The Headers on my Factory V8 Jeep CJ 5 were cheap Headman Headers. They rusted over several years. Needed to pull them off for a valve-job. Since they were off, I gasket matched the tube ports, degreased, and removed remaining paint, then, what to do about the rust.....?

I tried several methods, blasting, abrasive disks and a die grinder. Worked for flat surfaces, not so great on the tubes. I went a tiny bit radical. I found a large'ish rectangular plastic tub, filled it with Swimming Pool (hydrochloric) Acid (wearing gloves and safety goggles, etc, and dipped the headers into the acid. The rust instantly disappeared. I washed the headers with baking soda and water, rinsed. They flash rust very lightly, but very quickly as they air dry, so I had to dry with compressed air, but that flash rust was not harmful.

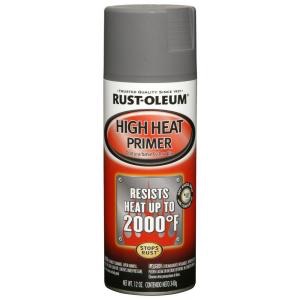

After fully dry, I used 2,000 degree high heat gray primer followed by 2,000 degree high heat Silver paint and it has held up for nearly 10-years so far. VHT and RustOleum make 2,000 degree paint products. I think the Primer really, really helps the longevity. I now paint all clean, bare metal exhaust pipes, blasted cast iron exhaust manifolds, etc, with the 2,000 degree primer and paint products.

The 1,200 degree Barbecue-Type Paints (without using high temp primer) all seem to fall short and eventually blister and flake off over time, even when you do your best to remove all grease and rust prior to application.

Rustoleum 2000 degree primer

Rustoleum 2000 degree primer