Heres a cut & paste of an Email I sent John Passerman @ US CarTool before he did the 518 install.

> > Hello John

> >

> > I don't know if you've already seen this, but I saw the thread on

moparts

> > about doing a 518 conversion to an ebody. I've done it without cutting

the

> > crossmember

> > & still maintaining proper drivline angle, so if your interested I

> included

> > photos & some of what I did hope you can use it

> >

> > Not mentioned it the following desciption is the fact that the 518 I

used

> > had 618 O/D internals.

> >

> > The first thing I did was take a measurment of the distance from the

> center

> > of the original trans. output shaft to the floor pan for referance

later,

> > then I bolted the trans to the engine & attemptted to raise it , I

trimmed

> > the interferance areas on the trans., then when the output shaft to

floor

> > pan measurment was correct, I fabricated a new mount out of cardboard,

> then

> > used that as a template to make a steel one.

> >

> > The 500 is basicaly a 904 with O/D & the 518 is a 727 with O/D. the 500

> may

> > live depending on horsepower & how it is treated.

> > The shifting can be handled many ways, most guys install two switches on

> the

> > dash one to control O/D & the other for lockup, Kiesleris rumoured to be

> > working on a control box. The way I handled it is, a vehicle speed

sensor

> in

> > a custom made speedo cable sends it's signal to two RPM switches one is

> set

> > to allow convertor lockup at 43 mph the other to allow O/D at 52 mph

these

> > are hooked to bosch relays as the ground leg, a Hobbs switch (vacuum) is

> > connected to apply power to both relays so if vacuum is below 2hg (

> > moderatly heavy throttle) it kicks out of O/D & lockup as far as

bypassing

> > the lockup just don,t apply power & it won't lock,

> > but it's good for a 450 rpm drop at 70 mph on the vehicle I preformed

> this

> > swap to.

> >

> > BTW the vehicle is a 70 challenger convertible 340 with edelbrock heads,

> > etc., making 425 hp & running 4.30 gears that in O/D are like 2.94's the

> > vehicle when finished left central california & drove to Austin Tx. no

> > problems

----- Original Message -----

From: <John@UsCarTool.com>

To: "Randy Reddig" <js27@earthlink.net>

Sent: Wednesday, May 26, 2004 6:10 AM

Subject: Re: 518

> Thanks for the great info Randy! I hadn't considered modifying the trans

> case, but that seems like a "less invasive" method than cutting into the

> floor.

>

> You've given me a whole new approach to the conversion - thanks!

>

> John P.

Hello John

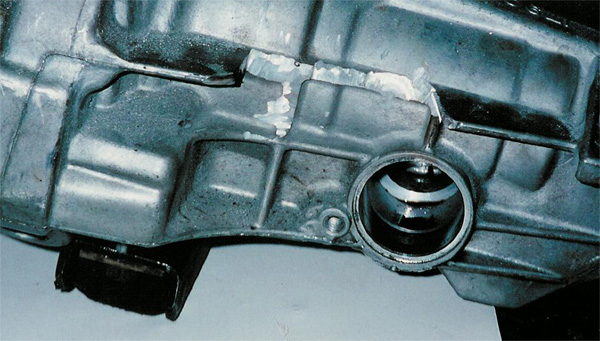

It works great on the E bodies & the 71& later B bodies, it won't work on

earlier B bodies & I haven't tried A bodies. Some people get squimish about

cutting the trans case but my first thought was I'm more squimish about

cutting the car, second if you look at the way the trans is built theres

nothing stressed in the areas that are cut. When you try it you'll find the

only trouble area is the speedo cable but I've been able to shift the engine

mounts as far back is the holes between the mount & engine bracket allows &

obtained clearance on both cars I've done this too. In some applications it

may require a small notch to the trans/torsion crossmember I do notch the

bolt in crossmember & only use 3 through bolts & 1 7/16 self tapping bolt in

the front hole where I notch the crossmember, check it out yourself, if you

come up with something better let me know but it isn't a problem, I've seen

Much worse make the magazine guys very happy

Good Luck Randy