|

Poly / Hemi Build

#2584566

Poly / Hemi Build

#2584566

11/29/18 06:53 AM

11/29/18 06:53 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

A while back there was a thread “…..Chrysler,Dodge and Desoto early Hemi, what interchanges…..” and the discussion got around to whether Chrysler Poly (Spitfire) heads could be swapped onto a HEMI block. I ended up in one of those right time and place deals and picked up a basket case 55 331 HEMI and 2 pairs of 55 301 Chrysler Poly heads (not to be confused with the Plymouth 301 heads). Poly info is a bit scarce but as far as I can tell the major difference between the 301 and 354 Ploy heads is intake valve size and I got a new set of 354 Poly valves on order. Poly Parts  YJ3 YJ3 by M Patterson, on Flickr I’ve still got to get everything cleaned up and checked but if that goes well plans are to build the short block ……possibly taking it out to 354 if the sonic test goes well….. and setting it up for both the Poly and HEMI heads. I’m mostly curious to see how the Poly heads stack up to the HEMI heads……it may do well, or it could run like a 273 with a burned valve, but there is only one way to find out. At least the Tri-Power I pulled off the HEMI in the 57 Plymouth won’t go to waste as it will fit either combination.  T1 T1 by M Patterson, on Flickr

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2586027

Re: Poly / Hemi Build

[Re: Mike P]

#2586027

12/02/18 08:23 AM

12/02/18 08:23 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

Right now I'm just in the feasibility/parts collecting stage of the project. While I really want to build the engine as a Poly initially, chances are after I'm thru playing with that it's final configuration will be as a HEMI.

I'm aware that common belief is that switching to HEMI heads on a Poly will drop the compression by at least a point and that valve clearance reliefs are in different locations. Piston selection will be critical and possibly even require a piston change from one to the other.

I know that a lot of the initial figuring can be done on paper and researching the few sources I've come across. For me the real test will come when I actually have the parts in my hands and can do real world measurements and testing. It ought to be interesting...so far I haven't found any real show stoppers but you never know.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2590988

Re: Poly / Hemi Build

[Re: Mike P]

#2590988

12/12/18 06:17 PM

12/12/18 06:17 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

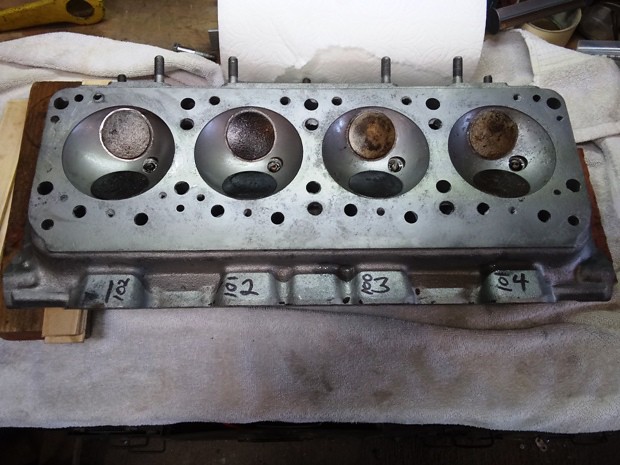

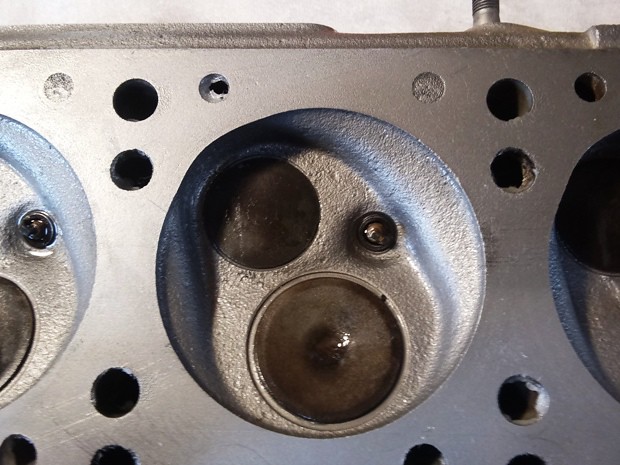

I’ve been working mostly on collecting, cleaning and inspecting parts. One of my concerns was getting the water jackets in the heads and block clean. The old caustic Hot Tanks that the machine shops used to use did a good job on dissolving the rust and scale but around here the last one of those went away 20 years ago. I’ve used citric acid in the past to de-rust old tools etc and always wanted to see how well it would do on engine parts. I picked up the largest tub WalMart and a 5 pound bag of citric acid off Amazon.  Y Citric Y Citric by M Patterson, on Flickr The first batch to go in was the HEMI heads, a spare set of rockers and the main caps.  Y Soak Y Soak by M Patterson, on Flickr I put in enough water to submerge the parts and started out with about 2 pounds of citric acid……I eventually added another 2 pounds as the solution became more saturated with rust and gunk and I changed out the cylinder heads eventually doing all 4 Poly heads too. It took about 4 days for the parts to soak to get them clean but I’m pretty happy with the results. From past experience it would have taken about half that time if I was doing this in the summer when it‘s warmer.  H3 H3 by M Patterson, on Flickr I’m happy with the water jackets, which was really the main reason for doing this,  WJ WJ by M Patterson, on Flickr With the heads cleaned (jet washed and bead blasted after the acid bath) I was able to start getting some of the information I’ve been curious about. Almost every article about the Polys indicates that Chrysler started producing them to create a “cheaper and lighter head and valve train”. They succeeded on 2 out of 3. After moving the heads around I was not surprised to find out the bare HEMI heads weighed in at 64 pounds…….the bare Poly heads was a “light weight” 63 pounds. With the heads cleaned, but before any machine work was done, I CC’ed the combustion chambers to get an idea about where I was going to be compression wise with the different heads. The Hemi heads came in between 100 and 102 CCs.  HH HH by M Patterson, on Flickr And then came the biggest surprise so far. Common belief (including mine) is that Poly heads have a much smaller combustion chamber than the Hemi heads and that when doing a head swap to convert a Poly to a Hemi that a piston change is required to get the compression back up. A glance at the chambers would seem to confirm that.  P2 P2 by M Patterson, on Flickr Actually CCing the chambers tells a completely different story. On the first 2 heads that I checked chamber volume ranged between 102 to 104 CC (the 104 cc chamber was on the other head). Practically speaking going from Poly to Hemi or the other way around will not cause a compression change.  P1 P1 by M Patterson, on Flickr Once I get the other pair of heads cleaned and inspected we'll make the decision on what two to build. These 301 Poly heads and the 331 2 bbl heads use a 1.812 intake valves. I've already picked up a set of the 331 4bbl/354 intake valves that are 1.94s. All the Poly heads used a 1.5 exhaust valve and Dave and I are currently looking into a cheaper and larger alternative to the stock exhaust valve. I've also been looking at the options for a roller cam.......any of the early HEMI guys out running a street roller cam they would recommend?

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2591192

Re: Poly / Hemi Build

[Re: Mike P]

#2591192

12/13/18 05:06 AM

12/13/18 05:06 AM

|

Joined: Aug 2003

Posts: 44,299

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 44,299

Bend,OR USA

|

Last edited by Cab_Burge; 12/13/18 05:08 AM.

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2591332

Re: Poly / Hemi Build

[Re: Mike P]

#2591332

12/13/18 02:05 PM

12/13/18 02:05 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

One of my friends owns a speed shop and usually brings the chassis Dyno in every 6 months or so and that will be when I do the testing.

What the eventual plan is to set the engine up initially as a carbureted Poly (probably using the Tri-Power)and then get it in a car. After doing the dyno runs, the next step will be to change the carburetors out for fuel injection (having 6 months in between tests will work out well). As I suspect the configuration I will eventually end up using will be the Hemi Heads and fuel injection that will be the final change.

I'm really as interested in the Torque results as I am the HP numbers. Comparing factory numbers on the standard 1956 300B 354 to the 58 4bbl 354 Poly shows some interesting results. The 300B engine made 340 HP and 385 ft lbs of torque. The Poly made 310 hp and 405 ft lbs.

It should be interesting.

Last edited by Mike P; 01/03/19 07:41 AM.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2600821

Re: Poly / Hemi Build

[Re: Mike P]

#2600821

01/03/19 07:40 AM

01/03/19 07:40 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

One thing I want to mention concerns the citric acid de-rusting. I am very pleased with the results but have a word of caution if the parts you de-rust are going to a machine shop. Most of the jet washes use a caustic solution as the cleaner which is a base. As acids and bases react with each other it is very important to clean/neutralize any residual acid from the parts to prevent foaming in the jet wash (yeah found out the hard way). In addition to a clean water rinse and air drying the parts before I send them in I am now adding a quick soak in water and baking soda followed by another clean water rinse and blow dry before I send the parts to the machine shop. I did get the block picked up and de-rusted.  BR BR by M Patterson, on Flickr I didn't get a picture of the block after it's soak, but it came out as clean as the rest of the parts. The one surprise on the block was that at some point it had already been bored to .030 .....and then driven enough to wear it out again. I'm pretty sure it can go out to at least .060 and the sonic check should tell me it will take the additional .065 to get it to 3.9375 354 bore size. While my wrist is healing Dave at the machine shop should be able to get a lot of the initial machining done so I can get some decisions made about the pistons and cam. .

Last edited by Mike P; 01/03/19 07:46 AM.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2601526

Re: Poly / Hemi Build

[Re: Mike P]

#2601526

01/04/19 02:49 PM

01/04/19 02:49 PM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

Everything I've read is that it should go the 3 15/16" 354 bore size without any problem.....provided there wasn't significant core shift. Just to be safe we're going to be doing a sonic check before we go forward.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2601831

Re: Poly / Hemi Build

[Re: Mike P]

#2601831

01/05/19 05:49 AM

01/05/19 05:49 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

. "......One of my friends owns a speed shop and usually brings the chassis Dyno in every 6 months or so and that will be when I do the testing.

What the eventual plan is to set the engine up initially as a carbureted Poly (probably using the Tri-Power) and then get it in a car. After doing the dyno runs, the next step will be to change the carburetors out for fuel injection (having 6 months in between tests will work out well). As I suspect the configuration I will eventually end up using will be the Hemi Heads and fuel injection that will be the final change......"

Right now I'm kicking around where I want the static compression ratio to come in at. As I want to eventually drive whatever car it goes into cross country I've resigned myself to limiting it to crap premium pump gas. Locally the only thing that is available is E10 92 octane and I suspect that by the end of the year that will change to E15. The last I checked the closest place (short of a small local airport 25 miles away) to buy non-ethanol gas is Phoenix (180 miles away).

I'm leaning towards about 9:1 static compression (I'll be playing with dynamic compression numbers when I choose a cam.). With that in mind I picked up a set of NOS standard 1956 Chrysler 354 Hemi Pistons which should put me close to the 9:1 compression ratio. Provided the block can go to 354 CI at least I can use the pistons for mockup and get the information I need to have a set of custom pistons made if needed.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2602888

Re: Poly / Hemi Build

[Re: Mike P]

#2602888

01/07/19 12:23 PM

01/07/19 12:23 PM

|

Joined: Sep 2007

Posts: 14,889

up yours

Supercuda

About to go away

|

About to go away

Joined: Sep 2007

Posts: 14,889

up yours

|

A Dodge 270 is not a Chrysler 331.

Other than some nuts and bolts and the term Hemi they have nothing in common.

They are not in the same family at all.

He's taking the 331 out .065" over, which always ups the compression ratio some. 677.93 cc for stock bore 331 vs 722.67 cc for stock bore 354 (0.65 over)

The 331 heads he has CC at 102, 354 heads (which these are not) average 108 cc's. That will up the compression as well.

So you have almost 45 cc more bore volume going into 6cc less chamber volume.

They say there are no such thing as a stupid question.

They say there is always the exception that proves the rule.

Don't be the exception.

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2603790

Re: Poly / Hemi Build

[Re: Mike P]

#2603790

01/09/19 08:53 AM

01/09/19 08:53 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

Thanks Supercuda, that was a good explanation, and I did not have the cc data on the 354 car head.

Truck, I have had the same experience when measuring various 50s and 60 engines (from all of the big 3) as your builder. Generally speaking advertised factory compression ratios and HP & TQ numbers were optimistic at best. I'm not saying the factory was making the numbers up, but rather what they (all) were delivering for testing was a truly blueprinted engine.

The blocks would have been square decked, line honed, crankshaft indexed, and heads CCed then equalized and taken to the minimum volume allowed. While the heads would not have been ported you can rest assured they would have been aggressively cleaned up. Pistons would be selected for the correct compression height. The rotating assembly would have been lightened as much as possible in accordance with the engine blueprint and then balanced.

Clearances on the bearings and pistons would have been set on the loose side of the specs to cut down friction.

Out on the production floor things were quite a were quite a bit different. Deck heights were generally taller and more often than not one was taller than the other. Combustion chambers were generally always larger than advertised and varied from mold to mold. A good example of this are the 301 heads i pulled. Both pair were 1555768 casting numbers but one pair was suffixed as -1 (the ones I'm using) and CCed at 102-104. The other pair were -2s and measured in at only 95-97 CCs.

The 331/354 Hemi heads I've measured over the years have been all over the place. I had a 354 truck head come in at 112 CCs and the other at around 105 CCs on the same engine.

As far as the projected 9:1 compression with the pistons I picked up. These are factory 1956 354 pistons with an "advertised" 9:1 compression ratio. Like the factory preparing a test engine, the first steps the block will undergo will be line honing and square decking. Provided we get the deck heights close to the factory specs it "should" be close to advertised compression. I'm also keeping in mind that the factory used a steel shim head gasket with compressed thickness of .026 and all that are currently available are composite gaskets with a compressed height that is .015-.025 thicker (resulting in about a 1/4 point lower compression). Milling the heads to compensate is not out of the question.

Now admittedly this all sounds good on paper but the only way to really find out will be to mock everything together and get real world measurements. This is something I have to do anyway so I can determine if the valve notches need to be modified for the Poly heads or worse case have a set of custom pistons made. The mock up is also critical to determine how much cam I get away with.

One of the purposes of this exercise was in part to find out if the blanket statement about converting a 301/331/354 Poly to a Hemi or converting a 392 Hemi to a big inch Poly by swapping on 354 Poly heads were true. So far some of the results have been surprising.....BUT ONLY APPLY TO MY SPECIFIC BUILD WITH THE SPECIFIC PARTS I'M USING.

For instance if I were to start with a 55 301 with an advertised compression ratio of 8:1 (and realistically truly only being in the 7-7.5:1 range) and throw a pair of 112 cc truck heads on with the thicker composite head gasket I would end up with an engine that would run, but performance wise be very disappointing. While the blanket statement that going from Poly to Hemi heads results in a compression drop would hold true in this case, it does not apply to mine as the Poly and Hemi heads I am using have virtually identical volumes.

Sorry about being so long winded but hopefully this provides some insight about where I'm going with the project. I'm really looking forward to comparing the test results in the 2 configurations (provided I don't run into any show stoppers along the way). My initial thoughts are the Hemi heads will make more HP, but I wouldn't be surprised to see better Torque from the Poly heads.

Last edited by Mike P; 03/07/19 06:29 AM.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

Re: Poly / Hemi Build

[Re: Mike P]

#2608502

Re: Poly / Hemi Build

[Re: Mike P]

#2608502

01/18/19 10:34 AM

01/18/19 10:34 AM

|

Joined: Aug 2007

Posts: 1,542

AZ

Mike P

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Aug 2007

Posts: 1,542

AZ

|

".........For some reason, I assumed that the Chrysler Hemi/Poly had the same factory compression rating as the Dodge......." The mid 50s thru the 60s were an interesting time for engine development. As performance increased so did the quality of the fuel to support it. The guy who could afford the top of the line car didn't have a problem with the few extra cents for the better grade of gas. From 55-58 Chryslers gradually went from 8:1 to 10:1 advertised (optimistic) compression. The guy who went in and bought a Plymouth or Dodge with a grocery getter 6 or 2 bbl Poly was more likely to appreciate only having to pay for regular grade gas. Historically trucks and industrial got whatever cheap crap gas was available resulting in a requirement to keep compression low. "........This discussion raises a question... probably could end up hijacking this otherwise useful thread... what do we call these engines? The group that includes: DeSoto Hemi Dodge Hemi Dodge Poly Chrysler Hemi Chrysler Poly ........" MOPAR ?  Adding the Polys and Hemis to the mix sure made keeping track of parts interesting.......likely a big part of the reason Chrysler became a leader in standardizing engines across corporate lines in the late 50s. As far as Plymouth having its own V8 engine that occurred in 57 with the 301/318. Just speculating, but with the 318 being a "new" design I suspect that its development had an eye on corporate sharing.

1957 Plymouth (Hemi, Dual Quads, A833 4 Speed 9 1/4 w 4.10) Sold

1937 Dodge Pickup (Hemi, 6X2 intake, 46RH, Dana 60 w 4.56) Sold

1968 Plymouth Valiant 2dr sedan (354 HEMI, 46RH w/4.30 gears) under construction

|

|

|

|

|