|

Re: How to adjust valve lash???

[Re: MR_P_BODY]

#275393

Re: How to adjust valve lash???

[Re: MR_P_BODY]

#275393

04/04/09 07:47 AM

04/04/09 07:47 AM

|

Joined: Jan 2007

Posts: 3,695

nc

emarine01

master

|

master

Joined: Jan 2007

Posts: 3,695

nc

|

Quote:

Adjust the intake when the exhaust is starting to open

adjust the exhaust when the intake is starting to close

Hey Mr P , your adjusting the exhaust just after full intake lift when intake starts to close, how far closed? I was told to roll the intake almost to its seat? thanks craig

|

|

|

Re: How to adjust valve lash???

[Re: B-STUNG]

#275395

Re: How to adjust valve lash???

[Re: B-STUNG]

#275395

04/04/09 08:32 AM

04/04/09 08:32 AM

|

Joined: Jan 2003

Posts: 16,932

NC

440Jim

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 16,932

NC

|

Quote:

Quote:

Quote:

That doesnt work with big duration cams

This method always works, as it relates to firing order, and not cam size. For example, When #1 is at TDC, #2 intake will *always* be on the base circle if the standard Mopar v8 firing order is used (irrespective of how large or small the cam is) and the relationship applies all the way through.

I agree with this statement (it works). The EOIC method also works, but you have to be careful to know exactly what the words mean, and stop the motor exactly there or it will be slightly different every time you set it. But in reality, it works too.

The 4 point method is getting touchy with long duration cams.

|

|

|

Re: How to adjust valve lash???

[Re: challenger73400]

#275396

Re: How to adjust valve lash???

[Re: challenger73400]

#275396

04/04/09 08:35 AM

04/04/09 08:35 AM

|

Joined: Jan 2007

Posts: 3,695

nc

emarine01

master

|

master

Joined: Jan 2007

Posts: 3,695

nc

|

Quote:

How can you go wrong with the method of adjusting #1 at TDC on the compression stoke then Rotate 90 degress and follow the firing order. The valves are always on the base circle when the plug fires, right?

I guess you cant co wrong your way , but thats a lot of walking side to side for me, I like doing one side at a time just seems faster

|

|

|

Re: How to adjust valve lash???

[Re: 440Jim]

#275397

Re: How to adjust valve lash???

[Re: 440Jim]

#275397

04/04/09 08:36 AM

04/04/09 08:36 AM

|

Joined: Jan 2003

Posts: 16,932

NC

440Jim

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 16,932

NC

|

Quote:

If you look at the math, the MP sticker method and the E.O.I.C method are very close. And from a lobe profile stand point, the small difference doesn't matter. For example using the MP 0.620" solid cam, the tappet events are very close to this (depending on installed position). I am using the 0.050" tappet lift, because that is about when the eye ball will see it open/close after taking up the 0.028" lash.

Intake opens 34 BTC, closes 69 ABC

Exhaust opens 67 BBC, closes 35 ATC

The EOIC method would get you this:

Set Intake at 67 BBC, which is (180-67)= 113 ATC

Set Exhaust at 69 ABC, which is (180-69)=111 BTC

The MP sticker has the Intake set at 90 ATC

and the Exhaust set at 90 BTC. These are only about 20 degrees different. Have you looked at the base circle of a cam? And the cam is turning half that, so 10 deg on the cam opposite the max lift part is nothing.

Now the rocker shaft deflection issue is real when you are trying to get that last 0.001" setting. So, you really want to set the intake before that 113 ATC point to avoid the exhaust putting pressure on the shaft. And the MP sticker method does it 23 degrees before the EOIC method. Likewise you want to set the exhaust after the 111 BTC, and the MP sticker method does that too, by 21 degrees.

I use both, it just depends... and you can turn that 20 degrees when doing the EOIC method too, but sometimes it requires turning backwards after you see it.

|

|

|

Re: How to adjust valve lash???

[Re: challenger73400]

#275398

Re: How to adjust valve lash???

[Re: challenger73400]

#275398

04/04/09 08:47 AM

04/04/09 08:47 AM

|

Joined: Jan 2003

Posts: 16,932

NC

440Jim

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 16,932

NC

|

Quote:

How can you go wrong with the method of adjusting #1 at TDC on the compression stoke then Rotate 90 degress and follow the firing order. The valves are always on the base circle when the plug fires, right?

Again, do the math, you are off the "best" position by over 90 degrees.

Again using the MP 0.620" cam for example (283 degrees duration at 0.050"):

To be exactly opposite max lift on the intake lobe (installed at 106 ATC centerline), the "best" position is 106 ATC on the next crank revolution (cam is 1/2 speed).

The EOIC method would get you this:

Set Intake at 67 BBC, which is (180-67)= 113 ATC

The MP sticker has the Intake set at 90 ATC

But on most cams, the base circle is so long, does it really matter??? The worst part of the EOIC method is people get the words wrong, and don't stop at the "exact" point, causing variation.

|

|

|

Re: How to adjust valve lash???

[Re: emarine01]

#275399

Re: How to adjust valve lash???

[Re: emarine01]

#275399

04/04/09 08:47 AM

04/04/09 08:47 AM

|

Joined: Jul 2005

Posts: 8,647

ELYRIA,OH

blownzoom440

|

Joined: Jul 2005

Posts: 8,647

ELYRIA,OH

|

Quote:

Quote:

How can you go wrong with the method of adjusting #1 at TDC on the compression stoke then Rotate 90 degress and follow the firing order. The valves are always on the base circle when the plug fires, right?

I guess you cant co wrong your way , but thats a lot of walking side to side for me, I like doing one side at a time just seems faster

for some like myself going side to side is a safety thing making sure all the pushrods are in there place and rockers,spacers are moving freely...if your checking between rounds or at the beginning or end of the yr for summer cruising is much simpler.

|

|

|

Re: How to adjust valve lash???

[Re: blownzoom440]

#275400

Re: How to adjust valve lash???

[Re: blownzoom440]

#275400

04/04/09 09:18 AM

04/04/09 09:18 AM

|

Joined: Feb 2005

Posts: 5,207

Menomonee Falls

DemonDust

master

|

master

Joined: Feb 2005

Posts: 5,207

Menomonee Falls

|

Wow you guys are going through alot of arguing for something so simple. Starting at #1 cylinder, rotate the engine until the #1 exhaust rocker just starts to open the exhaust valve. Set the valve lash on #1 intake rocker at this time. Continue rotating the assembly and stop when #1 intake rocker starts returning from full lift. The lash on #1 exhaust can now be set. Continue this procedure for the remaining cylinders. There can be no failure this way. There is nothing to memorize and you don't need a decal pasted under your hood to do it. You can go down the left bank then the right, not have to jump back and forth.

|

|

|

Re: How to adjust valve lash???

[Re: DemonDust]

#275401

Re: How to adjust valve lash???

[Re: DemonDust]

#275401

04/04/09 09:58 AM

04/04/09 09:58 AM

|

Joined: Jan 2003

Posts: 6,531

Jacksonville, FL

Chris2581

master

|

master

Joined: Jan 2003

Posts: 6,531

Jacksonville, FL

|

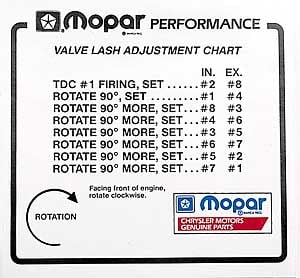

I've used both ways.....Mr P's version and the MP decal way.Tried it both ways on a MP cam and a older Ultra Dyne cam.Works great either way,but that chart for me is handy to look at and it is accurate.And how often are you running the valves? It got to the point where I was checking lash and they always were in spec.

Nautilus Racing-

We use Superformance gaskets and Turbo Action converters/products.

|

|

|

Re: How to adjust valve lash???

[Re: aarcuda]

#275405

Re: How to adjust valve lash???

[Re: aarcuda]

#275405

04/04/09 10:29 PM

04/04/09 10:29 PM

|

Joined: Jan 2004

Posts: 27,347

Today? Who Knows?

1_WILD_RT

Management Trainee

|

Management Trainee

Joined: Jan 2004

Posts: 27,347

Today? Who Knows?

|

Quote:

i dont use the 90 degree method for a pretty simple reason- my clutch fan, radiator shroud, power steering pump, fan pulley and crank pulley are all conspiring together to make my life a living hell. Its almost impossible to get on the crank bolt. turning it is another problem because of the limited movement coming down from the top.

yes, i have done it but is is NOT easy and results in extreme cussing and tool tossing

Next time your up to running the valves shoot some video, I need a good laugh...

|

|

|

Re: How to adjust valve lash???

[Re: 1_WILD_RT]

#275406

Re: How to adjust valve lash???

[Re: 1_WILD_RT]

#275406

04/05/09 09:27 PM

04/05/09 09:27 PM

|

Joined: Mar 2003

Posts: 15,493

the boonies

aarcuda

I Live Here

|

I Live Here

Joined: Mar 2003

Posts: 15,493

the boonies

|

Quote:

Quote:

i dont use the 90 degree method for a pretty simple reason- my clutch fan, radiator shroud, power steering pump, fan pulley and crank pulley are all conspiring together to make my life a living hell. Its almost impossible to get on the crank bolt. turning it is another problem because of the limited movement coming down from the top.

yes, i have done it but is is NOT easy and results in extreme cussing and tool tossing

Next time your up to running the valves shoot some video, I need a good laugh...

haha, i did it today. but i used the less aggravating method of bumping the starter. sorry, no video and no cussing or tool tossing as it went smooth as silk

btw, i dont know if anyone mentioned this but i have two sets of feeler gauges- i set to the min and the other set to max and then i use them as a go/no go gauge. for instance, on intakes, one gets set to .018 and the other for .020 for intake. i adjust so the .018 goes in but the .020 wont.

then i do the exhausts set at .020 and .022. i have the slotted adjusters with the locknut and sometimes

many times, the slotted adjust likes to turn in and tighten slightly when i tighten that down the locknut so i came up with the go/no go gauge method

|

|

|

|

|