Mopar 440 block deck height vary

#2724705

Mopar 440 block deck height vary

#2724705

12/17/19 05:40 AM

12/17/19 05:40 AM

|

Joined: Dec 2019

Posts: 138

Sweden

Mopar493

OP

OP

member

|

OP

OP

member

Joined: Dec 2019

Posts: 138

Sweden

|

Hi! I have built a Mopar 440 to 493cui stroker, Mahle 4340 flatop forged pistons with file fit rings, Compcam xe275hl( 231/237@050 and .525 lift both int/ext), Edelbrock e-street 84cc heads, Edelbrock rpm intake, Edelbrock 800 cfm avs2. Its running great and have a huge low end, no detonation at 93 octane and ignition timing curve 16 degrees initial, 34 full advance at 3200 rpm. Now, im a bit confused over the truth deck height, i have thinking a bit after wards and looking at pictures from the building and so on, the deck height on a Mopar 440 block from all years(my from -77) should have a deck height of 10,725" right? I have a eagle crank 4,150" stroke lenght, eagle H-beam rods 6,760" and this Mahle flat top pistons with a compression height of 1,865". When you counting of compression height(half stroke 2,075"+rod lenght cc 6,760"=8,835" and take that from deck height 10,725"-8,835"=1,89") i shold have a piston with compression height 1,89" to reach zero deck, my piston has 1,865" and i should than have 0,025" left to zero deck right. I have more like 0,043" to zero deck as you can see in the picture i share you almost can see the whole chamfer in top of the bore with piston at TDC. I use Fel pro head gasket with .039" compressed thicknes that gives about 9,48cc, pistons valve relifes 8cc, heads 84cc that should theoreticly give me a compression ratio 10,33:1 and a dynamic at about 8,05:1, but with the real measurement and the piston down 0,043" in the hole i get more like 9,97:1 and a dynamic at 8,02:1, the chamfer on top of the bore probably give a few cc combustion chamber more. Do the 440 block really vary this much? The measurement dont lie so probably. What do you say?

|

|

|

Re: Mopar 440 block deck height vary

[Re: AndyF]

#2724796

Re: Mopar 440 block deck height vary

[Re: AndyF]

#2724796

12/17/19 01:01 PM

12/17/19 01:01 PM

|

Joined: Dec 2019

Posts: 138

Sweden

Mopar493

OP

OP

member

|

OP

OP

member

Joined: Dec 2019

Posts: 138

Sweden

|

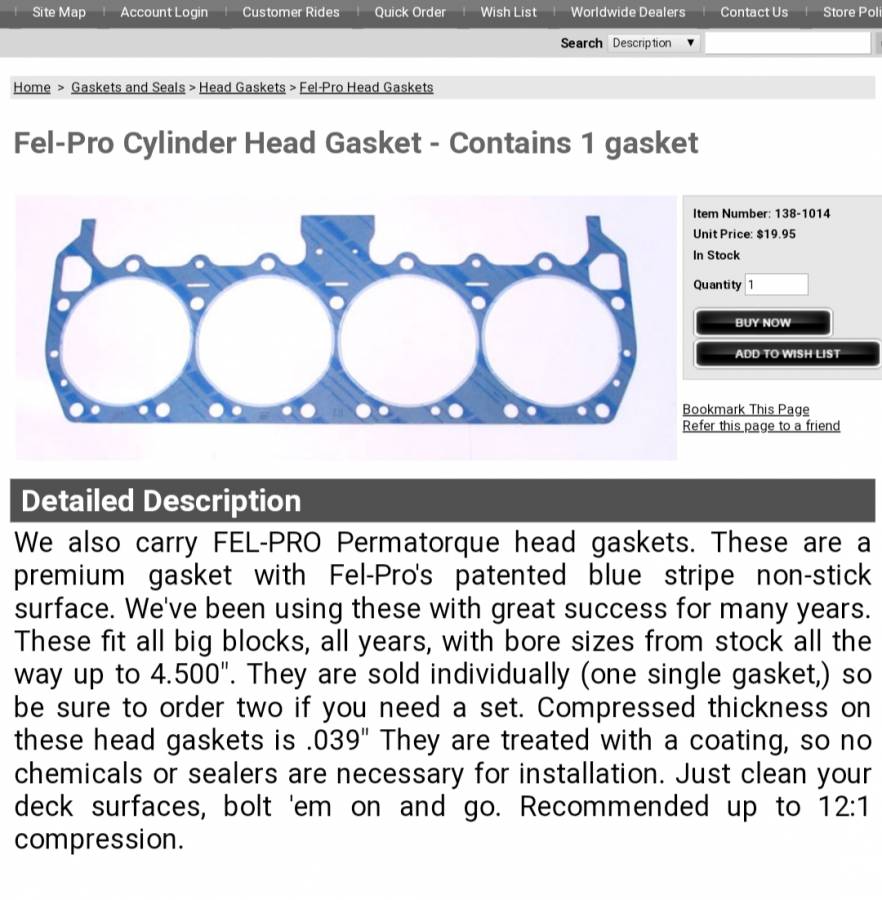

1970's quality baby!

You can't trust anything on a Mopar block until you measure it yourself. If the block wasn't decked by a high quality machine shop then you probably have 8 cylinders with different compression ratios. Thanks for your answer! The block is straight, its have been checked by the machinist where i leave the block for bore.030" over, i wanted him to mill it but he told me its waste money if im not wanted it for more compression ratio, i not needed the line honing either, the block was in good shape really, he just bore it .030" over with stress plate and than honing after the pistons. The deck height just seems to be 0.018" higher than it should after specs, also this -77 block have pretty big chamfers in top of the bore and that gives a few more cc's combustion chamber, they bee little smaller after he bore it but still there. Also one more thing i came to think about is the 440 source Fel pro gasket i show in the picture, it stands in the description that it can be used up to 4,500" bore, is the bore in the gaskets really that big, i not remember how it looks when i assembled the cylinder heads, just that they fits good and have done their job under this 400 miles i have drive the car so far, it that so there is a 1 or 2 cc's more that lower the static compression ratio.

|

|

|

Re: Mopar 440 block deck height vary

[Re: Cab_Burge]

#2724858

Re: Mopar 440 block deck height vary

[Re: Cab_Burge]

#2724858

12/17/19 03:19 PM

12/17/19 03:19 PM

|

Joined: Dec 2019

Posts: 138

Sweden

Mopar493

OP

OP

member

|

OP

OP

member

Joined: Dec 2019

Posts: 138

Sweden

|

U Thanks for the answer! I have understood that vary in deck height is not unusuall on these engine blocks. The engine is assembled and camshaft broken in, i have around 400 trouble free miles on it so far and it runs great, have huge torque, i havent beat it yet with more than about 4500 rpm, it really makes my 300 -64 on over 4000 lbs to move, no detonation problems on pump gas, it running great, i know where i be around in compression ratio, it be from 9,97:1 to 10,3:1 in static and dynamic from 8 to 8,05:1 so it should work well on pump gas and it do. The accurate ratio depends on how accurate my measurements of how far the piston in the bore is but for sure they all eight is more than the theoretical .025", that i can see with only eye on the picture and i meassure them all 8 to around .040", it also depends on if the gasket bore is 4,38 or 4,50, the edelbrock e-street i have just trust they are 84cc

Last edited by Mopar493; 12/17/19 03:20 PM.

|

|

|

Re: Mopar 440 block deck height vary

[Re: A727Tflite]

#2725028

Re: Mopar 440 block deck height vary

[Re: A727Tflite]

#2725028

12/18/19 04:41 AM

12/18/19 04:41 AM

|

Joined: Dec 2019

Posts: 138

Sweden

Mopar493

OP

OP

member

|

OP

OP

member

Joined: Dec 2019

Posts: 138

Sweden

|

You’re only problem is you are assuming the deck is 10.725”.

Unless you checked it on the mill or using proper tools on the block you don’t know how tall the deck is. Thank you for answer! My machinist check the decks for straightnes and say im not need to mill but he not check any deck height. I meassure all 8 pistons in different area using a steel ruler and a caliper and find them all be around 0.040" under so i know the deckheight is about .018" taller all over than it theoretical should be, i just wonder and thats why i ask if it is common and i have understand that its common the blocks are not straight all over but this one are straight, just slightly taller and in my case thats just good i belive because it keeps the compression down a bit.

|

|

|

Re: Mopar 440 block deck height vary

[Re: dragon slayer]

#2725060

Re: Mopar 440 block deck height vary

[Re: dragon slayer]

#2725060

12/18/19 10:01 AM

12/18/19 10:01 AM

|

Joined: Jan 2003

Posts: 13,363

Marion, South Carolina [><]

an8sec70cuda

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 13,363

Marion, South Carolina [><]

|

You're also assuming that those Eagle rods are 6.76" long too. If they are like all the other Eagle rods I've seen, they needed to be resized to be useable...which will change their length slightly.

CHIP

'70 hemicuda, 575" Hemi, 727, Dana 60

'69 road runner, 440-6, 18 spline 4 speed, Dana 60

'71 Demon, 340, low gear 904, 8.75

'73 Chrysler New Yorker, 440, 727, 8.75

'90 Chevy 454SS Silverado, 476" BBC, TH400, 14 bolt

'06 GMC 2500HD LBZ Duramax

|

|

|

Re: Mopar 440 block deck height vary

[Re: an8sec70cuda]

#2725074

Re: Mopar 440 block deck height vary

[Re: an8sec70cuda]

#2725074

12/18/19 10:42 AM

12/18/19 10:42 AM

|

Joined: Dec 2019

Posts: 138

Sweden

Mopar493

OP

OP

member

|

OP

OP

member

Joined: Dec 2019

Posts: 138

Sweden

|

You're also assuming that those Eagle rods are 6.76" long too. If they are like all the other Eagle rods I've seen, they needed to be resized to be useable...which will change their length slightly. I bought the eagle crank, eagle rods and Mahle pistons þhrough a good machine shop here in Sweden just because i know things need to be checked up, this shop also building their own engines and has been doing drag racing since the 70's, they go under name Ppm racing, they check everything up for proper clearance and do the resizing if needed, they also balance the whole rotation within 1 gram and that really feels in the engine, no shaking there i can say, its running great. I have building this engine with no rush and everything is checked more than once, that the deck is slightly higher i did know about but i not care about it because the deck is straight and i not wanted more compression ratio, its good now for pump gas around 10,04:1static and 8,05:1dynamic, the main bore is also straight to the deck and so on, its a healthy block. The engine fired right up for cam break in 25 minutes on 2-2500rpm and has now 400 problem free miles on it. I only asked if it is common that the deck height vary, lower, higher than it theoretical should bee after specs, that the decks on some blocks are not straight i know of but this one is straight but only slightly higher OR it can also bee that the manufactor of the piston has caunting their compression height on slightly lower deck height to leave margin to the customer.

|

|

|

Re: Mopar 440 block deck height vary

[Re: Neil]

#2725163

Re: Mopar 440 block deck height vary

[Re: Neil]

#2725163

12/18/19 04:56 PM

12/18/19 04:56 PM

|

Joined: Aug 2007

Posts: 6,095

Valencia, España

NachoRT74

master

|

master

Joined: Aug 2007

Posts: 6,095

Valencia, España

|

It sounds like you have a new crank, but I had a machinist tell me BB mopar cranks have a rep for being out of square on the throws so the piston deck height can vary from hole to hole when you check them. He index grinds them to cure that.

I had a block decked once and had to have it redone by another shop as out of square was the best work the first shop was capable of. Some people make a living getting things close enough and hope you never check their work. Live and learn. I had to get "squared" my block 4 times on diff machine shops... last time IT SEEMS finally got it right, but KB pistons leaving around .040 out of the holes... nice HUH????!!!! so now that block can be used just for stock pistons and shorter pushrods ( yes I know cometic gaskets can be used same as the Felpro Copper shim along with a composite gasket but didn't want to be depending on special parts being outside USA ). Had to get another block and it seems one side is with pistons .017-9 down the hole, and the other into the .015-6 range... that's enough for me.

Last edited by NachoRT74; 12/18/19 04:57 PM.

With a Charger born in Chrysler assembly plant in Valencia, Venezuela

|

|

|

Re: Mopar 440 block deck height vary

[Re: Neil]

#2725172

Re: Mopar 440 block deck height vary

[Re: Neil]

#2725172

12/18/19 05:44 PM

12/18/19 05:44 PM

|

Joined: Dec 2019

Posts: 138

Sweden

Mopar493

OP

OP

member

|

OP

OP

member

Joined: Dec 2019

Posts: 138

Sweden

|

6 It sounds like you have a new crank, but I had a machinist tell me BB mopar cranks have a rep for being out of square on the throws so the piston deck height can vary from hole to hole when you check them. He index grinds them to cure that.

I had a block decked once and had to have it redone by another shop as out of square was the best work the first shop was capable of. Some people make a living getting things close enough and hope you never check their work. Live and learn. Sounds terrible, the machinist i use here in Sweden is a good well known one, he know what he doing and because of that he have alot of work, in here they not be long lived if they makes mistake like that. The crank is new and checked up. The engine running great so its all good, i was just courious about if it was common with varyation in deck height.

|

|

|

Re: Mopar 440 block deck height vary

[Re: Neil]

#2725385

Re: Mopar 440 block deck height vary

[Re: Neil]

#2725385

12/19/19 01:29 PM

12/19/19 01:29 PM

|

Joined: Aug 2007

Posts: 1,271

Vista, California

67Satty

pro stock

|

pro stock

Joined: Aug 2007

Posts: 1,271

Vista, California

|

It sounds like you have a new crank, but I had a machinist tell me BB mopar cranks have a rep for being out of square on the throws so the piston deck height can vary from hole to hole when you check them. He index grinds them to cure that.

I had a block decked once and had to have it redone by another shop as out of square was the best work the first shop was capable of. Some people make a living getting things close enough and hope you never check their work. Live and learn. When I swapped my heads last summer I measured and found each cylinder varied from .009" in the hole to .001" in the whole. I had asked for zero deck when the machine work was being done and was told that's what I got. Having them all perfectly .005" in the hole would satisfy my OCD but the way it is still gets me in the .040"-.050" quench range for all of cylinders with a .039" gasket and I doubt the way the engine runs is affected that much for my mild build. I'm just glad none of the pistons were sticking up out of the cylinder.

|

|

|

Re: Mopar 440 block deck height vary

[Re: Mopar493]

#2725392

Re: Mopar 440 block deck height vary

[Re: Mopar493]

#2725392

12/19/19 02:30 PM

12/19/19 02:30 PM

|

Joined: Jan 2003

Posts: 17,844

S.E. Michigan

ZIPPY

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 17,844

S.E. Michigan

|

Good job measuring what you actually have.

Check it on all 4 corners to get an idea if it is square.

1/7

2/8

Sometimes one bank will have one end higher than the other and so on.

Rich H.

Esse Quam Videri

|

|

|

Re: Mopar 440 block deck height vary

[Re: ZIPPY]

#2725427

Re: Mopar 440 block deck height vary

[Re: ZIPPY]

#2725427

12/19/19 06:05 PM

12/19/19 06:05 PM

|

Joined: Aug 2003

Posts: 43,173

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,173

Bend,OR USA

|

Good job measuring what you actually have.

Check it on all 4 corners to get an idea if it is square.

1/7

2/8

Sometimes one bank will have one end higher than the other and so on.

Make sure and use the same rod and piston in all four cylinders to make sure there all measure with the same parts  You might want to put a degree wheel on it at the same time and check the indexing of those four crank throws also

Last edited by Cab_Burge; 12/19/19 06:06 PM.

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

|

|