It could take a fairly simple rig to test the compliance of the K, however accurately representing loads applied from the engine, steering and suspension could be fairly entertaining.

I completely disagree ("simple"), and 100% agree ("accurately representing" and "entertaining". I would welcome this exercise, and any knowledge that may be found to be useful. How useful, I have no idea.

There might have been something lost in translation here. With the original post in mind, referencing,

....I'll build a rig and do a test to compare rigidity.

is where I was referring to a fairly simple rig

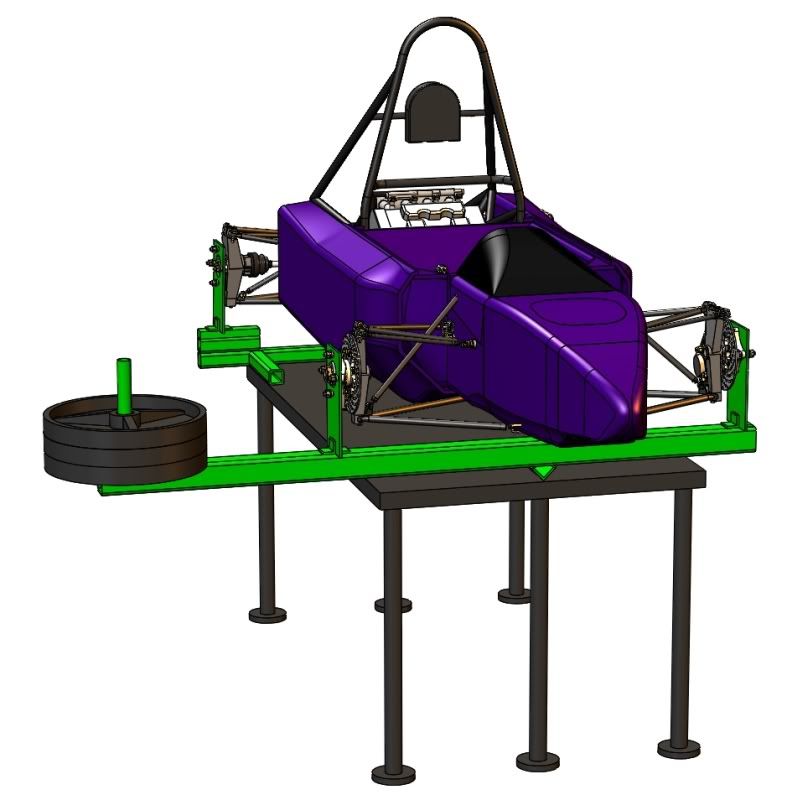

could be required. Something like torsional rigidity with a static load applied across the frame mounts would not be complicated, in fact, simple. Long "infinitely stiff" moment arm and apply a weight while the other side is constrained. Constrained to something like the couple thousand pound lathe that resides in Feet's shop.

One could deduct K-A is X% more compliant than K-B, given this simple, very repeatable test with minimal variation. That may, or may not, be very useful data, but data nonetheless.

Where I was referencing testing real loads through the K as "entertaining" was a sarcastic twist for not easily done. Such as,

"it'd be entertaining to mow your lawn with a pair of scissors"

Possible, but likely more complicated than it was worth. In other words, I agree, it would not be easily done. Depending on the fidelity of the information that is expected from the test would determine the required testing rigs.

FSAE teams have been using very simple test rigs to determine their chassis deg/ft-lb torsional stiffness to compare against FEA results. Something similar was my basis for a "simple" k-member rig.