|

Re: Rod knock or Cracked Flexplate or ??

[Re: StealthWedge67]

#2178985

Re: Rod knock or Cracked Flexplate or ??

[Re: StealthWedge67]

#2178985

10/20/16 03:04 AM

10/20/16 03:04 AM

|

Joined: Dec 2004

Posts: 182

USA

Nitrofish

OP

OP

member

|

OP

OP

member

Joined: Dec 2004

Posts: 182

USA

|

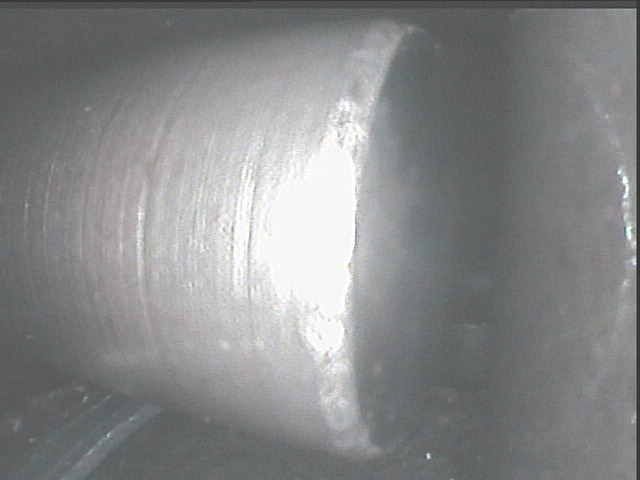

I cant see anything abnormal with the fuel pump. I worked the fuel pump arm against a piece of wood and I didnt hear anything abnormal. The fuel pump is a CV products billet Alum pump. The arm extends about 1.50 inches from the mounting flange of the pump. I dont have a stock pump to compare to. Fuel pump pushrod measured 3.205 inches in length. The condition looks good. Both ends of the pushrod still show chromoly hardened finishes. OD is 0.435. It was a little tight pulling it out of the bore, but it seemed to move freely when I moved it through its normal range of motion. This was once the engine cooled down enough to work on it. Cam lobe is in good condition. However, is the pushrod supposed to ride on the camshaft at all times like a camshaft lifter? Is the correct pushrod length 3.220 or 3.250? Does anyone have a stock mechanical fuel pump to measure the extension of the arm from the fuel pump mounting flange? Note the attached picture, there is a gap between the pushrod and camshaft lobe. Not sure if this is normal or not.  Either way I would think this would cause a noise at all times not just on a hot engine....

|

|

|

Re: Rod knock or Cracked Flexplate or ??

[Re: Nitrofish]

#2179108

Re: Rod knock or Cracked Flexplate or ??

[Re: Nitrofish]

#2179108

10/20/16 12:07 PM

10/20/16 12:07 PM

|

Joined: Aug 2009

Posts: 1,324

Ohio

jlatessa

pro stock

|

pro stock

Joined: Aug 2009

Posts: 1,324

Ohio

|

On both the OE pump from our RT and the new one just out to check the rod,

1-5/8" from flange face to tip and 1-1/2" to wear witness mark.

Hope this helps, Joe

PS measurements on Comp Cams pump rods:

Comp's #4646, with tip for roller cam, 3.211" (new in package)

Comp's #4626, out of Engine w/knock, showing acceptable tip wear, 3.222"

Last edited by jlatessa; 10/20/16 12:19 PM.

|

|

|

Re: Rod knock or Cracked Flexplate or ??

[Re: Nitrofish]

#2179157

Re: Rod knock or Cracked Flexplate or ??

[Re: Nitrofish]

#2179157

10/20/16 01:29 PM

10/20/16 01:29 PM

|

Joined: Aug 2003

Posts: 43,863

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,863

Bend,OR USA

|

I have never had a stock OEM pump or a Holley or after market Hi Po Carter pump have any clearances between the pump arm and the pushrod, NEVER. They where all preloaded some  I make it SOP to rotate the motor over on the starter with the pump out and the plug out and use a small thin screw driver to push on the pump rod while bumping the starter over to find the closed position on the cam fuel pump lobe and then finish the pump install by putting grease on the pushrod to hold it in place and put the plug back in before installing the pump  IHTHs I do have several stock OEM pushrods as well as some new D.C. Mopar Hi Po pushrods, the new ones aren't worth using  The ends are real course finish, not like the stock ones at all

Last edited by Cab_Burge; 10/20/16 01:31 PM.

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Rod knock or Cracked Flexplate or ??

[Re: Nitrofish]

#2179315

Re: Rod knock or Cracked Flexplate or ??

[Re: Nitrofish]

#2179315

10/20/16 06:52 PM

10/20/16 06:52 PM

|

Joined: Aug 2003

Posts: 43,863

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,863

Bend,OR USA

|

jlatessa, Perfect! Thank you for the measurements. Exactly what I needed. I appreciate the support!

Cab Burge,

Thank you also. I'm using a CV products fuel pump and I'm comparing the arm length/extension etc.

I may have a lead on a stock pump that I will borrow just to see if the pump arm is higher up or applying more preload to the fuel pump pushrod.

I will report back... Please do  I'm wondering what's up on your deal now

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Rod knock or Cracked Flexplate or ??

[Re: Nitrofish]

#2184991

Re: Rod knock or Cracked Flexplate or ??

[Re: Nitrofish]

#2184991

10/28/16 10:36 PM

10/28/16 10:36 PM

|

Joined: Aug 2003

Posts: 43,863

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,863

Bend,OR USA

|

I think I would pull that rod and piston out and check the big end for roundness instead of wondering why that bearing failed   Was it checked before assembling the motor? If so what was the bearing to crank clearances? Any chance of debris in the oil passage to that rod bearing being stuck up in the oil passage in the crankshaft  I'm sure the crank journal should polish up well enough to be usable  When I was a lot younger, and a lot less knowledgeable than now, I would have tried to polish that journal in the motor in the car  Now I would remove the crank and take it to a good crankshaft grinding company and have them look at it to see if it would polish and still be useable

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Rod knock or Cracked Flexplate or ??

[Re: Clanton]

#2206581

Re: Rod knock or Cracked Flexplate or ??

[Re: Clanton]

#2206581

12/02/16 05:36 PM

12/02/16 05:36 PM

|

Joined: Jun 2003

Posts: 52,972

Romeo MI

MR_P_BODY

Master

|

Master

Joined: Jun 2003

Posts: 52,972

Romeo MI

|

Do you have a radiused crank(fillets).. if so those bearings could have pushed things tight (side clearance)

|

|

|

Re: Rod knock or Cracked Flexplate or ??

[Re: Nitrofish]

#2206588

Re: Rod knock or Cracked Flexplate or ??

[Re: Nitrofish]

#2206588

12/02/16 05:58 PM

12/02/16 05:58 PM

|

Joined: Sep 2014

Posts: 4,457

Washington

madscientist

master

|

master

Joined: Sep 2014

Posts: 4,457

Washington

|

When you see cam bearings getting smashed down, there is an OILING issue. Don't know if your restricting oil or something, but there is no way those spring pressures would drive the cam into the bearings like that if they had oil.

I used to run 360 pounds on the seat with new springs. I also grooved the number 2 & 4 cam bearing journals to get oil upstairs all the time. The cam bearing a always showed witness marks from the groove in the cam on the bottom of the bearing.

The next upgrade was going to be roller bearings on number 1 and 5 cam bearings. I sold it all instead.

Anyway, you have an oil issue.

Just because you think it won't make it true. Horsepower is KING. To dispute this is stupid. C. Alston

|

|

|

|

|