjustments to have an ideal, functioning set-up, but once you take the time to do this, you'll appreciate your efforts!,....as far as altering the end carb secondary springs in the vacumm pods,.....I like a sixpack to come in quick,....you'll have to buy 2 sping kits, replace with the "white" springs if you want a quick responding set-up,....if you what a mid range set-up use the "yellow" springs,.....any thing in the brown or black range is worthless.,,,,,Hell I could write a book here, I probally have, if you have any other questions, PM me.......I wrote this for others, to utilize as well,.......

Last edited by macmic87; 05/22/10 04:02 PM.

|

|

|

Re: Six Pack Idle question

[Re: macmic87]

#704216

Re: Six Pack Idle question

[Re: macmic87]

#704216

07/27/10 06:33 AM

07/27/10 06:33 AM

|

Joined: Jan 2009

Posts: 118

Winesburg Ohio

mattpar

member

|

member

Joined: Jan 2009

Posts: 118

Winesburg Ohio

|

ive made a great tool to adjust the rear carb i used a flag that is used for marking out utilities or any other reason, but it is 18" long and is smaller than a pencil lead. I then took the end and smashed it on my anvil to make a small flat screw driver end. Next you need a 7mm wrench hold this wrench between the center and rear carb, and as you thread the wire back let it thread through the closed part of the wrench to act as a guide. And boom your rear carb can be adjusted without taking it off.

|

|

|

Re: Six Pack Idle question

[Re: mattpar]

#704217

Re: Six Pack Idle question

[Re: mattpar]

#704217

07/29/10 07:41 AM

07/29/10 07:41 AM

|

Joined: Aug 2003

Posts: 2,467

Answering the call of the wild

ThermoQuad

top fuel

|

top fuel

Joined: Aug 2003

Posts: 2,467

Answering the call of the wild

|

Here is a guide to tune six packs. It's not everything but gets you close enough. Quality cap rotor, wires and plugs that are not too hot or cold in heat range. Distributor vacuum port on carb disconnected and plugged Make sure that your ignition advance curve is such that you can run at 15 - 18 deg advance at idle. This is important. Car in neutral-auto or 4 sp, emergency brake set A good quality vacuum gage is required, a digital tach if you have that as well. Connect vac gauge to manifold vacuum source. Outboards idle adj screws out 1/8 turn ccw THIS IS IMPORTANT 64 jets in ctr carb If you have new carbs(untouched) they will have 62 jets in the center carb Black springs in the secondaries You must know what power valve is in the ctr carb. Typically a 6.5 The slotted screw on top of the float adjuster, is just a lock screw, you can remove it for now, the 5/8" nut is the adjuster/needle seat nut, rotating it counter clockwise will raise fuel level in the bowl, clockwise will lower it Make small 1/2 turns & let the car run a 3 or more minutes so the fuel levels off check the fuel in the clear site window, at the bottom on the ctr carb and up to half the window the front and rear carbs, After you set the fuel level in all 3 carbs, reset the idle on the center carb Floats are adjusted properly Ctr carb bottom of the sight hole end carbs a very slight trickle out the sight hole Starting point for Jets. center 65, front 78, rear 80. If the weather gets cold you might want to increase that to center 66, front 80, rear 82 Check the center carb and be sure to adjust the idle screw until the throttle blades are closed and the transfer slot is exposed no larger than a square. [carb would have to be off the car to see this] You only want about .040" of the transfer slots exposed below the throttle plates. If the idle screw is adjusted too high, you will be into the transition circuit, exposing too much of the vertical rectangular slot. Many times the idle screw is adjusted incorrectly to compensate for other issues. This puts the carb into the transition circuit and at that point you have no mixture control on the center carb. Start car, set idle to 1000 rpm and allow engine to reach operating temp. 195 degree thermostat required or fuel will puddle in the intake. This is a must. If the car won’t idle: Is engine vacuum reading at least 2 hg higher than the power valve rating? This must be correct this before proceeding If ok proceed, if not correct power valve issue and proceed. Note some engines only pull 5 hg of vacuum Now set the initial timing to where it wants to be. Somewhere between 10-20 degrees BTDC. The engine will tell you by increasing vacuum and rpm at this point. In some applications the engine does not care, so set it to 12 degrees BTDC. Cams with 106-degree ctrlines seem to like initial timing set at 15-22 BTDC Cams with 108-degree ctrlines seem to like initial timing set at 12-18 BTDC Cams with 110-112 degree ctrlines seem to like initial timing set at 8-12 BTDC center carb idle mixture screws out ccw 1.5 turns Re-Set the rpm for 900-See if you have "control" over the idle mixture screws on the ctr carb. Using a good vacuum gage adj mixture to highest reading of vacuum. If you do not have control over the idle mixture you have issues that need to be taken care of before proceeding. Issues such as poor intake sealing, the wrong pcv valve, a vacuum leak from the brake booster or other places, wrong pwr valve etc. Recheck idle rpm and set to 900 Drive car. Is the car rich? Jet down 2 steps until you find the min jet size. You will know when you are lean, no power. Most times you are over jetted.... Do not over jet! Now reset the initial timing again. Somewhere between 10-20 degrees BTDC. The engine will tell you by increasing vacuum and rpm at this point. In some applications the engine does not care, so set it to 15 degrees BTDC. Re-Set the rpm for 900-See if you have "control" over the idle mixture screws. Using a good vacuum gage adj mixture to highest reading of vacuum. Recheck idle rpm and set to 900 How do you know when you are "there”? You should be able to idle most cars down to 800-900 rpm in neutral and the response is crisp. You do not smell raw gas in the exhaust. The bottom of the intake is not soaked with fuel. The spark plugs are clean. The car starts runs and drives smoothly when cold. The car restarts immediately when hot without touching the throttle. When you whack the throttle from an idle the engine immediately returns to idle. Note: If your initial timing exceeds 12 degrees BTDC with a MP distributor typically you need to modify the advance curve so the total timing is not more than 34 degrees BTDC.

|

|

|

|

|