Posted By: 71birdJ68

Distributor Phasing - 10/24/16 02:41 PM

I have heard about this before, and wondered exactly what it is, and is it really needed on a street engine.

Posted By: jbc426

Re: Distributor Phasing - 10/24/16 05:35 PM

It depends if the street motor's distributor is out of phase or not. It will cost you a distributor cap to check it out. Drill a hole between the coil tower and the #1 cylinder tower, and shine your timing light in there.

Posted By: RapidRobert

Re: Distributor Phasing - 10/24/16 05:56 PM

Rotor Phasing (my baby). what JBC said, drill a 1/2" hole in the top dist cap flat 2/3 of the way between the center post and the #1 post & shine your light down in there with it running & see how it is clocked in relation to the cap terminal. try it with vac advance (above idle if on ported) and with the vac can hose off and plugged. Holler back with what you find & we can go from there if it needs to be adjusted

Posted By: AndyF

Re: Distributor Phasing - 10/24/16 07:09 PM

It can be a problem with the MP distributors. I figured this out a few years back and ended up reworking the reluctor in order to fix it.

On my setup the rotor wasn't pointed directly at the tower when the ignition fired. Then when the vacuum advance rotated the assembly the rotor would swing far enough over that the spark would jump to the wrong tower.

I was able to solve it by machining the reluctor in order to put the rotor on the other side of the tower with no vacuum. Then when the vacuum advance kicked in the rotor only swung from one side of the tower to the other side and it never got close to the wrong tower.

Posted By: jbc426

Re: Distributor Phasing - 10/24/16 09:22 PM

This might be worth mentioning to someone out there. My Billet MSD distributor had a bad case of incorrect phasing. I was able to bring it into spec using the adjustable rotor kit from MSD.

I happened to mention this to our local smart guy who is our go to guy for EFI set-ups, and he told me that MSD sent out a bunch of the Billet Dizzy's with the wires plugged in swapped. I looked and the colors were swapped/ I popped them out of the distributor plug-in and swapped them. Sure enough, they were placed in the plug-in wrong from MSD.

I'm back to a regular rotor now, and the car no longer does a compression stall at first crank-over. I used to have to almost always had to always have to hit the starter twice once the motor was warm.

Posted By: John Brown

Re: Distributor Phasing - 10/25/16 01:31 AM

The reversed wire thing on MSD's was the hot news tip in the pits back around 2002, but pretty much swept under the rug at MSD. Had major problems with a MSD retarding big time instead of advancing. Local warehouse sales rep suggested swapping the wires and problem was cured. No idea where he got the information from or how many he shared it with, but it was a life saver.

Posted By: RapidRobert

Re: Distributor Phasing - 10/25/16 02:02 AM

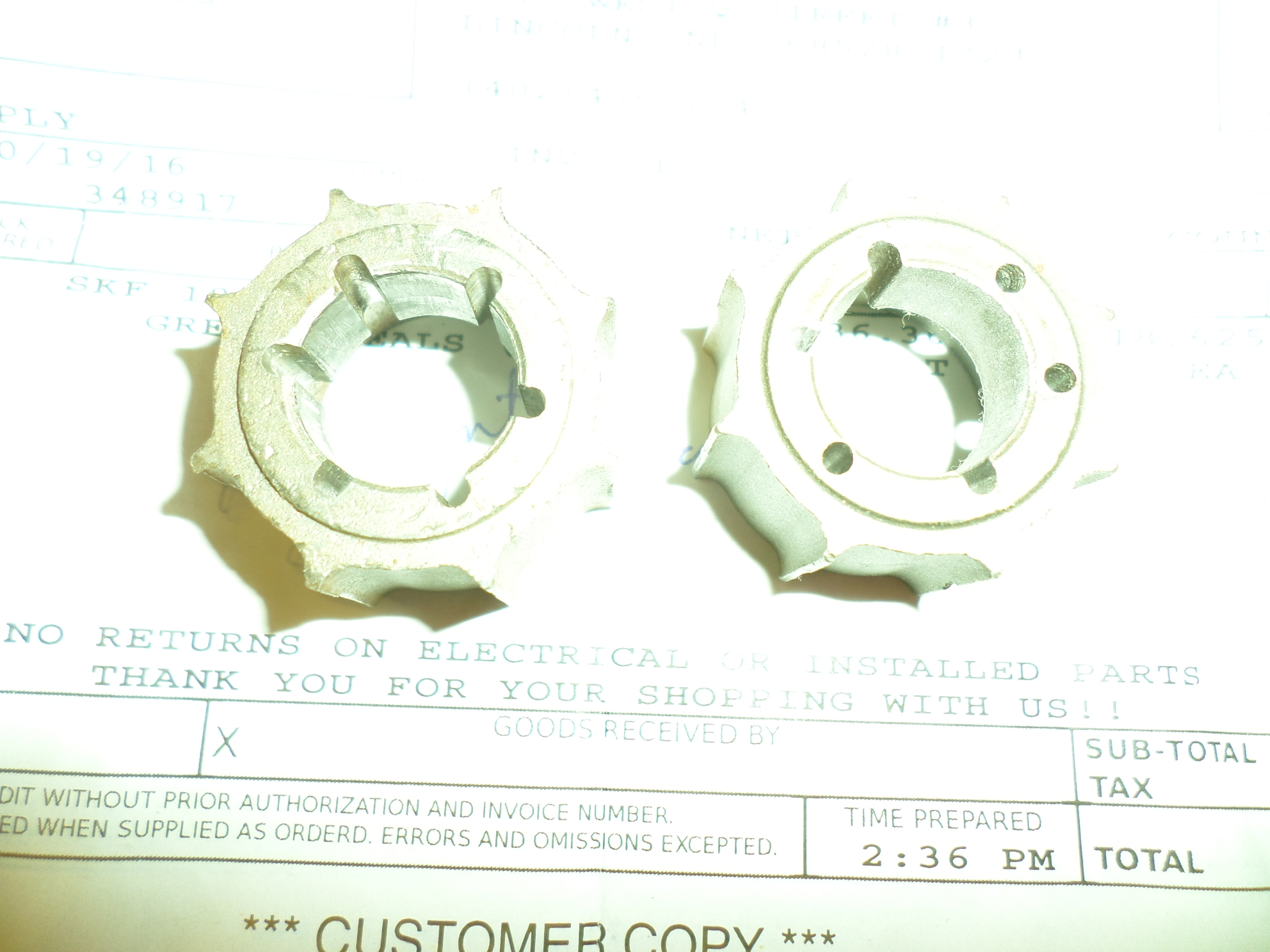

Here's a pic of one of Andys' masterpieces. I don't think they are still available but you can redrill yours. here is one I started way back. drill to 3/32 then open it up to the ID with a mini rattail file. with carefull measureing you only need (1) new hole for the roll pin. at rest you want the leading edge of the rotor blade to be just at the edge of the cap terminal so when vacuum advance shifts the phasing you have maximum contact distance thruout the vac adv arm travel. A 11 deg can for instance will shift the rotor (phasing) .270" around the arc, CCW on a SB and CW on a BB. The cap terminal (brass is better than aluminum) is .214" wide and the rotor blade terminal is .244" wide. You want the rotor to be in close proximity to the cap terminal when at rest/zero vacuum (pull/cap the line at idle if on manifold) cuz that is where the rotor will be at WOT when the required voltage is the greatest and the available voltage is the lowest. EDIT Also you want the rotor blade tip to be as close as .015 to the dist cap terminal. NAPA has an Echlin rotor (MO3000) that has an .060" longer blade for $8 & change. and that might not be long enough & if not you can drill out the rivet & make your own blade. MORE EDIT keep the edges of the rotor/cap terminals sharp as it takes less voltage to jump from sharp surfaces than it does smooth(er) ones. Use a point file or a dremel tool

Posted By: Skeptic

Re: Distributor Phasing - 10/25/16 02:56 AM

I bought mine on E-bay, E-booger was selling them.

Posted By: AndyF

Re: Distributor Phasing - 10/25/16 03:49 AM

Yep, I made a ton of those for Eberg and then the supply dried up as Mopar Performance shut down production.

Posted By: 383man

Re: Distributor Phasing - 10/25/16 03:12 PM

I always figured the newer electronic units that use a dist that advance and retard timing by the unit and not by the dist will be more problems since they advance and retard timing without the dist rotor and reluctor moving in relationship to the dist shaft and timing advance. So the fully electronic units using a dist will move timing without the rotor and reluctor moving their posistion related to timing advance or retard. So if its a locked dist with no advance in it and the rotor lines up with the cap tower at say 10 degrees before TDC when the unit advances the timing to say 35 degrees before TDC the rotor still lines up at 10 degrees before TDC but the coil is firing when the rotor is at 35 degrees before TDC which is now 25 degrees sooner. How much farther away from the cap tower is the rotor now and how close is it to another cap terminal ? Close enough to fire the wrong cyl ? At least with a mech advance dist the rotor and reluctor will keep the same posistion with the cap tower.

I guess if your car runs good with no ign problems should you worry about it ? Its nice that we now have coil packs and coil-on-plug units to eliminate dist phasing on fully electronic units. Ron