Car has had OD for several years, went EFI in early 2009:

http://www.theturboforums.com/smf/index.php?topic=119842.0This is an abridged version of the nearly complete build from tmf:

been learning with that and learning to be a daddy since then. Now it's time to pressurize the intake. Going to use my turbocoupe T3 60 trim .63 a/r's and hope for a very responsive street car that doesn't choke too bad to 5000rpm. Will be using twin turbosmart 38's instead of any internal gates, both for packaging and for hopefully better control/less choking.

AF helps me get a good flange on the rv/van manifolds

Big Brown Truck

AF and Shaun got me out of a jam helping to bust the turbine housings free and get the broken off bolts out:

This update brought to you by the letter U

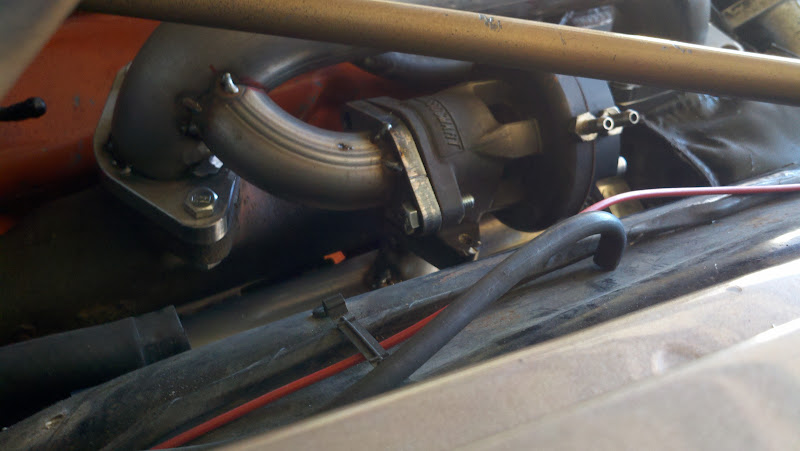

On the bracket for first test fit

Dang, that's higher than I expected it to be....

I made a very simple bracket that put the turbo in a great place in free space, but it's too high, the pipe from the mani would be right at the hood with it closed. This is with 3" radius 2.25" pipe.

It's almost like Plymouth thought a turbo should sit right there :2thumbs: But it looks like I may need to extend that cutout several inches further back. Also looks like I need to either cut and bend down or trim off some of the lower part of the inner well for the dp to get by the mani. To drop the turbo down it needs to go outboard to avoid the alternator (or I need to relocate the alt). I have room to swing the alt down and use a shorter belt, but I'm a little concerned about belt engagement then, esp if I keep the rv2, it gets tugged pretty hard. Outboard means enlarging that dimple in the well.

Might be able to switch to a 1.5" radius weld ell for the bend, starts to look a little frankenstein with pipe and ell though

Took the day off to work on the car....I'm a slow fabricator, not much to show for 5 hours of work. But, I didn't waste any metal, so that's something I guess.

time for a trim....the air hammer made quick work of it.

Alt may need to move to keep it from burning up. I've got blankets on the way, we'll see. AF and I looked at dropping it way down, but I'd need to redo all the belts then and get the waterpump and ps on the same belt.

was able to drop the turbo down 1.5" or so once I decided I was ok with cutting the well. I've got a couple spares at the shop if for some reason I would go back stock.

First suitcase handle

and as it turns out, room for the WG underneath

A couple questions about the WG, will the diaphragm live in there? I plan on wrapping both the 'handle' and the manifold. Is teeing off a 90* off the beginning of the 'handle' an ok spot? There's no room to go at less than 90*.

Started to look at the dp but ran out of time. Where the turbo is now makes it simpler though, it's ~1' straight shot then hopefully a 45* down and another to get out to the existing pipes.

Another day off work, a little more progress. Both dp's are now complete, but I need to spot weld them together and refit. Also need to add another v band into the driver's side one- in 1 piece it won't go in the car from the top or bottom. I think it would if I put the dp in first, then installed the manifold, then the turbo, but that's a real pain.

dr's side dp

bottom part of the pass dp

CASUALTY!!! Tape came loose on the dp just as I was pulling it up out of the car and chipped the paint. Ugh. There's 2 other chips on that side, and the paint was done in 1999, but it still sucks.

another day, some more mistakes :P

lowered feed pipe

cut a hole and then regretted it, routing the air around the wrong way. I will redo this

and do it like this

Was suggested to try it up here, there's room for it but I think I'd rather keep the package tight

So close to having the hot sides all done, hit a snag getting the driver's side dp aligned that kept me from getting the wg on that side done, but it's close. It all needs to be finish welded, painted, and wrapped of course.

Will this cook the alt with the blanket on?

Pass wg rerouted and wrong hole patched up

driver's side upper down pipe, had to split both down pipes (and of course not in between existing pieces, had to make more cuts to get them located in a place they fit and could be reached) as neither would install as 1 piece into the car from the top or bottom

driver's side lower down pipe

pass side down pipe

The driver's side wg is close, have both holes cut and both pipes cut, just need to do some more trimming to fit them. Then finish weld, including a few joints that need some gaps filled in. I had been hoping to make a May 22nd Mopar show about 10min from my house, not sure that's going to happen.....maybe without the sanden a/c conversion done and the pipes only welded, not painted and wrapped. Having not done and real welding for years, I'm finding myself to be very inconsistent. Some of the stuff I've done on this is very passable, some of it laughable :doh: