|

Full Groove vs. 3/4 Groove Mains for BB Mopar

#3217299

Full Groove vs. 3/4 Groove Mains for BB Mopar

#3217299

03/01/24 03:44 PM

03/01/24 03:44 PM

|

Joined: Jun 2022

Posts: 31

Pennsylvania

19_Dart_68

OP

OP

member

|

OP

OP

member

Joined: Jun 2022

Posts: 31

Pennsylvania

|

According to Mahle-Aftermarket's documentation, 3/4 groove bearings promote less HP loss and don't suffer any lubrication loss vs. Full Groove bearings.

Is there any reason to not use 3/4 groove bearings in a BB Mopar stroker engine? Or any better reason(s) to use Full Groove instead of the 3/4-groove?

68 Dart - 440 Swap in Progress...please stand by

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: 19_Dart_68]

#3217306

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: 19_Dart_68]

#3217306

03/01/24 04:28 PM

03/01/24 04:28 PM

|

Joined: Mar 2003

Posts: 2,499

PA

moparacer

top fuel

|

top fuel

Joined: Mar 2003

Posts: 2,499

PA

|

I have a pretty good reason for not using 3/4 groove in my BB. 400 Mains.  That being said, the regular ol 876P full groove bearings I am replacing in my engine were put in it in 2018, and I could reused the rod bearings if I wanted to at 800+ hp. And they have a LOT of passes on them. Like 200 a year except for covid year when I only put 110 on it.

67 Barracuda street/bracket car 11.27-119

68 Dart 502 BB 8.70s-152

414 cid SB Dragster 7.65-174

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: moparacer]

#3217307

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: moparacer]

#3217307

03/01/24 04:38 PM

03/01/24 04:38 PM

|

Joined: Jun 2022

Posts: 31

Pennsylvania

19_Dart_68

OP

OP

member

|

OP

OP

member

Joined: Jun 2022

Posts: 31

Pennsylvania

|

Man, that's awesome! Glad they held up that well for you!

Yeah, guess I should have said RB based stroker...

Last edited by 19_Dart_68; 03/01/24 04:39 PM.

68 Dart - 440 Swap in Progress...please stand by

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: Cab_Burge]

#3217312

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: Cab_Burge]

#3217312

03/01/24 04:49 PM

03/01/24 04:49 PM

|

Joined: Jun 2022

Posts: 31

Pennsylvania

19_Dart_68

OP

OP

member

|

OP

OP

member

Joined: Jun 2022

Posts: 31

Pennsylvania

|

Are those the same as the MS-1277HG Clevite 77's?

68 Dart - 440 Swap in Progress...please stand by

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: 19_Dart_68]

#3217315

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: 19_Dart_68]

#3217315

03/01/24 04:54 PM

03/01/24 04:54 PM

|

Joined: Aug 2003

Posts: 43,163

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,163

Bend,OR USA

|

Are those the same as the MS-1277HG Clevite 77's? I can't answer that sorry. I use to use the Seal Power part number M4500 for the RB motors and their M4400 for the B motors, I think they discontinued the M 4400 several years back  I prefer to build the 400 blocks over the 440 blocks due to the thicker main webbing

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: Cab_Burge]

#3217316

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: Cab_Burge]

#3217316

03/01/24 04:58 PM

03/01/24 04:58 PM

|

Joined: Jun 2022

Posts: 31

Pennsylvania

19_Dart_68

OP

OP

member

|

OP

OP

member

Joined: Jun 2022

Posts: 31

Pennsylvania

|

Are those the same as the MS-1277HG Clevite 77's? I can't answer that sorry. I use to use the Seal Power part number M4500 for the RB motors and their M4400 for the B motors, I think they discontinued the M 4400 several years back  I prefer to build the 400 blocks over the 440 blocks due to the thicker main webbing   Ok, I get ya. I think they are the same bearing. I have a '78 440 and I think it is similar to the 400's in that respect.

68 Dart - 440 Swap in Progress...please stand by

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: 19_Dart_68]

#3217321

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: 19_Dart_68]

#3217321

03/01/24 05:47 PM

03/01/24 05:47 PM

|

Joined: Jan 2003

Posts: 31,027

Oregon

AndyF

I Win

|

I Win

Joined: Jan 2003

Posts: 31,027

Oregon

|

According to Mahle-Aftermarket's documentation, 3/4 groove bearings promote less HP loss and don't suffer any lubrication loss vs. Full Groove bearings.

Is there any reason to not use 3/4 groove bearings in a BB Mopar stroker engine? Or any better reason(s) to use Full Groove instead of the 3/4-groove? I use 3/4 groove if I can find them. Sometimes it is really hard to find bearings these days so you just live with what you can get. In the old days when parts were available we used 3/4 groove on everything.

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: 19_Dart_68]

#3217331

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: 19_Dart_68]

#3217331

03/01/24 06:34 PM

03/01/24 06:34 PM

|

Joined: Dec 2021

Posts: 1,126

Loudoun County, VA

Brad_Haak

super stock

|

super stock

Joined: Dec 2021

Posts: 1,126

Loudoun County, VA

|

I like the Speed Pro 119M 3/4-groove main (although they're really more like a 5/8 with a wide groove if you look closely). That said, I wouldn't think twice about running a traditional full-groove, which I have in the past. I know Cab is a big proponent of the narrow-type full-groove and I'd consider those if I couldn't get my preferred 119Ms.

2021 Challenger 6.4L Scat Pack 1320

100% stock: 1.680, 11.894 at 113.75 (DA 175 ft)

weight reduction, wheels, tires, Hellcat air box: 1.661, 11.686 at 115.97 (DA 710 ft)

1973 Challenger 452 ci street/strip [2008]

pump gas, DOT radials: 1.454, 10.523 at 126.44 (DA 514 ft)

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: 19_Dart_68]

#3217355

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: 19_Dart_68]

#3217355

03/01/24 08:01 PM

03/01/24 08:01 PM

|

Joined: Mar 2003

Posts: 2,499

PA

moparacer

top fuel

|

top fuel

Joined: Mar 2003

Posts: 2,499

PA

|

Man, that's awesome! Glad they held up that well for you!

Yeah, guess I should have said RB based stroker... I was just commenting for the sake of the full groove 3/4 groove debate. I would probably run a 3/4 groove if it was an option but it isn't. And I never had any problems I could link to full.

67 Barracuda street/bracket car 11.27-119

68 Dart 502 BB 8.70s-152

414 cid SB Dragster 7.65-174

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: dvw]

#3218003

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: dvw]

#3218003

03/04/24 01:56 PM

03/04/24 01:56 PM

|

Joined: Dec 2006

Posts: 2,110

Byron, NY

W.I.N. Racing

top fuel

|

top fuel

Joined: Dec 2006

Posts: 2,110

Byron, NY

|

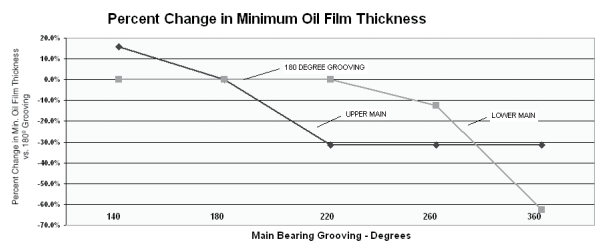

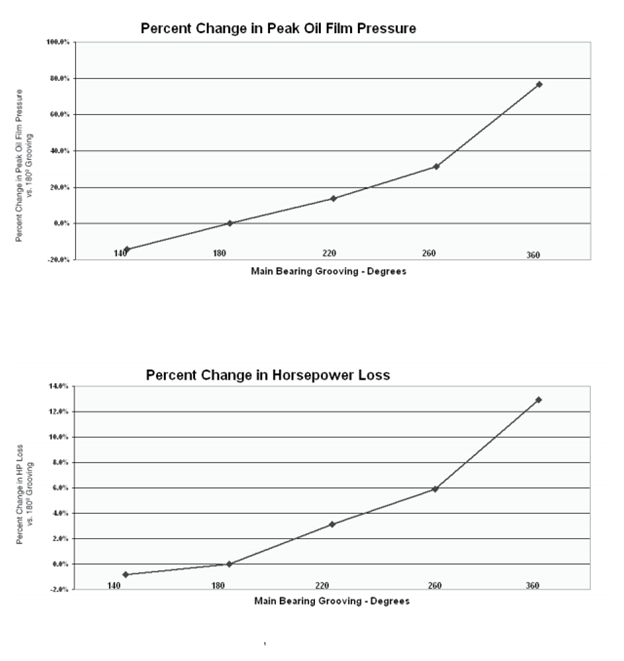

Here is the info from Clevite with the attached Graphs

Various forms of main bearing grooving have been used over the years. We are frequently asked what difference grooving makes. First, it’s essential to understand that bearings depend on a film of oil to keep them separated from the shaft surface. This oil film is developed by shaft rotation. As the shaft rotates it pulls oil into the loaded area of the bearing and rides up on this film much like a tire hydroplaning on wet pavement. Grooving in a bearing acts like tread in a tire to break up the oil film. While you want your tires to grip the road, you don’t want your bearings to grip the shaft. The primary reason for having any grooving in a main bearing is to provide oil to the connecting rods. Without rod bearings to feed, a simple oil hole would be sufficient to lubricate a main bearing. Many early engines used full grooved bearings and some even used multiple grooves. As engine and bearing technology developed, bearing grooving was removed from modern lower main bearings. The result is in a thicker film of oil for the shaft to ride on. This provides a greater safety margin and improved bearing life. Upper main shells, which see lower loads than the lowers, have retained a groove to supply the connecting rods with oil. In an effort to develop the best possible main bearing designs for performance engines, we’ve investigated the effects of main bearing grooving on bearing performance. The graphs illustrate that a simple 180-degree groove in the upper main shell is still the best overall design. While a slightly shorter groove of 140 degrees provides a marginal gain, most of the benefit is to the upper shell, which doesn’t need improvement. On the other hand, extending the groove into the lower half, even as little as 20 degrees at each parting line (220 degrees in total), takes away from upper bearing performance without providing any benefit to the lower half. It’s also interesting to note that as groove length increases so do horsepower loss and peak oil film pressure which is transmitted directly to the bearing.

'01 P1500, Blown/Inj BAE,/Veney ,Bruno/CS2,Dana 60

'01 Dodge 3500 S Cummins Auto, Fresh air kit, 4" Exhaust,

'05 Dodge Magnum R/T - Too Much to list

'60 Willys CJ5

'01 International LPX - Project,DT466, Allison

'64 Plymouth Valiant, Inj 528 Hemi, 2spd

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: W.I.N. Racing]

#3219890

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: W.I.N. Racing]

#3219890

03/12/24 07:57 AM

03/12/24 07:57 AM

|

Joined: Jun 2022

Posts: 31

Pennsylvania

19_Dart_68

OP

OP

member

|

OP

OP

member

Joined: Jun 2022

Posts: 31

Pennsylvania

|

Here is the info from Clevite with the attached Graphs

Various forms of main bearing grooving have been used over the years. We are frequently asked what difference grooving makes. First, it’s essential to understand that bearings depend on a film of oil to keep them separated from the shaft surface. This oil film is developed by shaft rotation. As the shaft rotates it pulls oil into the loaded area of the bearing and rides up on this film much like a tire hydroplaning on wet pavement. Grooving in a bearing acts like tread in a tire to break up the oil film. While you want your tires to grip the road, you don’t want your bearings to grip the shaft. The primary reason for having any grooving in a main bearing is to provide oil to the connecting rods. Without rod bearings to feed, a simple oil hole would be sufficient to lubricate a main bearing. Many early engines used full grooved bearings and some even used multiple grooves. As engine and bearing technology developed, bearing grooving was removed from modern lower main bearings. The result is in a thicker film of oil for the shaft to ride on. This provides a greater safety margin and improved bearing life. Upper main shells, which see lower loads than the lowers, have retained a groove to supply the connecting rods with oil. In an effort to develop the best possible main bearing designs for performance engines, we’ve investigated the effects of main bearing grooving on bearing performance. The graphs illustrate that a simple 180-degree groove in the upper main shell is still the best overall design. While a slightly shorter groove of 140 degrees provides a marginal gain, most of the benefit is to the upper shell, which doesn’t need improvement. On the other hand, extending the groove into the lower half, even as little as 20 degrees at each parting line (220 degrees in total), takes away from upper bearing performance without providing any benefit to the lower half. It’s also interesting to note that as groove length increases so do horsepower loss and peak oil film pressure which is transmitted directly to the bearing.

Yep, that's the info I was referring to. Good research on their part.

68 Dart - 440 Swap in Progress...please stand by

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: AndyF]

#3219891

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: AndyF]

#3219891

03/12/24 07:58 AM

03/12/24 07:58 AM

|

Joined: Jun 2022

Posts: 31

Pennsylvania

19_Dart_68

OP

OP

member

|

OP

OP

member

Joined: Jun 2022

Posts: 31

Pennsylvania

|

According to Mahle-Aftermarket's documentation, 3/4 groove bearings promote less HP loss and don't suffer any lubrication loss vs. Full Groove bearings.

Is there any reason to not use 3/4 groove bearings in a BB Mopar stroker engine? Or any better reason(s) to use Full Groove instead of the 3/4-groove? I use 3/4 groove if I can find them. Sometimes it is really hard to find bearings these days so you just live with what you can get. In the old days when parts were available we used 3/4 groove on everything. That is the way I am going. The 3/4 groove set wound up fitting much better across all of the mains than the full groove set did.

68 Dart - 440 Swap in Progress...please stand by

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: 19_Dart_68]

#3219892

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: 19_Dart_68]

#3219892

03/12/24 07:58 AM

03/12/24 07:58 AM

|

Joined: Jun 2022

Posts: 31

Pennsylvania

19_Dart_68

OP

OP

member

|

OP

OP

member

Joined: Jun 2022

Posts: 31

Pennsylvania

|

Thanks for all the replies, all!

68 Dart - 440 Swap in Progress...please stand by

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: 19_Dart_68]

#3223579

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: 19_Dart_68]

#3223579

03/29/24 07:30 PM

03/29/24 07:30 PM

|

Joined: Aug 2005

Posts: 760

Southington Ct.

turbobitt

super stock

|

super stock

Joined: Aug 2005

Posts: 760

Southington Ct.

|

So what are people opinions of 3/4 groove Speed pro 119M vs. Clevite MS-2233HG ?

Also, Has anyone ever measured bearing eccentricity ? I'm dial boring my engine bearings now to calculate clearance and don't know what to expect.

AG.

1970 Challenger w/572 Hemi street car and my pride and joy.

1986 T-Type with 272 Stage 2 Buick V6 engine - True 8 second street car. Just updated the engine and put down 928 HP @ 35# boost to the ground on chasis dyno.

1976 Cee Bee Avenger Jet Boat - 460 Ford powered.

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: AndyF]

#3223660

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: AndyF]

#3223660

03/30/24 09:37 AM

03/30/24 09:37 AM

|

Joined: Jan 2012

Posts: 2,645

Stuttgart, Arkansas

rickseeman

master

|

master

Joined: Jan 2012

Posts: 2,645

Stuttgart, Arkansas

|

If both of them fit (meaning no interference with the radius or the block) I would run the ones that gave me closest to the clearance I wanted.

2011 Drag Pak Challenger

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: rickseeman]

#3223667

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: rickseeman]

#3223667

03/30/24 10:02 AM

03/30/24 10:02 AM

|

Joined: Jan 2012

Posts: 2,645

Stuttgart, Arkansas

rickseeman

master

|

master

Joined: Jan 2012

Posts: 2,645

Stuttgart, Arkansas

|

I don't think we are supposed to think about eccentricity. I don't believe we know anything about that nor is it something we can change. I think our job is to make sure the hole is the right size (2.9425"-2.943") and that we have the proper bearing

to crankshaft clearance in the vertical dimension.

2011 Drag Pak Challenger

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: Cab_Burge]

#3223713

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: Cab_Burge]

#3223713

03/30/24 01:50 PM

03/30/24 01:50 PM

|

Joined: Aug 2005

Posts: 760

Southington Ct.

turbobitt

super stock

|

super stock

Joined: Aug 2005

Posts: 760

Southington Ct.

|

On the 119M mains I'm seeing about .002" eccentricity and consistent from hole to hole and the housing bores are perfect so I know its in the bearings.

AG.

Last edited by turbobitt; 03/30/24 01:51 PM.

1970 Challenger w/572 Hemi street car and my pride and joy.

1986 T-Type with 272 Stage 2 Buick V6 engine - True 8 second street car. Just updated the engine and put down 928 HP @ 35# boost to the ground on chasis dyno.

1976 Cee Bee Avenger Jet Boat - 460 Ford powered.

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: rickseeman]

#3223743

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: rickseeman]

#3223743

03/30/24 03:55 PM

03/30/24 03:55 PM

|

Joined: Aug 2005

Posts: 760

Southington Ct.

turbobitt

super stock

|

super stock

Joined: Aug 2005

Posts: 760

Southington Ct.

|

Is that a bad thing? What is your vertical clearance? I don't have a crank to calculate actual clearance but If I get a crank at nominal diameter than clearance will be .0025-.003( .003 on the center thrust main) . If I base it on the last K1 crank I had(main journals were slightly below min spec) than my clearance will be .0035-.004 (.004 on the center thrust main). I had a set of full groove Clevite 877P bearings and mounted one in the #1 main to spot check and was pretty much the same. AG.

1970 Challenger w/572 Hemi street car and my pride and joy.

1986 T-Type with 272 Stage 2 Buick V6 engine - True 8 second street car. Just updated the engine and put down 928 HP @ 35# boost to the ground on chasis dyno.

1976 Cee Bee Avenger Jet Boat - 460 Ford powered.

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: AndyF]

#3227177

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: AndyF]

#3227177

04/15/24 12:20 PM

04/15/24 12:20 PM

|

Joined: Aug 2003

Posts: 1,313

Charlotte, NC

LSP

pro stock

|

pro stock

Joined: Aug 2003

Posts: 1,313

Charlotte, NC

|

Bearings can be hard to find these days so you should feel lucky that you have a couple of sets to pick from. I've noticed the same thing, any idea why?

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: turbobitt]

#3227189

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: turbobitt]

#3227189

04/15/24 12:48 PM

04/15/24 12:48 PM

|

Joined: Dec 2006

Posts: 2,110

Byron, NY

W.I.N. Racing

top fuel

|

top fuel

Joined: Dec 2006

Posts: 2,110

Byron, NY

|

Is that a bad thing? What is your vertical clearance? I don't have a crank to calculate actual clearance but If I get a crank at nominal diameter than clearance will be .0025-.003( .003 on the center thrust main) . If I base it on the last K1 crank I had(main journals were slightly below min spec) than my clearance will be .0035-.004 (.004 on the center thrust main). I had a set of full groove Clevite 877P bearings and mounted one in the #1 main to spot check and was pretty much the same. AG. Taken from the Cleveite bearing catalogue “The wall is thickest at 90 degrees from the split and drops off a prescribed amount toward each parting line, depending on the bearings intended application. This drop off is called “Eccentricity.” In addition, there is a relief at the parting lines. Eccentricity is used to tailor the bearing shell to its mating hardware and to provide for hardware deflections in operation. Eccentricity also helps to promote oil film formation by providing a wedge shape in the clearance space. The relief at each parting line insures that there will not be a step at the split line due to bearing cap shift or the mating of bearing shells that differ slightly in thickness within allowed tolerance limits”Its a good read if you want to know bearing specifics..

'01 P1500, Blown/Inj BAE,/Veney ,Bruno/CS2,Dana 60

'01 Dodge 3500 S Cummins Auto, Fresh air kit, 4" Exhaust,

'05 Dodge Magnum R/T - Too Much to list

'60 Willys CJ5

'01 International LPX - Project,DT466, Allison

'64 Plymouth Valiant, Inj 528 Hemi, 2spd

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: W.I.N. Racing]

#3227209

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: W.I.N. Racing]

#3227209

04/15/24 01:57 PM

04/15/24 01:57 PM

|

Joined: Aug 2005

Posts: 760

Southington Ct.

turbobitt

super stock

|

super stock

Joined: Aug 2005

Posts: 760

Southington Ct.

|

Is that a bad thing? What is your vertical clearance? I don't have a crank to calculate actual clearance but If I get a crank at nominal diameter than clearance will be .0025-.003( .003 on the center thrust main) . If I base it on the last K1 crank I had(main journals were slightly below min spec) than my clearance will be .0035-.004 (.004 on the center thrust main). I had a set of full groove Clevite 877P bearings and mounted one in the #1 main to spot check and was pretty much the same. AG. Taken from the Cleveite bearing catalogue “The wall is thickest at 90 degrees from the split and drops off a prescribed amount toward each parting line, depending on the bearings intended application. This drop off is called “Eccentricity.” In addition, there is a relief at the parting lines. Eccentricity is used to tailor the bearing shell to its mating hardware and to provide for hardware deflections in operation. Eccentricity also helps to promote oil film formation by providing a wedge shape in the clearance space. The relief at each parting line insures that there will not be a step at the split line due to bearing cap shift or the mating of bearing shells that differ slightly in thickness within allowed tolerance limits”Its a good read if you want to know bearing specifics.. Thanks but I have already read it and well aware that there is eccentricity built in but was hoping the catalogs would have more specific informataion than just low/medium/high ecentricity.... AG.

1970 Challenger w/572 Hemi street car and my pride and joy.

1986 T-Type with 272 Stage 2 Buick V6 engine - True 8 second street car. Just updated the engine and put down 928 HP @ 35# boost to the ground on chasis dyno.

1976 Cee Bee Avenger Jet Boat - 460 Ford powered.

|

|

|

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: LSP]

#3227211

Re: Full Groove vs. 3/4 Groove Mains for BB Mopar

[Re: LSP]

#3227211

04/15/24 02:01 PM

04/15/24 02:01 PM

|

Joined: Aug 2005

Posts: 760

Southington Ct.

turbobitt

super stock

|

super stock

Joined: Aug 2005

Posts: 760

Southington Ct.

|

Bearings can be hard to find these days so you should feel lucky that you have a couple of sets to pick from. I've noticed the same thing, any idea why? The same old story, global supply chain issues..... The middle east is in turmoil and King bearings is in Jerusalem from what I understand. I was in contact with king on there +/- ,001 race main bearing sets and they tell me the production date is scheduled for 8/24. AG/

1970 Challenger w/572 Hemi street car and my pride and joy.

1986 T-Type with 272 Stage 2 Buick V6 engine - True 8 second street car. Just updated the engine and put down 928 HP @ 35# boost to the ground on chasis dyno.

1976 Cee Bee Avenger Jet Boat - 460 Ford powered.

|

|

|

|

|