I haven't posted anything in awhile but I'm still working on some things. I started working on the engine last month. I think I mentioned earlier that the short block is a MP piece I bought back in 2000. The short blocks were made from reconditioned non Magnum roller blocks. It's the 10 to 1 compression version. I believe there was also a 9 to 1 version. The engine has been sitting since 2004 or 2005.

I previously ran a Weiand X-cellerator single plane intake on the engine. Last fall I bought an Edelbrock RPM Air-Gap for it. I pulled the Weiand and started mocking up the intake and carb but ran into an issue. The secondaries on the carb would hit the intake. It looked like the intake was cast wrong. After talking with tech support a few times, they had me send the intake in for them to look at. They ended up sending me a new intake but by that time it was the middle of winter and I had moved on to other things.

Last month I moved the engine over to my place. I pulled the plastic off the engine and found a mouse next in the valley. The nest was made from grass clippings so I knew it hadn't been there long. It wasn't there last fall when I was test fitting the new intake. I vacuumed up the nest and put the engine on the stand. I pulled the heads, water pump and front cover.

I didn't want to spin the engine on the stand incase there was crap in the pan. I pulled the pan with the engine upright and removed the windage tray. Sure enough, there were some grass clippings and mouse foot prints on the tray. There wasn't much of anything in the pan though. I think I got lucky and caught it early.

Other then the nest, the engine looked really good inside. Everything still looked clean without any rust from sitting.

Then came the task of cleaning up the block. There were a couple layers of orange paint and layers of dirt, saw dust and oil to remove. What a nasty, crappy job that was. I think it took at least four cleanings to get everything off. Even after wearing gloves and goggles, some paint stripper would end up on my skin and start burning. I'm glad that job is over!

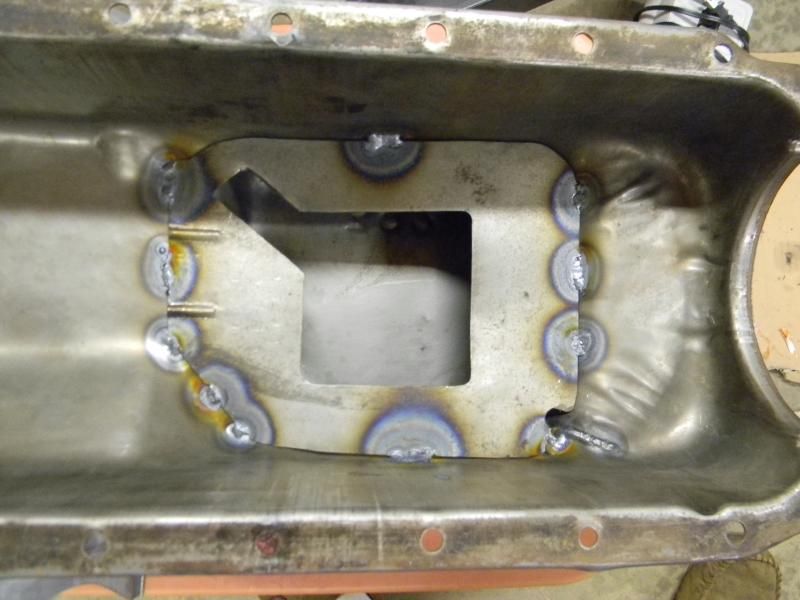

I installed the timing cover and put a new water pump on. Then I primed the everything. After that I moved on to the oil pan. The pan that was on the engine had seen better days. The sides were heavily pitted and would have taken a lot of work to refinish. A friend of mine had a 360 pan he wasn't using so he donated it to the cause. I saw and old Car Craft article on making a baffle for the stock oil pan. It didn't look too difficult so I thought I'd give it a try. I made a template out of card board and taped it onto the pan. I test fit it a few times onto the engine to make sure it cleared the pickup tube, then I transferred the template to a piece of metal.

I taped the metal baffle to the pan and test fit again. So far so good. I had clearance around the pickup tube and nothing was hitting.

I soaked the baffle in EvapoRust and then added some drain back slots.

Here is the baffle welded in place. It works really good on deceleration but doesn't seem to do much on acceleration. I could have gotten the clearances tighter to the pickup tube if I would have had a bare block to test fit it on. I would have been able to look down through an empty cylinder and see how close it came to hitting. The pan isn't installed yet so I guess I could still add some metal around the back if I found someone local with a bare block I could borrow.

That's all the progress I have on the engine right now. I need to take the heads in and have them looked at. They only have a few hundred miles on them but I did the valve job and guides when I was in school. I want someone to double check my work so I don't have any issues down the road. I also need to get the intake surface of the heads milled down a little so the intake sits a little lower on the engine. I could barely get the intake bolts started when I was test fitting things.