|

Re: Moving up to Jesel

[Re: AndyF]

#33899

Re: Moving up to Jesel

[Re: AndyF]

#33899

01/10/07 04:28 PM

01/10/07 04:28 PM

|

Joined: Apr 2003

Posts: 2,708

jax. fla.

70Dustmite440

master

|

master

Joined: Apr 2003

Posts: 2,708

jax. fla.

|

Quote:

One thing I see from the rocker arm kit is that it uses the 440-1 offset. Evidently Jesel doesn't have a standard offset kit for the Indy SR and EZ

so there is a great big offset where you don't need it?

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33910

Re: Moving up to Jesel

[Re: AndyF]

#33910

01/13/07 08:55 PM

01/13/07 08:55 PM

|

Joined: Jan 2004

Posts: 512

IL

acme383

mopar

|

mopar

Joined: Jan 2004

Posts: 512

IL

|

andy, what size springs and cups are you using?

"Beating the competition with a stick is just automatic!"

|

|

|

Re: Moving up to Jesel

[Re: sunroofgtx]

#33911

Re: Moving up to Jesel

[Re: sunroofgtx]

#33911

01/14/07 12:23 AM

01/14/07 12:23 AM

|

Joined: Jan 2003

Posts: 31,021

Oregon

AndyF

OP

OP

I Win

|

OP

OP

I Win

Joined: Jan 2003

Posts: 31,021

Oregon

|

Thanks Rick, I figured since Indy and Jesel didn't provide instructions I'd just go ahead and document how to do this conversion. I actually think this Jesel setup is probably the way to go for guys who are getting serious with their motors. The Harland Sharp or Erson stuff costs almost as much but doesn't have some of the advantages that the Jesel individual shafts bring.

Acme - I'm going to be running PSI 1246 springs. They are 1.645 x 2.00 high with 300 lbs on the seat. I'm setting up the valvetrain so I can run .800 lift. My old springs were installed at 1.950 height so I just had to use some +0.050 locks to move up to a 2.00 installed height. It looks like that is about the limit for this setup. Much taller than that and the retainer will hit the rocker arm.

Now that I have it mocked up, I'm pretty sure that Jesel could easily make a standard offset intake setup using mostly the same parts that are in this kit. I'm going to talk to Jesel engineering next week about doing a custom kit for me so I can try it out. These exhaust rocker arms have .250 offset and it looks like that offset will work just fine on the intake side as well.

Last edited by AndyF; 01/14/07 12:29 AM.

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33912

Re: Moving up to Jesel

[Re: AndyF]

#33912

01/14/07 04:24 AM

01/14/07 04:24 AM

|

Joined: Nov 2003

Posts: 1,664

North Sweden

RT540

top fuel

|

top fuel

Joined: Nov 2003

Posts: 1,664

North Sweden

|

Quote:

I'm going to talk to Jesel engineering next week about doing a custom kit for me so I can try it out. These exhaust rocker arms have .250 offset and it looks like that offset will work just fine on the intake side as well.

But if you keep the 0.800" offset int rockers you leave the option to straigthen out the pushrod wall for more CA in the future.

I don´t know how the EZ heads are in CA in different places, but my b1bs heads would like the 440-1 offsets better.

Straigthen out the pushrod walls do involve welding or the use of epoxy.

Keep up the good work, and keep the pics comming

Another thing I am interested in, will the rockers clear Ø1.645 springs ??

I have 1.625 and if the Jesel clears better than the T&D, I will know which ones to get if or when I upgrade my rockers.

|

|

|

Re: Moving up to Jesel

[Re: ToddP]

#33914

Re: Moving up to Jesel

[Re: ToddP]

#33914

01/14/07 04:14 PM

01/14/07 04:14 PM

|

Joined: Jan 2003

Posts: 31,021

Oregon

AndyF

OP

OP

I Win

|

OP

OP

I Win

Joined: Jan 2003

Posts: 31,021

Oregon

|

Thanks for the link to www.moparmax.com, I hadn't seen that before. The interesting thing about that article is they said they got instructions from Jesel as well as a shaft checking tool. My kit didn't come with instructions or a tool. And when I called Indy they said they couldn't help me. Jesel tech line also told me that there weren't any instructions available for this kit and they didn't offer to send me a height checking tool. I think I'll be back on the phone on Monday.

|

|

|

Re: Moving up to Jesel

[Re: ToddP]

#33917

Re: Moving up to Jesel

[Re: ToddP]

#33917

01/16/07 04:24 PM

01/16/07 04:24 PM

|

Joined: Jan 2003

Posts: 31,021

Oregon

AndyF

OP

OP

I Win

|

OP

OP

I Win

Joined: Jan 2003

Posts: 31,021

Oregon

|

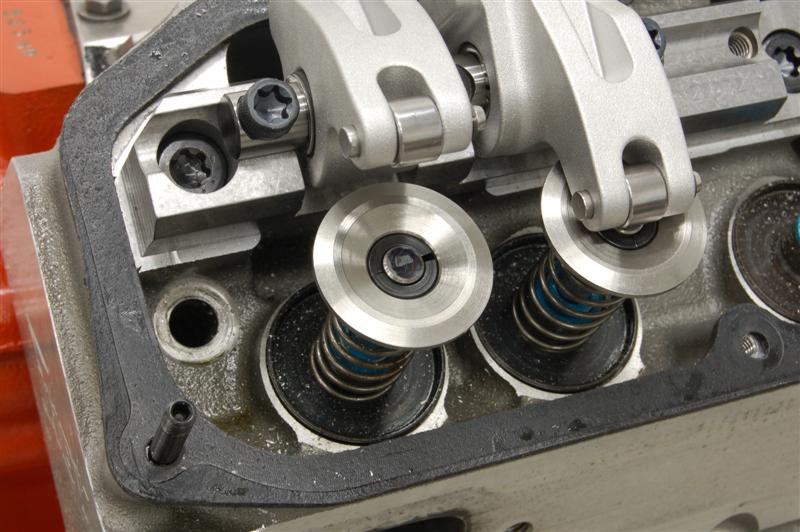

I got a reply from Indy and they told me the location of the stand as well as how far to machine the heads. They said to machine the stands down until they are 0.500 inches above the tall head bolt counterbores. I swung by the local circle track engine builder and he loaned me a Jesel shaft height checking tool. According to the tool I need to lower the shafts about 0.125 from where they are right now. That seems to agree with the number that Indy gave me so I think I'm closing in on it. Here is a picture of the Jesel tool in action. The top of the valve tip is supposed to be flush with the top of the tool but in this picture you can tell that the valve tip is down in the hole a bit. So I need to mount the heads back up in the Bridgeport and mill the stands down some more.

Last edited by AndyF; 01/16/07 04:26 PM.

|

|

|

Re: Moving up to Jesel

[Re: 70Dustmite440]

#33920

Re: Moving up to Jesel

[Re: 70Dustmite440]

#33920

01/17/07 10:08 PM

01/17/07 10:08 PM

|

Joined: Jan 2003

Posts: 3,136

Palm Coast, FL (near Daytona B...

Blown_Hemi

master

|

master

Joined: Jan 2003

Posts: 3,136

Palm Coast, FL (near Daytona B...

|

When installing the crank cog make sure to check the installation dot. Some Mopar kits had the dot in the incorrect place. I returned mine to Jesel and had them check it for me. They told me that only a few kits went out the door with the incorrect indexing. I e-mailed you the instructions that came with my beltdrive kit. I could not attatch them for some reason?

Ask me my opinion of Frank Mitchell....... A Mopar crook!

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33922

Re: Moving up to Jesel

[Re: AndyF]

#33922

01/28/07 12:22 AM

01/28/07 12:22 AM

|

Joined: Jan 2003

Posts: 31,021

Oregon

AndyF

OP

OP

I Win

|

OP

OP

I Win

Joined: Jan 2003

Posts: 31,021

Oregon

|

I finished up the machine work today to mount the Jesel stand onto the EZ heads. I had to machine down the pads some more and then drill and tap the 7 holes for 7/16-14 thread. The bolts included in the Jesel kit are a little too long so I'm going to order new ones. I sure am glad that Jesel faxed me a blueprint. Without that I would have had a really hard time getting the holes drilled and tapped in the correct locations. Here is a shot of the pattern left by the roller tip for .800 lift. It looks pretty good. It could be moved out on the valve stem by 0.020 or so to be perfect but there isn't any easy way to do that once the holes in the head are drilled and tapped.

Last edited by AndyF; 02/02/07 12:01 PM.

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33923

Re: Moving up to Jesel

[Re: AndyF]

#33923

01/28/07 09:48 PM

01/28/07 09:48 PM

|

Joined: Jan 2003

Posts: 31,021

Oregon

AndyF

OP

OP

I Win

|

OP

OP

I Win

Joined: Jan 2003

Posts: 31,021

Oregon

|

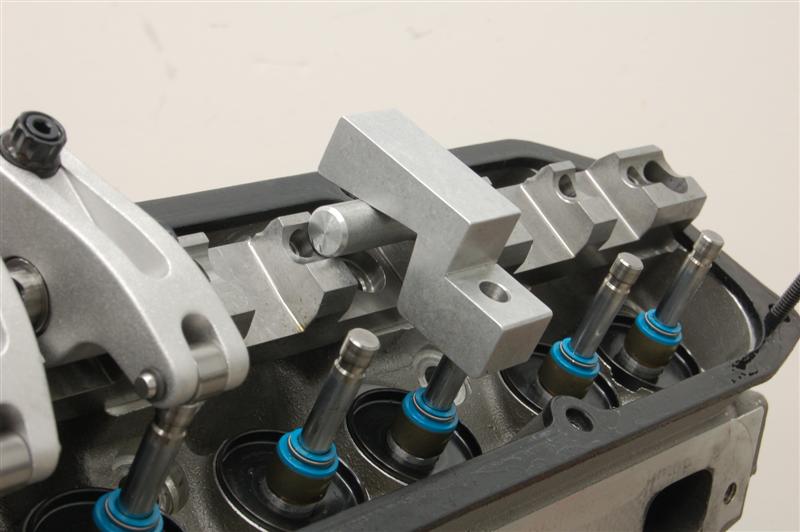

Here is how the head looks after the pads have been machined down and the new holes drilled and tapped for the hold down screws. The Jesel stand uses seven 7/16-14 bolts to hold it down rather than the five 3/8-16 bolts for the factory setup. It is a little tricky re-drilling the end holes for the larger 7/16 screws since the proper tap drill is smaller than 3/8ths. So basically a small amount of the existing threads are left in the hole and you then have to retap thru that. It cleans up okay but if you're going to run the Jesel setup you should really buy the heads setup that way in the beginning.

Last edited by AndyF; 01/28/07 09:49 PM.

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33925

Re: Moving up to Jesel

[Re: AndyF]

#33925

01/28/07 10:28 PM

01/28/07 10:28 PM

|

Joined: Jan 2003

Posts: 14,496

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,496

So. Burlington, Vt.

|

will you be pushrod oiling, or using spray bar valve covers for the roller cam tests?

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

Re: Moving up to Jesel

[Re: Monte_Smith]

#33929

Re: Moving up to Jesel

[Re: Monte_Smith]

#33929

01/29/07 08:15 AM

01/29/07 08:15 AM

|

Joined: Jan 2003

Posts: 75,004

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 75,004

U.S.S.A.

|

Quote:

Andy, In my own experience with this setup, you should probably go ahead and use heli-colis or thread-inserts. With large cams and the large spring pressure that goes with them, I have yet to have the threads NOT pull out of the heads, especially the end holes. I have had to make this repair so many times at the track, it is ridiculous. Now I just do them up front.

Monte

i was going to say something similar regarding using helicoils in those end holes , everything we do at work that is milspec , satellites and portable radars ,uses helicoils in alum .

|

|

|

Re: Moving up to Jesel

[Re: JohnRR]

#33930

Re: Moving up to Jesel

[Re: JohnRR]

#33930

02/01/07 07:47 PM

02/01/07 07:47 PM

|

Joined: Jan 2003

Posts: 31,021

Oregon

AndyF

OP

OP

I Win

|

OP

OP

I Win

Joined: Jan 2003

Posts: 31,021

Oregon

|

Just got some super good news from Jesel. They created instructions for this kit and posted them on their webpage. The instructions show the proper machining operations for various installed valve heights. Basically, the longer the valves are then the closer you need to move your rocker shaft to the intake side of the head. Here is a link to the Jesel instruction page. The kit of the Indy head is INS-07238 in the middle of the page. Maybe someone knows how to link directly to a pdf document? http://www.jeselonline.com/index.php?categoryid=49

|

|

|

Re: Moving up to Jesel

[Re: 2QUICK4U]

#33934

Re: Moving up to Jesel

[Re: 2QUICK4U]

#33934

02/03/07 07:25 PM

02/03/07 07:25 PM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

I wrote the article you referred to in www.moparmax.com and the initial one in www.dragracingonline.com as well. The fixture tool came with mine and I am surprised Jesel missed it on yours. Two years, ZERO problems. We set the final plate height pretty much like you did and ended up with a very similar rocker tip print on the valve. I would recommend the offset intake roller from Comp Cams to straighten the pushrod. (We send the rollers in at 150 runs to prevent a disaster, only $165.00 for rebuild and peasce of mind. We will be doing more and more Mopar Tech now that our newest magazine is getting over 3500 readers per day, check it our when you get a chance- www.MoparMax.comGreat series of photos and tech on your install I just read here on Moparts, nicely done. Jok Nicholson dragsterboy@mchsi.com

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33936

Re: Moving up to Jesel

[Re: AndyF]

#33936

02/04/07 11:59 PM

02/04/07 11:59 PM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

I think you are right, they should offer a kit for those heads. The Jesels have been the best thing I have done to my 572. I ate up Indy rockers at about 3 per year. So I was buying a new set each year. When I talked to Jesel they said I am done replacing rockers from fatigue, 450 runs later, they are still correct!

This is a great site, enjoting looking at all the Mopar Stuff...;-)

Jok

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33939

Re: Moving up to Jesel

[Re: AndyF]

#33939

02/07/07 12:20 AM

02/07/07 12:20 AM

|

Joined: Jan 2003

Posts: 14,496

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,496

So. Burlington, Vt.

|

what did you end up getting for a cam?

dont need all that much clearance for dyno work, especially if you have plenty of spring..

i had a 383 Chevy i was doing some cam testing with, and one of the cams i tried had about .035 intake/.050 exhaust clearance.

no issues.

i know some of the SS guys routinely run around .030 clearance on the intake side.

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33945

Re: Moving up to Jesel

[Re: AndyF]

#33945

02/08/07 10:50 PM

02/08/07 10:50 PM

|

Joined: Jan 2003

Posts: 14,496

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,496

So. Burlington, Vt.

|

Quote:

When you talk about running 0.030 VP clearance is that with the valves lashed, or with the rocker tight against the valve tip when the cam is on the base circle?

i dont bother checking V/P clearance with zero lash......since thats not how the motor runs(unless its a hyd cam).

i check everything with the correct lash.

so, to answer your question, i ran that 383 with that little amount of clearance.

what your seeing is part of the reason many of the longer duration BBC cams are put on wider LSA's.

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33950

Re: Moving up to Jesel

[Re: AndyF]

#33950

02/11/07 07:25 PM

02/11/07 07:25 PM

|

Joined: Jan 2003

Posts: 14,496

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,496

So. Burlington, Vt.

|

the test i would do......is compare the new Comp with another cam that has very similar seat to seat, and .050 numbers, and if possible.....similar .200 numbers....but with noticably less lift, to see if the big lift is really going to buy you anything in that application. and if it does....how much? in other words....does it justify the added expense and wear and tear of the really big springs that are required to be able to use that type of cam for "X" amount of added power??. as i had mentioned before, in that 383 SBC, going from .625 lift to .715 lift, while maintaining the seat to seat and .050 numbers of the 2 cams....showed no increase in power for the added lift. that motor was making about 1.56hp/ci. the test between the cams would be to try and determine which was more beneficial in that motor.....higher lift, or a higher discharge coefficient. Quote:

Any thoughts on the Crower 300R cam?

i'd expect that with the short duration and tight lsa.....it would make a pretty big number in the middle somewhere.....but probably not provide the kind of overall power curve someone building that kind of motor is going to be looking for.

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33958

Re: Moving up to Jesel

[Re: AndyF]

#33958

02/21/07 02:53 AM

02/21/07 02:53 AM

|

Joined: Aug 2003

Posts: 43,157

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,157

Bend,OR USA

|

Andy, where your clearance checks made with checking springs or the ones your going to run? If with checking springs you can expect .035 to .045 more clearance with the regular springs depending on how stout the valve train is and how much everything deflects.

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Moving up to Jesel

[Re: Cab_Burge]

#33959

Re: Moving up to Jesel

[Re: Cab_Burge]

#33959

02/21/07 07:33 AM

02/21/07 07:33 AM

|

Joined: Nov 2003

Posts: 10,384

Upstate NY

Bigcube

I Live Here

|

I Live Here

Joined: Nov 2003

Posts: 10,384

Upstate NY

|

My jesel rockers have a ball end on the rocker side. The ball end is smaller then the lifter side of the pushrod. Perhaps you may need to change the adjusters to the ones that use the other type of pushrod?

Jim

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33960

Re: Moving up to Jesel

[Re: AndyF]

#33960

02/21/07 10:59 PM

02/21/07 10:59 PM

|

Joined: Jan 2003

Posts: 14,496

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,496

So. Burlington, Vt.

|

it looks to me like the pushrod cup is for an adjuster screw thats bigger than whats on that rocker arm.

the adjuster looks like it probably has a 5/16 ball and, and the pushrod looks like its designed for a 3/8 ball.

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33967

Re: Moving up to Jesel

[Re: AndyF]

#33967

03/03/07 10:37 AM

03/03/07 10:37 AM

|

Joined: Jan 2003

Posts: 16,925

NC

440Jim

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 16,925

NC

|

Quote:

I got a set of Jesel pushrods today....

Only problem with them is that they cost $42.75 each or $684 per set!

Is the roller cam you plan on putting in so radical it can't use thick wall 3/8" pushrods?

The last test with the Comp MM305S flat tappet cam was thousands of dollars cheaper. It will be interesting how much more power the Jessel setup and roller cam makes on the dyno.

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33970

Re: Moving up to Jesel

[Re: AndyF]

#33970

03/04/07 03:04 PM

03/04/07 03:04 PM

|

Joined: Jan 2003

Posts: 14,496

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,496

So. Burlington, Vt.

|

i know its too late to go back now, but the test i would have liked to see(its easy to want stuff when you're spending someone elses money), would have been a roller cam swap similar to what the MM305 cam was, using the same basic valvetrain you used in that test.....then step up to the big dollar stuff like you have now, to show how much power you're getting for the added expense of the high lift cams, and the associated parts required to run them with any kind of reliability.

in any case.....i'll be interested in hearing the dyno results with the new combo.

is this next test going to have the new oil pan on it right away, or will that be a seperate test?

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

Re: Moving up to Jesel

[Re: fast68plymouth]

#33971

Re: Moving up to Jesel

[Re: fast68plymouth]

#33971

03/04/07 03:53 PM

03/04/07 03:53 PM

|

Joined: Jan 2003

Posts: 1,807

Mopar Country, Mi

ccdave

The Ultimate

|

The Ultimate

Joined: Jan 2003

Posts: 1,807

Mopar Country, Mi

|

Quote:

i know its too late to go back now, but the test i would have liked to see(its easy to want stuff when you're spending someone elses money), would have been a roller cam swap similar to what the MM305 cam was, using the same basic valvetrain you used in that test.....then step up to the big dollar stuff like you have now, to show how much power you're getting for the added expense of the high lift cams, and the associated parts required to run them with any kind of reliability.

in any case.....i'll be interested in hearing the dyno results with the new combo.

is this next test going to have the new oil pan on it right away, or will that be a seperate test?

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33973

Re: Moving up to Jesel

[Re: AndyF]

#33973

03/05/07 09:22 PM

03/05/07 09:22 PM

|

Joined: Jan 2003

Posts: 14,496

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,496

So. Burlington, Vt.

|

well, i didnt mean anything that extreme in terms of low buck.

more along the lines of what i see the majority of guys running, and similar to what i was running when i had the roller in my old 448.

i thought you already had the Racer Brown rockers on this motor for the previous tests, so what i was thinking was more like just swap the cam/lifters/springs/distributor gear, and use a cam with a similar profile to the MM305, and just see what the roller set up was worth.

then go to the big dollar set-up like what you did.

as for the pan.....no telling what its worth without testing, but dont kid yourself....ive seen pretty substantial gains(15-20hp at higher rpms) by using pans that provide better oil control.

ive also seen high doller hi-tech pans not work that well at all.

changing the pan on the dyno isnt all that fun....but its not really that bad either.

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

Re: Moving up to Jesel

[Re: fast68plymouth]

#33974

Re: Moving up to Jesel

[Re: fast68plymouth]

#33974

03/06/07 01:40 AM

03/06/07 01:40 AM

|

Joined: Jul 2003

Posts: 12,129

Cleveland

sunroofgtx

I Live Here

|

I Live Here

Joined: Jul 2003

Posts: 12,129

Cleveland

|

Andy, great work. Great documenting, also. My buddy and I had a long phone meeting with Mike @ Primedia today, about working with MM mag and our wires. There was a lot of interest at the Indy show last weekend with out race wires, and there will be dyno tests coming up shortly. Would you be interested in using the wires we sent you for the upcoming dyno pulls ?? If so, do you have everything you need ?? Please let me know, as you seem very resourceful.. .

Join the quickest team in motorsports. Team FireCore. CustomWiresets.com

|

|

|

Re: Moving up to Jesel

[Re: fast68plymouth]

#33975

Re: Moving up to Jesel

[Re: fast68plymouth]

#33975

03/09/07 11:34 PM

03/09/07 11:34 PM

|

Joined: Jan 2003

Posts: 31,021

Oregon

AndyF

OP

OP

I Win

|

OP

OP

I Win

Joined: Jan 2003

Posts: 31,021

Oregon

|

I got a new set of Smith Bros pushrods today. These don't cost nearly as much as the Jesel pushrods but should work just fine. They are 7/16 x 0.120 wall and the end is tapered down to 3/8 and there is a 9/64 cup end. These are the pushrods I'll run in the motor. The motor is almost back together. I just need to double check pushrod clearance and then install the big mondo valve springs and we're ready to light it off.

Last edited by AndyF; 03/09/07 11:36 PM.

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33976

Re: Moving up to Jesel

[Re: AndyF]

#33976

03/09/07 11:37 PM

03/09/07 11:37 PM

|

Joined: Jan 2003

Posts: 14,496

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,496

So. Burlington, Vt.

|

Andy, how much will those pushrods end up costing? looks like the did a nice job with them.

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33978

Re: Moving up to Jesel

[Re: AndyF]

#33978

03/14/07 06:26 PM

03/14/07 06:26 PM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

Hey I am new to this site and have been following your comments on Jessel. First of all thanks very much for the great pictures on installing the Jessel rockers.

I was lost after talking to Indy, as said before they aren't much help.

I have a couple of questions if you guys could help I would appreciate it.

1) I am going to have push rod oiling with bushed lifter bores. Anyone else running the same and if so is there any concerns? Jessel said it should be okay but I forgot to mention that the lifter bores were bushed (only a 0.060" feed hole)

2) Does anyone have any instructions or pictures on a spray bar install.

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33980

Re: Moving up to Jesel

[Re: AndyF]

#33980

03/14/07 07:46 PM

03/14/07 07:46 PM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

Thanks for the quick response. The pictures of the spray bars would be great! I got my kit from Indy.

If the oil feed hole is in the right location when the valve is closed but not in lift is that a problem?

I actually have to put it together to check and see where things line up.

|

|

|

Re: Moving up to Jesel

[Re: AndyF]

#33982

Re: Moving up to Jesel

[Re: AndyF]

#33982

03/16/07 12:23 PM

03/16/07 12:23 PM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

Hey andy any luck on the spray bar pictures?

|

|

|

Re: Moving up to Jesel

[Re: RT540]

#33984

Re: Moving up to Jesel

[Re: RT540]

#33984

03/16/07 12:36 PM

03/16/07 12:36 PM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

Thanks for the picture. What does the other side look like? Do you run a baffle under your breather?

Very Nice looking Coronet by the way.

Last edited by 540 Daytona; 03/16/07 12:41 PM.

|

|

|

Re: Moving up to Jesel

#33985

Re: Moving up to Jesel

#33985

03/16/07 01:43 PM

03/16/07 01:43 PM

|

Joined: Nov 2003

Posts: 1,664

North Sweden

RT540

top fuel

|

top fuel

Joined: Nov 2003

Posts: 1,664

North Sweden

|

Quote:

Thanks for the picture. What does the other side look like? Do you run a baffle under your breather?

Very Nice looking Coronet by the way.

Thanks

No breather, the other side looks the same, I have a dry sump oil system.

|

|

|

|

|