|

Re: "hate this piston design"

[Re: slantzilla]

#3206298

Re: "hate this piston design"

[Re: slantzilla]

#3206298

01/19/24 06:18 PM

01/19/24 06:18 PM

|

Joined: Jan 2003

Posts: 14,499

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,499

So. Burlington, Vt.

|

What is the purpose of those grooves? Contact Reduction Grooves

These grooves are machined into the top ring land above the top ring to minimize contact drag when the piston rocks over upon reversal. They add minimal volume to the crevice volume, and they also help resist detonation by disrupting flame travel into the crevice volume where pressure spikes might unseat the ring.

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

Re: "hate this piston design"

[Re: AndyF]

#3206386

Re: "hate this piston design"

[Re: AndyF]

#3206386

01/19/24 11:28 PM

01/19/24 11:28 PM

|

Joined: Sep 2018

Posts: 166

West Palm Beach, Florida

Craig J

OP

OP

member

|

OP

OP

member

Joined: Sep 2018

Posts: 166

West Palm Beach, Florida

|

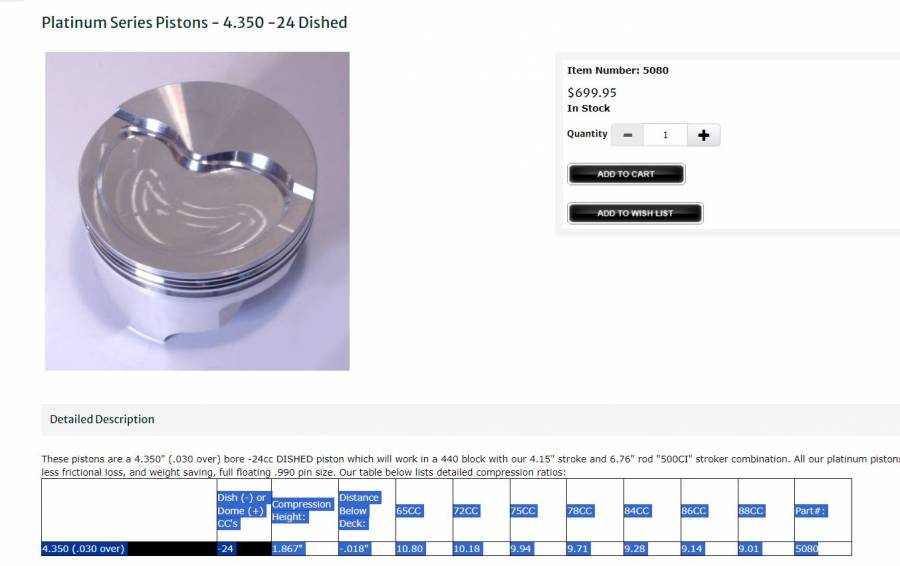

The grooves are a good idea, but it looks like the top groove was too high. Maybe a design error, maybe a machining error. I don't really know without seeing them. Sometimes pictures don't show everything. I believe the pistons I have are just an older version of this one from 440source. This discussion now has me a bit curious....I am certainly not a professional engine builder, and have never had an engine assembled in my garage on a dyno. Due to covid parts shortages I have a not very good combination in my car: 440 +0.032 (yes...32 over) with very old style L2295F30 TRW pistons, LY rods, 75 cc Performer RPM heads, a Hughes "real 6 pack" cam, performer 440 intake (fits under a flat e body hood) and iron hp manifolds. It has sky high cranking compression, but I think it would probably be safe on an engine dyno up to 6000 rpm with 112 octane fuel and conservative timing. If I can find a dyno around West Palm that would put up with my nonsense it would be amusing to make 3 pulls with this not so great ~12.1:1 440, then go home and put the same heads, intake, carb, exhaust manifolds, and cam onto this ~9.8:1 CR 493 with the 'hate' pistons and run it again on the same dyno to compare the results... does ~10% increase in displacement overcome ~20% lower static static compression ratio?

Last edited by Craig J; 01/19/24 11:37 PM.

|

|

|

Re: "hate this piston design"

[Re: Craig J]

#3206409

Re: "hate this piston design"

[Re: Craig J]

#3206409

01/20/24 01:38 AM

01/20/24 01:38 AM

|

Joined: Jan 2003

Posts: 20,179

Park Forest, IL

slantzilla

Too Many Posts

|

Too Many Posts

Joined: Jan 2003

Posts: 20,179

Park Forest, IL

|

What is the purpose of those grooves? I have heard them referred to as anti-detonation grooves however, I do not know if that’s correct Thank you.

"Everybody funny, now you funny too."

|

|

|

Re: "hate this piston design"

[Re: fast68plymouth]

#3206410

Re: "hate this piston design"

[Re: fast68plymouth]

#3206410

01/20/24 01:39 AM

01/20/24 01:39 AM

|

Joined: Jan 2003

Posts: 20,179

Park Forest, IL

slantzilla

Too Many Posts

|

Too Many Posts

Joined: Jan 2003

Posts: 20,179

Park Forest, IL

|

What is the purpose of those grooves? Contact Reduction Grooves

These grooves are machined into the top ring land above the top ring to minimize contact drag when the piston rocks over upon reversal. They add minimal volume to the crevice volume, and they also help resist detonation by disrupting flame travel into the crevice volume where pressure spikes might unseat the ring. Thank you too.

"Everybody funny, now you funny too."

|

|

|

Re: "hate this piston design"

[Re: Craig J]

#3206444

Re: "hate this piston design"

[Re: Craig J]

#3206444

01/20/24 10:00 AM

01/20/24 10:00 AM

|

Joined: May 2005

Posts: 1,989

Apollo, PA.

B1MAXX

top fuel

|

top fuel

Joined: May 2005

Posts: 1,989

Apollo, PA.

|

The grooves are a good idea, but it looks like the top groove was too high. Maybe a design error, maybe a machining error. I don't really know without seeing them. Sometimes pictures don't show everything. I believe the pistons I have are just an older version of this one from 440source. This discussion now has me a bit curious....I am certainly not a professional engine builder, and have never had an engine assembled in my garage on a dyno. Due to covid parts shortages I have a not very good combination in my car: 440 +0.032 (yes...32 over) with very old style L2295F30 TRW pistons, LY rods, 75 cc Performer RPM heads, a Hughes "real 6 pack" cam, performer 440 intake (fits under a flat e body hood) and iron hp manifolds. It has sky high cranking compression, but I think it would probably be safe on an engine dyno up to 6000 rpm with 112 octane fuel and conservative timing. If I can find a dyno around West Palm that would put up with my nonsense it would be amusing to make 3 pulls with this not so great ~12.1:1 440, then go home and put the same heads, intake, carb, exhaust manifolds, and cam onto this ~9.8:1 CR 493 with the 'hate' pistons and run it again on the same dyno to compare the results... does ~10% increase in displacement overcome ~20% lower static static compression ratio? Cranking compression would probably still be up there with the same cam I bet.

|

|

|

Re: "hate this piston design"

[Re: B1MAXX]

#3206730

Re: "hate this piston design"

[Re: B1MAXX]

#3206730

01/21/24 04:21 AM

01/21/24 04:21 AM

|

Joined: Sep 2014

Posts: 4,457

Washington

madscientist

master

|

master

Joined: Sep 2014

Posts: 4,457

Washington

|

I called Icon about these pistons several years ago. For use with open chamber heads you can run the pad proud of the deck. On closed chamber heads you run them to zero deck.

They reduced the outer band as a way to increase piston volume while keeping the dish reasonably shallow.

That’s all it is.

Just because you think it won't make it true. Horsepower is KING. To dispute this is stupid. C. Alston

|

|

|

|

|