|

my theory based on some real testing LONG

[Re: moparniac]

#828287

my theory based on some real testing LONG

[Re: moparniac]

#828287

10/13/10 08:52 PM

10/13/10 08:52 PM

|

Joined: Nov 2004

Posts: 4,330

Lynchburg, VA

Leon441

master

|

master

Joined: Nov 2004

Posts: 4,330

Lynchburg, VA

|

I have raced several rod ratios in a small blocks with 9.580" decks and a 4.125" stroke. First I ran a 6.385 rod and ran a 1.125 piston. I had pulled a desired rod ratio out of thin air based on some old racers and articles. 1.55 or 3.10 doing it streetwizes method(I like the method makes more sense in relationship to what changes but I have never had anyone want it that way).

This thing ate pistons like crazy because the piston was so thin.

I built a new engine and started off with a 6.250 rod to put more meat in the piston. I later needed some more VP to ring groove so I switched to a 6.200" rod. The 6.250" rod gave a 1.52 ratio. The 6.200" rod gave a 1.50. The difference in these number is nothing right. Noticed the bores showed more wear than the old engine with the 6.385 rod. So won winter I murdered some pistons and installed a different rod piston combo on three different cylinders. And I borowed some other rods to try some more extreme ratios. I then put a dial indicator on the piston and started recording data. If you know geometry you will laugh at some of the misinformation you read on some test some people claim to have done.

If you calculate piston speed by using Stroke and RPM you get an average piston speed. Many comp guys worry about this as they have a FPS they want to stay under. So they figure in Rod Ratio. The formula I have uses the rod length and stroke/2 as streetwize suggest. The average speed at 9,000 rpm with a 4.125 stroke is the same with any rod from 5.5-7 inches. That does not tell you the max fps the piston sees. In order to do that you have to have rod ratio. A long rod say 7" will slow the piston down at TDC and BDC and the piston will move a lot faster in the middle of stroke. A 5.5" rod will cause the piston to move much faster at TDC and BDC but the piston will move slower in the middle.

I did my test and recorded DATA simply because I fealt I was in uncharted territory and people would tell me anything to sell a part. Racing an engine I could not afford to begin with I wanted to know what effect I would have changine Rod Ratio. I got my answers as to what changed. I turned the engine with the 6.385 rod 9,000 a couple races with no issues. If I had done the same with the 6.200 rod it may have made a fatal difference.

Rod Ratio is neat to theorize about and a lot of things come in to play like cylinder heads and dwell. But, a local engine builder who's "Mountain Motor" stuff usually has huge cylinder heads builds 800+ CID engines with absolulety scary rod ratios and in IHRA Prostock they turned them things more than I would have ever thought and got away with it. He told me most important build a big bore with a strong piston. Then pack all the stroke the rules and block can take and connect the two as long as you can stay over a certain number in rod ratio(very low #) Then if the piston is going to be too thick and heavy use a shorter deck block. Personally I think anything over 1.3 is useable. I would prefer to stay over 1.5. Stock 340's were 1.71 which is really too much IMO for drag racing.

My current stuff is 1.58 and made a very broad torque curve for a 3.800 stroke. This may be why I have so much luck with converters builders don't think will work.

Career best 8.02 @ 169 at 3050# and 10" tires small block power.

|

|

|

Re: my theory based on some real testing LONG

[Re: Leon441]

#828288

Re: my theory based on some real testing LONG

[Re: Leon441]

#828288

10/13/10 09:56 PM

10/13/10 09:56 PM

|

Joined: Jan 2003

Posts: 9,876

Weddington, N.C.

Streetwize

master

|

master

Joined: Jan 2003

Posts: 9,876

Weddington, N.C.

|

my theory with regard to the 451 using a 6.36 vs 6.76 goes back many years, probably to the early days of the internet. as I recall Andy's 451 manifesto actually favored the longer rod but he may have seen the light since then  the reason I favor a shorter rod for dual purpose cars is that they spend a lto more time below the torque peak RPM and at part throttle where roll on torque is more important than Dyno pull type numbers. A shortewr rod provided just a touch more draw on the intake port by virtue of the faster pull away speed form TDC....all else being equal a shorter rod will tolerate a little more cam duration and/or port cfm without upsetting torque production....all in you tend to get a somewhat more responsive motor. Look at your OEM big port motors 396 through 454 Chevies and 351 Cleveland Fords....big intake ports but relatively short rodss comparedto the stroke length. Is it a cure, no not at all but if you can run a bit more cam and plenty of head for big power and still have decent drivabiulity....well it's the best of both worlds. With todays abundant heads it's a slam dunk, most bottom ends can't hold the power these heads are capable of anyway so why not use up as much as you can in the useable RPM band? we could go on and on but back and forth but I'm sure somebody somewhere has archived all the debated throughout the years

|

|

|

Re: Great info on rod ratio!!

[Re: polyspheric]

#828289

Re: Great info on rod ratio!!

[Re: polyspheric]

#828289

10/13/10 10:49 PM

10/13/10 10:49 PM

|

Joined: Jan 2003

Posts: 6,591

Canton, Ohio

Sport440

master

|

master

Joined: Jan 2003

Posts: 6,591

Canton, Ohio

|

Quote:

The difference in piston position B/ATDC with even large changes in rod ratio are very, very small. I have yet to read an analysis that explains the changes in engine function.

Example 1: 4" stroke, 8" rod = 2:1.

In 10° rotation, the piston moves down .0379".

Example 2: 4" stroke, 6" rod = 1.5:1 (25% lower ratio).

In 10° rotation, the piston moves down .0404".

The difference is 2.5 thousandths, or 1/16th of 1% of the stroke. BFD.

The problem with this statement is the shown difference at Only one point/perimeter of a 10* rotation.

While in reality its not the same difference at every 10* of crank rotation. How about the difference between the other "35" 10* points of reference.

And nope, I Still cant fire up that deqree symbol on my home computer. But at the shop pute, no problem. mike

|

|

|

Re: my theory based on some real testing LONG

[Re: AndyF]

#828291

Re: my theory based on some real testing LONG

[Re: AndyF]

#828291

10/13/10 11:21 PM

10/13/10 11:21 PM

|

Joined: Jan 2003

Posts: 6,591

Canton, Ohio

Sport440

master

|

master

Joined: Jan 2003

Posts: 6,591

Canton, Ohio

|

Quote:

I don't really care about the length of the rod all that much so I'm not sure why my name is in this discussion.

I'm more interested in combinations that go together easily because lots of people have trouble with anything more than a basic combination. My recommendations tend towards whatever is commercially available that actually works.

So I tend to recommend things such as the 4.250 stroke with a 6.800 long rod in the RB motor. That combination works, there is plenty of room for a good ring pack, the piston is tall enough to be stable, the rod ratio is good enough to work with off the shelf heads, etc.

Most people on here will never build a motor where the rod ratio actually matters while almost everyone on here has to work within a budget. So my advice is directed towards the budget aspect of engine building rather than finding the last hp in a build.

I can agree with this! Without being arguementitive  mike mike

|

|

|

Re: my theory based on some real testing LONG

[Re: sixpackgut]

#828293

Re: my theory based on some real testing LONG

[Re: sixpackgut]

#828293

10/14/10 11:31 AM

10/14/10 11:31 AM

|

Joined: Jan 2007

Posts: 3,695

nc

emarine01

master

|

master

Joined: Jan 2007

Posts: 3,695

nc

|

The original post mentioned ... failure and ware in the opening statement... then showed the positive points of a longer rod vs short.... its pretty much a given that if you stay between 1.5 -2.0 it will work, Piston speed is a product of stroke, rod ratio and rpm... longer stroke pulling the piston down from TDC faster than shorter stroke, putting more stress on the rod... the shorter rod has less weight and beam, aside from rod bolt failure it seems that rods fail @ the narrow point under the piston pin... so a longer rod has more length in this area, Max piston speed VS max acceleration and the points of rotation where the max stress occurs needs to looked at to see if the difference is worth fooling with, as mentioned before the dwell @ tdc is very short, I think choosing the proper materials and staying within a realistic rpm out weighs the rod ratio. the fact that the shorter rod ratio does pull the piston away from TDC faster can be used for better cylinder filling @ the start of the intake stroke if the heads, intake and cam are designed to take advantage of the fast piston speed.... a topic rarely discussed ... another topic rarely talked about is fuel burn rate and spark timing for longer stroke shorter rod ratios to take advantage of crank angle in race engines.... anyhow this is all good stuff much better than lug nut posts

|

|

|

Re: Great info on rod ratio!!

[Re: moderncylinder]

#828294

Re: Great info on rod ratio!!

[Re: moderncylinder]

#828294

10/14/10 01:36 PM

10/14/10 01:36 PM

|

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

BradH

Taking time off to work on my car

|

Taking time off to work on my car

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

|

Quote:

... ill use a ss hemi reference again,,, cause thats what i run,, and i run the [Edited by Moparts - Family Friendly Site - Keep it clean] out of them on the dyno,, if i advance the cam youd think it would gain tq always once you are in your ideal position due to the intake valve closing earlier,, but i can advance the cam and loose tq,, maybe it made more at 5000, but when i peak at 7000,, it lost

Sorry for going a bit  , but Jeff's comments on how advancing the cam doesn't necessarily improve peak torque fits in w/ something I was looking into myself earlier this week. I was trying to decide whether I should follow the advice of a well-known "tech expert / writer" to advance my cam 6 degrees due to it fitting right into his definition of an "undervalved" wedge engine (2.14" intake for 4.38" bore x 3.75" stroke). , but Jeff's comments on how advancing the cam doesn't necessarily improve peak torque fits in w/ something I was looking into myself earlier this week. I was trying to decide whether I should follow the advice of a well-known "tech expert / writer" to advance my cam 6 degrees due to it fitting right into his definition of an "undervalved" wedge engine (2.14" intake for 4.38" bore x 3.75" stroke).

First, my Engine Analyzer Pro simulation, in which I've spec'd out a baseline program that mimics the real dyno results of my combination pretty closely, predicted that would be the wrong move, as it showed a loss of about 13 HP and 6 Tq compared to being advanced only 2 degrees.

Then, I came across a cam drive comparison test that Steve Dulcich did that also included testing one of his 440 dyno mules at 0, 2, 4 and 6 degrees advanced. For his particular test, the results for 6 degrees advanced vs. 2 were... a loss of 11 HP and 4 Tq. My EA Pro results didn't look as odd as I'd thought they were after seeing a "real world" example that basically mirrored them.

|

|

|

Re: Great info on rod ratio!!

[Re: BradH]

#828295

Re: Great info on rod ratio!!

[Re: BradH]

#828295

10/14/10 01:51 PM

10/14/10 01:51 PM

|

Joined: Jun 2003

Posts: 52,972

Romeo MI

MR_P_BODY

Master

|

Master

Joined: Jun 2003

Posts: 52,972

Romeo MI

|

Quote:

Quote:

... ill use a ss hemi reference again,,, cause thats what i run,, and i run the [Edited by Moparts - Family Friendly Site - Keep it clean] out of them on the dyno,, if i advance the cam youd think it would gain tq always once you are in your ideal position due to the intake valve closing earlier,, but i can advance the cam and loose tq,, maybe it made more at 5000, but when i peak at 7000,, it lost

Sorry for going a bit  , but Jeff's comments on how advancing the cam doesn't necessarily improve peak torque fits in w/ something I was looking into myself earlier this week. I was trying to decide whether I should follow the advice of a well-known "tech expert / writer" to advance my cam 6 degrees due to it fitting right into his definition of an "undervalved" wedge engine (2.14" intake for 4.38" bore x 3.75" stroke). , but Jeff's comments on how advancing the cam doesn't necessarily improve peak torque fits in w/ something I was looking into myself earlier this week. I was trying to decide whether I should follow the advice of a well-known "tech expert / writer" to advance my cam 6 degrees due to it fitting right into his definition of an "undervalved" wedge engine (2.14" intake for 4.38" bore x 3.75" stroke).

First, my Engine Analyzer Pro simulation, in which I've spec'd out a baseline program that mimics the real dyno results of my combination pretty closely, predicted that would be the wrong move, as it showed a loss of about 13 HP and 6 Tq compared to being advanced only 2 degrees.

Then, I came across a cam drive comparison test that Steve Dulcich did that also included testing one of his 440 dyno mules at 0, 2, 4 and 6 degrees advanced. For his particular test, the results for 6 degrees advanced vs. 2 were... a loss of 11 HP and 4 Tq. My EA Pro results didn't look as odd as I'd thought they were after seeing a "real world" example that basically mirrored them.

I dont think you are looking at this in the right

direction(JMO) but if you advance the cam you move

the torque lower in the rpm range and most likely

it did increase at that rpm BUT it lost some on the

higher rpm so it did increase it at the lower rpm

but it needs to be in the working range of the engine

and drive line set up.... JMO

|

|

|

Re: my theory based on some real testing LONG

[Re: Sport440]

#828296

Re: my theory based on some real testing LONG

[Re: Sport440]

#828296

10/14/10 01:58 PM

10/14/10 01:58 PM

|

Joined: Jan 2003

Posts: 9,876

Weddington, N.C.

Streetwize

master

|

master

Joined: Jan 2003

Posts: 9,876

Weddington, N.C.

|

USing the 10 degree .379 vs .404 example given above......when you calculate how many times in cycle that is happening (at only 4500 rpm that minute dfferennce is occuring 37 times PER SECOND) you can see where these cumulative effects can make a difference. One could argue the totoal duration of time in a minute of operation a valve is between .050 up and.050 down between 2 cams with one having 6 degrees of duration sounds pretty insignificant too.  And so does .020 thou of extra lift...it's not so much when you think in terms of 1 revolution....it's the cumulative effect in terms of power production...think about how many times that piston is cycling....now multiply that by the number of cylinders too  Think of what all goes on in a motor at 6000 or 7000 or more RPM, thousanths of seconds or inches add up...they have to or else none of it would work.

Last edited by Streetwize; 10/14/10 02:04 PM.

|

|

|

Re: my theory based on some real testing LONG

[Re: Streetwize]

#828297

Re: my theory based on some real testing LONG

[Re: Streetwize]

#828297

10/14/10 02:29 PM

10/14/10 02:29 PM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

Man! I LOVE This! This is the debate? Rod length? Truth is most guys run too much cam, a crappy distributor ( untuned let's say) and have the carb so out in left field it is a wonder it don't catch on fire---then add the WRONG converter--- THESE are the things that matter more to most everyone on this board. FWIW I have been present for a ton of dyno runs on the SBC 2 barrel circle track engines--limited engines in every way--cam, intake, valve size, CR, carb etc The conventional wisdom says go 6 in rod but the 5.7 rod will make better dyno numbers and win more on the track all else being equal based on real observation over several years for engines running at the same track, same racers, same rules. On the 451's I have done I can't say I have ever noticed any diff from 6760 rod to the shorter ones. The piston is lighter for sure but does it rock and maybe not seal as well--who really knows??? There are correct answers for a test question on the issue but real world answers are always hard to nail down. I always refer to Smokey Yunnick "The price of progress is trouble"

|

|

|

Re: my theory based on some real testing LONG

[Re: ]

#828298

Re: my theory based on some real testing LONG

[Re: ]

#828298

10/14/10 02:59 PM

10/14/10 02:59 PM

|

Joined: Oct 2003

Posts: 7,506

Az

Crizila

master

|

master

Joined: Oct 2003

Posts: 7,506

Az

|

Interesting how much of the testing and posted results are done on a static basis, leaving out the dynamics of the situation altogether. Not pointing any fingers - just an observation.

Fastest 300

|

|

|

Re: my theory based on some real testing LONG

[Re: Crizila]

#828299

Re: my theory based on some real testing LONG

[Re: Crizila]

#828299

12/02/10 06:07 AM

12/02/10 06:07 AM

|

Joined: Oct 2010

Posts: 9

California, USA

Tiger Core

member

|

member

Joined: Oct 2010

Posts: 9

California, USA

|

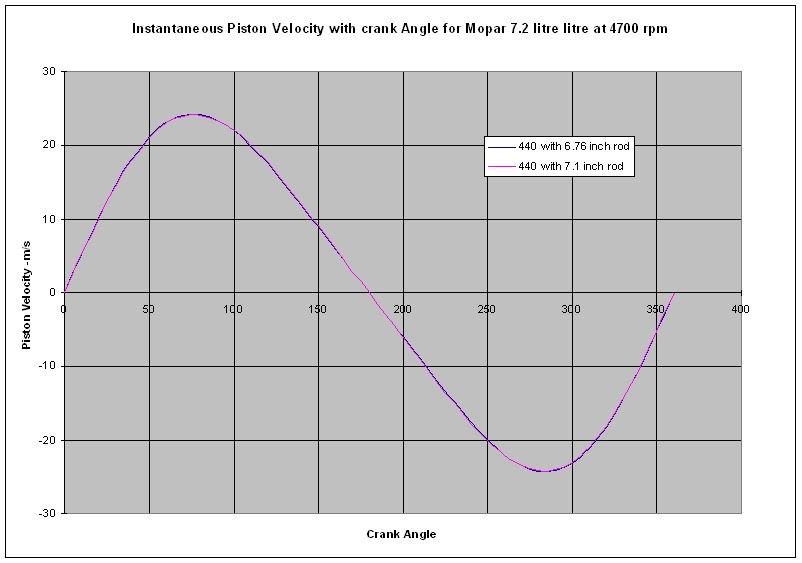

From an experienced engine designers perspective the long rod ratio argument is vaguely valid but vastly over stated on the internet.  The above shows the instantaneous piston velocity over crank angle calculated for the 440 Dodge engine for both 6.76 inch rod (stock) versus the often used 7.1 inch length rod (standard stroke of 3.75 inches). As you can see the piston velocity profile is barely effected. Put into numbers, at 4700 rpm, using the stock rod/stroke combination the peak piston velocity is about 24.28 m/s where as going to the longer 7.1 inch rod reduced this peak piston velocity to 24.2 m/s- barely anything at all. This fact basically makes the arguments for Engine ignition and breathing issues: "* A piston that dwells at TDC longer allows the air/fuel charge a longer time to burn. This allows less ignition timing for peak power. Less ignition timing is useful because it reduces detonation allowing (slightly) higher compression ratios. * A piston that dwells at TDC shorter increases the speed of the exhaust gasses during the overlap period. This increases the scavenging effect at low rpm and the engine makes more torque at low RPM. * Reducing and delaying peak piston velocity allows the intake valves more time to open more to fill the cylinder. This allows a smaller intake running volume (and plenum) and better high RPM breathing." ....Negiligible and effectively invalid. It becomes obvious that the arguments constructed for longer rod were done with a serious agenda and bias in mind from the start and not from real world engine development/design experience. And quite frankly the arguments about knock limit change due to longer rods on a wedge type combustion chambered engine with the plug over to one side, big bore and associated long flame paths (bad for knock limit), even with the closed chamber squish of a 915 type chamber- are quite ridiculous. Regarding the rod angularity/friction argument- this has greater strength, however the fact that the 440 RB engine has such oversized main bearings (2.75 inches) versus the more sensible "B" engines 2.62 inches makes this point moot. In addition two very well respected and durable low friction engines out in the field today will further put some perspective on this point: Honda S2000, revs to 9000 rpm, makes 120 Bhp/litre, has a rod to stroke ratio of 1.82- very low friction engine BMW S54 M3 motor- revs to 8000 rpm makes over 105 Bhp/litre has a rod to stroke length ratio of 1.52- incredibly low friction engine. Dodge 440 RB engine- as standard produces peak power at 4700 rpm, makes 54 Bhp/litre (ignoring for the moment that the homologation SAE standards of the time were wildly optimistic!), has a rod length stroke ratio of 2.01- high friction engine. Conclusion- the rod to stroke ratio has an effect but there are bigger fish to fry. Especially when you have the ridiculously oversized bottom end bearings of the RB engine to contend with, the collosal 10.75 inch deck height which has a HUGE weight penalty.

|

|

|

Re: Great info on rod ratio!!

[Re: bigtimeauto]

#828300

Re: Great info on rod ratio!!

[Re: bigtimeauto]

#828300

12/02/10 06:29 AM

12/02/10 06:29 AM

|

Joined: Jul 2010

Posts: 3,502

SOUTH JERSEY

HEMIFRED

master

|

master

Joined: Jul 2010

Posts: 3,502

SOUTH JERSEY

|

missing so far has been any mention of rod lengths effect on filling the cylinder and other things Quote:

Short Rod is slower at BDC range and faster at TDC range.

Long Rod is faster at BDC range and slower at TDC range.

I. LONG ROD

A. Intake Stroke -- will draw harder on cyl head from 90-o ATDC to BDC.

B. Compression Stroke -- Piston travels from BDC to 90-o BTDC faster than short rod. Goes slower from 90-o BTDC to TDC--may change ign timing requirement versus short rod as piston spends more time at top. However; if flame travel were too fast, detonation could occur. Is it possible the long rod could have more cyl pressure at ie. 30-o ATDC but less crankpin force at 70-o ATDC. Does a long rod produce more efficient combustion at high RPM--measure CO, CO2? Find out!!

C. Power Stroke -- Piston is further down in bore for any given rod/crank pin angle and thus, at any crank angle from 20 to 75 ATDC less force is exerted on the crank pin than a shorter rod. However, the piston will be higher in the bore for any given crank angle from 90-o BTDC to 90-o ATDC and thus cylinder pressure could be higher. Long rod will spend less time from 90-o ATDC to BDC--allows less time for exhaust to escape on power stroke and will force more exhaust out from BDC to 90-o BTDC. Could have more pumping loss! Could be if exhaust port is poor, a long rod will help peak power.

D. Exhaust Stroke -- see above.

II. Short Rod

A. Intake Stroke -- Short rod spends less time near TDC and will suck harder on the cyl head from 10-o ATDC to 90-o ATDC the early part of the stroke, but will not suck as hard from 90-o to BDC as a long rod. Will require a better cyl head than long rod to produce same peak HP. Short rod may work better for a IR or Tuned runner system that would probably have more inertia cyl filling than a short runner system as piston passes BDC. Will require stronger wrist pins, piston pin bosses, and connecting rods than a long rod.

B. Compression Stroke -- Piston moves slower from BDC to 90-o BTDC; faster from 90-o BTDC to TDC than long rod. Thus, with same ign timing short rod will create less cyl compression for any given crank angle from 90-o BTDC to 90-o ATDC except at TDC. As piston comes down, it will have moved further; thus, from a "time" standpoint, the short rod may be less prone to detonation and may permit higher comp ratios. Short rod spends more time at the bottom which may reduce intake charge being pumped back out intake tract as valve closes--ie. may permit longer intake lobe and/or later intake closing than a long rod.

C. Power Stroke -- Short rod exerts more force to the crank pin at any crank angle that counts ie.--20-o ATDC to 70-o ATDC. Also side loads cyl walls more than long rod. Will probably be more critical of piston design and cyl wall rigidity.

D. Exhaust Stroke -- Stroke starts anywhere from 80-o to 110-o BBDC in race engines due to exhaust valve opening. Permits earlier exhaust opening due to cyl pressure/force being delivered to crank pin sooner with short rod. Requires a better exhaust port as it will not pump like a long rod. Short rod has less pumping loss ABDC up to 90-o BTDC and has more pumping loss from 90-o BTDC as it approaches TDC, and may cause more reversion.

III. NOTES

A. Rod Length Changes -- Appears a length change of 2-1/2% is necessary to perceive a change was made. For R & D purposes it appears a 5% change should be made. Perhaps any change should be 2 to 3%--ie. Ignition timing, header tube area, pipe length, cam shaft valve event area, cyl head flow change, etc.

B. Short Rod in Power Stroke -- Piston is higher in the bore when Rod-Crank angle is at 90-o even though at any given crank angle the piston is further down. Thus, at any given "time" on the power stroke between a rod to crank pin angle of 10o and ie. 90-o, the short rod will generate a greater force on the crank pin which will be in the 70-o to 75-o ATDC range for most engines we are concerned with.

C. Stroke -- Trend of OEM engine mfgs to go to longer stroke and/or less over square (bore numerically higher than stroke) may be a function of L/R. Being that at slower engine speeds the effect of a short rod on Intake causes few problems. Compression/Power Stroke should produce different emissions than a long rod. Short rod Exhaust Stroke may create more reversion--EGR on a street engine.

D. More exhaust lobe or a earlier exhaust opening may defeat a longer rod. I am saying that a shorter rod allows a earlier exhaust opening. A better exhaust port allows a earlier exhaust opening.

E. Definition of poor exhaust port. Becomes turbulent at lower velocity than a better port. Flow curve will flatten out at a lower lift than a good port. A good exhaust port will tolerate more exhaust lobe and the engine will like it. Presuming the engine has adequate throttle area (so as not to cause more than 1" Hg depression below inlet throttle at peak power); then the better the exhaust port is, the greater the differential between optimum intake lobe duration and exhaust lobe duration will be--ie. exh 10-o or more longer than intake Carbon buildup will be minimal if cyl is dry.

IV. DEFINITIONS

Short Rod -- Min Rod/Stroke Ratio -- 1.60 Max Rod/Stroke Ratio -- 1.80

Long Rod -- Min Rod/Stroke Ratio -- 1.81 Max Rod/Stroke Ratio -- 2.00

Any ratio's exceeding these boundaries are at this moment labeled "design screw-ups" and not worth considering until valid data supports it.

home of the

Sox and Martin Hemi Duster

|

|

|

Re: Great info on rod ratio!!

[Re: Sport440]

#828301

Re: Great info on rod ratio!!

[Re: Sport440]

#828301

12/02/10 03:07 PM

12/02/10 03:07 PM

|

Joined: Oct 2007

Posts: 4,209

New York

polyspheric

master

|

master

Joined: Oct 2007

Posts: 4,209

New York

|

How about the difference between the other "35" 10* points of reference

They get smaller.

Please: I hope we can all agree that "dwell" (meaning literally to reside, stay, remain, rest) only means "move very slowly vs. motion at other points of rotation"?

The piston dwells at TDC exactly this long: .00000"

By comparison, it dwells at BDC this long: .00000".

This also gets repeated way too many times: "a long rod motor would dwell for a longer period of time & TDC & a short rod @ BDC , this was'nt so , dwell time is EXACTLY the same for a short & long rod @ TDC/BDC".

This is never, ever true in any engine (unless you have one of those very rare engines with infinite rod length - not really long like 12" - infinite like light years).

The zero change observed is actually so small that it's completely masked by stacked bearing clearances.

HTML note: degree sign is made by

Hold ALT down, then press 0, 1, 7, 6

Boffin Emeritus

|

|

|

Re: Great info on rod ratio!!

[Re: polyspheric]

#828302

Re: Great info on rod ratio!!

[Re: polyspheric]

#828302

12/02/10 03:35 PM

12/02/10 03:35 PM

|

Joined: Jan 2003

Posts: 9,876

Weddington, N.C.

Streetwize

master

|

master

Joined: Jan 2003

Posts: 9,876

Weddington, N.C.

|

While the (100% technical definition of) Dwell is instantaneous and constant, the rate of descent to and rise from that dwell is still measurably different between different strokes and rod combinations and it's effect may be 'mathematically' subtle...but one could argue that 2 different cam lobes with the same .050 durations are also subtle yet measurable...and since a crank is moving at 2X the speed of a cam the effects of those rates of change can be significant. 'Effective dwell' is the degrees of crank rotation on either side of the TDC and BDC where the piston is 'Virtually' parked as the crank rotates past those points (before reversing its direction). So when discussing this (in practical and not NASA Science Lab terms) it really depends how much 'Fly Sh!t you want to pick out of the pepper'.  Very slight changes to anything effecting differential pressure (flow through a manifold and into a cylinder) can make measurable differences in power output....remember we're mixing fuel and air under pressure here!!....as correctly stated above you often "trade off"...bottom for top or vice versa...but a saavy tuner can usually work a particular combination to an advantage for the application he has. Short rods are generally more tolerant of a larger cam for a given CR as well in terms of attaining good part throttle drivability and street manners. Just a couple things that come to mind. Typically for a given head flow a longer ratio favors top end breathing, a shorter ratio is advantageous for initiating low end torque...which in real world terms is likened to MOMENTUM...isn't it usually easier to keep something moving than to get it moving initially? (like from a standing start). Short rods to me work best in motors that have a relative abundance of head flow...lets say race heads on a stock block where you don't necessarily want to (or need to) wring out every last potential drop of top end horsepower....or as in the engine masters type build where the sum of the Average torque across the powerband is more critical than the peak HP numbers. BTW....Rod/stroke ratio is a misnomer....it should really be considered as R:1/2S as the rod angle can only be effected by 1/2 of the total stroke....in Pathagoreon terms 1/2 the stroke and the rod lengths are fixed (constants) and the 1/2 stokes rotation around its axis determines the (variable) triangle....which varies throughout the piston's motion.... any point other than TDC or BDC...where it is a straight line....but only for an instant.  I remember my shop teacher 35 years ago saying if you took a 1 cylinder motor and could park the trapped air fuel charge at precisely TDC and lit it off the explosive forces would be straight down and the crank wouldn't turn  Well that's wahat starters are for anyway...to tell the crank which way it's supposed to go  Hope somebody captures this thread this time, it seems we have this same discussion every 6-8 months or so

Last edited by Streetwize; 12/02/10 06:39 PM.

|

|

|

Re: Great info on rod ratio!!

[Re: 602heavy]

#828303

Re: Great info on rod ratio!!

[Re: 602heavy]

#828303

12/02/10 09:03 PM

12/02/10 09:03 PM

|

Joined: Oct 2004

Posts: 8,165

Left Coast

BobR

master

|

master

Joined: Oct 2004

Posts: 8,165

Left Coast

|

Quote:

Don't most stroked motors use a longer rod.

I'm in the camp whereby compression height rules over rod length , get ring placement right then get a rod to fit.

That's because you have an actual race engine. Rod ratio is the most overstated and unimportant aspect of an engine build. The rod connects the piston to the crank, period. Guess how BAE adjusts for compression? They lengthen or shorten the rod.

|

|

|

Re: Great info on rod ratio!!

[Re: BobR]

#828304

Re: Great info on rod ratio!!

[Re: BobR]

#828304

12/02/10 10:33 PM

12/02/10 10:33 PM

|

Joined: Dec 2008

Posts: 1,200

UK

602heavy

pro stock

|

pro stock

Joined: Dec 2008

Posts: 1,200

UK

|

|

|

|

Re: Great info on rod ratio!!

[Re: polyspheric]

#828305

Re: Great info on rod ratio!!

[Re: polyspheric]

#828305

12/03/10 12:47 AM

12/03/10 12:47 AM

|

Joined: Jan 2003

Posts: 6,591

Canton, Ohio

Sport440

master

|

master

Joined: Jan 2003

Posts: 6,591

Canton, Ohio

|

Quote:

How about the difference between the other "35" 10* points of reference

They get smaller.

Please: I hope we can all agree that "dwell" (meaning literally to reside, stay, remain, rest) only means "move very slowly vs. motion at other points of rotation"?

The piston dwells at TDC exactly this long: .00000"

By comparison, it dwells at BDC this long: .00000".

This also gets repeated way too many times: "a long rod motor would dwell for a longer period of time & TDC & a short rod @ BDC , this was'nt so , dwell time is EXACTLY the same for a short & long rod @ TDC/BDC".

This is never, ever true in any engine (unless you have one of those very rare engines with infinite rod length - not really long like 12" - infinite like light years).

The zero change observed is actually so small that it's completely masked by stacked bearing clearances.

HTML note: degree sign is made by

Hold ALT down, then press 0, 1, 7, 6

Jeff, I agree ATDC and a ABDC the dwell between the short/long rod is .00000

Its the Dwell degrees Near TDC that is being referenced to not just "Only TDC" witch backs your argument.

Now for my question about the other "35" 10* points of reference from your other post.

You say Smaller, I say Bigger

The differences only grow, IMO and after some limited measuring tests.

Off the Cuff, I have Vizard stating that the difference in a 3.75 stroke 1.48 RR vs a 1.63 RR is about 2* in crank position between the two before they both reach peak piston speed @ around 74* or so.

Was he correct, I dont know?? If he was what would that 2* difference equate to??

2* out of 360* BFD, right

Coming off of TDC the difference of 2* would be squat, .008 piston height maybe

If they were truely "2* apart" What would the difference in piston height be at say 60* ATDC between the two?

""Its as far down as my dial guage could measure easily"

With a 3.31 stroke the difference 2* crank changed the piston height was .063

A 3.75 stroke would see a slightly higher difference.

IMO, on the power stroke a longer rod sees more psi pressure on the piston because its higher up in the bore.

But, the shorter rod sees a better leverage angle quicker then the longer rod. so maybe the above is a wash.

But theres the intake stroke to consider too.

All in all, in the scheme of things, for a race motor Id want the longer rod if theres a choice and a shorter rod for the street.

On some strokers you dont have much of a choice, I would also never comprimise the ring pack and piston stability to get any extra rod length on a race motor.

No doubt the rod connects the piston, but in the same token it can be used to a slight advantage, if you have a choice one way or another. Lots of variables. mike

|

|

|

|

|