|

Re: dodge dakota frame swap, custom coils or air bags needed

[Re: 5280Dart]

#2149613

Re: dodge dakota frame swap, custom coils or air bags needed

[Re: 5280Dart]

#2149613

09/07/16 01:15 PM

09/07/16 01:15 PM

|

Joined: Jan 2003

Posts: 1,111

tri-cities Washington/Denver, ...

5280Dart

OP

OP

super stock

|

OP

OP

super stock

Joined: Jan 2003

Posts: 1,111

tri-cities Washington/Denver, ...

|

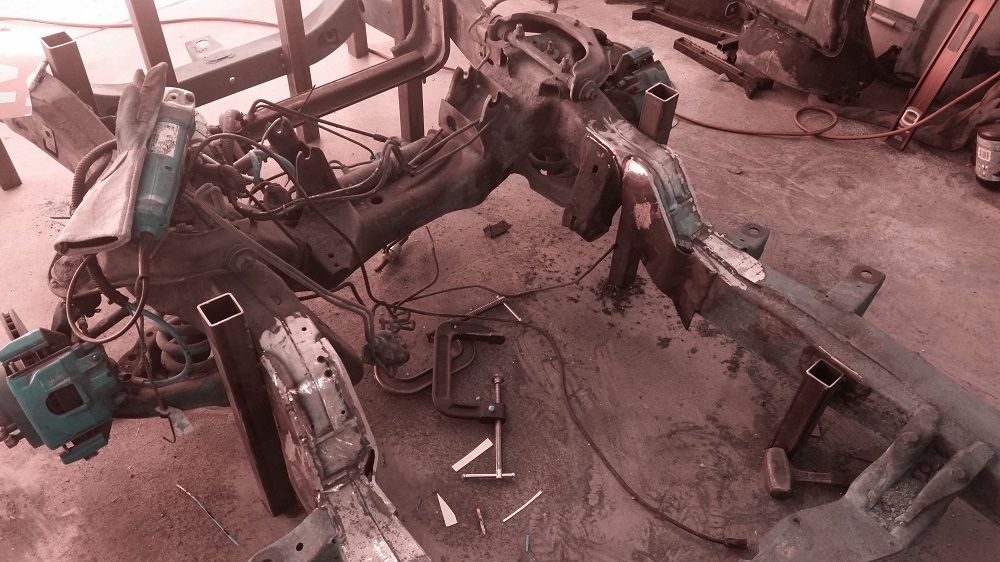

I tried to make sure the frame sections overlapped each other by a value nearly equal to the dimensions of the tubing. In other words if one section of frame was made of 3x5, I overlapped the sections by 5". I welded the portions of the frames together that matched up, which was not much as the dakota frame is narrower than the '57 and also positions higher when at factory ride height. I then used 3/16" plate to bridge across from one frame section to the other. I used an oxyacetylene rosebud, a vise, and hammer to form the plate steel pieces into rough shape, and then tacked and welded the pieces into position using large C-clamps, heat, and hammer for final shape.  Making sure you position the kick up from the parent frame to the dakota far enough forward as to avoid interference with the firewall is important.

Last edited by 5280Dart; 09/07/16 01:18 PM.

|

|

|

Re: dodge dakota frame swap, custom coils or air bags needed

[Re: 5280Dart]

#2149625

Re: dodge dakota frame swap, custom coils or air bags needed

[Re: 5280Dart]

#2149625

09/07/16 01:35 PM

09/07/16 01:35 PM

|

Joined: Jan 2003

Posts: 1,111

tri-cities Washington/Denver, ...

5280Dart

OP

OP

super stock

|

OP

OP

super stock

Joined: Jan 2003

Posts: 1,111

tri-cities Washington/Denver, ...

|

A lot of people will view this process as barbaric. I did not have anything beyond gravity holding the frame sections down to the floor. I considered buying 3/8" x 4' x 8' sheets and welding the legs positioning the frame sections to the sheeting. I was quoted a price of $370 a sheet for the steel, and would need 5 sheets. At that point I might as well buy a prefabricated frame fixture table.

I marked the locations of the legs on the floor using a sharpie to ensure that I had not moved anything around to a different part of the garage floor, as I leveled and positioned the frames in that location and the floor is not level across its surface.

That being said, the heat from welding did pull on the frame, causing some slight bowing upward of the rails. This distortion may have been minimized by welding the legs to plate or attachment to a fixture table. The distortion was nearly equal from the left side to the right side, and was equal to .125 to .1875 of an inch. Some will gasp at this result, but I am not building the space shuttle. Typically, automotive collision repair of unibody cars mandate that the dimensions between reference points on structural members be within 3mm to constitute an adequate repair. This is equal to .118 inches. Do your best to keep things within an 1/8th of an inch.

|

|

|

Re: dodge dakota frame swap, custom coils or air bags needed

[Re: 5280Dart]

#2149636

Re: dodge dakota frame swap, custom coils or air bags needed

[Re: 5280Dart]

#2149636

09/07/16 01:59 PM

09/07/16 01:59 PM

|

Joined: Sep 2007

Posts: 14,889

up yours

Supercuda

About to go away

|

About to go away

Joined: Sep 2007

Posts: 14,889

up yours

|

I've been known to rent a storage facility of sufficient size for projects that need more room. Don't know how long your frame work went, but two months of rental on a 20x10 storage place was worth it to me on occasion. A generator fixes power issues and I already have a portable one.

I've also been known to build a laundry room to clear out space in the garage. makes her happy to be out of the garage, makes me happy to have the room. I recently, well two years ago anyway, did just that.

They say there are no such thing as a stupid question.

They say there is always the exception that proves the rule.

Don't be the exception.

|

|

|

Re: dodge dakota frame swap, custom coils or air bags needed

[Re: Supercuda]

#2149674

Re: dodge dakota frame swap, custom coils or air bags needed

[Re: Supercuda]

#2149674

09/07/16 02:29 PM

09/07/16 02:29 PM

|

Joined: Jan 2003

Posts: 1,111

tri-cities Washington/Denver, ...

5280Dart

OP

OP

super stock

|

OP

OP

super stock

Joined: Jan 2003

Posts: 1,111

tri-cities Washington/Denver, ...

|

I've been known to rent a storage facility of sufficient size for projects that need more room. Don't know how long your frame work went, but two months of rental on a 20x10 storage place was worth it to me on occasion. A generator fixes power issues and I already have a portable one.

I've also been known to build a laundry room to clear out space in the garage. makes her happy to be out of the garage, makes me happy to have the room. I recently, well two years ago anyway, did just that. Yeah, I rented a 10x20 for the plymouth at $180 a month from December to July. Picked up the frame in December. Then the shop space opened up... $600 a month. The fab took longer than it should because I work 50 hours a week and am taking online college classes to finish up a B.S. I failed to finish years ago. I can build cars, I just cant make more time. All of the work up until July was done in the garage of a rental that my lease states will have absolutely no vehicle maintenance performed on premises. I don't have a full time her, so that is one hurdle of happiness that I have not had to clear.

|

|

|

Re: dodge dakota frame swap, custom coils or air bags needed

[Re: 5280Dart]

#2149689

Re: dodge dakota frame swap, custom coils or air bags needed

[Re: 5280Dart]

#2149689

09/07/16 02:46 PM

09/07/16 02:46 PM

|

Joined: Sep 2007

Posts: 14,889

up yours

Supercuda

About to go away

|

About to go away

Joined: Sep 2007

Posts: 14,889

up yours

|

Ow, rental costs are high. I understand about the time issue.

They say there are no such thing as a stupid question.

They say there is always the exception that proves the rule.

Don't be the exception.

|

|

|

Re: dodge dakota frame swap, custom coils or air bags needed

[Re: 5280Dart]

#2149829

Re: dodge dakota frame swap, custom coils or air bags needed

[Re: 5280Dart]

#2149829

09/07/16 06:07 PM

09/07/16 06:07 PM

|

Joined: Jan 2003

Posts: 10,950

Freeport IL USA

poorboy

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 10,950

Freeport IL USA

|

For those that may wish to follow the example of this build with their own, where the Dakota clip was welded on top of the original 57 frame is likely the reason the finished product now sits too low. Its more work, and more difficult, but if the Dakota clip would have been welded to the 57 frame with top of the 57 frame welded at 1/2 the height from the top of the Dakota frame, the ride height would probably been correct.

As is, the Dakota crossmember is raised up from the 57 frame too much because the Dakota was welded on top of the 57 frame. I don't know what the height (top to bottom) the 57 frame is, but lets assume that it is 4" high, measured between the top and the bottom of the frame.

If the Dakota frame was sunk into the 57 frame at 1/2 the 57 frame thickness (in our case 2") you would have raised the front of the 57 frame up 2" higher in the air then it is currently.

The body sits on top of the rear section of the frame. The suspension attaches to the front frame. When you want to determine ride height, you need to make your measurements from either the top of both sections, or from the bottom of both sections. Measuring from the top of one and the bottom of the other will result in something either being too high or too low. Its best to make these measurements while the vehicle weight and the motor weight is still on the frame sections. If the front frame section is 6" off the ground, measured from the top of the frame with the motor weight there, at the cut location, and the height o the top of the rear section of the frame is 6" to the top of the frame with the weight of the vehicle on it, at the cut location, when you splice to two sections together, you need to maintain the two height measurements to maintain the same vehicle ride height.

If you want to lower the vehicle ride height, you can rise the front section the amount you want to lower the the vehicle. That means that if you want to lower the front of the car 2", you will raise the front section 2" higher then your beginning measurements. Use caution here, this will be the actual height change at the weld joint, everything else will have to be adjusted accordingly, and any change in the equipment from the original equipment present at the time of measurement will alter the changes you are making.

In this case, he determined the front ride height from the bottom of the front crossmember, and from the top of the rear frame. Its easy to do. Had he taken both measurements from the top, he would probably have seen the 4" (or whatever the 57 frame height is) difference and thought it might be too much. Generally speaking, a 2" difference between the two measurements is a big difference on the ride height.

I sure hope this makes sense, sometimes things are lost in the translation. Gene

|

|

|

Re: dodge dakota frame swap, custom coils or air bags needed

[Re: 5280Dart]

#2149878

Re: dodge dakota frame swap, custom coils or air bags needed

[Re: 5280Dart]

#2149878

09/07/16 07:06 PM

09/07/16 07:06 PM

|

Joined: Sep 2007

Posts: 14,889

up yours

Supercuda

About to go away

|

About to go away

Joined: Sep 2007

Posts: 14,889

up yours

|

If the LCA's sit parallel to the ground right now then you are right.

If they sit with the inner pivot lower then it needs more spring.

They say there are no such thing as a stupid question.

They say there is always the exception that proves the rule.

Don't be the exception.

|

|

|

Re: dodge dakota frame swap, custom coils or air bags needed

[Re: poorboy]

#2150069

Re: dodge dakota frame swap, custom coils or air bags needed

[Re: poorboy]

#2150069

09/07/16 11:11 PM

09/07/16 11:11 PM

|

Joined: Jan 2003

Posts: 1,111

tri-cities Washington/Denver, ...

5280Dart

OP

OP

super stock

|

OP

OP

super stock

Joined: Jan 2003

Posts: 1,111

tri-cities Washington/Denver, ...

|

Poorboy,

For those that may wish to follow the example of this build with their own, where the Dakota clip was welded on top of the original 57 frame is likely the reason the finished product now sits too low. Its more work, and more difficult, but if the Dakota clip would have been welded to the 57 frame with top of the 57 frame welded at 1/2 the height from the top of the Dakota frame, the ride height would probably been correct.

For the record, the question asked at the start of this post was if anyone had experience ordering custom coils or air bags for a first gen Dakota. You have spent a bit of effort in your response, and I appreciate your interest. The photo do not show enough detail, but the Dakota frame is embedded into the '57 frame, not simply laid across the top of it and then attached. The section from the Dakota was cut away from the rest of the frame with fixtures attached to ensure the ride height was maintained along with the factory geometry of a-arm angles and steering rack output shaft/tie rod angle. Again, the photos I have provided are inadequate in giving enough prospective/information for that to be obvious.

As is, the Dakota crossmember is raised up from the 57 frame too much because the Dakota was welded on top of the 57 frame. I don't know what the height (top to bottom) the 57 frame is, but lets assume that it is 4" high, measured between the top and the bottom of the frame.

Again, the Dakota frame is sunk into/embedded into the '57 frame. The '57 has 6" of clearance from the ground to the bottom of the frame rail, and that was the clearance I provided with the fixtures prior to any cutting of the replacement frame. The clearance from the ground to the bottom of the crossmember under the engine was 9" on the Dakota prior to any cutting, which I provided with the fixtures prior to cutting as well. I am aware that a. that does not tell you what the distance from the underside or top of the frame rail of the Dakota was at the connection point, and b. 9" - 6" = 3", the amount I am attempting to recoup with different springs/bags. Hopefully by the end of this response, it will be understood that it is a coincidence that the difference in measurements provided is 3" and not an indicator of the cause.

If the Dakota frame was sunk into the 57 frame at 1/2 the 57 frame thickness (in our case 2") you would have raised the front of the 57 frame up 2"t higher in the air then it is currently.

Understood. No further explanation needed. I agree, sinking the Dakota sub-frame further into the '57 frame would cause the overall ride height to increase. However, as I have tried to explain, with the weak springs I would have ended up with a correct ride height, with no suspension travel, and poor suspension geometry.

The body sits on top of the rear section of the frame. The suspension attaches to the front frame. When you want to determine ride height, you need to make your measurements from either the top of both sections, or from the bottom of both sections. Measuring from the top of one and the bottom of the other will result in something either being too high or too low. Its best to make these measurements while the vehicle weight and the motor weight is still on the frame sections. If the front frame section is 6" off the ground, measured from the top of the frame with the motor weight there, at the cut location, and the height o the top of the rear section of the frame is 6" to the top of the frame with the weight of the vehicle on it, at the cut location, when you splice to two sections together, you need to maintain the two height measurements to maintain the same vehicle ride height.

I would think that it would be obvious that you would take your measurements from the same side of the frame rails, top or bottom and all sides/each end of the frames. Just to be clear however, you would not have to provided you accounted for the different datum points when calculating ride height.

If you want to lower the vehicle ride height, you can rise the front section the amount you want to lower the vehicle. That means that if you want to lower the front of the car 2", you will raise the front section 2" higher then your beginning measurements. Use caution here, this will be the actual height change at the weld joint, everything else will have to be adjusted accordingly, and any change in the equipment from the original equipment present at the time of measurement will alter the changes you are making.

Understood. What you are saying is that by raising the front suspension mounting locations i.e. the subframe/graft from the Dakota, as it relates to the frame you are attaching it to, you are effectively lowering the overall ride height of the car. No disagreement there.

In this case, he determined the front ride height from the bottom of the front crossmember, and from the top of the rear frame. Its easy to do. Had he taken both measurements from the top, he would probably have seen the 4" (or whatever the 57 frame height is) difference and thought it might be too much. Generally speaking, a 2" difference between the two measurements is a big difference on the ride height.

Incorrect. I did use the bottom of the front crossmember of the Dakota frame, along with measurement elsewhere on the subframe to provide the proper caster angles when completed, and I used the underside of the '57 frame to the ground as my frame of reference. Again, the pictures do not show enough detail.

As it currently sits, if I stand on the front horns of the frame with the engine and transmission installed, the lower a-arms run out of travel and contact the frame near the spring buckets. The angle of the upper a-arms even without my standing on the horns are angled upward from the center of the chassis to the outside of the chassis. The lower a-arms do as well though not as severely. Basically the suspension looks like a mini-truck with the coils cut too far. The springs need to be replaced. So my question was, does anyone have experience ordering custom coils or air bags for a first gen Dakota. It sounds like I might get away with just throwing some v8 springs in rather than custom order anything.

Shane

|

|

|

Re: Progress

[Re: 5280Dart]

#2163476

Re: Progress

[Re: 5280Dart]

#2163476

09/28/16 07:01 AM

09/28/16 07:01 AM

|

Joined: Mar 2005

Posts: 303

southwest Alabama

challenger73400

enthusiast

|

enthusiast

Joined: Mar 2005

Posts: 303

southwest Alabama

|

What oil pan are you using? Dipstick? Looking good!

One more question, what you got in mind for brake master cylinder and booster?

Last edited by challenger73400; 09/28/16 07:04 AM.

|

|

|

Re: Progress

[Re: 5280Dart]

#2163504

Re: Progress

[Re: 5280Dart]

#2163504

09/28/16 09:09 AM

09/28/16 09:09 AM

|

Joined: Sep 2003

Posts: 20,530

north of coder

moparx

"Butt Crack Bob"

|

"Butt Crack Bob"

Joined: Sep 2003

Posts: 20,530

north of coder

|

it looks like you got it as you want it now. also, it appears that your setup is like a M2, in regards to the engine placement directs almost the entire engine weight roughly at the center of the wheel. this was exactly why the M2 had 4, 6, and 8cylinder springs of differing rates. that is also why when the M2 setup is used in a prewar hot rod almost 100% of the time you will be using 4 or 6 cylinder springs even with a heavy big block, as the engine weight has been shifted behind the spindle center line, often by a large amount. as your new springs appear used, and you still need to install the front clip and fluids, if you had some idea how much those components weighed, you could get a couple of friends that weighed roughly the same weight to stand on the frame horns and get a pretty accurate idea how the car would sit at ride height. but i agree, i believe you will be real close to the stance you desire once those items are reinstalled. the car looks very nice by the way.

|

|

|

Re: Progress

[Re: challenger73400]

#2163563

Re: Progress

[Re: challenger73400]

#2163563

09/28/16 10:51 AM

09/28/16 10:51 AM

|

Joined: Jan 2003

Posts: 1,111

tri-cities Washington/Denver, ...

5280Dart

OP

OP

super stock

|

OP

OP

super stock

Joined: Jan 2003

Posts: 1,111

tri-cities Washington/Denver, ...

|

What oil pan are you using? Dipstick? Looking good!

One more question, what you got in mind for brake master cylinder and booster? I am using a jeep srt8 oil pan and dipstick. Ordered it from a website called moparoverstock.com if I remember right. Right now, I plan on using a jeep tj booster and master cylinder. The booster diameter is 8".

|

|

|

|

|