|

Re: Trick Flow heads

[Re: gearhead01]

#2081971

Re: Trick Flow heads

[Re: gearhead01]

#2081971

05/28/16 07:30 PM

05/28/16 07:30 PM

|

Joined: Jan 2004

Posts: 13,247

Mt. Vernon, Ohio

dartman366

I Live Here

|

I Live Here

Joined: Jan 2004

Posts: 13,247

Mt. Vernon, Ohio

|

So has anyone tried the Harlan Sharp S70015KE rocker set yet? those are the one's that TF says are the ones to use, curious about the geometry with those and they are about $230.00 more than the S70015K's according to Summit.  really like to know because thats my next purchase for the motor.

Light travels faster than the speed of sound,,,this is why some people seem bright untill you hear them speak.

|

|

|

Re: Trick Flow heads

[Re: dartman366]

#2082026

Re: Trick Flow heads

[Re: dartman366]

#2082026

05/28/16 08:57 PM

05/28/16 08:57 PM

|

Joined: Jul 2013

Posts: 561

USA

B3RE

mopar

|

mopar

Joined: Jul 2013

Posts: 561

USA

|

Here are some pics of PRW stainless rockers on Trick Flows. The geometry is perfect. If the rocker will fit under the valve cover, it can be "adjusted" to have perfect geometry also, at least on the valve side. The Harlands are not going to be better than any other rocker when just bolted on.

Mike Beachel

I didn't write the rules of math nor create the laws of physics, I am just bound by them.

|

|

|

Re: Trick Flow heads

[Re: dartman366]

#2082036

Re: Trick Flow heads

[Re: dartman366]

#2082036

05/28/16 09:15 PM

05/28/16 09:15 PM

|

Joined: Jan 2003

Posts: 31,250

Oregon

AndyF

I Win

|

I Win

Joined: Jan 2003

Posts: 31,250

Oregon

|

So has anyone tried the Harlan Sharp S70015KE rocker set yet? those are the one's that TF says are the ones to use, curious about the geometry with those and they are about $230.00 more than the S70015K's according to Summit.  really like to know because thats my next purchase for the motor. I'll have some of the Harland Sharp E rocker arms in a couple of week to try on the Trick Flow heads. From what I've seen so far they'll work just fine.

|

|

|

Re: Trick Flow heads

[Re: B3RE]

#2082039

Re: Trick Flow heads

[Re: B3RE]

#2082039

05/28/16 09:25 PM

05/28/16 09:25 PM

|

Joined: Jun 2003

Posts: 52,972

Romeo MI

MR_P_BODY

Master

|

Master

Joined: Jun 2003

Posts: 52,972

Romeo MI

|

You dont concern yourself with that gap on the bottom of your shim.. seems it will try and spread the stand and split it or crack it off

|

|

|

Re: Trick Flow heads

[Re: B3RE]

#2082040

Re: Trick Flow heads

[Re: B3RE]

#2082040

05/28/16 09:28 PM

05/28/16 09:28 PM

|

Joined: Jan 2004

Posts: 13,247

Mt. Vernon, Ohio

dartman366

I Live Here

|

I Live Here

Joined: Jan 2004

Posts: 13,247

Mt. Vernon, Ohio

|

just how good of quality are these rockers besides being good geometry wise, will they hold up to the rigors of a bracket motor? and what about service after the sale, never heard of this company is why I ask.

Light travels faster than the speed of sound,,,this is why some people seem bright untill you hear them speak.

|

|

|

Re: Trick Flow heads

[Re: MR_P_BODY]

#2082050

Re: Trick Flow heads

[Re: MR_P_BODY]

#2082050

05/28/16 09:47 PM

05/28/16 09:47 PM

|

Joined: Jul 2013

Posts: 561

USA

B3RE

mopar

|

mopar

Joined: Jul 2013

Posts: 561

USA

|

You dont concern yourself with that gap on the bottom of your shim.. seems it will try and spread the stand and split it or crack it off  Nope, not at all concerned. There is no gap, just a little high tack to hold them in place when installing the shafts. If they were shims, I would definitely be concerned about splitting the stands, but they are billet spacers, not flat shim stock.

Mike Beachel

I didn't write the rules of math nor create the laws of physics, I am just bound by them.

|

|

|

Re: Trick Flow heads

[Re: B3RE]

#2082058

Re: Trick Flow heads

[Re: B3RE]

#2082058

05/28/16 10:04 PM

05/28/16 10:04 PM

|

Joined: Jun 2003

Posts: 52,972

Romeo MI

MR_P_BODY

Master

|

Master

Joined: Jun 2003

Posts: 52,972

Romeo MI

|

You dont concern yourself with that gap on the bottom of your shim.. seems it will try and spread the stand and split it or crack it off  Nope, not at all concerned. There is no gap, just a little high tack to hold them in place when installing the shafts. If they were shims, I would definitely be concerned about splitting the stands, but they are billet spacers, not flat shim stock. Sure is contacting on the corner and not on the bottom... I buy those tapered spacers all the time at Mancinis... .030 out to 0 at the ends... maybe your are thicker

|

|

|

Re: Trick Flow heads

[Re: dartman366]

#2082062

Re: Trick Flow heads

[Re: dartman366]

#2082062

05/28/16 10:08 PM

05/28/16 10:08 PM

|

Joined: Jul 2013

Posts: 561

USA

B3RE

mopar

|

mopar

Joined: Jul 2013

Posts: 561

USA

|

just how good of quality are these rockers besides being good geometry wise, will they hold up to the rigors of a bracket motor? and what about service after the sale, never heard of this company is why I ask. You're kinda missing the point here. I'm not trying to talk you into running PRW rockers. What I'm trying to explain, is that all roller rockers need to have the geometry set, because it is not built into the rocker. You may find a rocker that fits on the head with the roller perfectly centered when the valve is on the seat, but that isn't good geometry. Nether is a centered sweep when the sweep is excessively wide. The pic is of a 505 pump gas street build with a .585" lift hydraulic roller and with that rocker, it has .029" sweep across the valve tip. The fact that it is centered, is because I offset the shaft accordingly when I raised the it to minimize the sweep. FWIW, I avoid rockers that use ball style adjusters. I know that makes me a heretic, but I know the negative effect they have on pushrod side geometry. I'll just have to live with the shame.

Mike Beachel

I didn't write the rules of math nor create the laws of physics, I am just bound by them.

|

|

|

Re: Trick Flow heads

[Re: MR_P_BODY]

#2082070

Re: Trick Flow heads

[Re: MR_P_BODY]

#2082070

05/28/16 10:22 PM

05/28/16 10:22 PM

|

Joined: Jul 2013

Posts: 561

USA

B3RE

mopar

|

mopar

Joined: Jul 2013

Posts: 561

USA

|

You dont concern yourself with that gap on the bottom of your shim.. seems it will try and spread the stand and split it or crack it off  Nope, not at all concerned. There is no gap, just a little high tack to hold them in place when installing the shafts. If they were shims, I would definitely be concerned about splitting the stands, but they are billet spacers, not flat shim stock. Sure is contacting on the corner and not on the bottom... I buy those tapered spacers all the time at Mancinis... .030 out to 0 at the ends... maybe your are thicker  I know it looks like a gap, Mike, but the dark area is just where the high tack squeezed out when the shafts were tightened. Probably had too much on it, but my high tack is starting to dry out some and getting a little thick. My spacers are always thicker than .030". I've had them as thick as .345", but the thinnest has been .075". The ones in the pic happen to be .100". It just depends on what the math says it needs to be for a given application.

Mike Beachel

I didn't write the rules of math nor create the laws of physics, I am just bound by them.

|

|

|

Re: Trick Flow heads

[Re: B3RE]

#2082204

Re: Trick Flow heads

[Re: B3RE]

#2082204

05/29/16 09:10 AM

05/29/16 09:10 AM

|

Joined: Jan 2004

Posts: 13,247

Mt. Vernon, Ohio

dartman366

I Live Here

|

I Live Here

Joined: Jan 2004

Posts: 13,247

Mt. Vernon, Ohio

|

just how good of quality are these rockers besides being good geometry wise, will they hold up to the rigors of a bracket motor? and what about service after the sale, never heard of this company is why I ask. You're kinda missing the point here. I'm not trying to talk you into running PRW rockers. What I'm trying to explain, is that all roller rockers need to have the geometry set, because it is not built into the rocker. You may find a rocker that fits on the head with the roller perfectly centered when the valve is on the seat, but that isn't good geometry. Nether is a centered sweep when the sweep is excessively wide. The pic is of a 505 pump gas street build with a .585" lift hydraulic roller and with that rocker, it has .029" sweep across the valve tip. The fact that it is centered, is because I offset the shaft accordingly when I raised the it to minimize the sweep. FWIW, I avoid rockers that use ball style adjusters. I know that makes me a heretic, but I know the negative effect they have on pushrod side geometry. I'll just have to live with the shame. not really missing the point, just asking about quality, I get it about having to adjust the shaft height to bring it all together, but it's been noted that some rockers are longer or shorter from fulcrum centerline to tip centerline,wouldn't using ones that are more correct in that respect be easier to start with?

Light travels faster than the speed of sound,,,this is why some people seem bright untill you hear them speak.

|

|

|

Re: Trick Flow heads

[Re: dartman366]

#2082222

Re: Trick Flow heads

[Re: dartman366]

#2082222

05/29/16 10:30 AM

05/29/16 10:30 AM

|

Joined: Jul 2013

Posts: 561

USA

B3RE

mopar

|

mopar

Joined: Jul 2013

Posts: 561

USA

|

just how good of quality are these rockers besides being good geometry wise, will they hold up to the rigors of a bracket motor? and what about service after the sale, never heard of this company is why I ask. You're kinda missing the point here. I'm not trying to talk you into running PRW rockers. What I'm trying to explain, is that all roller rockers need to have the geometry set, because it is not built into the rocker. You may find a rocker that fits on the head with the roller perfectly centered when the valve is on the seat, but that isn't good geometry. Nether is a centered sweep when the sweep is excessively wide. The pic is of a 505 pump gas street build with a .585" lift hydraulic roller and with that rocker, it has .029" sweep across the valve tip. The fact that it is centered, is because I offset the shaft accordingly when I raised the it to minimize the sweep. FWIW, I avoid rockers that use ball style adjusters. I know that makes me a heretic, but I know the negative effect they have on pushrod side geometry. I'll just have to live with the shame. not really missing the point, just asking about quality, I get it about having to adjust the shaft height to bring it all together, but it's been noted that some rockers are longer or shorter from fulcrum centerline to tip centerline,wouldn't using ones that are more correct in that respect be easier to start with? Yes it would, but I don't know of any that are as short as they should be. The custom T&Ds I mentioned in an earlier post were made with a shorter fulcrum length so they wouldn't require additional offset. Considering that when the shaft is raised, the shaft and valve get closer together, you have to offset the shaft to make up for it. Any extra length of the rocker fulcrum, means additional offset to make up for that length. That starts causing issues with pushrod clearance in the head in many cases. Higher rocker ratios will help some with clearance, but not usually enough to avoid grinding. In the case of the Trick Flows, they raised the stands .100", but didn't offset the stands any, so the rocker requirements are shorter yet. Since I am a Trick Flow dealer, I'm going to talk with their engineering department about some possible adjustments. It's nothing major, so hopefully they will be open to that adjustment.

Mike Beachel

I didn't write the rules of math nor create the laws of physics, I am just bound by them.

|

|

|

Re: Trick Flow heads

[Re: fast68plymouth]

#2088414

Re: Trick Flow heads

[Re: fast68plymouth]

#2088414

06/08/16 02:40 PM

06/08/16 02:40 PM

|

Joined: Jan 2003

Posts: 31,250

Oregon

AndyF

I Win

|

I Win

Joined: Jan 2003

Posts: 31,250

Oregon

|

I just need to find someone who sells a high quality 1.70 rocker arm that fits the Trick Flow head. I would say a head might have to make it's way to T&D for that. The pic of the scrub pattern with the RAS rockers on page 10 of this thread looks pretty good to me. I sent one of my TF heads to T&D a few weeks back. Sounds like they can do a 1.70 ratio kit that bolts in. To go higher than 1.70 they said they would need to machine off the stands and use an offset shaft. Harland Sharp also said they could do a 1.70 rocker arm based on their E rocker. I ordered a set of those and should have them before the end of the month.

|

|

|

Re: Trick Flow heads

[Re: fast68plymouth]

#2089158

Re: Trick Flow heads

[Re: fast68plymouth]

#2089158

06/09/16 03:27 PM

06/09/16 03:27 PM

|

Joined: Nov 2003

Posts: 1,033

Madison, Wisconsin

chrisnben

super stock

|

super stock

Joined: Nov 2003

Posts: 1,033

Madison, Wisconsin

|

Andy, those 1.6 Hughes rockers worked out slicker than snot! Pushrods are 8.80" on the low deck 470. I also put on the tool steel retainers Comp # 1732-16. Dyno time is early next week.

'70 Cuda "Badfish 2"- in the works

Home of MoPar University- We school 'em one at a time!!

|

|

|

Re: Trick Flow heads

[Re: B3RE]

#2090614

Re: Trick Flow heads

[Re: B3RE]

#2090614

06/12/16 12:22 PM

06/12/16 12:22 PM

|

Joined: Jul 2013

Posts: 561

USA

B3RE

mopar

|

mopar

Joined: Jul 2013

Posts: 561

USA

|

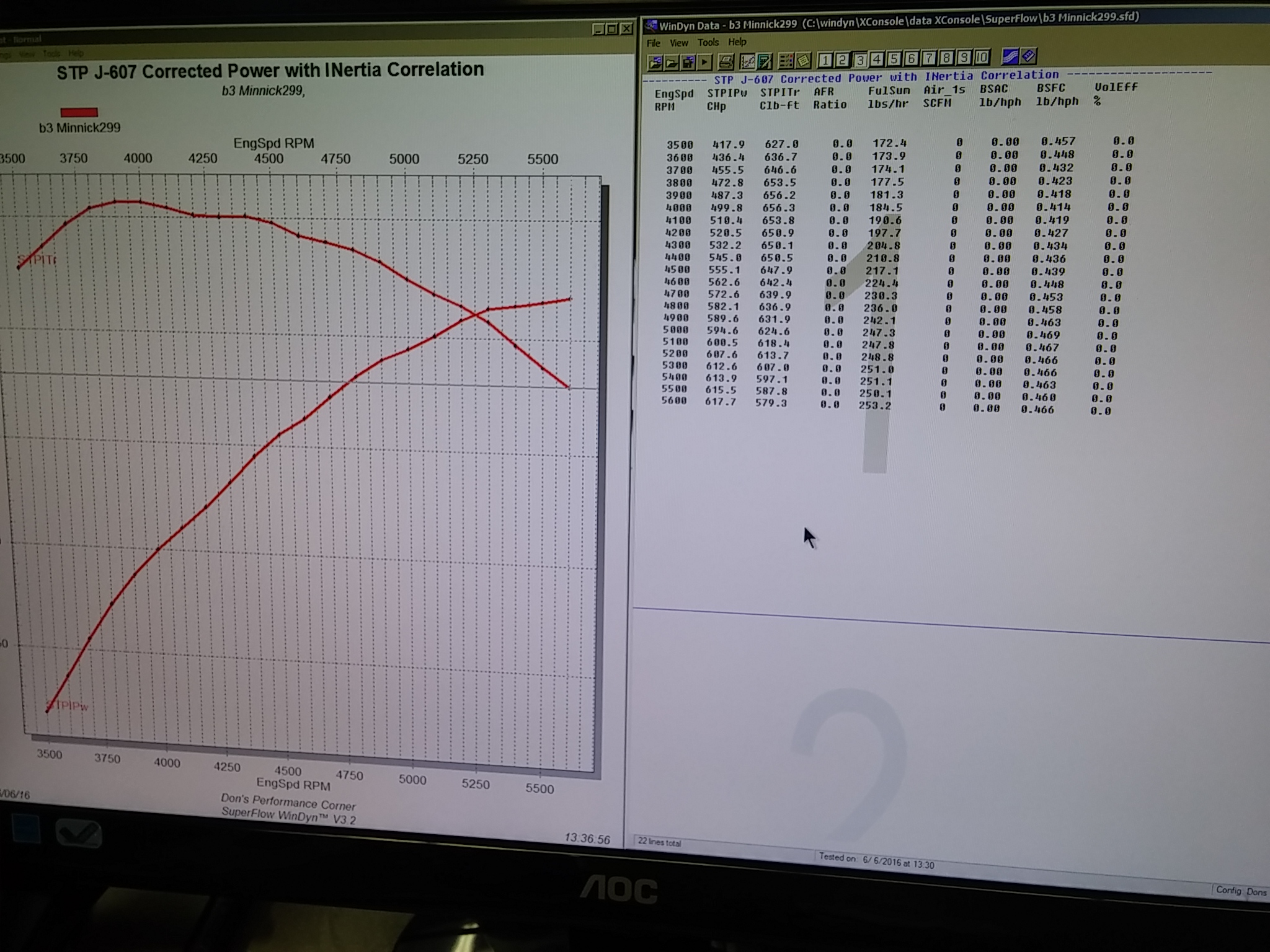

Here are some pics of PRW stainless rockers on Trick Flows. The geometry is perfect. If the rocker will fit under the valve cover, it can be "adjusted" to have perfect geometry also, at least on the valve side. The Harlands are not going to be better than any other rocker when just bolted on. I dynoed this 505 build on Monday, and I was pretty happy with the results. Just to set the stage, the customers demands were that it: 1-Make 600 Hp 2-Be easy to drive 3-Run on pump 93 4-Fit under a stock hood 5-Sound rowdy and mean. (I had to talk him back from the edge on this one) The application was a '70 RT/SE Challenger with a 727, 2800 advertised stall, 3.91 gear, that will be mostly cruised to and from car shows. He told me the only reason he wanted 600 Hp is because someone else told him that's what he should shoot for. Okey dokey! I pretty much built a similar combo to what Trick Flow advertises for their dyno results. Here are the differences: Cam is similar at 242/248, but less lift at .585" vs .600", and a different lobe separation. Compression is 10.1:1 vs 10.5:1. Cubic inches are 505 vs 446. Intake manifold is a low dual plane with a 1" open spacer vs a tall single plane. Carb is a 1000 cfm Holley with annular boosters vs the 950 Trick Flow. The only plusses to this combo, over the Trick Flow, is the cubic inches, and the bigger carb. The cubes make more torque, but horsepower stays about the same at a lower RPM. The carb could have been a little bigger yet but worked beautifully for this combo. Everything else, theoretically, should cost power. Results: 617 Hp @ 5600 rpm 656 Tq @ 4000 rpm The torque was 627 at 3500 where the pulls were started, and stayed over 600 through 5300 rpm. I'm certain it would have been over 600 at 3000 but we ran out of time to do additional pulls at lower rpms. With more time, I think we could have picked up a few more but we didn't need to be greedy. That brings me to a question. Has anyone had any trouble with the Trick Flow heads not purging the air from the cooling system? We spent all morning trying to get the motor to stop running too warm during the warm up before starting pulls. I had the same trouble running it on my test stand before going to the dyno, and once the air gets out it is fine. It just seemed to take a long time. I had to run for some parts, and left the electric pump run for about an hour on my test stand, and it still didn't clear the air.

Mike Beachel

I didn't write the rules of math nor create the laws of physics, I am just bound by them.

|

|

|

Re: Trick Flow heads

[Re: B3RE]

#2090714

Re: Trick Flow heads

[Re: B3RE]

#2090714

06/12/16 03:33 PM

06/12/16 03:33 PM

|

Joined: Jan 2013

Posts: 126

Oregon

Jamie McGrath

member

|

member

Joined: Jan 2013

Posts: 126

Oregon

|

Has anyone had any trouble with the Trick Flow heads not purging the air from the cooling system? We spent all morning trying to get the motor to stop running too warm during the warm up before starting pulls. I had the same trouble running it on my test stand before going to the dyno, and once the air gets out it is fine. It just seemed to take a long time. I had to run for some parts, and left the electric pump run for about an hour on my test stand, and it still didn't clear the air. I will stick my neck out on this one, maybe its not the heads.... Maybe its the water pump housing not moving enough water? I think the better/best aluminum housing is the MP/DC housing. Take a look at the housing passages, if there smaller than stock or you find a bottle neck restriction, I think you found the problem.

Last edited by Jamie McGrath; 06/12/16 03:37 PM.

|

|

|

Re: Trick Flow heads

[Re: Jamie McGrath]

#2090737

Re: Trick Flow heads

[Re: Jamie McGrath]

#2090737

06/12/16 04:19 PM

06/12/16 04:19 PM

|

Joined: Jul 2013

Posts: 561

USA

B3RE

mopar

|

mopar

Joined: Jul 2013

Posts: 561

USA

|

Has anyone had any trouble with the Trick Flow heads not purging the air from the cooling system? We spent all morning trying to get the motor to stop running too warm during the warm up before starting pulls. I had the same trouble running it on my test stand before going to the dyno, and once the air gets out it is fine. It just seemed to take a long time. I had to run for some parts, and left the electric pump run for about an hour on my test stand, and it still didn't clear the air. I will stick my neck out on this one, maybe its not the heads.... Maybe its the water pump housing not moving enough water? I think the better/best aluminum housing is the MP/DC housing. Take a look at the housing passages, if there smaller than stock or you find a bottle neck restriction, I think you found the problem. I considered that, but the passages are not restricted, and it had no trouble staying cool once the air got out. I had a similar combo with Edelbrock heads, and it purged the air with no issues. Who knows, maybe I just got a cantankerous one. Just thought I'd ask if anyone else experienced this with the Trick Flows.

Mike Beachel

I didn't write the rules of math nor create the laws of physics, I am just bound by them.

|

|

|

|

|