|

Re: Degreeing a cam in..

[Re: BobsProFab]

#437241

Re: Degreeing a cam in..

[Re: BobsProFab]

#437241

08/14/09 08:07 AM

08/14/09 08:07 AM

|

Joined: Jan 2003

Posts: 16,123

Grand Haven, MI

patrick

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 16,123

Grand Haven, MI

|

Quote:

i do it @ .050 before and after max lift

add then divid by 2

Bob Bob

that's how I did mine. find max lift w/ the dial indicator, 0 it out, then go .050 on either side, taking degree measurements. add them up and divide by 2....I was checking at the lifter, heads weren't on the motor yet. that's how I did mine. find max lift w/ the dial indicator, 0 it out, then go .050 on either side, taking degree measurements. add them up and divide by 2....I was checking at the lifter, heads weren't on the motor yet.

Last edited by patrick; 08/14/09 08:10 AM.

1976 Spinnaker White Plymouth Duster, /6 A833OD

1986 Silver/Twilight Blue Chrysler 5th Ave HotRod **SOLD!***

2011 Toxic Orange Dodge Charger R/T

2017 Grand Cherokee Overland

2014 Jeep Cherokee Latitude (holy crap, my daughter is driving)

|

|

|

Re: Degreeing a cam in..

[Re: WILD BILL]

#437242

Re: Degreeing a cam in..

[Re: WILD BILL]

#437242

08/14/09 09:21 AM

08/14/09 09:21 AM

|

Joined: May 2006

Posts: 205

Chicago,Illinois

nosboy

enthusiast

|

enthusiast

Joined: May 2006

Posts: 205

Chicago,Illinois

|

ABSOLUTELY CORRECT BILL!!! You HAVE to find the TDC of the PISTON and NOT the mark on the balancer.. I've seen balancers OFF BIGTIME!!!. Also, use the LIFTER and NOT the pushrod or rocker or valve.. There is angles involved in the relative positions of pushrods,rockers,,etc,etc,etc, that WILL throw off your readings... the LIFTER ITSELF,,,, not the piston inside the lifter,, the OUTSIDE WALL of the lifter... I put my cam at 102 and I am really impressed with the performance!!!! I have a 5000 stall convertor and the cam wakes up WAY BEFORE 5000 and I waste some power,,,but,, my challenger still runs 10:40's CONSISTENTLY and it idles pretty good sometimes.. The trick is to LEAVE the mechanical advance springs IN the distributor and NOT TO PIN the dist together,,, so it will start RIGHT AWAY all the time!!! the advance kicks in at around 1800 rpms and my car runs between 5000 and 7000 all the time

|

|

|

Re: Degreeing a cam in..

[Re: ProSport]

#437244

Re: Degreeing a cam in..

[Re: ProSport]

#437244

08/14/09 10:01 AM

08/14/09 10:01 AM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

The big thing to remember here is --degree the cam to know where its at SO you know which way to go - if need be - AFTER you run it some--The recommended spot is a good GUESS at where it should be to get the desired results BUT if you are say 1/8 miler vs. 1/4 etc you may need to advance or retard to get the exact performance out of it that you are looking for--I have seen BIG inch engines make 50 Ft lbs more on the dyno by retarding a little I have seen small block 1/8 milers tear the chrome off the rear bumper and pull like a rocket in the 1/8 but run out of steam in the 1/4 so---going crazy over a degree or two is USELESS--a good smart racer will move it around a little to FIND where it needs ( after RUNNING it )to be for his combo and desired results OR if it dynos great and you are winning races WHO cares what it is degreed at? - except to be able to put it back in the same place after teardown - Getting picky over HOW to get there is missing the point IMO --just do whatever you do the same way every time. One of the best ways - accurate every time - is with the tool in the lifter bore that holds the mic and measures straight off the lobe--- make it run good for real --not on paper

Last edited by crabman173; 08/14/09 10:07 AM.

|

|

|

Re: Degreeing a cam in..

[Re: B5 Bee]

#437246

Re: Degreeing a cam in..

[Re: B5 Bee]

#437246

08/14/09 11:39 AM

08/14/09 11:39 AM

|

Joined: Dec 2007

Posts: 10,542

BROOK PARK, OH

WILD BILL

Senior Member of the Junior Dragster Club

|

Senior Member of the Junior Dragster Club

Joined: Dec 2007

Posts: 10,542

BROOK PARK, OH

|

Quote:

When checking .050 before and after, turn it in it's normal direction, check .050 before, then .050 after, all in one direction. This will keep the chain tight and not add in the chain slop to your readings that will happen if you turn it back and forth.

Forgot about that

Last cam I degreed was in the Jr and it has no chain

|

|

|

Re: Degreeing a cam in..

[Re: ]

#437247

Re: Degreeing a cam in..

[Re: ]

#437247

08/14/09 01:27 PM

08/14/09 01:27 PM

|

Joined: Oct 2006

Posts: 527

alaska,usa

9secondsatellite

mopar

|

mopar

Joined: Oct 2006

Posts: 527

alaska,usa

|

Quote:

The big thing to remember here is --degree the cam to know where its at SO you know which way to go - if need be - AFTER you run it some--The recommended spot is a good GUESS at where it should be to get the desired results BUT if you are say 1/8 miler vs. 1/4 etc you may need to advance or retard to get the exact performance out of it that you are looking for--I have seen BIG inch engines make 50 Ft lbs more on the dyno by retarding a little I have seen small block 1/8 milers tear the chrome off the rear bumper and pull like a rocket in the 1/8 but run out of steam in the 1/4 so---going crazy over a degree or two is USELESS--a good smart racer will move it around a little to FIND where it needs ( after RUNNING it )to be for his combo and desired results OR if it dynos great and you are winning races WHO cares what it is degreed at? - except to be able to put it back in the same place after teardown - Getting picky over HOW to get there is missing the point IMO --just do whatever you do the same way every time. One of the best ways - accurate every time - is with the tool in the lifter bore that holds the mic and measures straight off the lobe--- make it run good for real --not on paper

measure off the lobe, go right to the source. the right tool and procedure will make it accurate every time. measure off the lobe, go right to the source. the right tool and procedure will make it accurate every time.

|

|

|

Re: Degreeing a cam in..

[Re: Hunted Duck]

#437248

Re: Degreeing a cam in..

[Re: Hunted Duck]

#437248

08/14/09 05:50 PM

08/14/09 05:50 PM

|

Joined: Nov 2003

Posts: 7,348

Mt.Vernon ,Ohio

VernMotor

OP

OP

master

|

OP

OP

master

Joined: Nov 2003

Posts: 7,348

Mt.Vernon ,Ohio

|

Quote:

Quote:

i do it @ .050 before and after max lift

add then divid by 2

Bob Bob

This is how I do mine also. This is how I do mine also.

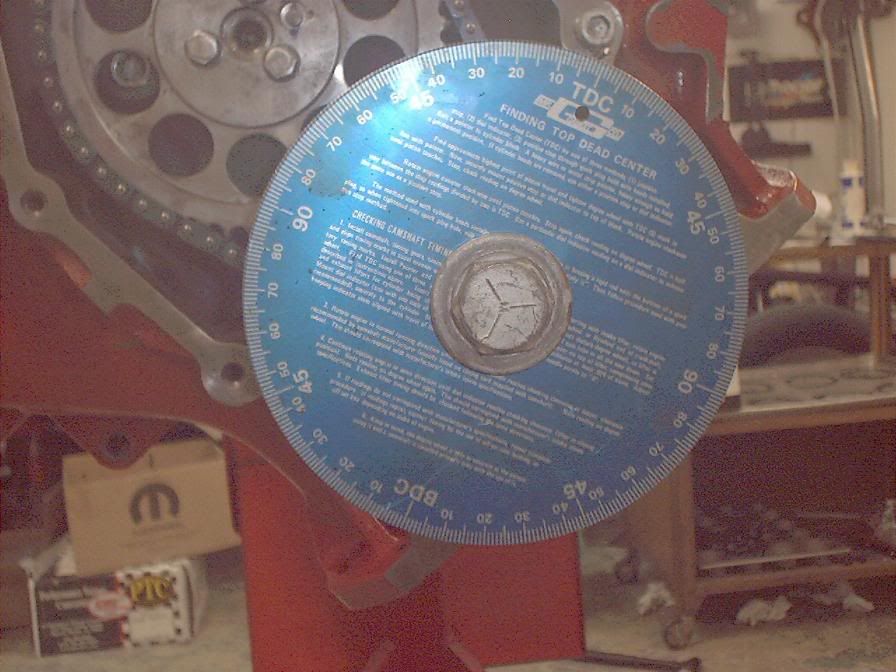

I would like to see picture of you guys degree wheels..something don't add up here. just to take the 2 numbers and add and then div. Like my numbers..60 and 35 deg add them =95 div them by 2 =47 ???

|

|

|

Re: Degreeing a cam in..

[Re: goldmember]

#437256

Re: Degreeing a cam in..

[Re: goldmember]

#437256

08/14/09 11:27 PM

08/14/09 11:27 PM

|

Joined: Mar 2008

Posts: 5,746

Ontario, Canada

Dodgem

master

|

master

Joined: Mar 2008

Posts: 5,746

Ontario, Canada

|

This is my small 11" wheel only one that will fit in the car. Have a bigger 14 or 16" real cool!

Last edited by Dodgem; 08/14/09 11:28 PM.

|

|

|

|

|