|

Need help diagnosing fueling issue from Open Road Race

#1613151

Need help diagnosing fueling issue from Open Road Race

#1613151

04/28/14 02:32 PM

04/28/14 02:32 PM

|

Joined: May 2005

Posts: 723

Houston Tx

Uhcoog1

OP

OP

super stock

|

OP

OP

super stock

Joined: May 2005

Posts: 723

Houston Tx

|

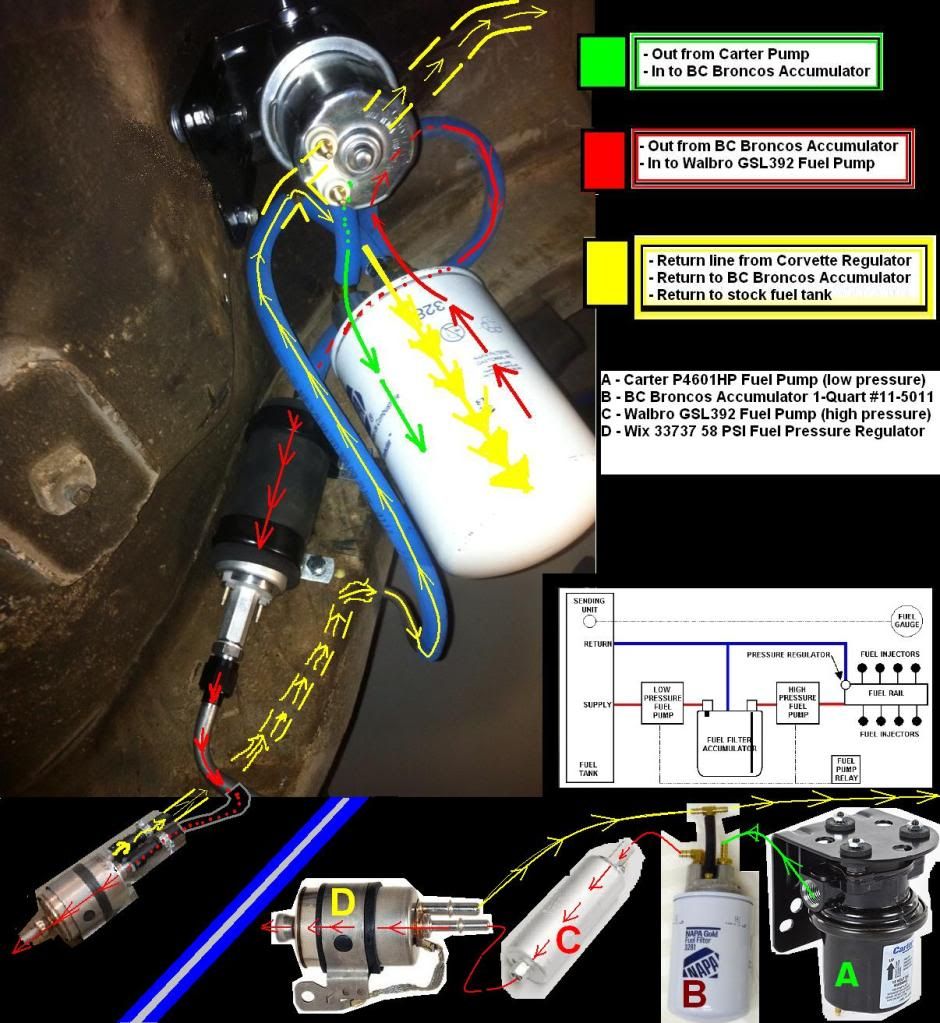

I just got back from the Big Bend Open Road Race. About 11 miles out from the finish, the AFR's spiked lean (22:1+ = lost fuel pressure to the rails). I pulled my foot out, got back in, did it again, pulled back out, waited a few seconds, and all was well when I got back in it. That happened every mile or so to the finish line. I had no other issues for the entire race (please note the second leg finish is straight and you're in the gas the entire time, while the first leg finish is not the same regarding throttle towards the finish line - there are a few corners that keep you from keeping your foot in it constant). As far as I can tell, I still had about 6 gallons in the factory tank when this occurred. My fuel system is as such: -Factory style 1/2" pickup with fuel sock -Carter 4600HP (100 gph low pressure). 1/2" in, 3/8" out. -BC Bronco's 1 quart fuel accumulator (diesel fuel filter with pickup reaching to bottom of filter) -Walbro GSL392 (mounted angled about even with the filter/accumulator) -Wix 33737 corvette regulator/filter (under passenger seat) -return line from regulator back to T above the BC Bronco's accumulator back to tank I've had the lean spike happen before, on a road course, with very low fuel (sub 2-3 gallons) and a looong sweeper. Since then, I plan my fuel usage to never go below about 4-5 gallons on the road course and I haven't had a problem since. Also, I had my original Walbro GSL392 fail on Wednesday of last week after the practice rounds and 60 mile drive back to the hotel. Ordered one overnight from summit, put it in, and that's what I ran the race with. I assumed it failed at 3,200 miles because I've ran it out of fuel once and had the issue on a road course with sweepers a few times. I'm going to pull the filter/accumulator and see what I see. I'll also pull the pickup and get an idea as to if the sock is okay, etc. At this point, I'm curious if the root cause of my first pump failure and my losing fuel pressure at the end of the race may be related. Possibilities: -130 mph sustained causing fuel slosh that didn't allow the carter to keep up with walbro demand -Dead-head system from under passenger seat to fuel rails causing issues -'return' line into a T above the BC Bronco's fuel filter/accumulator may not actually allow much returned fuel from the corvette regulator into the accumulator Anybody have any thoughts on this? Also, I wasn't thrilled that the GSL392 failed at 3200 miles. How reliable is that pump (if I never run it dry)? Here's a little diagram of my fuel system (diagram made by someone else).

-'02 Dodge Viper Ex-World Challenge racecar

-'73 Duster, 6.1 based 392 hilborn hemi, tko600, full floater rear 9", Hellwig custom bars, viper brakes, built for road course

|

|

|

Re: Need help diagnosing fueling issue from Open Road Race

[Re: RylisPro]

#1613153

Re: Need help diagnosing fueling issue from Open Road Race

[Re: RylisPro]

#1613153

04/28/14 03:34 PM

04/28/14 03:34 PM

|

Joined: May 2005

Posts: 723

Houston Tx

Uhcoog1

OP

OP

super stock

|

OP

OP

super stock

Joined: May 2005

Posts: 723

Houston Tx

|

Quote:

I really don't know much about fuel systems even though I just finished my fuel cell & have not run a track yet, but I would not use a filter as an accumulator. I would use a dedicated surge tank or swirl pot that holds a bigger volume of fuel than that little filter. Also I am a big fan of in-tank fuel pumps to keep them cool

The filter is 1 quart, which is about 15-20 seconds at WOT with a 600 hp motor, or 35-40 seconds at part throttle. This accumulator option is one of the only ones I found that was meant for mounting under the car and not in the trunk. Also, the carter flows ~100 gph vs the walbro 65 gph, so under most cases the carter should be able to provide enough fuel as long as it can maintain flow 2/3rds of the time.

I was actually checking out your fuel tank install last night. That's a big expense item, that's for sure. I'm definitely going to pull a few part numbers and see what pricing I can get on a couple of the items.

Part of the reason I initially chose the set-up I did was it allowed everything to remain under the body (i.e. out of the trunk), was low cost, didn't require cutting or welding of the original tank, and theoretically would support my flow requirements. If I'm going to spend much more 'fixing' my current set-up, then I'm definitely going to look at all options.

If I had my way, I would get all of the following:

-Accumulator tank in main fuel cell/tank with trap doors

-pump located in accumulator tank, not external on a frame rail

-no fuel lines in trunk

-reasonable pricing

The current set up is the compromise I settled on.

Quick question/thought - I wonder if the GSL392 is having the 'suck' the fuel through the filter element at all? might be worth testing what the free flow rate of the carter is through the filter/accumulator to the GSL392 pickup point.

Also worth noting: The walbro gets louder the longer it's been on. Thoughts?

-'02 Dodge Viper Ex-World Challenge racecar

-'73 Duster, 6.1 based 392 hilborn hemi, tko600, full floater rear 9", Hellwig custom bars, viper brakes, built for road course

|

|

|

Re: Need help diagnosing fueling issue from Open Road Race

[Re: ntstlgl1970]

#1613156

Re: Need help diagnosing fueling issue from Open Road Race

[Re: ntstlgl1970]

#1613156

04/28/14 09:09 PM

04/28/14 09:09 PM

|

Joined: May 2005

Posts: 723

Houston Tx

Uhcoog1

OP

OP

super stock

|

OP

OP

super stock

Joined: May 2005

Posts: 723

Houston Tx

|

Quote:

Did you measure the temp of the tank? I had a similar problem this year driving to MATS - boiled the fuel. I had no problems on the high speed track at willow springs. My system is (was) a return style system so it isn't quite the same as yours but I have a boxed sump in the stock tank where the -10 line goes in. The only reason I mention this is because you said that the pump got louder, my SX pump was doing the same thing, once it got loud, you only had a few minutes before it vapor locked. There were a number of people at MATS this year that had electric fuel pump issues. We had so many problems it took us 12 hours to get from LA to Vegas. Not fun. In Vegas, we added a pre supply (low pressure electric) pump right at the tank and had that feed the inlet of the main pump directly - the SX pump made no noise all the way home (9 hours). I pulled my entire external fuel system apart to replace with an in-tank pump using the corvette filter/regulator deadheaded to the engine like what you have. Seems like the in-tank pump is the only real solution to this issue.

Thanks for posting.

Any idea what contributed to your boiling fuel? It's very possible that I'm experiencing the same.

I stumbled across an aeromotive FAQ just now - almost describes my 'problem' to a T.

_____________________________________

After 30 minutes or so of driving, fuel pressure starts falling, then the fuel pump gets louder and/or seems to quit running altogether. The pump also seems hot to touch. Whatís wrong?

You may be experiencing EFI vapor lock. Fuel system hot spots, the cause of vapor lock in carbureted engines of the past, and modern EFI engines where no return line is employed, are eliminated with the use of a bypass regulator placed after the fuel rail, in the engine compartment. Still, thanks to underhood engine heat, fuel in the EFI bypass system does slowly warm up as it is recycled through the fuel rail(s) and back to the tank. The longer an EFI engine runs, the higher fuel tank temperatures can become. Unlike the more common carburetor vapor lock, where fuel is heated to boiling in the float bowl(s) or fuel line(s) under the hood, EFI vapor lock is often caused by hot fuel in the tank and/or cavitation. Excess fuel pump noise combined with fluctuating and/or falling fuel pressure, often indicate cavitation is occurring. The exact point where gasoline changes from liquid to vapor depends on its temperature and pressure. A combination of high fuel temperature and low pressure are the primary cause of cavitation. In a return style EFI fuel system, the most likely place for these conditions to exist in the same place, at the same time, is at fuel pump inlet. The most common cause of cavitation is installation error. Once cavitation starts, it will feed upon itself. As vapor enters the pump, it displaces liquid fuel required to lubricate the mechanism, allowing metal to touch metal, creating even more friction and heat. Once the pump begins to super heat, a complete vapor lock may develop. In order to prevent cavitation and vapor lock, correct fuel system design and installation are vital. Ensure inlet filters meet hi-flow, low restriction requirements and that both inlet and outlet filters are kept clean. Keep the tank full on hot days. Reduce fuel pump speed during low load, idle and cruise conditions. Carefully route fuel lines and plan component placement to avoid exhaust heat. Do not overlook proper tank ventilation, if the vent line or vent valve do not allow ample air to move freely in both directions, fuel delivery problems will never fully resolve. Any conditions that restrict the pumpís access to fuel in the tank must be addressed. Read Tech Bulletin #101, Fuel Filtration and call the Aeromotive Tech Line if you need further assistance.

________________________________

The exhaust and rear end are very close in proximity to the fuel pumps and accumulator (it's all tucked in above the exhaust and rear end, zero airflow, etc). I may do a little low-buck heat shielding to see what I can do to help. Or, maybe I will re-locate everything away from the exhaust and rear end and try to get some airflow over the fuel system.

Further, I added a vent after the first pump failed. When pulling the gas cap, a significant amount of built up pressure would release. That also supports the overheated fuel theory.

What all causes fuel heating? Obviously hot pumps, etc- but I'm wondering if restrictions on my return system could be causing an issue as well. I might need to get my hands on a fuel pressure gauge or two to see what my pressures look like at different areas of the system.

-'02 Dodge Viper Ex-World Challenge racecar

-'73 Duster, 6.1 based 392 hilborn hemi, tko600, full floater rear 9", Hellwig custom bars, viper brakes, built for road course

|

|

|

Re: Need help diagnosing fueling issue from Open Road Race

[Re: dangina]

#1613157

Re: Need help diagnosing fueling issue from Open Road Race

[Re: dangina]

#1613157

04/28/14 09:09 PM

04/28/14 09:09 PM

|

Joined: Feb 2011

Posts: 4,302

Nebraska

72Swinger

master

|

master

Joined: Feb 2011

Posts: 4,302

Nebraska

|

Someone on LX forums said the stock deadhead setup is fine to 700hp. I would run your return direct to tank, I think your current setup is creating a lot of heat, and the Carter is probably inadequate for the sustained load of the Open road deal. I like the gss340 Walbro's up to 600hp but they're an in-tank pump. After that go to a Walbro 400 or twin 340's.

Mopar to the bone!!!

|

|

|

Re: Need help diagnosing fueling issue from Open Road Race

[Re: 72Swinger]

#1613159

Re: Need help diagnosing fueling issue from Open Road Race

[Re: 72Swinger]

#1613159

04/29/14 01:13 AM

04/29/14 01:13 AM

|

Joined: Mar 2014

Posts: 40

upper So. CA

ntsqd

member

|

member

Joined: Mar 2014

Posts: 40

upper So. CA

|

How much pressure do you have between the filter and the HP pump? Some of the off-road user's of Chuck's accumulator have added a needle valve on the tank return to build some pressure in the accumulator and so that the LP pump has something to pump against and isn't free-wheeling. That will require some re-plumbing as the HP FRP's return shouldn't go thru that restriction. I know of a Holley Red that died from lack of something to push against while in the boonies. Fortunately we weren't too far from civilization and there were enough of us that a trail fix was soon remedied.

The Aeromotive thing hinted around the edges of something that I've seen to be fairly common off road. The suction side of any pump reduces the pressure on the fuel. That's obvious, what isn't so obvious is just how that affects the fuel. I looked into it once and failed to bookmark the relevant pages, but a seemingly small depression from atmospheric pressure on the fuel results in a surprisingly large lowering of the fuel's boiling point. I wish that I could recall the numbers, but as an example something like 1 psi pressure depression brought the average boiling point down to 80įF. Those aren't exact numbers, but they're surprisingly (scarily?) close!

I used to swerve around my hallucinations, now I drive right thru them.

|

|

|

Re: Need help diagnosing fueling issue from Open Road Race

[Re: ntsqd]

#1613160

Re: Need help diagnosing fueling issue from Open Road Race

[Re: ntsqd]

#1613160

04/29/14 01:14 PM

04/29/14 01:14 PM

|

Joined: May 2005

Posts: 723

Houston Tx

Uhcoog1

OP

OP

super stock

|

OP

OP

super stock

Joined: May 2005

Posts: 723

Houston Tx

|

That's good info fellas. Thanks.

I'm going to turn on the pumps and take temperature readings of different components over time. Then I'll do the same while driving. That should help determine where the excessive heat is coming from. I'll report back with results

-'02 Dodge Viper Ex-World Challenge racecar

-'73 Duster, 6.1 based 392 hilborn hemi, tko600, full floater rear 9", Hellwig custom bars, viper brakes, built for road course

|

|

|

Re: Need help diagnosing fueling issue from Open Road Race

[Re: Uhcoog1]

#1613161

Re: Need help diagnosing fueling issue from Open Road Race

[Re: Uhcoog1]

#1613161

04/29/14 05:31 PM

04/29/14 05:31 PM

|

Joined: May 2005

Posts: 723

Houston Tx

Uhcoog1

OP

OP

super stock

|

OP

OP

super stock

Joined: May 2005

Posts: 723

Houston Tx

|

Alright. Here's my data (all in degrees Fahrenheit):

0 min, 7.5-10 min, 17.5-20 min. 30 min. 40 min. 50 min. 1 hr.

Accumulator: 74.4 . 79.7. 82.0. 84.0-86.7. 84.7. 85.8. 88.1

Carter side top: 73.7. 82.7. 83.8. 82.0. 85.4. 87.0. 91.0.

Carter bottom: 75.2. 82.0. 82.9. 87.4. 84.9. 86.8. 88.7.

Tank: 75.0. 82.5. 82.9. 82.0-87.6. 84.7. 87.0. 89.7.

Walbro: 75.7. 82.0. 82.5. 83.8. 85.2. 85.4. 87.9.

Pickup: 75.2. 82.7. 83.4. 87.4. 87.0. 87.0. 87.9.

Wix: 74.3. 82.0. 82.9. 85.4. 85.8. 87.0. 88.1.

Further, at end of 1 hour, pumps still sound fine/ normal. Nothing is even warm to the touch. This is in contrast to the pumps getting louder after driving for an hour.

After I finished the test, I called Aeromotive and asked a few general questions. Here's a summary of what they told me (great help line, btw- will definitely bring them business in the future).

1- EPA regulations require minimal cranking when starting. Hence winter blend fuel has a higher concentration of lower boiling products in the blend.

2- 120* or less is a good rule of thumb to keep fuel temp under. Problems begin around 130-140* for a well designed fuel system.

3- most of the heat isn't generated by the pump(s) but instead by engine compartment, etc

4- ANY vacuum suction on inlet of pump drastically reduces the boiling point of the fuel at that point.

Also, he said they run a1000 pumps continuously on 3 gallon tanks and never generate enough heat to cavitate a pump.

-'02 Dodge Viper Ex-World Challenge racecar

-'73 Duster, 6.1 based 392 hilborn hemi, tko600, full floater rear 9", Hellwig custom bars, viper brakes, built for road course

|

|

|

Re: Need help diagnosing fueling issue from Open Road Race

[Re: Uhcoog1]

#1613162

Re: Need help diagnosing fueling issue from Open Road Race

[Re: Uhcoog1]

#1613162

04/29/14 06:56 PM

04/29/14 06:56 PM

|

Joined: Feb 2011

Posts: 4,302

Nebraska

72Swinger

master

|

master

Joined: Feb 2011

Posts: 4,302

Nebraska

|

One thing besides heat that will kill an inline pump, other than a Weldon pump, is having either air in the inlet side or a restriction in the inlet side. That will make the temp spike right now and kill a pump quick. Before you invest to much in another pump Wade seriously consider going to an in-tank setup IMO.

Mopar to the bone!!!

|

|

|

Re: Need help diagnosing fueling issue from Open Road Race

[Re: 72Swinger]

#1613163

Re: Need help diagnosing fueling issue from Open Road Race

[Re: 72Swinger]

#1613163

04/29/14 09:00 PM

04/29/14 09:00 PM

|

Joined: May 2005

Posts: 723

Houston Tx

Uhcoog1

OP

OP

super stock

|

OP

OP

super stock

Joined: May 2005

Posts: 723

Houston Tx

|

Quote:

One thing besides heat that will kill an inline pump, other than a Weldon pump, is having either air in the inlet side or a restriction in the inlet side. That will make the temp spike right now and kill a pump quick. Before you invest to much in another pump Wade seriously consider going to an in-tank setup IMO.

I can agree with that. But I'm not willing to put an in-tank pump in a factory tank. So if I can't get it done with my current components and a minimal monetary investment, then I'll probably purchase a fuel safe fuel cell and put a surge tank in it with an in-tank pump. But that's probably $1500+ when it's all said and done, so I'm going to try everything with my current components before I jump down that rabbit hole.

-'02 Dodge Viper Ex-World Challenge racecar

-'73 Duster, 6.1 based 392 hilborn hemi, tko600, full floater rear 9", Hellwig custom bars, viper brakes, built for road course

|

|

|

Re: Need help diagnosing fueling issue from Open Road Race

[Re: Uhcoog1]

#1613164

Re: Need help diagnosing fueling issue from Open Road Race

[Re: Uhcoog1]

#1613164

04/30/14 12:04 PM

04/30/14 12:04 PM

|

Joined: May 2005

Posts: 723

Houston Tx

Uhcoog1

OP

OP

super stock

|

OP

OP

super stock

Joined: May 2005

Posts: 723

Houston Tx

|

More data.

Did a running test this morning. Outdoor temp was 55 degrees (vs 95 degrees at race where I had the issue).

Temps taken at 0 min, after 10 min warmup, after 10 min hard run (4k-6k in 2nd gear back and forth at full throttle and braking for 10 min).

Accumulator: 76.2. 89. 107(93 within 3 min of sitting)

Carter: 76.2. 94. 113.

Muffler: 76.6. 220. 404. (220 within 3 min of sitting)

Rear: 76.6. 103. 143.

Based on the data, I'm positive heat shielding between the muffler/rear end and fuel system will solve my issue.

-'02 Dodge Viper Ex-World Challenge racecar

-'73 Duster, 6.1 based 392 hilborn hemi, tko600, full floater rear 9", Hellwig custom bars, viper brakes, built for road course

|

|

|

Re: Need help diagnosing fueling issue from Open Road Race

[Re: Uhcoog1]

#1613165

Re: Need help diagnosing fueling issue from Open Road Race

[Re: Uhcoog1]

#1613165

04/30/14 01:13 PM

04/30/14 01:13 PM

|

Joined: Nov 2005

Posts: 3,456

Fly Over States

PHJ426

master

|

master

Joined: Nov 2005

Posts: 3,456

Fly Over States

|

http://www.bangshift.com/forum/forum/ban...oblem-or-nothat What was your fuel level at race day? You might have mentioned earlier, is there any baffling in your fuel tank and its being drawn from the factory pickup tube? At your given level of performance level and track configuration is it a possibility of actually aerating the fuel?

|

|

|

Re: Need help diagnosing fueling issue from Open Road Race

[Re: PHJ426]

#1613166

Re: Need help diagnosing fueling issue from Open Road Race

[Re: PHJ426]

#1613166

04/30/14 02:30 PM

04/30/14 02:30 PM

|

Joined: May 2005

Posts: 723

Houston Tx

Uhcoog1

OP

OP

super stock

|

OP

OP

super stock

Joined: May 2005

Posts: 723

Houston Tx

|

Quote:

http://www.bangshift.com/forum/forum/ban...oblem-or-nothat

What was your fuel level at race day? You might have mentioned earlier, is there any baffling in your fuel tank and its being drawn from the factory pickup tube?

At your given level of performance level and track configuration is it a possibility of actually aerating the fuel?

Fuel level was ~5-6 gallons in the tank at that point in the race. I've run it lower on a road course with no ill effects (3-4 gallons), and even lower on the street (I've run it out of fuel before, and didn't have any issues until I actually ran out - I was looking for the lower limit). This is a 16 gallon tank, and I try to keep it between 4 gallons and 14 gallons for overly spirited driving. For this race, I believe I burned about 7 gallons (total =13-14 gallons) on the Southbound leg, then put 8 gallons (total = 14-15 gallons) in the tank for the return trip (i.e. - I had more gas in the tank when the problem occurred vs the previous trip southbound)

There is zero baffling in the stock tank. Carter 4600HP is drawing through the factory pickup location (1/2" pickup). Sock on pickup in tank.

Aeration is an interesting concern. I'm fairly confident that any aeration will work it's way to the top of the accumulator/filter, and be sent back to the main tank. The return is through the same factory pickup location with a twist - I have a T fitting on it that forces the returned fuel to the sides, as opposed to up, down, or straight in. I figured that was my best option for keeping the returned fuel from upsetting the fuel sitting at or around the pickup.

Some guys make accumulator tanks that have their inputs off-center and call the accumulator tanks 'swirl pots'. That's supposed to help avoid aeration.

At this point I think it was just the 'perfect storm' conditions for my fuel system. Winter grade 91 octane, 95* temps, high load for 59 miles = extra hot exhaust, 3000 ft elevation with 5000 ft density altitude, low enough fuel level to not be able to handle all the heat, minimal airflow around fuel system, close proximity to exhaust, etc etc.

In addition to the heat shielding, I'll probably run a full tank on both legs, and might go ahead and use 104 unleaded octane (or mix some in) for the run (should have a higher spectrum of boiling points vs 91 winter grade).

-'02 Dodge Viper Ex-World Challenge racecar

-'73 Duster, 6.1 based 392 hilborn hemi, tko600, full floater rear 9", Hellwig custom bars, viper brakes, built for road course

|

|

|

Re: Need help diagnosing fueling issue from Open Road Race

[Re: Uhcoog1]

#1613167

Re: Need help diagnosing fueling issue from Open Road Race

[Re: Uhcoog1]

#1613167

04/30/14 04:31 PM

04/30/14 04:31 PM

|

Joined: Feb 2005

Posts: 28,312

Cincinnati, Ohio

Challenger 1

Too Many Posts

|

Too Many Posts

Joined: Feb 2005

Posts: 28,312

Cincinnati, Ohio

|

Quote:

Quote:

Did you measure the temp of the tank? I had a similar problem this year driving to MATS - boiled the fuel. I had no problems on the high speed track at willow springs. My system is (was) a return style system so it isn't quite the same as yours but I have a boxed sump in the stock tank where the -10 line goes in. The only reason I mention this is because you said that the pump got louder, my SX pump was doing the same thing, once it got loud, you only had a few minutes before it vapor locked. There were a number of people at MATS this year that had electric fuel pump issues. We had so many problems it took us 12 hours to get from LA to Vegas. Not fun. In Vegas, we added a pre supply (low pressure electric) pump right at the tank and had that feed the inlet of the main pump directly - the SX pump made no noise all the way home (9 hours). I pulled my entire external fuel system apart to replace with an in-tank pump using the corvette filter/regulator deadheaded to the engine like what you have. Seems like the in-tank pump is the only real solution to this issue.

Thanks for posting.

Any idea what contributed to your boiling fuel? It's very possible that I'm experiencing the same.

I stumbled across an aeromotive FAQ just now - almost describes my 'problem' to a T.

_____________________________________

After 30 minutes or so of driving, fuel pressure starts falling, then the fuel pump gets louder and/or seems to quit running altogether. The pump also seems hot to touch. Whatís wrong?

You may be experiencing EFI vapor lock. Fuel system hot spots, the cause of vapor lock in carbureted engines of the past, and modern EFI engines where no return line is employed, are eliminated with the use of a bypass regulator placed after the fuel rail, in the engine compartment. Still, thanks to underhood engine heat, fuel in the EFI bypass system does slowly warm up as it is recycled through the fuel rail(s) and back to the tank. The longer an EFI engine runs, the higher fuel tank temperatures can become. Unlike the more common carburetor vapor lock, where fuel is heated to boiling in the float bowl(s) or fuel line(s) under the hood, EFI vapor lock is often caused by hot fuel in the tank and/or cavitation. Excess fuel pump noise combined with fluctuating and/or falling fuel pressure, often indicate cavitation is occurring. The exact point where gasoline changes from liquid to vapor depends on its temperature and pressure. A combination of high fuel temperature and low pressure are the primary cause of cavitation. In a return style EFI fuel system, the most likely place for these conditions to exist in the same place, at the same time, is at fuel pump inlet. The most common cause of cavitation is installation error. Once cavitation starts, it will feed upon itself. As vapor enters the pump, it displaces liquid fuel required to lubricate the mechanism, allowing metal to touch metal, creating even more friction and heat. Once the pump begins to super heat, a complete vapor lock may develop. In order to prevent cavitation and vapor lock, correct fuel system design and installation are vital. Ensure inlet filters meet hi-flow, low restriction requirements and that both inlet and outlet filters are kept clean. Keep the tank full on hot days. Reduce fuel pump speed during low load, idle and cruise conditions. Carefully route fuel lines and plan component placement to avoid exhaust heat. Do not overlook proper tank ventilation, if the vent line or vent valve do not allow ample air to move freely in both directions, fuel delivery problems will never fully resolve. Any conditions that restrict the pumpís access to fuel in the tank must be addressed. Read Tech Bulletin #101, Fuel Filtration and call the Aeromotive Tech Line if you need further assistance.

________________________________

The exhaust and rear end are very close in proximity to the fuel pumps and accumulator (it's all tucked in above the exhaust and rear end, zero airflow, etc). I may do a little low-buck heat shielding to see what I can do to help. Or, maybe I will re-locate everything away from the exhaust and rear end and try to get some airflow over the fuel system.

Further, I added a vent after the first pump failed. When pulling the gas cap, a significant amount of built up pressure would release. That also supports the overheated fuel theory.

What all causes fuel heating? Obviously hot pumps, etc- but I'm wondering if restrictions on my return system could be causing an issue as well. I might need to get my hands on a fuel pressure gauge or two to see what my pressures look like at different areas of the system.

Seems like the in-tank pump is the only real solution to this issue.

This is true, external electric fuel pumps are not the answer, no matter how tricked out it is.

|

|

|

Re: Need help diagnosing fueling issue from Open Road Race

[Re: Uhcoog1]

#1613170

Re: Need help diagnosing fueling issue from Open Road Race

[Re: Uhcoog1]

#1613170

04/30/14 06:46 PM

04/30/14 06:46 PM

|

Joined: Feb 2011

Posts: 4,302

Nebraska

72Swinger

master

|

master

Joined: Feb 2011

Posts: 4,302

Nebraska

|

A problem I had once was with push-n-lok hoses and I was burning up pumps. Come to find out I had a line on the suction side that basically had a one way check valve in it because upon hose assembly, with ALOT of oil, the fricken fitting turned into a potato peeler and peeled up the inner lining of the cheap push-n-lok hose. So if you blew through the line from the pump end it was all good but upon suction it would shut itself. This happened with all FAST supplied hoses and fittings. I was so pissed I sent it all back and luckily they refunded it all. Been in-tank ever since and will NEVER EVER RUN push-n-lok again.

Mopar to the bone!!!

|

|

|

|

|