|

Re: 430" small block build

[Re: BobR]

#912702

Re: 430" small block build

[Re: BobR]

#912702

01/26/11 08:35 PM

01/26/11 08:35 PM

|

Joined: Oct 2004

Posts: 8,165

Left Coast

BobR

master

|

master

Joined: Oct 2004

Posts: 8,165

Left Coast

|

Quote:

Quote:

care to comment on the side loading - side discussion here then?

dealing with the long stroke at almost 10 grand has to show you alot if there was an issue.

No issue at all. Of course we rebuild our motor about every 30-40 passes.

You guys are talking about a 4.25" stroke. We couldn't put that much stroke in our Ford motor due to rod to cam clearance. Read that we don't have enough. We have to slightly grind the big end of the rods for 4.09 stroke.

|

|

|

Re: 430" small block build

[Re: BobR]

#912703

Re: 430" small block build

[Re: BobR]

#912703

01/26/11 08:37 PM

01/26/11 08:37 PM

|

Joined: Dec 2009

Posts: 1,074

detroit, mi

POS Dakota

super stock

|

super stock

Joined: Dec 2009

Posts: 1,074

detroit, mi

|

Quote:

Quote:

care to comment on the side loading - side discussion here then?

dealing with the long stroke at almost 10 grand has to show you alot if there was an issue.

No issue at all. Of course we rebuild our motor about every 30-40 passes.

And here I am complaining if I have to rebuild mine in a year.

|

|

|

Re: 430" small block build

[Re: Devilbrad]

#912704

Re: 430" small block build

[Re: Devilbrad]

#912704

01/26/11 09:07 PM

01/26/11 09:07 PM

|

Joined: Jan 2003

Posts: 9,881

Weddington, N.C.

Streetwize

master

|

master

Joined: Jan 2003

Posts: 9,881

Weddington, N.C.

|

Closest comparison I can hands on relate to is I've built a number of Mitsu turbos to about 2Bar or ~30psi. Mitsubishi 4g63's have short rods ~(1.6 IIRC) and long strokes too and (believe it or not) can make close to the same (4-5 HP/cube) and RPM as BobR's Ford. Side loading primarily leads to accelerated ring and bore wear, (the durability "issue") and obviously that builds HEAT, scuffing of the pistons/bores can happen in ANY motor if the oil film breaks down/cokes and the engine load is high enough for long enough. Excessive side loading?, obviously not....I would only define Excessive as leading to damage and/or loss of power. But more side loading than an equivalent displacement 430" shorter stroke motor, definately. Not excessive but maybe significantly closer to it.... Those dart blocks have mega-thick walls compared to OEM, thinner bores move around more than thick ones. bobR, do you have the 302 or cleveland Mains? Just curious. On a 9.5" deck windsor the big end of the rods do get up in the cam at anything over about 4" with steel rods, I have a 4.17" stroke 427 and also had to relieve the big ends and run a reduced base circle cam. the proximity is something you try not to think about when you're

Last edited by Streetwize; 01/26/11 09:19 PM.

|

|

|

Re: 430" small block build

[Re: BobR]

#912705

Re: 430" small block build

[Re: BobR]

#912705

01/26/11 10:34 PM

01/26/11 10:34 PM

|

Joined: Feb 2003

Posts: 12,675

Columbia, CT

moper

I Live Here

|

I Live Here

Joined: Feb 2003

Posts: 12,675

Columbia, CT

|

Quote:

You guys are talking about a 4.25" stroke. We couldn't put that much stroke in our Ford motor due to rod to cam clearance. Read that we don't have enough. We have to slightly grind the big end of the rods for 4.09 stroke.

Bob, on other forums I've commented (and questioned) the combination of this low rod to stroke ratio on this package in regard to ring seal and ultimately life span... Any comment on a 1.3 compression height and 1.5 R/S? My assertion is that it should be expected to live a shorter life than a 4" arm and that the gain in power for that little more stroke isnt worth the expense.

Well, art is art, isn't it? Still, on the other hand, water is water! And east is east and west is west and if you take cranberries and stew them like applesauce they taste much more like prunes than rhubarb does. Now, uh... Now you tell me what you know.

|

|

|

Re: 430" small block build

[Re: moper]

#912706

Re: 430" small block build

[Re: moper]

#912706

01/26/11 11:29 PM

01/26/11 11:29 PM

|

Joined: Aug 2003

Posts: 11,179

Atco NJ

DJVCuda

OP

OP

I Live Here

|

OP

OP

I Live Here

Joined: Aug 2003

Posts: 11,179

Atco NJ

|

Quote:

Bob, on other forums I've commented (and questioned) the combination of this low rod to stroke ratio on this package in regard to ring seal and ultimately life span... Any comment on a 1.3 compression height and 1.5 R/S? My assertion is that it should be expected to live a shorter life than a 4" arm and that the gain in power for that little more stroke isnt worth the expense.

while i wont comment on the CH, RS ratio or any balancer issues ( LOL) I will tell you that I put the BPE crank, Pistons and compstar rods together cheaper then a 4" stock mopar rod sized combo - rod's pistons come with pins and rings and it was in fact cheaper then a standard 4" stroker combo.

|

|

|

Re: 430" small block build

[Re: DJVCuda]

#912707

Re: 430" small block build

[Re: DJVCuda]

#912707

01/26/11 11:42 PM

01/26/11 11:42 PM

|

Joined: Apr 2008

Posts: 333

So. Jersey

Somerdale Flash

enthusiast

|

enthusiast

Joined: Apr 2008

Posts: 333

So. Jersey

|

Quote:

Quote:

Bob, on other forums I've commented (and questioned) the combination of this low rod to stroke ratio on this package in regard to ring seal and ultimately life span... Any comment on a 1.3 compression height and 1.5 R/S? My assertion is that it should be expected to live a shorter life than a 4" arm and that the gain in power for that little more stroke isnt worth the expense.

while i wont comment on the CH, RS ratio or any balancer issues ( LOL) I will tell you that I put the BPE crank, Pistons and compstar rods together cheaper then a 4" stock mopar rod sized combo - rod's pistons come with pins and rings and it was in fact cheaper then a standard 4" stroker combo.

Nice!

|

|

|

Re: 430" small block build

[Re: moper]

#912709

Re: 430" small block build

[Re: moper]

#912709

01/27/11 12:45 AM

01/27/11 12:45 AM

|

Joined: Oct 2004

Posts: 8,165

Left Coast

BobR

master

|

master

Joined: Oct 2004

Posts: 8,165

Left Coast

|

Quote:

Quote:

You guys are talking about a 4.25" stroke. We couldn't put that much stroke in our Ford motor due to rod to cam clearance. Read that we don't have enough. We have to slightly grind the big end of the rods for 4.09 stroke.

Bob, on other forums I've commented (and questioned) the combination of this low rod to stroke ratio on this package in regard to ring seal and ultimately life span... Any comment on a 1.3 compression height and 1.5 R/S? My assertion is that it should be expected to live a shorter life than a 4" arm and that the gain in power for that little more stroke isnt worth the expense.

Dave,

We ask our motor to live 30-40 runs so longevity isn't in the equation. Since there are other aspects of the piston/rod/stroke that are much more critical to making power we don't even concern ourselves with that stuff. BAE doesn't either. They have a shelf piston that works for almost everything. Compression is controlled by rod length.

|

|

|

Re: 430" small block build

[Re: DJVCuda]

#912715

Re: 430" small block build

[Re: DJVCuda]

#912715

01/30/11 03:14 PM

01/30/11 03:14 PM

|

Joined: Aug 2003

Posts: 11,179

Atco NJ

DJVCuda

OP

OP

I Live Here

|

OP

OP

I Live Here

Joined: Aug 2003

Posts: 11,179

Atco NJ

|

OK - Whew - what a long day yesterday was - went to the machine shop for about 4 hours yesterday and got the following information: Block - Sonic'd out good and magged good - .400+ on the thrust sides ( X block) and mostly 200 - 300 on the other sides of the cylinders. after the steel shot machine the thing looks good as new - Before :  After:  On to the Crank - We checked a number of things to determine the overall quality and condition of the crank. - all measurements were taken at 62 degrees F 1 - straightness - .001 2 - OD of the Mains - 2.4998 3 - OD of the rod journals - 1.9995  4 - Taper of rods and mains - ( worst one ) .0002 5 - Out of round - NA 6 - OD of the snout ( to fit balancer later ) 1.532 7 - Stroke - we came up with 4.133" for all throws except one - that was the 3,4 journal and it was 4.134"  The stroke was longer then anticipated, and adds 2 cubic inches to the build, but they are all consistent with one being one thou longer. We can play with deck heights to get thins to work out fine, so it's not an issue and the other measurements were impressive to say the least. I dont know if the colder temps ( 62 ) had anything to do with the measurements since i think the standard is in the 70's. Just another thought when i got home last night I went to callies site and looked at the $1100 dragonslayer crank specs and what they guarantee their cranks to spec out at - here is the quote - Quote:

These shafts are machined to the tolerances demanded by today’s high performance engine builder. Roundness and taper are held to less than .0003 on all rod and main journal diameters. Our final polishing procedures produce excellent load carrying surfaces that ensure extended bearing life and trouble free operation.

So for half the price I got a crank within the spec of the Callies Dragonslayer - not bad in my opinion!

Last thing we checked for was the oiling holes were indeed drilled all the way - and they were!

Didnt want to leave any stone unturned with a new part and have an issue later.

BIG THANKS to Fonse Performance - they took good care of me yesterday!

Last edited by DJVCuda; 01/30/11 04:20 PM.

|

|

|

Re: 430" small block build

[Re: DavidDean]

#912718

Re: 430" small block build

[Re: DavidDean]

#912718

01/30/11 06:39 PM

01/30/11 06:39 PM

|

Joined: Jan 2003

Posts: 32,394

Quicktree

I Win

|

I Win

Joined: Jan 2003

Posts: 32,394

|

Quote:

Thanks for this post. I'm planning a simular build w/my X block & indy 360-1 CNC.This is to out power my 408 W-5. What is your bore size going to be ? My X block has some core shift between the cylinders(.180-.200 thickness currently) and I will most likly offset bore that bank .030-.050 and fill w/hardblock.I was hoping to bore mine 4.1-4.125.Thanks again for the post & pictures.

I doubt you get that much, sonic check it.

|

|

|

Re: 430" small block build

[Re: DavidDean]

#912719

Re: 430" small block build

[Re: DavidDean]

#912719

01/30/11 10:37 PM

01/30/11 10:37 PM

|

Joined: Aug 2003

Posts: 11,179

Atco NJ

DJVCuda

OP

OP

I Live Here

|

OP

OP

I Live Here

Joined: Aug 2003

Posts: 11,179

Atco NJ

|

Quote:

Thanks for this post. I'm planning a simular build w/my X block & indy 360-1 CNC.This is to out power my 408 W-5. What is your bore size going to be ? My X block has some core shift between the cylinders(.180-.200 thickness currently) and I will most likly offset bore that bank .030-.050 and fill w/hardblock.I was hoping to bore mine 4.1-4.125.Thanks again for the post & pictures.

I'm going 4.080 as of right now - i'll get it on the CNC machine shortly to check the dimensions out as we progress.

|

|

|

Re: 430" small block build

[Re: DJVCuda]

#912721

Re: 430" small block build

[Re: DJVCuda]

#912721

02/12/11 11:41 PM

02/12/11 11:41 PM

|

Joined: Aug 2003

Posts: 11,179

Atco NJ

DJVCuda

OP

OP

I Live Here

|

OP

OP

I Live Here

Joined: Aug 2003

Posts: 11,179

Atco NJ

|

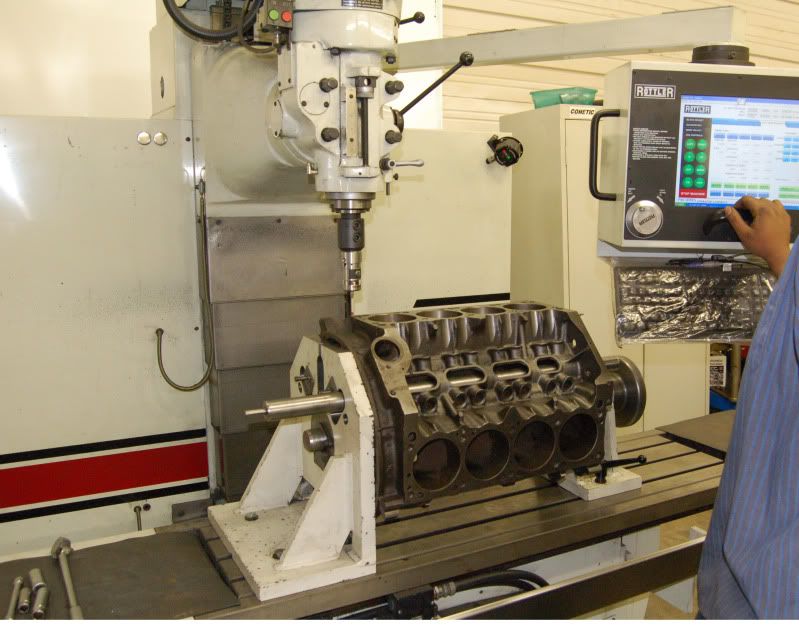

well just a quick update- the deck was a mess when we put it on the ROTTLER CNC machine - 12 thousands off on the drivers side and 10 thousands off on the passenger side. While the deck was flat - and this block was machined at a very reputable shop in the 80's the machinery of today has brought inconsistencies like this to the forefront of modern engine building. so I had a flat, crooked deck on this sucker. But it will clean up within spec for the rotating assembly.  Speaking about the rotating assembly - It measured out to 1794.6 grams for the bobweight - nice and light! Weights were consistent for everything : Rods: +/- 2 grams - 599-601 pistons - +/- 1 gram - 471-472  Just out of curiosity - does anyone know the stock 340 rotating assembly bobweight? The TCI Rattler had to be fitted to the crank which was 1.532" and the balancer was 2 1/2 thousands smaller - It was honed to fit with a 1 1/2 thou press fit.  so we're gettin there - slowly but surely.

|

|

|

|

|