|

Re: Degreeing a cam in..

[Re: VernMotor]

#437222

Re: Degreeing a cam in..

[Re: VernMotor]

#437222

08/13/09 09:44 PM

08/13/09 09:44 PM

|

Joined: Mar 2008

Posts: 5,746

Ontario, Canada

Dodgem

master

|

master

Joined: Mar 2008

Posts: 5,746

Ontario, Canada

|

I like duration at .050 /2 -32 268.5 /2 = 134.25 - 32 = 102.25 or your way. I have a milidon gear drive and you set the cam @ .050 then turn crank to desired BTDC number then line the top gear up to inner hub there are seven bolt holes. then go through various methods of checking @ .050 .0200 .050 before and after max lift and so on! I like where you are going to degree it help the big girl get moving!!!

|

|

|

Re: Degreeing a cam in..

[Re: BobsProFab]

#437224

Re: Degreeing a cam in..

[Re: BobsProFab]

#437224

08/13/09 09:50 PM

08/13/09 09:50 PM

|

Joined: Jan 2005

Posts: 1,163

Newark, OH

Hunted Duck

super stock

|

super stock

Joined: Jan 2005

Posts: 1,163

Newark, OH

|

Quote:

i do it @ .050 before and after max lift

add then divid by 2

Bob Bob

This is how I do mine also. This is how I do mine also.

|

|

|

Re: Degreeing a cam in..

[Re: BobsProFab]

#437225

Re: Degreeing a cam in..

[Re: BobsProFab]

#437225

08/13/09 09:52 PM

08/13/09 09:52 PM

|

Joined: Feb 2009

Posts: 1,532

off the grid

340B5

pro stock

|

pro stock

Joined: Feb 2009

Posts: 1,532

off the grid

|

I do it the same, after setting 0 the same way on the crank degree wheel.

Yeah, it's got a smallblock.

|

|

|

Re: Degreeing a cam in..

[Re: BobsProFab]

#437226

Re: Degreeing a cam in..

[Re: BobsProFab]

#437226

08/13/09 09:52 PM

08/13/09 09:52 PM

|

Joined: Nov 2003

Posts: 7,348

Mt.Vernon ,Ohio

VernMotor

OP

OP

master

|

OP

OP

master

Joined: Nov 2003

Posts: 7,348

Mt.Vernon ,Ohio

|

Quote:

i do it @ .050 before and after max lift

add then divid by 2

Bob Bob

I did that also..it come out the same way..

|

|

|

Re: Degreeing a cam in..

[Re: Dodgem]

#437227

Re: Degreeing a cam in..

[Re: Dodgem]

#437227

08/13/09 09:54 PM

08/13/09 09:54 PM

|

Joined: Nov 2003

Posts: 7,348

Mt.Vernon ,Ohio

VernMotor

OP

OP

master

|

OP

OP

master

Joined: Nov 2003

Posts: 7,348

Mt.Vernon ,Ohio

|

Quote:

I like where you are going to degree it help the big girl get moving!!!

Yea I had it at 104.5 ..thought this might help

|

|

|

Re: Degreeing a cam in..

[Re: VernMotor]

#437228

Re: Degreeing a cam in..

[Re: VernMotor]

#437228

08/13/09 10:01 PM

08/13/09 10:01 PM

|

Joined: Jun 2003

Posts: 52,972

Romeo MI

MR_P_BODY

Master

|

Master

Joined: Jun 2003

Posts: 52,972

Romeo MI

|

Quote:

Ok let talk about this some..I wanted my cam in at 102. numbers are intake open at 32 deg and close at 56.5 . that is @ .050 after opening and .050 before closing. Now there are two-three ways to do this.. Not saying any one way is wrong. This is how I do it.. might be wrong ??

add 32+56.5 + 180 = 268.5 div by 2 =134.25 - 32 =102.25

show me your numbers and how you do it.

Jamie thats the same way I check the numbers but

when I install it I sorta cheat. I have a gear drive

so I would (in your case) set the crank to 102 and

have the #1 intake at the top with my indicator on

it and slide the idler gear on... then make the before

and after(.050) checks to see if its correct and

adjust if needed

|

|

|

Re: Degreeing a cam in..

[Re: Hunted Duck]

#437229

Re: Degreeing a cam in..

[Re: Hunted Duck]

#437229

08/13/09 10:05 PM

08/13/09 10:05 PM

|

Joined: Dec 2007

Posts: 10,542

BROOK PARK, OH

WILD BILL

Senior Member of the Junior Dragster Club

|

Senior Member of the Junior Dragster Club

Joined: Dec 2007

Posts: 10,542

BROOK PARK, OH

|

Quote:

Quote:

i do it @ .050 before and after max lift

add then divid by 2

Bob Bob

This is how I do mine also. This is how I do mine also.

Make that three

|

|

|

Re: Degreeing a cam in..

[Re: WILD BILL]

#437233

Re: Degreeing a cam in..

[Re: WILD BILL]

#437233

08/13/09 10:32 PM

08/13/09 10:32 PM

|

Joined: Nov 2003

Posts: 7,348

Mt.Vernon ,Ohio

VernMotor

OP

OP

master

|

OP

OP

master

Joined: Nov 2003

Posts: 7,348

Mt.Vernon ,Ohio

|

Quote:

Quote:

Quote:

i do it @ .050 before and after max lift

add then divid by 2

Bob Bob

This is how I do mine also. This is how I do mine also.

Make that three

One thing comes in to play here is how your degree wheel reads ..my is broke in to 90 deg segments...not all degree wheels are this way.

|

|

|

Re: Degreeing a cam in..

[Re: VernMotor]

#437234

Re: Degreeing a cam in..

[Re: VernMotor]

#437234

08/13/09 10:48 PM

08/13/09 10:48 PM

|

Joined: Aug 2003

Posts: 43,180

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,180

Bend,OR USA

|

Your doing it the way the cam companys want you to  I don't like doing the lobe centers that way so I do it at the valve retainers, I also always check the exhaust after getting the intake lobe center where I want it. This makes sure the cam lobe centers are ground correctly on both lobes, the exhaust lobe center should be retarded the exact same amount the intake lobe is advanced. IE Lobe seperation angles are 108, you install the cam with four degrees advance on the intake lobe, which means the intake lobe is installed at 104 max lift after top dead center, the exahust lobe max lift should be exactly at 112 BTDC

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Degreeing a cam in..

[Re: VernMotor]

#437235

Re: Degreeing a cam in..

[Re: VernMotor]

#437235

08/13/09 10:50 PM

08/13/09 10:50 PM

|

Joined: Dec 2007

Posts: 10,542

BROOK PARK, OH

WILD BILL

Senior Member of the Junior Dragster Club

|

Senior Member of the Junior Dragster Club

Joined: Dec 2007

Posts: 10,542

BROOK PARK, OH

|

Ari440

First you need to find true TDC. Use a stop and bring the piston up to it and record the reading (i.e. 10* to the right of 0). Now go backwards till the piston hits the stop. If the reading is the same (10* to the left of 0) you have TDC. If not adjust the pointer (or move the wheel) till the #'s are the same on either side of 0 TDC.

Now place your dial indicator on the intake liffter. Bring the lifter to max lift and zero the indicator. Now rotate untill you read .050 and record the #. Rotate back to 0 (max lift) and continue till you read .050 the other way. Record this #.

Add the 2 #'s togheter and divide by 2 and that is your intake CL.

|

|

|

Re: Degreeing a cam in..

[Re: WILD BILL]

#437236

Re: Degreeing a cam in..

[Re: WILD BILL]

#437236

08/13/09 11:09 PM

08/13/09 11:09 PM

|

Joined: Jun 2003

Posts: 52,972

Romeo MI

MR_P_BODY

Master

|

Master

Joined: Jun 2003

Posts: 52,972

Romeo MI

|

Quote:

Quote:

Quote:

i do it @ .050 before and after max lift

add then divid by 2

Bob Bob

This is how I do mine also. This is how I do mine also.

Make that three

I do the install like you guys are saying with the

.050 before and after, add then /2

For what Cab is saying about checking at the valve,

I dont usually check it there.... I just advance the

cam basically to give more torque and compensate

for the valve train loss

|

|

|

Re: Degreeing a cam in..

[Re: Ari440]

#437240

Re: Degreeing a cam in..

[Re: Ari440]

#437240

08/14/09 07:16 AM

08/14/09 07:16 AM

|

Joined: Dec 2007

Posts: 10,542

BROOK PARK, OH

WILD BILL

Senior Member of the Junior Dragster Club

|

Senior Member of the Junior Dragster Club

Joined: Dec 2007

Posts: 10,542

BROOK PARK, OH

|

Quote:

THANK YOU VERY MUCH BILL

|

|

|

Re: Degreeing a cam in..

[Re: BobsProFab]

#437241

Re: Degreeing a cam in..

[Re: BobsProFab]

#437241

08/14/09 08:07 AM

08/14/09 08:07 AM

|

Joined: Jan 2003

Posts: 16,123

Grand Haven, MI

patrick

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 16,123

Grand Haven, MI

|

Quote:

i do it @ .050 before and after max lift

add then divid by 2

Bob Bob

that's how I did mine. find max lift w/ the dial indicator, 0 it out, then go .050 on either side, taking degree measurements. add them up and divide by 2....I was checking at the lifter, heads weren't on the motor yet. that's how I did mine. find max lift w/ the dial indicator, 0 it out, then go .050 on either side, taking degree measurements. add them up and divide by 2....I was checking at the lifter, heads weren't on the motor yet.

Last edited by patrick; 08/14/09 08:10 AM.

1976 Spinnaker White Plymouth Duster, /6 A833OD

1986 Silver/Twilight Blue Chrysler 5th Ave HotRod **SOLD!***

2011 Toxic Orange Dodge Charger R/T

2017 Grand Cherokee Overland

2014 Jeep Cherokee Latitude (holy crap, my daughter is driving)

|

|

|

Re: Degreeing a cam in..

[Re: WILD BILL]

#437242

Re: Degreeing a cam in..

[Re: WILD BILL]

#437242

08/14/09 09:21 AM

08/14/09 09:21 AM

|

Joined: May 2006

Posts: 205

Chicago,Illinois

nosboy

enthusiast

|

enthusiast

Joined: May 2006

Posts: 205

Chicago,Illinois

|

ABSOLUTELY CORRECT BILL!!! You HAVE to find the TDC of the PISTON and NOT the mark on the balancer.. I've seen balancers OFF BIGTIME!!!. Also, use the LIFTER and NOT the pushrod or rocker or valve.. There is angles involved in the relative positions of pushrods,rockers,,etc,etc,etc, that WILL throw off your readings... the LIFTER ITSELF,,,, not the piston inside the lifter,, the OUTSIDE WALL of the lifter... I put my cam at 102 and I am really impressed with the performance!!!! I have a 5000 stall convertor and the cam wakes up WAY BEFORE 5000 and I waste some power,,,but,, my challenger still runs 10:40's CONSISTENTLY and it idles pretty good sometimes.. The trick is to LEAVE the mechanical advance springs IN the distributor and NOT TO PIN the dist together,,, so it will start RIGHT AWAY all the time!!! the advance kicks in at around 1800 rpms and my car runs between 5000 and 7000 all the time

|

|

|

Re: Degreeing a cam in..

[Re: ProSport]

#437244

Re: Degreeing a cam in..

[Re: ProSport]

#437244

08/14/09 10:01 AM

08/14/09 10:01 AM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

The big thing to remember here is --degree the cam to know where its at SO you know which way to go - if need be - AFTER you run it some--The recommended spot is a good GUESS at where it should be to get the desired results BUT if you are say 1/8 miler vs. 1/4 etc you may need to advance or retard to get the exact performance out of it that you are looking for--I have seen BIG inch engines make 50 Ft lbs more on the dyno by retarding a little I have seen small block 1/8 milers tear the chrome off the rear bumper and pull like a rocket in the 1/8 but run out of steam in the 1/4 so---going crazy over a degree or two is USELESS--a good smart racer will move it around a little to FIND where it needs ( after RUNNING it )to be for his combo and desired results OR if it dynos great and you are winning races WHO cares what it is degreed at? - except to be able to put it back in the same place after teardown - Getting picky over HOW to get there is missing the point IMO --just do whatever you do the same way every time. One of the best ways - accurate every time - is with the tool in the lifter bore that holds the mic and measures straight off the lobe--- make it run good for real --not on paper

Last edited by crabman173; 08/14/09 10:07 AM.

|

|

|

Re: Degreeing a cam in..

[Re: B5 Bee]

#437246

Re: Degreeing a cam in..

[Re: B5 Bee]

#437246

08/14/09 11:39 AM

08/14/09 11:39 AM

|

Joined: Dec 2007

Posts: 10,542

BROOK PARK, OH

WILD BILL

Senior Member of the Junior Dragster Club

|

Senior Member of the Junior Dragster Club

Joined: Dec 2007

Posts: 10,542

BROOK PARK, OH

|

Quote:

When checking .050 before and after, turn it in it's normal direction, check .050 before, then .050 after, all in one direction. This will keep the chain tight and not add in the chain slop to your readings that will happen if you turn it back and forth.

Forgot about that

Last cam I degreed was in the Jr and it has no chain

|

|

|

Re: Degreeing a cam in..

[Re: ]

#437247

Re: Degreeing a cam in..

[Re: ]

#437247

08/14/09 01:27 PM

08/14/09 01:27 PM

|

Joined: Oct 2006

Posts: 527

alaska,usa

9secondsatellite

mopar

|

mopar

Joined: Oct 2006

Posts: 527

alaska,usa

|

Quote:

The big thing to remember here is --degree the cam to know where its at SO you know which way to go - if need be - AFTER you run it some--The recommended spot is a good GUESS at where it should be to get the desired results BUT if you are say 1/8 miler vs. 1/4 etc you may need to advance or retard to get the exact performance out of it that you are looking for--I have seen BIG inch engines make 50 Ft lbs more on the dyno by retarding a little I have seen small block 1/8 milers tear the chrome off the rear bumper and pull like a rocket in the 1/8 but run out of steam in the 1/4 so---going crazy over a degree or two is USELESS--a good smart racer will move it around a little to FIND where it needs ( after RUNNING it )to be for his combo and desired results OR if it dynos great and you are winning races WHO cares what it is degreed at? - except to be able to put it back in the same place after teardown - Getting picky over HOW to get there is missing the point IMO --just do whatever you do the same way every time. One of the best ways - accurate every time - is with the tool in the lifter bore that holds the mic and measures straight off the lobe--- make it run good for real --not on paper

measure off the lobe, go right to the source. the right tool and procedure will make it accurate every time. measure off the lobe, go right to the source. the right tool and procedure will make it accurate every time.

|

|

|

Re: Degreeing a cam in..

[Re: Hunted Duck]

#437248

Re: Degreeing a cam in..

[Re: Hunted Duck]

#437248

08/14/09 05:50 PM

08/14/09 05:50 PM

|

Joined: Nov 2003

Posts: 7,348

Mt.Vernon ,Ohio

VernMotor

OP

OP

master

|

OP

OP

master

Joined: Nov 2003

Posts: 7,348

Mt.Vernon ,Ohio

|

Quote:

Quote:

i do it @ .050 before and after max lift

add then divid by 2

Bob Bob

This is how I do mine also. This is how I do mine also.

I would like to see picture of you guys degree wheels..something don't add up here. just to take the 2 numbers and add and then div. Like my numbers..60 and 35 deg add them =95 div them by 2 =47 ???

|

|

|

Re: Degreeing a cam in..

[Re: goldmember]

#437256

Re: Degreeing a cam in..

[Re: goldmember]

#437256

08/14/09 11:27 PM

08/14/09 11:27 PM

|

Joined: Mar 2008

Posts: 5,746

Ontario, Canada

Dodgem

master

|

master

Joined: Mar 2008

Posts: 5,746

Ontario, Canada

|

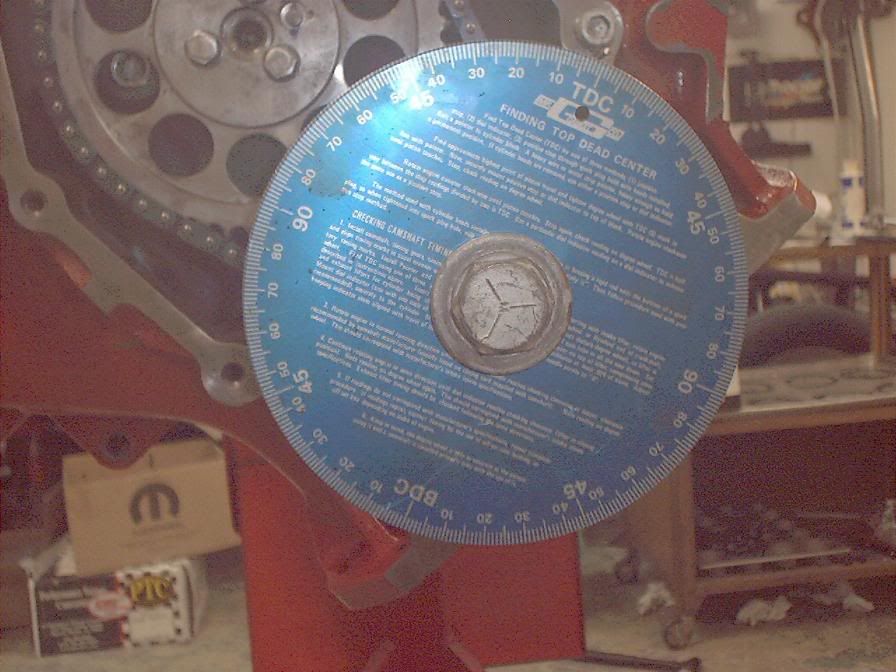

This is my small 11" wheel only one that will fit in the car. Have a bigger 14 or 16" real cool!

Last edited by Dodgem; 08/14/09 11:28 PM.

|

|

|

Re: Degreeing a cam in..

[Re: Dodgem]

#437261

Re: Degreeing a cam in..

[Re: Dodgem]

#437261

08/14/09 11:35 PM

08/14/09 11:35 PM

|

Joined: Feb 2004

Posts: 4,501

Gainesville,FL

goldmember

master

|

master

Joined: Feb 2004

Posts: 4,501

Gainesville,FL

|

Quote:

This is my small 11" wheel only one that will fit in the car. Have a bigger 14 or 16" real cool!

I don't own the smaller degree wheels,can you tell us the difference between them?

|

|

|

Re: Degreeing a cam in..

[Re: goldmember]

#437264

Re: Degreeing a cam in..

[Re: goldmember]

#437264

08/14/09 11:42 PM

08/14/09 11:42 PM

|

Joined: Mar 2008

Posts: 5,746

Ontario, Canada

Dodgem

master

|

master

Joined: Mar 2008

Posts: 5,746

Ontario, Canada

|

Quote:

Quote:

This is my small 11" wheel only one that will fit in the car. Have a bigger 14 or 16" real cool!

I don't own the smaller degree wheels,can you tell us the difference between them?

I originally in the days before time had a direct connection 7"

http://chucker54.stores.yahoo.net/mopdegwheel2.html

then later as the earth began to cool I got the 11 " fits just right down in the car

and now I have an 18"

http://chucker54.stores.yahoo.net/mor18degprow.html

The bigger they are the larger the numbers this does two things makes it easier to read and more accurate. I assume that's what your asking!!

|

|

|

Re: Degreeing a cam in..

[Re: VernMotor]

#437266

Re: Degreeing a cam in..

[Re: VernMotor]

#437266

08/14/09 11:58 PM

08/14/09 11:58 PM

|

Joined: Aug 2003

Posts: 43,180

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,180

Bend,OR USA

|

I had one Moroso degree wheel and one Mr Gasket, I gave one of them to 9secondPhil years ago, my point is that , as already pointed out, that some of the degree wheels will mislead you. I bought one form Comp Cams last year as the center of the old ones was getting worn and wouldn't always center good  , The new one doesn't have a centering adapter so I have to hold it on center and tighten the bolt up and hope it stays in the center     LOL  The intake cylce begins with the intake valve opening before top dead center and ends up closing after bottom dead center with max lift somewhere bewteen 90 degrees after top dead center and 120 after top dead center, some people will call that 90 degrees before bottom dead center and 60 degrees BBDC  The thing to remember on checking the cam timing on both lobes at .050 lifter rise is to add the 180 degrees between TDC and BDC that happens every time the valves open and close, if the intake valve opens at 35 .050 lifter rise before top dead center and closes at 56 degrees after bottom dead center you have 35+180+56 which equals 271 degrees intake valve duration at .050  Same thing on the other side but the exhaust valve timing starts before BBDC and closes ATDC, so its maximum valve opening is always going to occur before top dead center. On finding and checking lobe center you measure in relation to max lift .050 before and after, I measure in three places to make sure what the valve is seeing as it reaches maximum lift  don't be suprised to occasionally see one degree variation on those three places  My point on bringing this up is you can check it at .300 begore max lift or .050 BML, the lobe center will stay where the cam grinder made it  As far as degree wheels, here is a picture of the two I have now, they are confusing if you don't use them as a way to measure cranksaft degrees only

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Degreeing a cam in..

[Re: goldmember]

#437267

Re: Degreeing a cam in..

[Re: goldmember]

#437267

08/15/09 12:01 AM

08/15/09 12:01 AM

|

Joined: Jun 2003

Posts: 52,972

Romeo MI

MR_P_BODY

Master

|

Master

Joined: Jun 2003

Posts: 52,972

Romeo MI

|

Quote:

I was looking for accuracy and whether there was over 1 degree difference between them.I thought with all the pics,I might learn something important.

Well in a 11" wheel you have .095 per degree and in a

18" wheel you have .157 per degree... you can get much

closer with the big wheel

|

|

|

Re: Degreeing a cam in..

[Re: goldmember]

#437270

Re: Degreeing a cam in..

[Re: goldmember]

#437270

08/15/09 07:48 AM

08/15/09 07:48 AM

|

Joined: Jan 2003

Posts: 16,123

Grand Haven, MI

patrick

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 16,123

Grand Haven, MI

|

mine's marked 0-180, not 0-90-0....

1976 Spinnaker White Plymouth Duster, /6 A833OD

1986 Silver/Twilight Blue Chrysler 5th Ave HotRod **SOLD!***

2011 Toxic Orange Dodge Charger R/T

2017 Grand Cherokee Overland

2014 Jeep Cherokee Latitude (holy crap, my daughter is driving)

|

|

|

Re: Degreeing a cam in..

[Re: goldmember]

#437272

Re: Degreeing a cam in..

[Re: goldmember]

#437272

08/15/09 08:51 AM

08/15/09 08:51 AM

|

Joined: Jan 2003

Posts: 16,925

NC

440Jim

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 16,925

NC

|

Quote:

It's obvious the larger wheel SHOULD be more accurate. I was looking for some testing to confirm enough to replace my old unit. Guess I'll keep it.

The larger wheel is easier to read, but even a 7" when used carefully and correctly will get the job done "accurately". If you can repeat the setup and ICL less than 1 degree, that is all you need. The operator is more important...But better tools make it easier. IMO, setting the wheel to TDC is the place to spend time getting it the best you can.

When I buy a cam, I map the duration from 0.020" to 0.350" lobe lift, that is close to 0.050" before max lift depending on cam. Once you get to 0.050", the ICL should be the same (less than 1 degree different measurement). If you do it at 0.006, 0.008, 0.020, 0.050" you will see the difference in the opening and closing ramps.

|

|

|

|

|