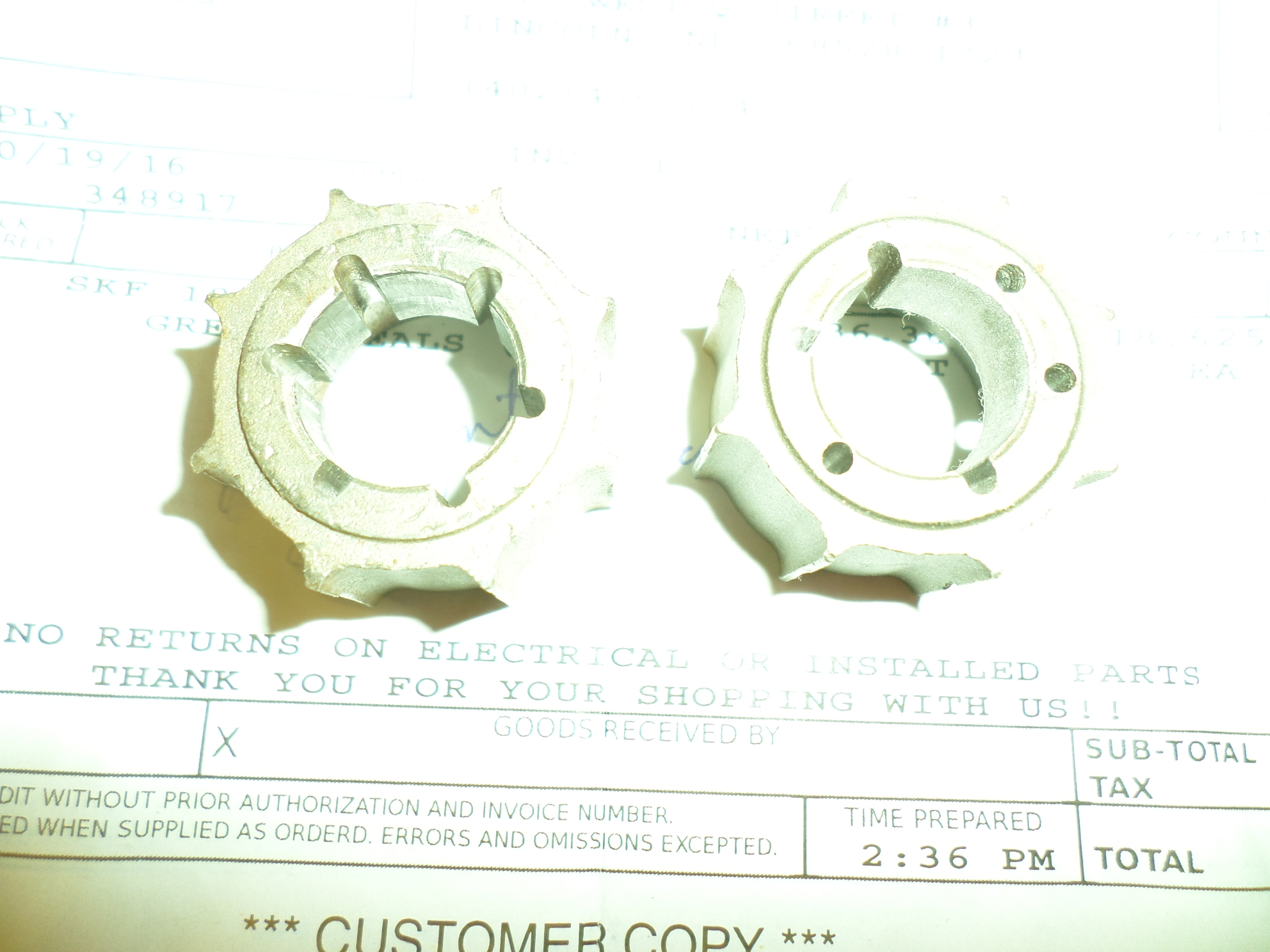

Here's a pic of one of Andys' masterpieces. I don't think they are still available but you can redrill yours. here is one I started way back. drill to 3/32 then open it up to the ID with a mini rattail file. with carefull measureing you only need (1) new hole for the roll pin. at rest you want the leading edge of the rotor blade to be just at the edge of the cap terminal so when vacuum advance shifts the phasing you have maximum contact distance thruout the vac adv arm travel. A 11 deg can for instance will shift the rotor (phasing) .270" around the arc, CCW on a SB and CW on a BB. The cap terminal (brass is better than aluminum) is .214" wide and the rotor blade terminal is .244" wide. You want the rotor to be in close proximity to the cap terminal when at rest/zero vacuum (pull/cap the line at idle if on manifold) cuz that is where the rotor will be at WOT when the required voltage is the greatest and the available voltage is the lowest. EDIT Also you want the rotor blade tip to be as close as .015 to the dist cap terminal. NAPA has an Echlin rotor (MO3000) that has an .060" longer blade for $8 & change. and that might not be long enough & if not you can drill out the rivet & make your own blade. MORE EDIT keep the edges of the rotor/cap terminals sharp as it takes less voltage to jump from sharp surfaces than it does smooth(er) ones. Use a point file or a dremel tool

Last edited by RapidRobert; 10/28/16 01:01 PM. Reason: bored