|

Poly / Hemi Build

#2584566

Poly / Hemi Build

#2584566

11/29/18 06:53 AM

11/29/18 06:53 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

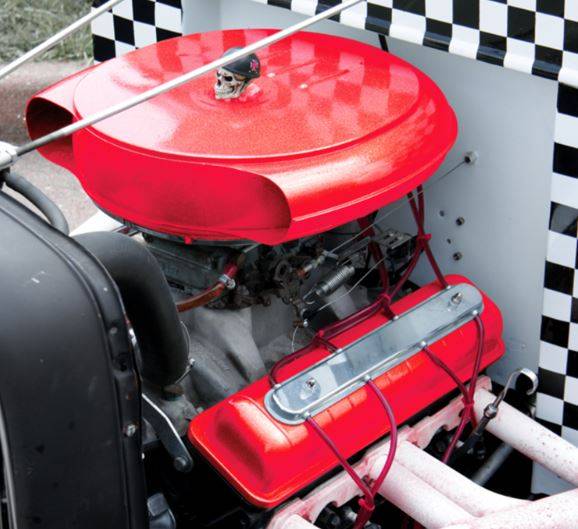

A while back there was a thread “…..Chrysler,Dodge and Desoto early Hemi, what interchanges…..” and the discussion got around to whether Chrysler Poly (Spitfire) heads could be swapped onto a HEMI block. I ended up in one of those right time and place deals and picked up a basket case 55 331 HEMI and 2 pairs of 55 301 Chrysler Poly heads (not to be confused with the Plymouth 301 heads). Poly info is a bit scarce but as far as I can tell the major difference between the 301 and 354 Ploy heads is intake valve size and I got a new set of 354 Poly valves on order. Poly Parts  YJ3 YJ3 by M Patterson, on Flickr I’ve still got to get everything cleaned up and checked but if that goes well plans are to build the short block ……possibly taking it out to 354 if the sonic test goes well….. and setting it up for both the Poly and HEMI heads. I’m mostly curious to see how the Poly heads stack up to the HEMI heads……it may do well, or it could run like a 273 with a burned valve, but there is only one way to find out. At least the Tri-Power I pulled off the HEMI in the 57 Plymouth won’t go to waste as it will fit either combination.  T1 T1 by M Patterson, on Flickr

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2586027

Re: Poly / Hemi Build

[Re: Mike P]

#2586027

12/02/18 08:23 AM

12/02/18 08:23 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

Right now I'm just in the feasibility/parts collecting stage of the project. While I really want to build the engine as a Poly initially, chances are after I'm thru playing with that it's final configuration will be as a HEMI.

I'm aware that common belief is that switching to HEMI heads on a Poly will drop the compression by at least a point and that valve clearance reliefs are in different locations. Piston selection will be critical and possibly even require a piston change from one to the other.

I know that a lot of the initial figuring can be done on paper and researching the few sources I've come across. For me the real test will come when I actually have the parts in my hands and can do real world measurements and testing. It ought to be interesting...so far I haven't found any real show stoppers but you never know.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2590988

Re: Poly / Hemi Build

[Re: Mike P]

#2590988

12/12/18 06:17 PM

12/12/18 06:17 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

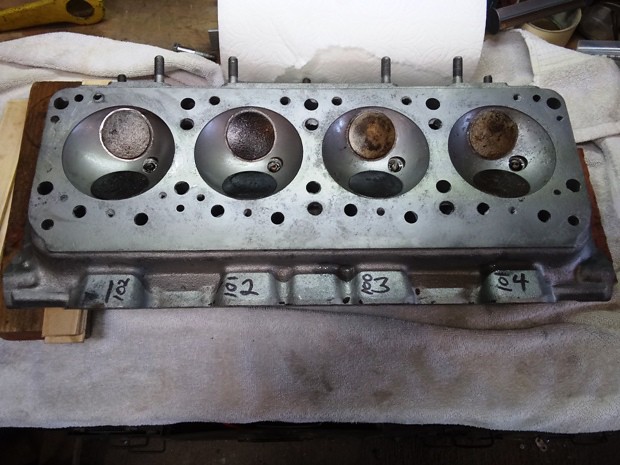

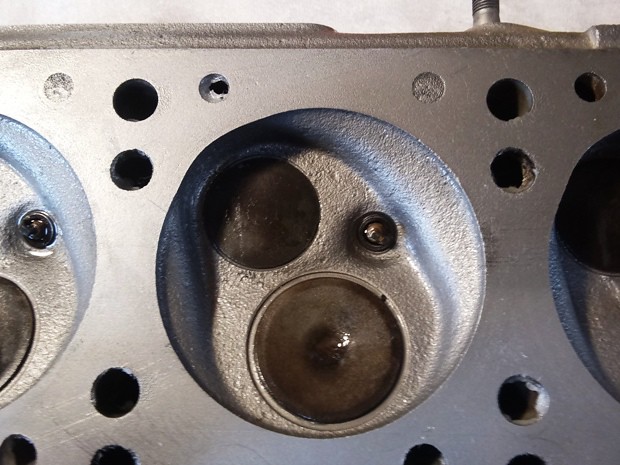

I’ve been working mostly on collecting, cleaning and inspecting parts. One of my concerns was getting the water jackets in the heads and block clean. The old caustic Hot Tanks that the machine shops used to use did a good job on dissolving the rust and scale but around here the last one of those went away 20 years ago. I’ve used citric acid in the past to de-rust old tools etc and always wanted to see how well it would do on engine parts. I picked up the largest tub WalMart and a 5 pound bag of citric acid off Amazon.  Y Citric Y Citric by M Patterson, on Flickr The first batch to go in was the HEMI heads, a spare set of rockers and the main caps.  Y Soak Y Soak by M Patterson, on Flickr I put in enough water to submerge the parts and started out with about 2 pounds of citric acid……I eventually added another 2 pounds as the solution became more saturated with rust and gunk and I changed out the cylinder heads eventually doing all 4 Poly heads too. It took about 4 days for the parts to soak to get them clean but I’m pretty happy with the results. From past experience it would have taken about half that time if I was doing this in the summer when it‘s warmer.  H3 H3 by M Patterson, on Flickr I’m happy with the water jackets, which was really the main reason for doing this,  WJ WJ by M Patterson, on Flickr With the heads cleaned (jet washed and bead blasted after the acid bath) I was able to start getting some of the information I’ve been curious about. Almost every article about the Polys indicates that Chrysler started producing them to create a “cheaper and lighter head and valve train”. They succeeded on 2 out of 3. After moving the heads around I was not surprised to find out the bare HEMI heads weighed in at 64 pounds…….the bare Poly heads was a “light weight” 63 pounds. With the heads cleaned, but before any machine work was done, I CC’ed the combustion chambers to get an idea about where I was going to be compression wise with the different heads. The Hemi heads came in between 100 and 102 CCs.  HH HH by M Patterson, on Flickr And then came the biggest surprise so far. Common belief (including mine) is that Poly heads have a much smaller combustion chamber than the Hemi heads and that when doing a head swap to convert a Poly to a Hemi that a piston change is required to get the compression back up. A glance at the chambers would seem to confirm that.  P2 P2 by M Patterson, on Flickr Actually CCing the chambers tells a completely different story. On the first 2 heads that I checked chamber volume ranged between 102 to 104 CC (the 104 cc chamber was on the other head). Practically speaking going from Poly to Hemi or the other way around will not cause a compression change.  P1 P1 by M Patterson, on Flickr Once I get the other pair of heads cleaned and inspected we'll make the decision on what two to build. These 301 Poly heads and the 331 2 bbl heads use a 1.812 intake valves. I've already picked up a set of the 331 4bbl/354 intake valves that are 1.94s. All the Poly heads used a 1.5 exhaust valve and Dave and I are currently looking into a cheaper and larger alternative to the stock exhaust valve. I've also been looking at the options for a roller cam.......any of the early HEMI guys out running a street roller cam they would recommend?

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2591192

Re: Poly / Hemi Build

[Re: Mike P]

#2591192

12/13/18 05:06 AM

12/13/18 05:06 AM

|

Joined: Aug 2003

Posts: 44,299

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 44,299

Bend,OR USA

|

Last edited by Cab_Burge; 12/13/18 05:08 AM.

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2591332

Re: Poly / Hemi Build

[Re: Mike P]

#2591332

12/13/18 02:05 PM

12/13/18 02:05 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

One of my friends owns a speed shop and usually brings the chassis Dyno in every 6 months or so and that will be when I do the testing.

What the eventual plan is to set the engine up initially as a carbureted Poly (probably using the Tri-Power)and then get it in a car. After doing the dyno runs, the next step will be to change the carburetors out for fuel injection (having 6 months in between tests will work out well). As I suspect the configuration I will eventually end up using will be the Hemi Heads and fuel injection that will be the final change.

I'm really as interested in the Torque results as I am the HP numbers. Comparing factory numbers on the standard 1956 300B 354 to the 58 4bbl 354 Poly shows some interesting results. The 300B engine made 340 HP and 385 ft lbs of torque. The Poly made 310 hp and 405 ft lbs.

It should be interesting.

Last edited by Mike P; 01/03/19 07:41 AM.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2600821

Re: Poly / Hemi Build

[Re: Mike P]

#2600821

01/03/19 07:40 AM

01/03/19 07:40 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

One thing I want to mention concerns the citric acid de-rusting. I am very pleased with the results but have a word of caution if the parts you de-rust are going to a machine shop. Most of the jet washes use a caustic solution as the cleaner which is a base. As acids and bases react with each other it is very important to clean/neutralize any residual acid from the parts to prevent foaming in the jet wash (yeah found out the hard way). In addition to a clean water rinse and air drying the parts before I send them in I am now adding a quick soak in water and baking soda followed by another clean water rinse and blow dry before I send the parts to the machine shop. I did get the block picked up and de-rusted.  BR BR by M Patterson, on Flickr I didn't get a picture of the block after it's soak, but it came out as clean as the rest of the parts. The one surprise on the block was that at some point it had already been bored to .030 .....and then driven enough to wear it out again. I'm pretty sure it can go out to at least .060 and the sonic check should tell me it will take the additional .065 to get it to 3.9375 354 bore size. While my wrist is healing Dave at the machine shop should be able to get a lot of the initial machining done so I can get some decisions made about the pistons and cam. .

Last edited by Mike P; 01/03/19 07:46 AM.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2601526

Re: Poly / Hemi Build

[Re: Mike P]

#2601526

01/04/19 02:49 PM

01/04/19 02:49 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

Everything I've read is that it should go the 3 15/16" 354 bore size without any problem.....provided there wasn't significant core shift. Just to be safe we're going to be doing a sonic check before we go forward.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2601831

Re: Poly / Hemi Build

[Re: Mike P]

#2601831

01/05/19 05:49 AM

01/05/19 05:49 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

. "......One of my friends owns a speed shop and usually brings the chassis Dyno in every 6 months or so and that will be when I do the testing.

What the eventual plan is to set the engine up initially as a carbureted Poly (probably using the Tri-Power) and then get it in a car. After doing the dyno runs, the next step will be to change the carburetors out for fuel injection (having 6 months in between tests will work out well). As I suspect the configuration I will eventually end up using will be the Hemi Heads and fuel injection that will be the final change......"

Right now I'm kicking around where I want the static compression ratio to come in at. As I want to eventually drive whatever car it goes into cross country I've resigned myself to limiting it to crap premium pump gas. Locally the only thing that is available is E10 92 octane and I suspect that by the end of the year that will change to E15. The last I checked the closest place (short of a small local airport 25 miles away) to buy non-ethanol gas is Phoenix (180 miles away).

I'm leaning towards about 9:1 static compression (I'll be playing with dynamic compression numbers when I choose a cam.). With that in mind I picked up a set of NOS standard 1956 Chrysler 354 Hemi Pistons which should put me close to the 9:1 compression ratio. Provided the block can go to 354 CI at least I can use the pistons for mockup and get the information I need to have a set of custom pistons made if needed.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2602888

Re: Poly / Hemi Build

[Re: Mike P]

#2602888

01/07/19 12:23 PM

01/07/19 12:23 PM

|

Joined: Sep 2007

Posts: 14,889

up yours

Supercuda

About to go away

|

About to go away

Joined: Sep 2007

Posts: 14,889

up yours

|

A Dodge 270 is not a Chrysler 331.

Other than some nuts and bolts and the term Hemi they have nothing in common.

They are not in the same family at all.

He's taking the 331 out .065" over, which always ups the compression ratio some. 677.93 cc for stock bore 331 vs 722.67 cc for stock bore 354 (0.65 over)

The 331 heads he has CC at 102, 354 heads (which these are not) average 108 cc's. That will up the compression as well.

So you have almost 45 cc more bore volume going into 6cc less chamber volume.

They say there are no such thing as a stupid question.

They say there is always the exception that proves the rule.

Don't be the exception.

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2603790

Re: Poly / Hemi Build

[Re: Mike P]

#2603790

01/09/19 08:53 AM

01/09/19 08:53 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

Thanks Supercuda, that was a good explanation, and I did not have the cc data on the 354 car head.

Truck, I have had the same experience when measuring various 50s and 60 engines (from all of the big 3) as your builder. Generally speaking advertised factory compression ratios and HP & TQ numbers were optimistic at best. I'm not saying the factory was making the numbers up, but rather what they (all) were delivering for testing was a truly blueprinted engine.

The blocks would have been square decked, line honed, crankshaft indexed, and heads CCed then equalized and taken to the minimum volume allowed. While the heads would not have been ported you can rest assured they would have been aggressively cleaned up. Pistons would be selected for the correct compression height. The rotating assembly would have been lightened as much as possible in accordance with the engine blueprint and then balanced.

Clearances on the bearings and pistons would have been set on the loose side of the specs to cut down friction.

Out on the production floor things were quite a were quite a bit different. Deck heights were generally taller and more often than not one was taller than the other. Combustion chambers were generally always larger than advertised and varied from mold to mold. A good example of this are the 301 heads i pulled. Both pair were 1555768 casting numbers but one pair was suffixed as -1 (the ones I'm using) and CCed at 102-104. The other pair were -2s and measured in at only 95-97 CCs.

The 331/354 Hemi heads I've measured over the years have been all over the place. I had a 354 truck head come in at 112 CCs and the other at around 105 CCs on the same engine.

As far as the projected 9:1 compression with the pistons I picked up. These are factory 1956 354 pistons with an "advertised" 9:1 compression ratio. Like the factory preparing a test engine, the first steps the block will undergo will be line honing and square decking. Provided we get the deck heights close to the factory specs it "should" be close to advertised compression. I'm also keeping in mind that the factory used a steel shim head gasket with compressed thickness of .026 and all that are currently available are composite gaskets with a compressed height that is .015-.025 thicker (resulting in about a 1/4 point lower compression). Milling the heads to compensate is not out of the question.

Now admittedly this all sounds good on paper but the only way to really find out will be to mock everything together and get real world measurements. This is something I have to do anyway so I can determine if the valve notches need to be modified for the Poly heads or worse case have a set of custom pistons made. The mock up is also critical to determine how much cam I get away with.

One of the purposes of this exercise was in part to find out if the blanket statement about converting a 301/331/354 Poly to a Hemi or converting a 392 Hemi to a big inch Poly by swapping on 354 Poly heads were true. So far some of the results have been surprising.....BUT ONLY APPLY TO MY SPECIFIC BUILD WITH THE SPECIFIC PARTS I'M USING.

For instance if I were to start with a 55 301 with an advertised compression ratio of 8:1 (and realistically truly only being in the 7-7.5:1 range) and throw a pair of 112 cc truck heads on with the thicker composite head gasket I would end up with an engine that would run, but performance wise be very disappointing. While the blanket statement that going from Poly to Hemi heads results in a compression drop would hold true in this case, it does not apply to mine as the Poly and Hemi heads I am using have virtually identical volumes.

Sorry about being so long winded but hopefully this provides some insight about where I'm going with the project. I'm really looking forward to comparing the test results in the 2 configurations (provided I don't run into any show stoppers along the way). My initial thoughts are the Hemi heads will make more HP, but I wouldn't be surprised to see better Torque from the Poly heads.

Last edited by Mike P; 03/07/19 06:29 AM.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2608502

Re: Poly / Hemi Build

[Re: Mike P]

#2608502

01/18/19 10:34 AM

01/18/19 10:34 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

".........For some reason, I assumed that the Chrysler Hemi/Poly had the same factory compression rating as the Dodge......." The mid 50s thru the 60s were an interesting time for engine development. As performance increased so did the quality of the fuel to support it. The guy who could afford the top of the line car didn't have a problem with the few extra cents for the better grade of gas. From 55-58 Chryslers gradually went from 8:1 to 10:1 advertised (optimistic) compression. The guy who went in and bought a Plymouth or Dodge with a grocery getter 6 or 2 bbl Poly was more likely to appreciate only having to pay for regular grade gas. Historically trucks and industrial got whatever cheap crap gas was available resulting in a requirement to keep compression low. "........This discussion raises a question... probably could end up hijacking this otherwise useful thread... what do we call these engines? The group that includes: DeSoto Hemi Dodge Hemi Dodge Poly Chrysler Hemi Chrysler Poly ........" MOPAR ?  Adding the Polys and Hemis to the mix sure made keeping track of parts interesting.......likely a big part of the reason Chrysler became a leader in standardizing engines across corporate lines in the late 50s. As far as Plymouth having its own V8 engine that occurred in 57 with the 301/318. Just speculating, but with the 318 being a "new" design I suspect that its development had an eye on corporate sharing.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2609765

Re: Poly / Hemi Build

[Re: Mike P]

#2609765

01/21/19 08:07 AM

01/21/19 08:07 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

I was mistaken. The Plymouth Polys (the "A" series of motors) was apparently introduced in 1956. The Plymouth 301 (often misidentified by owners/potential buyers as a 318) was a one year only engine in 1957. Other than the factory designated displacement of 301 cubic inches they are completely different from the Chrysler 301 Spitfire engines. https://en.wikipedia.org/wiki/Chrysler_A_engine

Last edited by Mike P; 01/21/19 07:03 PM.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Old Ray]

#2634975

Re: Poly / Hemi Build

[Re: Old Ray]

#2634975

03/20/19 07:55 PM

03/20/19 07:55 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

Not much of an update, but I did find something interesting today while I was sorting thru the Poly parts. Turns out the Poly pushrods are only .065 shorter than the intake (short) pushrods for the 331/354 Hemi. ![[Linked Image]](https://farm8.staticflickr.com/7860/47430055361_54a62fee53_z.jpg) Hemi poly PR Hemi poly PR by M Patterson, on Flickr Regardless of the cam I use in the short block I'll be ordering adjustable pushrods, and it was kind of a pleasant surprise to find out that I won't have to worry about having to have oddball length custom pushrod made (the .065 difference is well within the adjustable range). So it looks like I'll be able to just order a complete set of pushrods for the hemi heads and an extra 8 intake pushrods to cover the Poly heads.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2636769

Re: Poly / Hemi Build

[Re: Mike P]

#2636769

03/25/19 05:56 AM

03/25/19 05:56 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

My wrist is getting a little better so I was able to get some light parts cleaning done. This weekend was spent getting the valley cover cleaned up. The original valley covers have the oil fill tube and provisions for a PCV valve (the original location for the road draft tube). The cover is made in 2 pieces and also acts as the oil separator for the for the PCV system. Most of the aftermarket valley covers I looked at have a flush mount oil fill which looks nice but can be a PIA to add a quart of oil to when you are on the road. They also have no provisions for a PCV valve. The common work around for the PCV is a bolt on breather kit for the valve covers. IMO they look OK on aftermarket valve covers but not so much on stock stamped ones like I'll be using let alone the Poly covers the engine will start out with. With that in mind I decided to use the original valley cover rather than go the aftermarket market route. ![[Linked Image]](https://farm8.staticflickr.com/7862/32518131657_d953dd033b_z.jpg) VP1 VP1 by M Patterson, on Flickr The biggest problem with using the original cover is getting them clean......years of running non-detergent oil usually leaves a bunch of crud on the inside. It was not a problem years ago when most machine shops used a hot tank and they could be soaked to dissolve the stuff but the jet washes most shops use now don't do much good on the inside of them. The top and bottom of the cover are spot welded together and some guys split them for cleaning. I took an easier route and after I had it jet washed to get the outside crud off I soaked it in my 5 gallon bucket of carb cleaner for a couple of days. I managed to get a flashlight and dental mirror in to verify that it was completely clean and this is ready for a coat of paint. ![[Linked Image]](https://farm8.staticflickr.com/7880/32518131687_88c06affd2_z.jpg) VP2 VP2 by M Patterson, on Flickr OK saving almost $300 on aftermarket parts is also a big plus.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: moparx]

#2637015

Re: Poly / Hemi Build

[Re: moparx]

#2637015

03/25/19 02:54 PM

03/25/19 02:54 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

The grommet is available from Hot Heads (saves me having to figure out the size I need)....and of course I forgot to include it in the order I placed last week.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: moparx]

#2641573

Re: Poly / Hemi Build

[Re: moparx]

#2641573

04/05/19 12:21 PM

04/05/19 12:21 PM

|

Joined: Feb 2009

Posts: 98

Peoples Republic of Oregon

wayfarer

member

|

member

Joined: Feb 2009

Posts: 98

Peoples Republic of Oregon

|

that turned out pretty good mike. is the PVC hole a commonly available grommet size, or will you have to weld on a bung/collar [whatever you want to call it] adapter for the grommet ?  The best grommet that I have found is either Standard Motor Parts GV1 or Dorman 452324. The PCV is either Wells PCV48 or Standard Motor Parts V180. This fits all of the valley covers with a road draft tube. ...and yes, the Spitfire engines are hard runners.

|

|

|

Re: Poly / Hemi Build

[Re: moparx]

#2642189

Re: Poly / Hemi Build

[Re: moparx]

#2642189

04/07/19 07:48 AM

04/07/19 07:48 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

thanks for those numbers wayfarer ! X2 By mutual agreement my block has been pretty much sitting in queue at the machine shop while my hand heals. In the mean time I've been collecting parts and making a few measurements. Dave currently has 2 other 331 HEMIs under construction at his shop so I've been able to get some measurements off those for reference when I make a decision of what pistons I'll be using in my engine. One engine is a customer's 331 that is using Hot Heads stock replacement (.030) pistons. This is just pretty much a stock rebuild so it's not going thru the steps to figure what the actual compression ratio, but I did get piston pin height on the pistons before they were installed and deck height numbers off it for comparison. ![[Linked Image]](https://live.staticflickr.com/7813/47555066291_c3e4b4e257_z.jpg) Y SR Y SR by M Patterson, on Flickr We haven't sonic checked my block yet so it's still up in the air as to what pistons I'll be using. I got a couldn't pass up deal on a set of NOS standard bore 354 Pistons that may go in it. These are about .060 taller than the stock replacement pistons HH sells but have a lot more valve relief. ![[Linked Image]](https://live.staticflickr.com/7917/47555066331_0cfbe36b49_z.jpg) Y NOS Y NOS by M Patterson, on Flickr Just fort grins this is the 331 Dave is building for himself using Ross pistons. With the aluminum heads that will go on it will be right at 10:1 compression. ![[Linked Image]](https://live.staticflickr.com/7908/47555066311_037f15de30_z.jpg) Y 10 1 Y 10 1 by M Patterson, on Flickr I've also been collecting more parts for my build. My Hot Heads order came in.....mostly the parts I know I'll need regardless of the heads and cam I'll be using. I'm using the Hot Heads thin timing cover and lower pulleys which are the same as what I currently have on the 354 in my 57 Plymouth. The water pump pulley is actually an aftermarket 2 groove pulley for a small block Chevy with short water pump. It lines up perfectly with the HH lower pulleys and is about 1/3 the cost of HH billet one. I also stumbled across a OLD Fel Pro head gasket set the 331/354 Poly. It had been mis-advertised as being for an early Hemi and had no takers so the price was right. It's got the steel shim head gaskets (worth about a 1/4 point compression over the composite gaskets). I was also pleasantly surprised to find out HH sells the solid copper exhaust flange gaskets. The set I bought from a different vendor for the Hemi in the 37 turned out to be composite with thin sheets of copper on either side. ![[Linked Image]](https://live.staticflickr.com/7888/47555066241_4bde027bd0_z.jpg) Y inv Y inv by M Patterson, on Flickr When I built the 331 and 354 HEMIs back in 2006 I didn't add the lower spark plug tube seals HH sells. I've pulled the plugs on both engines a couple of time. When I restart the 354 afterwards it gives off a little puff of smoke when it's started again and then it's fine. When I pull the plugs on the 331 and restart it smokes like a train until the oil that falls in the cylinder is burned off. As the HEMI heads that will eventually go on this engine are the same triple nickel heads that the other 331 uses I'll be using HH lower tube seals on this one. I like the looks of the 426 spark plug boots on the early HEMIs. When I built my other HEMIs they sold custom spark plug tubes that were flanged at the top for stock 426 boots. Those tubes are apparently no longer available but HH sells a push in 426 "style" boot for use with the stock spark plug tubes. Their site didn't have a real good picture of what the boots looked like so here's a better picture. I can live with them especially as I have a bunch of good stock plug tubes I can use (which saves about $150 by not having to buy the custom tubes if they were even available). ![[Linked Image]](https://live.staticflickr.com/7922/47555066271_76f672f210_z.jpg) Y PT Y PT by M Patterson, on Flickr So that's about were I'm currently at.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2643633

Re: Poly / Hemi Build

[Re: Mike P]

#2643633

04/10/19 10:56 AM

04/10/19 10:56 AM

|

Joined: Feb 2009

Posts: 98

Peoples Republic of Oregon

wayfarer

member

|

member

Joined: Feb 2009

Posts: 98

Peoples Republic of Oregon

|

thanks for those numbers wayfarer !

X2

I like the looks of the 426 spark plug boots on the early HEMIs. When I built my other HEMIs they sold custom spark plug tubes that were flanged at the top for stock 426 boots. Those tubes are apparently no longer available

So that's about were I'm currently at.

A decade or two back I made a die to re-shape a 426 tube top to give a 45° flair that the 426 boot fits nicely on and the overall length works with most of the engines. If interested I'll (try to) post a pic when I get back to the shop (out and about for a week or so). I also have alot of 426 boots available. Lets try a pic...

Last edited by wayfarer; 05/03/19 10:26 AM.

|

|

|

Re: Poly / Hemi Build

[Re: wayfarer]

#2967697

Re: Poly / Hemi Build

[Re: wayfarer]

#2967697

09/27/21 06:18 AM

09/27/21 06:18 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

Between the surgery, moving into a new house and life in general the project got put on the back burner for the last 2 ½ years. Now that my buddy at the machine shop and I have some time again it’s at least moving forward now. Shortly after the last post I ran into a show stopper on the Poly portion of the build. Something I should have thought about when I started doing my initial measurements was whether there would be interference issues between the combustion chamber in the 301 Poly head and the size of the cylinder bore on a 354 block (there is .3125 difference between bore size on the 301 and 354). Basically the head overhangs the cylinder bore. I’ve got some feelers out for 354 Poly heads/a complete motor but so far not a lot of luck. For now we’re going to go ahead with the hemi portion of the build. We got the block sonic checked to be sure it will safely go out the .125” to standard bore 354. It’s been line honed and should get square decked and maybe bored and honed sometime this week. Once that’s done I’ll send out the rotating assembly to be balanced. One of the things we did a while back was to change the block over to use cup style freeze plugs. Now I’ve never had problems getting the stock disc type plugs to seal when I’ve rebuilt engines in the past. The problem was always when a customer came in with a leaking freeze plug that had to be replaced in car. Anybody who has had to fight getting a punch centered on the new plug and have room to swing a hammer under the car knows exactly what I’m talking about. Chances are I won’t live long enough for the plugs to go bad but if I do, it’s a hell of a lot easier to do a cup plug. ![[Linked Image]](https://live.staticflickr.com/7857/40261360913_198b11018f_z.jpg) fp1 fp1 by M Patterson, on Flickr ![[Linked Image]](https://live.staticflickr.com/7813/32639456867_f736224f50_z.jpg) FP 1 FP 1 by M Patterson, on Flickr I also got around and ordered the rest of the stuff I needed to get the put the engine together. I ended up going with one of Hot Heads flat tappet cams and adjustable push rods. The cam’s on back order but should be here in a month or so. I also ordered of a set of stainless valves, springs and retainers. With luck I should have the engine together sometime this winter. On a side note I also found a great deal on a 46RH so I picked that up and had it rebuilt. ![[Linked Image]](https://live.staticflickr.com/65535/51092941611_236ff68e9a_z.jpg) 46RH 46RH by M Patterson, on Flickr I’m just not real sure right now not where it will end up at. Initially it was supposed to go behind this engine (and still may). Lately though I’ve been kicking around pulling the 4 speed out of the 57 Plymouth and stuffing it in there (occasional problems with my left leg……the golden years suck). If I do put it in the Plymouth, this engine will end up with the 4 speed behind it. Either way I’ll be drilling the back of the crank for a pilot bearing before the crank goes out for grinding and balancing. .

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2967747

Re: Poly / Hemi Build

[Re: Mike P]

#2967747

09/27/21 08:47 AM

09/27/21 08:47 AM

|

Joined: Sep 2016

Posts: 260

British Columbia, Canada

Old Ray

enthusiast

|

enthusiast

Joined: Sep 2016

Posts: 260

British Columbia, Canada

|

Thanks for the update, not that I understand all of it but I can appreciate it. Your sure right about the golden years, somebody was full of it. After two weeks of lying on the floor under the dash on my '56 doing aftermarket A/C I hurt everywhere.

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2967778

Re: Poly / Hemi Build

[Re: Mike P]

#2967778

09/27/21 10:32 AM

09/27/21 10:32 AM

|

Joined: Feb 2003

Posts: 16,232

Mesa, Arizona

dart4forte

I Live Here

|

I Live Here

Joined: Feb 2003

Posts: 16,232

Mesa, Arizona

|

Not much of an update, but I did find something interesting today while I was sorting thru the Poly parts. Turns out the Poly pushrods are only .065 shorter than the intake (short) pushrods for the 331/354 Hemi. ![[Linked Image]](https://farm8.staticflickr.com/7860/47430055361_54a62fee53_z.jpg) Hemi poly PR Hemi poly PR by M Patterson, on Flickr Regardless of the cam I use in the short block I'll be ordering adjustable pushrods, and it was kind of a pleasant surprise to find out that I won't have to worry about having to have oddball length custom pushrod made (the .065 difference is well within the adjustable range). So it looks like I'll be able to just order a complete set of pushrods for the hemi heads and an extra 8 intake pushrods to cover the Poly heads. Just got done adjusting my adjustable push rods on my 330. All I can say they were a PIA. I’m doing a 241 right now. I found a shop that will convert my rocker assembly to adjustable rockers. Once I get them back and installed on the motor we can order push rods from smith brothers. FWIW I have a set of adjustable push rods I’ll sell.

“So if it’s on the internet it must be true”

Abe Lincoln

|

|

|

Re: Poly / Hemi Build

[Re: dart4forte]

#2967901

Re: Poly / Hemi Build

[Re: dart4forte]

#2967901

09/27/21 04:02 PM

09/27/21 04:02 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

"........After two weeks of lying on the floor under the dash on my '56 doing aftermarket A/C I hurt everywhere........"

I hear you Ray, it took me almost a month to recover from putting the Power Steering on the 57 Plymouth last year.

Yeah adjusting the push rods on an engine stand is no fun and doing it in-car is a giant PIA stretching out over the fenders. I'd be interested to know how the adjustable rockers turn out once you get them back. Are you going to need to do something about valve covers for adjuster clearance?

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: moparx]

#2968155

Re: Poly / Hemi Build

[Re: moparx]

#2968155

09/28/21 12:30 PM

09/28/21 12:30 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

".....i believe the valve covers with adjustable rockers had "bumps" in them to clear the adjusters......"

Yeah they did on the ones with adjustable rockers. I didn't know if Dodge did the same thing, so I looked it up in Tex Smiths HEMI book (bought a copy back when they were affordable) and they show the covers with the dimples.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2968386

Re: Poly / Hemi Build

[Re: Mike P]

#2968386

09/29/21 09:49 AM

09/29/21 09:49 AM

|

Joined: Feb 2003

Posts: 16,232

Mesa, Arizona

dart4forte

I Live Here

|

I Live Here

Joined: Feb 2003

Posts: 16,232

Mesa, Arizona

|

"........After two weeks of lying on the floor under the dash on my '56 doing aftermarket A/C I hurt everywhere........"

I hear you Ray, it took me almost a month to recover from putting the Power Steering on the 57 Plymouth last year.

Yeah adjusting the push rods on an engine stand is no fun and doing it in-car is a giant PIA stretching out over the fenders. I'd be interested to know how the adjustable rockers turn out once you get them back. Are you going to need to do something about valve covers for adjuster clearance? After talking with them they have a process to relive the adjusters allowing them to be used with regular valve covers. I’ve talked with several HAMB members that had their valvetrain converted. They said that their valvetrain clears their valve covers. Only complaintI heard was the cost however given what you get it’s worth it for me.

“So if it’s on the internet it must be true”

Abe Lincoln

|

|

|

Re: Poly / Hemi Build

[Re: dart4forte]

#2968398

Re: Poly / Hemi Build

[Re: dart4forte]

#2968398

09/29/21 10:40 AM

09/29/21 10:40 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

“…….After talking with them they have a process to relive the adjusters allowing them to be used with regular valve covers……”

Cool. I saw where Hot Heads sells a 1” valve cover spacer kit for the Chrysler HEMIs but they don’t seem to offer one for the Dodge HEMI’s. Their pricy though, I suspect in part because they also include a set of longer spark plug tubes. By the time you buy the spacers you’re most of the way to what a set of aluminum covers cost.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: moparx]

#2968650

Re: Poly / Hemi Build

[Re: moparx]

#2968650

09/29/21 10:41 PM

09/29/21 10:41 PM

|

Joined: Feb 2003

Posts: 16,232

Mesa, Arizona

dart4forte

I Live Here

|

I Live Here

Joined: Feb 2003

Posts: 16,232

Mesa, Arizona

|

I dont have them back yet. I called them today to verify they got my cores. It will take around 8 weeks to get them back.

“So if it’s on the internet it must be true”

Abe Lincoln

|

|

|

Re: Poly / Hemi Build

[Re: dart4forte]

#3012195

Re: Poly / Hemi Build

[Re: dart4forte]

#3012195

02/04/22 03:07 PM

02/04/22 03:07 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

All the machine work is done on the block. The “month or so” I expected it to take to get the backordered cam in turned out to be closer to 5 months, but it finally made it last week. My machinist likes to have the cam on hand when he installs the cam bearings (so he can make sure there won’t be any binding issues). With that done the block finally came home and I chased the threaded holes, painted it and installed the freeze plugs and pipe plugs. It’s lot nicer looking than the ball of rust I brought home 3 years ago. ![[Linked Image]](https://live.staticflickr.com/65535/51860707261_6eb051f2b2_z.jpg) 354 block 354 block by M Patterson, on Flickr The crank’s out to be ground and then it and the rotating assembly will be balanced. So back to waiting  .

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Cab_Burge]

#3012394

Re: Poly / Hemi Build

[Re: Cab_Burge]

#3012394

02/05/22 09:13 AM

02/05/22 09:13 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

“……I'm thinking the pushrod holes in the block are not round like in your block picture…..Maybe now is the time to make sure the exhaust pushrods will clear oaky in your block …….” Cab, frankly if this hadn’t started out as a potential POLY build I probably would not have understood what you are talking about. You are right about the pushrod holes on the late 55 and up HEMI blocks not being round. My block as an early 55 HEMI block, hence the round holes . From late 1955 on the “HEMI blocks” had drilled/teardrop shaped pushrod holes as shown below. ![[Linked Image]](https://live.staticflickr.com/4856/46132820841_8f99710d57_z.jpg) Y valve Relief 2 Y valve Relief 2 by M Patterson, on Flickr ![[Linked Image]](https://live.staticflickr.com/4803/46132820801_44aa4444a4_z.jpg) Y Valve relief 1 Y Valve relief 1 by M Patterson, on Flickr Reshaping the pushrod holes was necessary when the blocks were fitted with Poly heads because of the different pushrod angles required for the single rocker-shaft and rockers they used. 1955 was the first year for the Poly engine (in the Windsors and Saratoga wagons) and was a 301CI one year only engine. In 56 Chrysler used the 55 331 CI blocks with Poly heads for the Windsor/Saratoga and in 57 and 58 they based the Windsor and Saratoga Polys on the 354 blocks. By reshaping the holes the blocks could be used with either HEMI or Poly heads. Some of these engines in both Hemi and Poly form also found their way into Dodge trucks (but I’m not real sure on the years or models). I had been planning on doing the pushrod hole mods to this block for the poly heads until I figured out the 301 Poly heads I have wouldn’t work with the bore size we went with. For now it’s just going together as a HEMI and the factory holes will be fine. As far as building a Poly, I may have a line on a complete 57 354 Poly…….what’s another engine sitting around the shop  .

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#3015230

Re: Poly / Hemi Build

[Re: Mike P]

#3015230

02/14/22 01:50 AM

02/14/22 01:50 AM

|

Joined: Aug 2003

Posts: 44,299

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 44,299

Bend,OR USA

|

Chrysler call their poly motor Spitfires is what I remember now   I'm almost positive that Plymouths had V8 in 1956 in the Furys and maybe in 1955 also  I think they were 301 C.I. poly motors in both years, 1957 was the first year for the Plymouth 318 poly motors

Last edited by Cab_Burge; 02/14/22 01:53 AM.

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Poly / Hemi Build

[Re: Cab_Burge]

#3015258

Re: Poly / Hemi Build

[Re: Cab_Burge]

#3015258

02/14/22 08:08 AM

02/14/22 08:08 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

Yeah Cab it can get a bit confusing trying to keep track of all the engines Chrysler, DeSoto, Dodge and Plymouth produced during the 50’s. Here’s a pretty good breakout of the 50s Plymouth poly engines. https://en.wikipedia.org/wiki/Chrysler_A_engineThe Chrysler 301 Poly (Spitfire) engine shares nothing with the Plymouth 301 other than the displacement. The Spitfire 301 is based on the 331/354 HEMI block (with smaller bores) and the blocks are externally (dimensionally) the same. On a side note it’s amazing how many 1957 Plymouth 301s are misidentified as 318s by their owners.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#3019355

Re: Poly / Hemi Build

[Re: Mike P]

#3019355

02/27/22 10:47 AM

02/27/22 10:47 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

Figured as long as I’m waiting on the rotating assembly to get back I’d take care of some small things. I’m going to be running a Hot Heads dual plane intake on this one with an eye on eventually adding fuel injection. ![[Linked Image]](https://live.staticflickr.com/65535/51902983720_c7247049fb_z.jpg) HHI1 HHI1 by M Patterson, on Flickr I ended up doing a little relieving on some of the runners so it would be easier to get the cap screws to start straight when it gets bolted to the heads and also drilled and tapped the passenger side water port for a heater hose fitting. ![[Linked Image]](https://live.staticflickr.com/65535/51901374317_5deaa3345c_z.jpg) HHI2 HHI2 by M Patterson, on Flickr When I got the 301 Spitfire heads I also salvaged a couple of 301 distributors out of the engines. They are the right length to fit the 331/354 HEMIs and Polys. ![[Linked Image]](https://live.staticflickr.com/65535/51901374337_eac6e77b66_z.jpg) Dist 1 Dist 1 by M Patterson, on Flickr They are also pretty easy to convert over to Electronic Ignition using stock SB Mopar parts. One was set up with mechanical and vacuum advance and the other has the advances locked out (for use with the fuel injection). The lockout was pretty easy to do using parts from a Lean Burn/Electronic Spark Control distributor. ![[Linked Image]](https://live.staticflickr.com/65535/51903287862_7638a5cea2_z.jpg) Dist Conv Dist Conv by M Patterson, on Flickr I went thru a swap meet AFB I’d picked up a while back, it was a little corroded on the outside but beautiful on the inside so it got a kit. It’s only 600 CFM but will do fine on the test stand to break in the cam and run occasionally. ![[Linked Image]](https://live.staticflickr.com/65535/51906148759_4ba58b9a04_z.jpg) carb 354 carb 354 by M Patterson, on Flickr and I got a few other parts painted. ![[Linked Image]](https://live.staticflickr.com/65535/51905835046_53baf3cbef_z.jpg) misc parts misc parts by M Patterson, on Flickr I still need to build an Air Cleaner, PS Pump Bracket, Alternator Bracket and AC compressor bracket, but that will all have to wait until I get the engine assembled.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: moparx]

#3019363

Re: Poly / Hemi Build

[Re: moparx]

#3019363

02/27/22 11:07 AM

02/27/22 11:07 AM

|

Joined: May 2019

Posts: 6,710

nowhere

Sniper

master

|

master

Joined: May 2019

Posts: 6,710

nowhere

|

They are also pretty easy to convert over to Electronic Ignition using stock SB Mopar parts. Doing similar with my flathead 6 distributor, using /6 parts.

|

|

|

Re: Poly / Hemi Build

[Re: Sniper]

#3019395

Re: Poly / Hemi Build

[Re: Sniper]

#3019395

02/27/22 12:10 PM

02/27/22 12:10 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

“……Doing similar with my flathead 6 distributor, using /6 parts……”

Cool. Have you figured out cap and rotor? On the conversions I did on the V8 distributor I had to use the later Mopar rotor and the 56 and up cap. The 56 distributor cap is taller than the 55 and earlier cap which allows room for the taller upper shaft and rotor.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#3023711

Re: Poly / Hemi Build

[Re: Mike P]

#3023711

03/13/22 07:12 PM

03/13/22 07:12 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

The engine is going together. The rotating assembly got back from the balancer. The first order of business was getting the crankshaft in the block. ![[Linked Image]](https://live.staticflickr.com/65535/51927122088_e075d4e049_z.jpg) crank 354 crank 354 by M Patterson, on Flickr For the last few decades I’ve used Plastigauge for a quick check on the Mains and Rods when I assemble an engine. Normally everything’s fine. I’ve had a couple over the years where it did catch some problems……making me a believer that it’s important to do on every engine I build. When I was checking the mains the clearance was coming out a little loose (as in about a thousands bigger than it should be). So I pulled the crank and torqued the caps and bearings back in place. I pulled out the gauges and everything was right on the money (I did the rods the same way). Don’t know if I just got a bad stick of plastigauge or what. I don’t think it goes bad with age, even if it does, I just picked this batch up a couple weeks ago and it was about 65 degrees in the shop when I was doing the checking. When I posted this on another site I found out I’m not the only one who has run into this recently. With the crank, rods and piston in, I installed the Hot Heads SB MOPAR oil pump, adapter and pickup. The instructions say a bit of fitting might be needed to get the neck on the drive to fully seat in the main cap (and on mine there was). ![[Linked Image]](https://live.staticflickr.com/65535/51935755914_0ac6eafcda_z.jpg) 354 OP 354 OP by M Patterson, on Flickr There are 2 basic styles of passenger car oil pans for the 331/354/392 Hemi’s and Polys; the rear sump pans (foreground) used from 1951thru 1956 and the center sump used in 1957-8. For now I’m setting this engine up with a rear sump pan (and this became a bit of an issue a little later). ![[Linked Image]](https://live.staticflickr.com/65535/51935863704_1d28944558_z.jpg) 2 oil pans 2 oil pans by M Patterson, on Flickr I normally like to run a windage tray. Back when I built the 331 (in my 37 Dodge truck) and the 354 (in my 57 Plymouth) there were a couple of options available. If you can find one, the factory actually used a windage tray the first couple of years of the 331 HEMI with the rear sump pan. The tray was bolted to the pan rail area on 4 legs. I used this setup with on the 331 I built with the rear sump pan. ![[Linked Image]](https://live.staticflickr.com/65535/51935621188_b18d2bfc2c_z.jpg) 3 0il pickup 331 Cap 3 0il pickup 331 Cap by M Patterson, on Flickr When I built the 354 for the Plymouth they (can’t remember if it was Hot heads or PAW) offered a modified SB MOPAR windage tray for the early HEMIs’. ![[Linked Image]](https://live.staticflickr.com/65535/51936159015_3ac09ea439_z.jpg) 4 SB windage tray 4 SB windage tray by M Patterson, on Flickr Basically they relocated the tabs that bolt to the main cap bolts to move the windage tray up a bit for counter weight clearance. This setup worked great with the center sump oil pan on the 57 Plymouth. ![[Linked Image]](https://live.staticflickr.com/65535/51934563707_15a36d875d_z.jpg) 5 Oil pickup 354 cap 5 Oil pickup 354 cap by M Patterson, on Flickr I had a SM MOPAR windage tray and bolts set aside and figured modifying it should be fairly easy. This is when I discovered that the front section of the rear sump oil pan is a little shallower than the center sump pan. Basically I couldn’t get the windage tray high enough to clear the counter weights on the front throws without interfering with the oil pan. ![[Linked Image]](https://live.staticflickr.com/65535/51937047289_4a3c50f105_z.jpg) 340 WT 340 WT by M Patterson, on Flickr I looked up the windage tray Hot Heads sells to see how theirs looked. Basically their windage tray is shorter and stops just shy of the #2 main cap. The windage tray main cap bolts are now bolted on the #3 and #4 main caps. It was a pretty simple mod so what the heck. Now do I NEED windage tray on a street motor that may at the most might see a drag strip once or twice…..NO. If I didn’t have the windage tray would I spend the money to buy one for this motor…..NO. Would it really bother me not to have a windage tray in this motor…..NO. Basically I had the windage tray laying around so all I had tied up in it was some time. ![[Linked Image]](https://live.staticflickr.com/65535/51936733341_f2566c39c4_z.jpg) Mod Tray Mod Tray by M Patterson, on Flickr So at the end of the day I now have a 354 short block. ![[Linked Image]](https://live.staticflickr.com/65535/51936733361_4598e81b4a_z.jpg) 354 SB 354 SB by M Patterson, on Flickr .

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#3023818

Re: Poly / Hemi Build

[Re: Mike P]

#3023818

03/14/22 02:20 AM

03/14/22 02:20 AM

|

Joined: Aug 2003

Posts: 44,299

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 44,299

Bend,OR USA

|

Those pistons look like Hemi pistons to me in a poly block, correct? Will the hemi pushrod clear in that block without grinding?

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Poly / Hemi Build

[Re: Cab_Burge]

#3023866

Re: Poly / Hemi Build

[Re: Cab_Burge]

#3023866

03/14/22 08:57 AM

03/14/22 08:57 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

“…..Those pistons look like Hemi pistons to me in a poly block, correct?

Will the hemi pushrod clear in that block without grinding?......”

No those are HEMI pistons in a HEMI (only) block.

The grinding would only be necessary if I was running POLY heads on this block.

Cab I think you probably missed the post I made back in September.

“…….Shortly after the last post I ran into a show stopper on the Poly portion of the build. Something I should have thought about when I started doing my initial measurements was whether there would be interference issues between the combustion chamber in the 301 Poly head and the size of the cylinder bore on a 354 block (there is .3125 difference between bore size on the 301 and 354). Basically the head overhangs the cylinder bore. I’ve got some feelers out for 354 Poly heads/a complete motor but so far not a lot of luck.

For now we’re going to go ahead with the hemi portion of the build. We got the block sonic checked to be sure it will safely go out the .125” to standard bore 354……….”

So basically the engine is going back together as a plain Jane old HEMI.

This is probably a good time to recap what I’ve learned so far so I’ll do that in the next post.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#3023867

Re: Poly / Hemi Build

[Re: Mike P]

#3023867

03/14/22 09:02 AM

03/14/22 09:02 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

RECAP

This whole project started because of

“….A while back there was a thread “…..Chrysler,Dodge and Desoto early Hemi, what interchanges…..” and the discussion got around to whether Chrysler Poly (Spitfire) heads could be swapped onto a HEMI block……”

The part of that discussion that intrigued me was if a “sleeper” Poly motor could be built by swapping POLY heads onto a 392 block. That’s what started me down this road.

Doing the 331/354 instead of the tall deck 392 would still prove if it was possible or not. When I hit the show stopper of the head overhang with the 301 heads on the 354 bore and not having a pair of 354 POLY heads I decided to go ahead and built it back as the HEMI it originally was.

I only have access to the 301 heads I started with so some of this is still supposition. I still think it’s possible….with the right POLY heads.

Chrysler lists different part numbers for the 301, 331 and 354 Poly heads and based on what I ran into on the 301 heads I suspect the chambers are larger on the 331 heads and even more so on the 354 heads.

As far as just swapping a pair of Hemi Heads on a Poly or vice versa without any other changes other than the pushrods, it might be possible on a low compression engine without any problems. High compression pistons, high lift cam and/or larger valves would probably create issues and require a piston swap due to the location of the needed valve reliefs. One of the things I was going check was the feasibility of was just cutting a second pair of valve releifs into the stock 354 pistons.

As far as gaining or loosing compression with a head swap that will depend entirely on what you’re starting with and what you’re changing to. One of the things that really surprised me was that the 301 Poly heads and the triple nickel HEMI heads had virtually the same volume (about 101-102 CCs). I suspect the 331 and 354 heads have a larger chamber but without having the heads to measure that is still up in the air. The volume of the HEMI heads are also all over the place depending on the casting (for instance the 354 HEMI truck heads we measured have a larger chamber volume than the 55 passenger car heads).

On the combustion chamber overhanging the cylinder (the show stopper I ran into), I’m sure the heads were designed to accommodate a potential overbore of probably at least .060 oversize or so. So say 354 Poly heads on a .060 over 354 HEMI block should not be a problem. The issue might become using a 354 Poly head on a 392 HEMI block. The standard bore on a first gen 392 is approximately .062 larger than a first gen 354. At that point there should be no issue, but if you bore the 392 .060 over you’re now talking about a total of .122 total oversized and may run into the same combustion overhang into the bore problem.

Pushrod holes in the block going from a poly to a hemi head are a non issue. Going the other way may be. The angle of the pushrods when using poly heads required notches to be drilled/ground in into the block. 1955 was the first year of the POLY head and some HEMI blocks got the notches and some didn’t. If you’re going to the Poly heads on hemi block you will have to add these notches if they are not already there. Pictures I’ve seen of 392 HEMI blocks do not show the notches so going to the POLY heads will require they be added. On the plus side, modern composite head gaskets already are cut for either POLY or HEMI heads.

As far as pushrods, on the low deck 331/354 engines, the stock POLY pushrods are only about .065 shorter than the intake (short) pushrods on the HEMI, which is within the adjustment range of the adjustable pushrods Hot Heads sells. I suspect the same would be true for pushrods Hot Heads sells for the 392 tall deck motor.

So there are still some questions to answer that I can’t really do without having the parts in hand to check. I do believe that doing a HEMI to POLY conversion is still a possibility without having to do a lot of custom one off parts sourcing, just coming up with the right parts.

Why? I suppose just to have something a little different……and it would still be interesting to see what the difference in performance level really is…..remember the factory rated the 354 HEMI with more HP than the 354 POLY, but according to the factory manuals the POLY actually produced more Torque than the HEMI.

Last edited by Mike P; 03/14/22 02:09 PM.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#3025848

Re: Poly / Hemi Build

[Re: Mike P]

#3025848

03/20/22 07:34 PM

03/20/22 07:34 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

The heads aren’t back yet but I got the front cover and pan on this week and I got the balancer taken care of. There are a few options for bolt-on balancers available for the early HEMI. The “stock replacement” balancer that Hot Heads sells is not currently available. These were off the shelf 318/340 balancers for the internally balanced small blocks. They had a new keyway cut for the larger key the HEMI crankshaft uses and are indexed so the timing marks lined up with the timing pointer on the Hot Heads timing cover. Even if they had been available it was still cheaper to have the machine shop cut the new keyway in the balancer I bought. ![[Linked Image]](https://live.staticflickr.com/65535/51949738931_54a905df7d_z.jpg) MB MB by M Patterson, on Flickr I decided to build my own accessory brackets for this engine. Nothing against the aluminum brackets that Hot Heads sells but they are a little gaudy for how I want this engine to look. Saving a few bucks is always a plus too so this is pretty much a win win. For the Power Steering Pump I just duplicated the brackets I had previously made for the 57 Plymouth. It’s basically a slightly modified SB Chevy Saginaw bracket and a couple of braces to hold the pump solid. ![[Linked Image]](https://live.staticflickr.com/907/26743065977_aa13945167_z.jpg) HP1 HP1 by M Patterson, on Flickr ![[Linked Image]](https://live.staticflickr.com/892/26743066007_8282da5efd_z.jpg) HP3 HP3 by M Patterson, on Flickr ![[Linked Image]](https://live.staticflickr.com/65535/51949987397_7fe8a2a1d9_z.jpg) PSI PSI by M Patterson, on Flickr The alternator bracket is pretty easy to do. On my pervious 2 HEMIs I modified a 69-82 SB Chevy Truck/Corvette bracket. ![[Linked Image]](https://live.staticflickr.com/65535/51951080248_37062836b4_z.jpg) SBPS SBPS by M Patterson, on Flickr I actually have a spare bracket I’d previously modified laying around. I’d also picked up a different bracket for a 69-71 Chevy truck with AC a while back and decided to modified that one too (which entailed nothing more than elongating the mounting holes and grinding a small clearance notch). I’m not sure which one I’ll be using yet, the 69-71 bracket moves the alternator out and up a bit which may be helpful with the 6 pack air cleaner. ![[Linked Image]](https://live.staticflickr.com/65535/51949987427_a27264bb7f_z.jpg) AB AB by M Patterson, on Flickr I got some of the pieces for the AC compressor bracket rough cut but can’t really do much with that until I get the heads and water crossover are on the engine. So back to staring at the short block and waiting on parts. LOL

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: earlymopar]

#3025951

Re: Poly / Hemi Build

[Re: earlymopar]

#3025951

03/21/22 08:05 AM

03/21/22 08:05 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

Good catch. You're correct the PS pump is stationary. I failed to mention the belt for the PS pump also drives the water pump and alternator. The alternator will be the tensioner for that belt. Here's the same setup on my 57 Plymouth. ![[Linked Image]](https://live.staticflickr.com/815/26743066017_bb12b61885_z.jpg) HP4 HP4 by M Patterson, on Flickr

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: earlymopar]

#3026215

Re: Poly / Hemi Build

[Re: earlymopar]

#3026215

03/21/22 09:31 PM

03/21/22 09:31 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

Something I forgot to post is that as the HEMI and Poly blocks are the same, the information I posted about the oil pans, windage trays, timing cover, water pump conversion, balancer,and pulleys apply whether it's a 301/331/354 HEMI or Poly engine.

Also as far as the brackets I'm building (or the ones Hot Heads sells) they should also interchange between Poly and HEMI motors. The power steering pump bracket mounts to the timing cover and the alternator bracket uses the water crossover bolts to retain it. The AC bracket that I'm building will use 2 manifold bolts and the water crossover bolts on the passenger side.

Even the intake manifold interchanges between the 2 engines.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#3027834

Re: Poly / Hemi Build

[Re: Mike P]

#3027834

03/26/22 05:45 PM

03/26/22 05:45 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

Aaahhhh…..what could have been. LOL ![[Linked Image]](https://live.staticflickr.com/65535/51957318756_f2ef8828f6_z.jpg) WCB 1 WCB 1 by M Patterson, on Flickr I got the flywheel and bellhousing on this week so I could move the short-block over to the run stand for final assembly. Still waiting on the heads so I figured I’d go ahead and throw the Poly heads on and finish up the brackets. I couldn’t resist digging out the old Tri-Power just to see how it would have looked. Spent entirely too much time staring at it LOL. I finally took the Tri-Power off and installed the Hot Heads intake and went ahead and built the AC Compressor brackets. I duplicated the PAW AC bracket I’m using on the 57 Plymouth. The design is pretty simple, just a bit of work getting everything lined up with the bolt holes before welding it together. I had enough material left over I ended up making 2 sets (just in case I ever do come across a buildable Spitfire). I only did one set of spacers as they are unique to whatever manifold I use. ![[Linked Image]](https://live.staticflickr.com/65535/51961392839_78951fed95_z.jpg) AC B AC B by M Patterson, on Flickr So that pretty much wraps up the accessories. The more I study the Poly the more impressed I am with what Chrysler did. They designed a completely new head but with the exception of the pistons everything in the short-block is the same between the Poly and HEMI. They incorporated design features that allowed all external parts (with the exception of the exhaust manifolds) to interchange between the HEMI and POLY. Basically pretty much anything you can bolt to a HEMI will also fit a Poly. ![[Linked Image]](https://live.staticflickr.com/65535/51962545619_2bc09976ed.jpg) ACB ACB by M Patterson, on Flickr .

Last edited by Mike P; 03/27/22 06:22 PM.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: earlymopar]

#3028433

Re: Poly / Hemi Build

[Re: earlymopar]

#3028433

03/28/22 05:10 PM

03/28/22 05:10 PM

|

Joined: Sep 2003

Posts: 20,812

north of coder

moparx

Buying your homeless and unwanted bolt on battery terminals

|

Buying your homeless and unwanted bolt on battery terminals

Joined: Sep 2003

Posts: 20,812

north of coder

|

|

|

|

Re: Poly / Hemi Build

[Re: moparx]

#3030366

Re: Poly / Hemi Build

[Re: moparx]

#3030366

04/03/22 05:59 PM

04/03/22 05:59 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

The heads got done last week. ![[Linked Image]](https://live.staticflickr.com/65535/51976215148_a523dab6fc_z.jpg) TNH TNH by M Patterson, on Flickr As I posted earlier one was pretty badly pitted from sitting in a car trunk for at least 40 years. It took milling .040 off to clean it up. It’s actually not as much as it sounds though as when the factory put it together they used a steel shim head gasket with a compressed thickness of .024. The FelPro head gaskets I’m using are between .041 and .047 (depending on which reference you believe) so from a compression standpoint it’s effectively only about a .020 cut. The rest was pretty straight forward. New stainless valves, stock 1 ¾” exhaust and we stepped up the intake to 2” (from the stock 1 15/16”). They also got new springs, keepers and locks. The only thing that was really added are the lower spark plug tube seals. I’m running the same heads on the 331 in the 37 Dodge truck and any time you pull a plug it ends up coating the tip in oil (makes it awful hard to take a plug reading) and then it smokes like a train when you start it because of all the oil in the cylinders. It’s funny the 354 in the Plymouth doesn’t seem to have that problem. Anyway the heads are on, pushrods adjusted and the oil system primed. With any luck I may here it run sometime this week. .

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#3032340

Re: Poly / Hemi Build

[Re: Mike P]

#3032340

04/10/22 12:47 PM

04/10/22 12:47 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|